Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

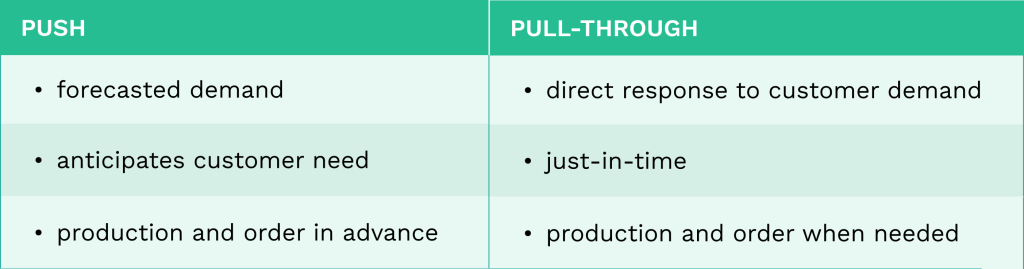

Try for freeInventory management is critical for balancing supply and demand in any business. The Push and Pull inventory management systems are two primary strategies for managing inventory.

- Push Systems relies on forecasted demand to determine production and inventory levels. Goods are produced or ordered in advance, anticipating customer needs.

- Pull Systems respond directly to customer demand, triggering production or replenishment only when needed.

Source: WorkTrek

Understanding the pros and cons of each approach is key to optimizing supply chain efficiency, reducing costs, and meeting customer expectations.

This article will explore push-pull systems’ mechanics, applications, and implications to help you identify the best fit for your operational goals.

Pull Through Manufacturing

A pull inventory management system is a lean approach based on actual customer demand, not forecasts. It’s part of the Just-in-Time (JIT) framework that reduces waste and improves efficiency by synchronizing material delivery with production needs.

This approach keeps inventory at the minimum levels required for current production. This approach can improve operational effectiveness and reduce the costs of excess stock.

Lean Inventory Policy

The pull inventory management and control systems align with lean manufacturing principles, with more output, fewer resources, and minimal waste.

These systems allow you to limit inventory to what’s necessary and synchronize production schedules with current market demand to streamline your workflow and avoid overproduction.

These systems efficiently use resources, reducing waste and costs and improving cash flow—a good outcome for any business.

How Pull-Through Works

In the pull inventory system approach, production only follows consumer demand, unlike push systems driven by forecasts.

Work is initiated when there is a need, which means production is aligned to immediate market demand, reducing the risks of overproduction and excess inventory.

This is also referred to as JIT within lean manufacturing principles; raw materials are delivered just in time for production.

Inventory inventory strategy in a pull system is based on actual sales and stock usage data, not forecasts, so you don’t overstock.

Toyota does this. As part of its pull strategy, it keeps minimal raw materials at different stations along the production line.

By doing this, you align material availability with real customer demand patterns and achieve continuous production without waste, thereby increasing efficiency across the operation.

Benefits of Pull-Through Systems

Pull inventory management systems can deliver significant benefits, especially cost reduction and operational efficiency.

The most significant benefit is lower initial costs of lower stock levels.

Companies can reduce excess and unnecessary spending by producing according to customer orders. This reduces storage costs and frees up funds for use elsewhere.

Pull systems have a big advantage in being aligned to actual customer demand versus push systems, based on forecasts that often result in overproduction. Pull inventory management can respond quickly to real-time demand, so you get a better match to market requirements and reduce preparation time.

This approach will satisfy customers and give you a competitive edge in a fast-changing market.

Understanding Push-Through Inventory Systems

A push inventory management system is where anticipated demand forecasts drive production and inventory levels.

Illustration. WorkTrek / Data: StockIQ

This approach relies heavily on predictions and historical sales data to determine how much inventory should be produced and stocked ahead of consumer orders.

By manufacturing goods based on expected demand, businesses aim to ensure product availability and minimize the risk of stockouts.

