Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeEffective maintenance management is crucial for organizations seeking to optimize their operations and reduce downtime. A Computerized Maintenance Management System (CMMS) provides powerful tools to set and track maintenance goals, helping to mitigate equipment failures and enhance operational efficiency. Implementing SMART (Specific, Measurable, Achievable, Relevant, Time-bound) goals within a CMMS framework enables companies to enhance equipment reliability and extend asset lifecycles.

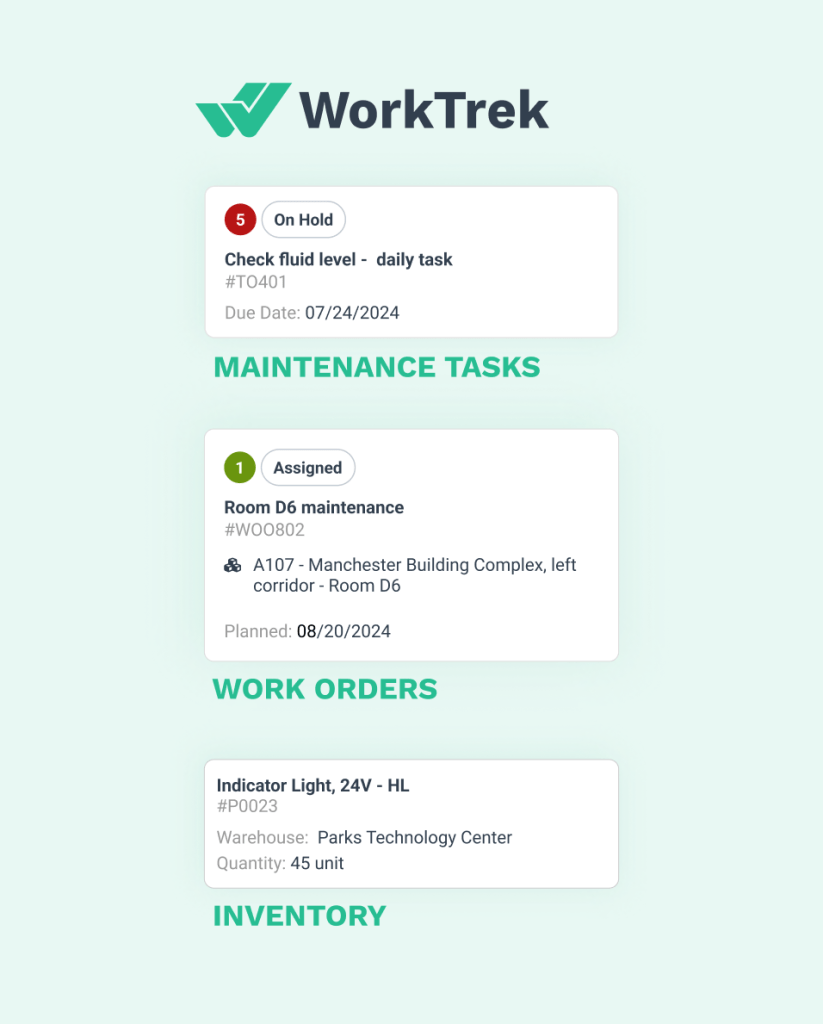

CMMS software offers work order tracking, asset management, and reporting capabilities. These tools allow maintenance teams to establish clear objectives and monitor progress over time. By leveraging CMMS data, organizations can identify areas for improvement and make informed decisions about resource allocation.

Setting SMART maintenance goals with a CMMS helps align maintenance activities with broader business objectives. This approach ensures that maintenance efforts contribute directly to organizational success, improving efficiency and reducing costs in the long run.

Source: Western North Carolina Conference

Understanding Computerized Maintenance Management System

Computerized Maintenance Management Systems (CMMS) have revolutionized how organizations and maintenance leaders handle maintenance operations. These powerful software tools streamline processes, improve efficiency, and provide valuable data insights.

Definition and Purpose of CMMS

A CMMS is a software platform designed to centralize maintenance information and facilitate the management of maintenance operations. Its primary purpose is to help organizations track, plan, and optimize maintenance activities.

CMMS software typically includes features for:

- Asset management

- Work order creation and tracking

- Preventive maintenance scheduling

- Inventory control

- Reporting and analytics

- Scheduled maintenance

- Maintenance Workflows

- Overview of maintenance work

Implementing a CMMS can optimize maintenance processes, leading to substantial cost savings, improved operational efficiency, and enhanced decision-making among maintenance teams.

A CMMS enables maintenance teams to work more efficiently and make data-driven decisions by centralizing these functions. It helps reduce equipment downtime, extend asset lifespan, and control maintenance costs.