Benefits of Push-Through Systems

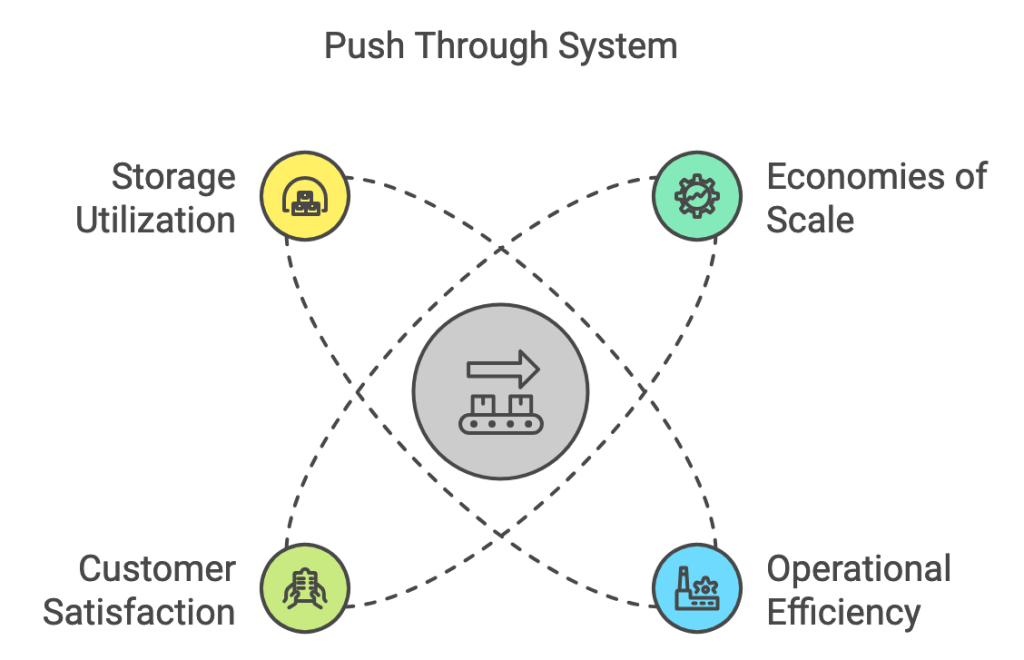

Push inventory management systems, sometimes called push systems, offer several advantages, particularly in maintaining product availability and optimizing production scheduling.

Illustration. WorkTrek / Data: Hollingsworth

One key benefit is the ability to plan and manage long production runs, which can lead to economies of scale and lower per-unit manufacturing costs.

By producing in bulk, businesses can reduce the frequency of production line changes, minimize downtime, and improve operational efficiency.

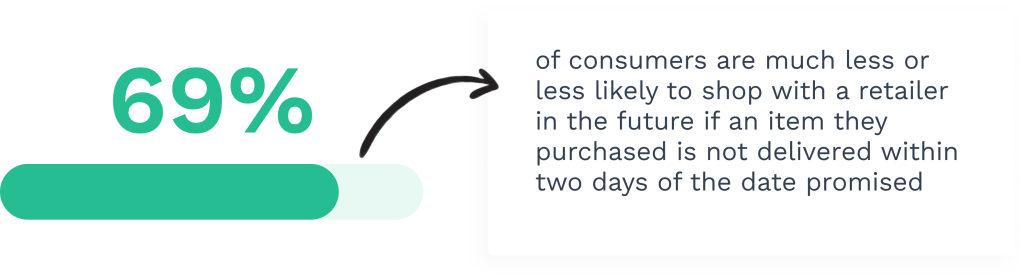

Additionally, push systems can buffer against sudden spikes in demand, ensuring that products are readily available for consumers without delays.

Illustration: WorkTrek / Data: SupplyChainBrain

This readiness can improve customer satisfaction and loyalty, reducing the likelihood of stockouts and backorders.

Furthermore, push systems allow for better utilization of storage facilities, as inventory can be strategically placed in locations that facilitate quick distribution to retailers or end consumers.

Overall, push systems require accurate demand forecasting to be effective, but when appropriately managed, they offer significant benefits regarding production efficiency, cost savings, and customer satisfaction.

Push vs. Through Systems

Pull systems and push systems differ in how they trigger production. Push systems produce based on forecasted market demand, delivering ahead of actual sales to ensure product availability.

Source: WorkTrek

However, this preventive approach can result in overproduction, excess inventory, and extra costs when demand doesn’t meet the forecast.

On the other hand, pull systems only produce when there is a specific customer order, so output is aligned to immediate market demand. This approach reduces waste by keeping just enough stock for current demand and minimizes the risk of overproduction.

Pull systems achieve operational efficiency and flexibility by producing to current market demand through customer orders.

These characteristics make them ideal for industries with short lead times, and demand fluctuates wildly.

Inventory Management Strategies

Both push and pull inventory management systems require reasonable stock control.

Push systems rely on forecasts of customer demand to inform production and buying decisions, which can result in excess stock if projections are wrong—the need for a significant initial investment in inventory results in higher storage costs and lower cash flow.

On the other hand, pull inventory management is triggered by actual customer orders, so you don’t accumulate unnecessary stock and reduce storage costs.

Pull strategies use past sales data to fine-tune the production schedule to market demand.

This is ideal for industries like consumer electronics, where products move quickly through the market. This approach reduces waste and improves cash flow and operational efficiency.

Cost Implications

In inventory management, the cost implications of push and pull systems are big. Push systems can result in higher costs because of the need for precise demand forecasting and the risks of unsold goods.

These systems require a big initial investment in inventory, which can result in higher storage costs and waste if sales don’t materialize. Excess stock can occupy valuable storage space and immobilize capital that can be used elsewhere.

Conversely, pull inventory management systems lower total costs by reducing waste and excess inventory.

Pull systems aim to reduce storage costs and improve operational efficiency by producing confirmed orders and keeping low inventory buffers.

These systems also have risks, such as higher manufacturing costs due to repeated need-based reordering or difficulty meeting customer demand if not appropriately controlled.

Agility and Responsiveness

Push and pull systems are different in their ability to adapt and respond to market changes.

Production adjustments in pull systems can be immediately based on customer demand, reducing the risk of overproduction or stockout and improving responsiveness and operational efficiency.

By matching inventory to current consumption trends, manufacturers ensure that production is aligned with market demand, reducing excess stock and increasing customer satisfaction.

Conversely, push systems are highly dependent on accurate forecasts of customer demand, a task that becomes more challenging as markets move quickly.

Pull systems’ inherent flexibility and agility give them a competitive advantage by allowing businesses to react faster to changing customer demand and market shifts.

Pull Through System

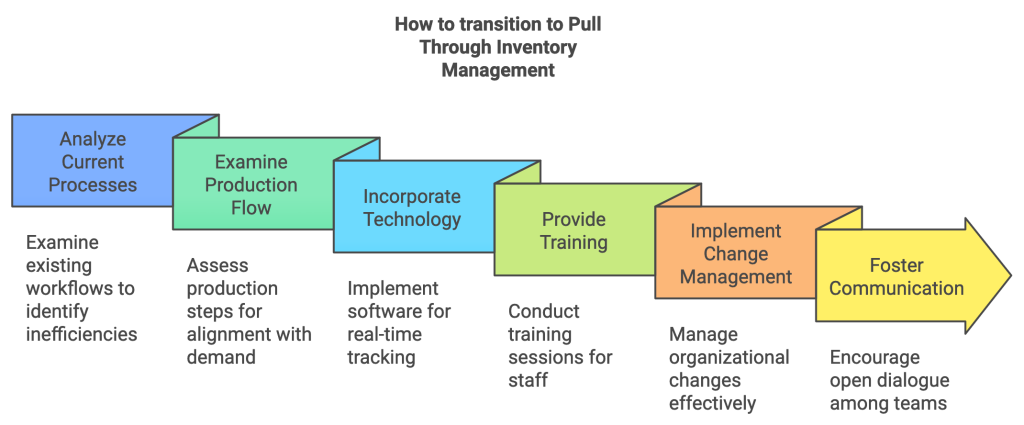

Moving to a pull system requires careful planning and strategy to navigate the challenges. Start by analyzing your current processes and identifying the areas that need attention.

Examine your production flow, inventory management, and supply chain processes thoroughly to ensure alignment with actual demand and reduce waste.

Incorporating technology is key to a successful pull system. Advanced inventory management software or CMMS software with inventory management can significantly improve real-time tracking and data consolidation, allowing manufacturers to respond quickly to market demand and supply chain changes.

Comprehensive training and robust change management are required to ensure people can use pull systems properly. Open communication and consistent feedback build trust, which makes the transition smoother for all parties involved in the shift from traditional to pull-based systems within the modern supply chain.

Source: WorkTrek

Current Processes

Assessing the current manufacturing process is critical to moving to a pull system. As part of the assessment, you should identify inefficiencies and opportunities to improve and align the production process with actual demand.

Streamlining the process and adopting flexible inventory management will reduce waste and improve operational efficiency.

Identifying the operational constraints that hinder performance is important. This ensures that the new system will be tailored to customer needs as they arise, responsive to real-time demand.

Training and Change Management

Training and change management are key to a successful pull system. Training programs should focus on the principles of pull systems, such as just-in-time and kanban, to ensure employees understand the new process.

Simulation helps employees understand the impact of the pull system on operations and prepares them for the transition.

Open communication and employee feedback builds trust and buy-in for the change.

Push-Pull Hybrid

In a push-pull hybrid, the benefits of push and pull systems are combined to create a new manufacturing approach.

By incorporating push strategies that forecast demand with pull strategies for actual customer needs, this hybrid system allows producers to produce components ahead of time and adapt quickly by shifting to a more responsive push-pull system when market demand surges.