Source: WorkTrek

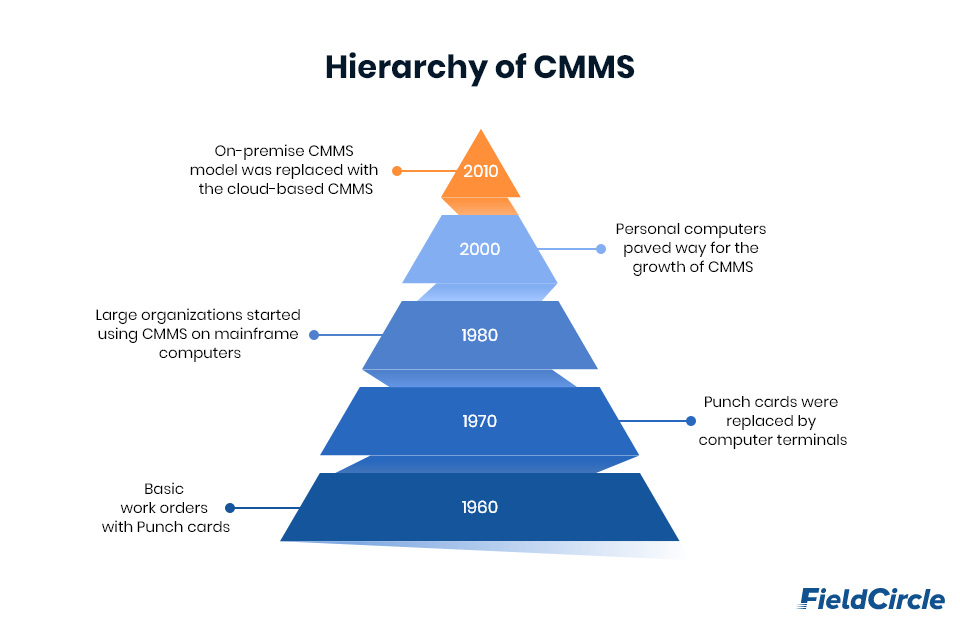

The Evolution of Maintenance Management

Maintenance management has undergone significant changes over the years. In the past, organizations relied on paper-based systems and manual processes to track maintenance activities.

The advent of computers in the 1980s brought the first generation of CMMS software. These early systems digitized basic maintenance records but had limited functionality.

As technology advanced, CMMS software became more sophisticated. Modern systems offer cloud-based solutions, mobile accessibility, and integration with other business systems. They incorporate advanced features like predictive maintenance algorithms and Internet of Things (IoT) connectivity.

Today’s CMMS platforms provide real-time data analysis, enabling proactive maintenance strategies. This evolution has transformed maintenance from a reactive, cost-center approach to a strategic, value-adding function within organizations.

Source: FieldCircle

The Pillars of Smart Maintenance Goals

Smart maintenance goals focus on key areas that drive operational excellence and efficiency. These pillars form the foundation for a robust maintenance strategy.

Asset Reliability and Performance

Asset reliability and equipment performance are critical for maintaining smooth operations. A CMMS helps track equipment uptime, failure rates, and overall equipment effectiveness (OEE).

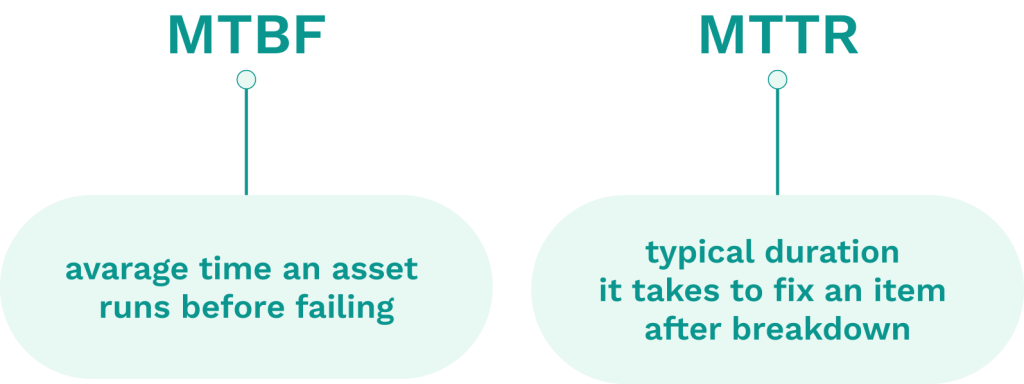

Setting goals for Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR) can significantly improve asset performance. For example, aiming to increase MTBF by 15% annually pushes teams to identify and address recurring issues.

Implementing condition-based monitoring enables proactive maintenance, reducing unexpected breakdowns. Goals might include installing sensors on 25% of critical assets each quarter or reducing reactive maintenance by 20% yearly.

Source: WorkTrek

Maintenance Planning and Scheduling Efficiency

Efficient planning and scheduling maximize resource utilization and minimize equipment downtime. A CMMS provides tools to optimize these processes.

Setting goals for schedule compliance, such as achieving 90% within six months, encourages teams to complete work as planned. Tracking wrench time helps identify inefficiencies in technician productivity.

Another crucial goal is reducing the maintenance backlog. Aim to keep the backlog under four weeks of work or decrease it by 10% each month. This ensures timely completion of preventive tasks and reduces the risk of equipment failure.