This synergy will perfect inventory management and operational efficiency.

This two-pronged approach is ideal for industries with variable customer demand. It handles flow items through predictive pushes and unique items in reactive mode.

This will increase agility and quick response, and inventory will sync with customer demand fluctuations.

By combining the strengths of push and pull, production can achieve the efficiency needed to stay competitive in fast-paced markets.

Hybrid Benefits

Hybrid push-pull systems combine push and pull elements, with a push strategy for core products and a pull strategy for special products. This will maintain optimal inventory levels.

This integrated approach will manage variable demand by applying push to base product lines and pull to final customization. In short, the hybrid approach will have more control over inventory and agility to respond to market demand changes.

Hybrid Examples

Several companies have employed a hybrid push-pull system. Below are a few examples:

Zara (Inditex)

Zara, the fast-fashion retailer, is renowned for its innovative hybrid push-pull system:

- Push component: Based on historical data and forecasts, Zara produces and promotes basic clothing items (e.g., plain T-shirts and jeans).

- Pull component: For trendy, fashion-forward items, Zara uses a pull strategy, quickly responding to real-time sales data and customer preferences.

This approach allows Zara to balance having staple items always in stock while remaining highly responsive to fashion trends.

Toyota

Toyota’s production system is a classic example of a hybrid push-pull approach:

- Push component: Long-term production planning and procurement of raw materials are based on forecasts.

- Pull component: The actual assembly of vehicles is triggered by customer orders using a Just-In-Time (JIT) system.

This strategy helps Toyota maintain efficiency while remaining flexible to market demands.

Walmart

Walmart utilizes a sophisticated hybrid push-pull system:

- Push component: Based on forecasts, staple goods and products with predictable demand are pushed to stores.

- Pull component: Walmart uses real-time sales data for items with variable demand to pull inventory through its supply chain.

This strategy helps Walmart maintain its reputation for always having a wide range of products in stock while minimizing waste and overstock situations.

These real-world examples demonstrate how companies across various industries leverage hybrid push-pull systems to balance their supply chains’ efficiency, responsiveness, and cost-effectiveness.

The key is identifying which products or components are best suited for push or pull strategies within each business’s context.

Demand Forecasting in Pull Through

Pull inventory management relies on demand forecasting, which is critical to sync production with customer needs.

Aligning production to market demand will minimize stockouts and excess inventory. A thorough analysis of historical sales, current market conditions, and customer behavior is required to forecast future demand accurately.

Exact forecasting is key to minimal inventory and a production schedule that matches immediate customer demand.

To manage inventory through pull systems, you need real-time information and communication with suppliers for timely replenishment.

By using advanced analytics and artificial intelligence, such as machine learning, manufacturers can improve forecasting accuracy and be more agile in responding to market changes.

This will improve operational efficiency, facilitate faster fulfillment of customer expectations, and make them more competitive.

Ways to Improve Forecasting

Pull systems can use various methods to get accurate demand forecasting. Forecasting from sales data uses current transactions and future business to estimate future manufacturing requirements and keep inventory in sync with customer demand. More accurate forecasting can be achieved through advanced analytics and machine learning, which look into many factors, such as industry trends, customer behavior, and broader economic variables.

Forecasting from qualitative analysis uses market knowledge and expert insight to capture changes in customer preferences that historical data may miss. Graphical forecasting plots trend lines in the data so companies can see variations in sales that raw numbers can’t.

Using these methods will allow producers to refine their demand forecasting. This will ensure that the production schedule meets customer needs and reduces excesses.

Historical Sales Data

Pull systems rely heavily on demand forecasting, which relies heavily on historical sales data to identify patterns and customer buying behavior from previous seasons. This data is used with quantitative analysis to forecast future demand and is good for companies with stable sales histories.

Adding qualitative analysis, such as expert insights, to these quantitative methods will improve forecasting accuracy. For companies that want to practice just-in-time production, this refined forecasting is critical—it will allow them to keep inventory optimal and align production with actual customer needs in the market.

Challenges and Solutions in Pull-Through

Implementing pull systems in inventory management is complex, especially when dealing with an unpredictable supply chain and getting suppliers to cooperate.

Synchronizing many operational processes to match customer demand can be tricky and, if not done right, results in shortages, lost sales, and unhappy customers. Companies may also encounter resistance from employees who are used to pushing systems. So, they will need thorough training and support to make this transition.

To overcome these challenges, you need strategies and contingency plans. Employees should be involved in continuous improvement and open communication channels to ease the cultural shift to pull systems.

Build strong partnerships with suppliers and introduce advanced inventory management practices to reduce supply chain variability and operational efficiency.

Supply Chain Variability

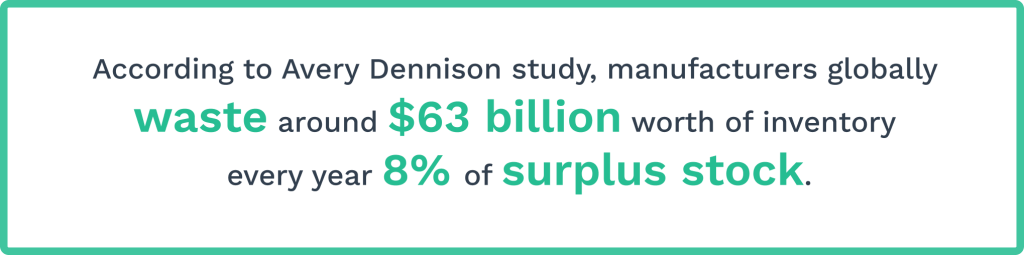

Managing inventory in pull systems to match customer demand can be challenging, especially when dealing with supply chain variability that can cause stockpiling, longer lead times, and not meeting service levels.

Illustration. WorkTrek / Data: Avery Dennison

To mitigate these issues, tactics like reducing lot sizes and increasing the frequency of deliveries can be beneficial, making them more agile and quick to respond to changes.

Contingency plans are critical to overcome supply chain disruptions and production schedules to match customer demand.

Advanced inventory management systems and real-time data integration can help producers respond more to supply chain variability. Monitoring current inventory and using advanced analytics for forecasting is key to predicting future demand scenarios.

This will make operations more efficient and keep inventory lean without sacrificing on-time delivery to customers.

Supplier Collaboration

To keep the pull process going, it would help if you built strong partnerships with suppliers. Sharing information and data with suppliers will enable them to respond faster and supply to actual demand.

Illustration: WorkTrek / Data: Relex Solutions

Frequent interaction and shared goals between manufacturers and suppliers will build trust in each other and make the supply chain more efficient.

This is key to controlling supply chain variability and ensuring inventory is adjusted to meet customer needs.

Pull Through Case Studies

Many industries have proven the benefits of pull systems in real life. Toyota is well known for its Just-In-Time (JIT) system, where they only procure raw materials when needed for production orders. This has made Toyota more efficient in production and has helped it quickly respond to market demand changes.

Case studies from the automotive and consumer electronics industries show how pull strategies benefit these industries.

Pull systems can optimize inventory management, reduce lead times, and improve manufacturing efficiency.

Case Study 1: Dell Just-In-TimeModel

Dell revolutionized the computer industry with its pull-based, just-in-time (JIT) inventory management strategy

Some key aspects of Dell’s approach include:

- Materials for production are received only when needed, based on actual customer orders

- Inventory is not held for more than six days to reduce storage costs

- Demand forecasting must be highly accurate to make the system work

- Waste is eliminated where possible, including waste from defects and overproduction

By implementing this pull system, Dell minimized unnecessary inventory storage while still efficiently meeting customer demand. This allowed them to reduce costs and offer customized products with short lead times.

Countdown NZ’s Real-Time Inventory App

New Zealand grocery chain Countdown launched an innovative pull-based inventory system using a real-time sales app called Compass

Key features include:

- Suppliers can monitor sales of their products in any Countdown supermarket nationwide in real-time

- The system provides data on stock levels, orders, pricing, and sales trends

- Historical data is used to predict sales and alert suppliers if actual sales deviate from expectations

- Suppliers can quickly identify issues and take action to replenish stock as needed

This pull system allows Countdown to maintain optimal inventory levels by giving suppliers the information and lead time needed to deliver the right products to the right stores at the right time. It has improved on-shelf availability and reduced excess inventory.

Dell and Countdown demonstrate how pull-based systems can help companies reduce costs, improve efficiency, and match supply with customer demand. The key is using real-time data and close supplier collaboration to respond quickly to changing needs.

Conclusion

In summary, it is important to understand the difference between push and pull strategies when building efficient manufacturing systems. Focusing on just-in-time demand in pull systems will result in cost savings, operational efficiency, and quick response using lean inventory management practices. This will ensure the production schedule is aligned with customer needs, reduce excess, and increase agility.

Preparation, technology, and change leadership are key to transitioning to a pull strategy in inventory management. Hybrid push-pull models are a strategic compromise that uses the best of both worlds to keep inventory levels optimal and be agile to market changes. Examples from various industries show how these can transform traditional manufacturing.