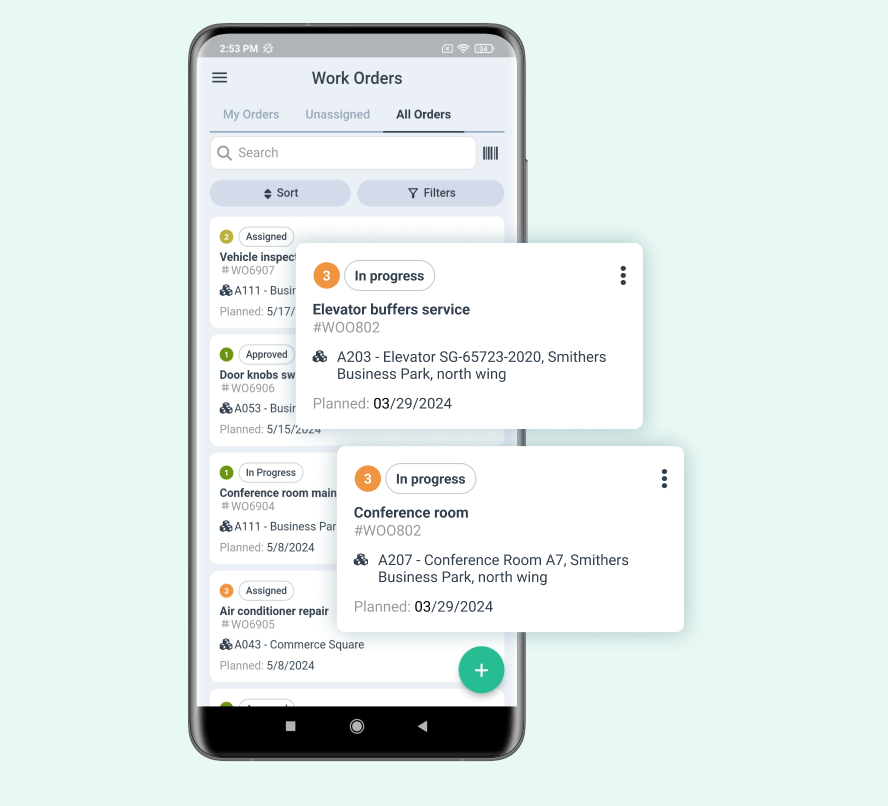

Work Order Management

Effective work order management streamlines maintenance operations and improves data quality. A CMMS centralizes work order information, enabling better tracking and analysis.

Goals might include reducing averageadoption and improve real-time data capture, such as completing 80% of work orders on mobile devices within three months.

Source: WorkTrek

Setting Goals Within the CMMS Framework

Implementing a Computerized Maintenance Management System (CMMS) provides a structured framework for setting and achieving maintenance goals. This approach enables organizations to align their maintenance strategies with broader business objectives.

Illustration: WorkTrek / Data: OfficeRnD

Defining Measurable Objectives

Effective goal-setting within a CMMS framework begins with defining clear, measurable objectives. These objectives should be specific, time-bound, and quantifiable. For example:

- Reduce equipment downtime by 15% within six months

- Increase preventive maintenance completion rate to 95% by the end of Q3

- Decrease maintenance overtime hours by 20% in the next fiscal year

Maintenance teams can track progress and make data-driven decisions by setting precise targets. The CMMS 4dccccAligning Goals with Business Outcomes

Maintenance goals should directly support broader organizational objectives. This alignment ensures that maintenance efforts contribute to the company’s overall success. Key considerations include:

- Cost reduction

- Asset reliability

- Safety improvements

- Regulatory compliance

For instance, if a business aims to increase production output, maintenance goals might focus on improving equipment availability and reducing unplanned downtime. The CMMS helps track these metrics and their impact on production targets.

Benchmarking and Performance Metrics

Establishing benchmarks and key performance indicators (KPIs) is crucial for measuring progress towards maintenance goals. Common maintenance KPIs include:

- Mean Time Between Failures (MTBF)

- Overall Equipment Effectiveness (OEE)

- Planned Maintenance Percentage (PMP)

- Maintenance Cost as a Percentage of Replacement Asset Value (RAV)

Tracking maintenance metrics, in addition to KPIs, is essential for uncovering insights and steering continuous improvements in maintenance strategies.

The CMMS facilitates data collection and analysis for these metrics, allowing organizations to compare performance against industry standards or internal targets. Regularly reviewing these KPIs helps identify areas for improvement and adjust maintenance strategies as needed.

Leveraging CMMS for Proactive Maintenance

A Computerized Maintenance Management System (CMMS) enables organizations to shift from reactive to proactive maintenance approaches and implement smart maintenance goals. This powerful tool provides data-driven insights and automation capabilities to optimize maintenance strategies.

Implementing Predictive Maintenance Strategies

CMMS software facilitates predictive maintenance by analyzing equipment data to forecast potential failures. It collects and processes information from sensors, IoT devices, and historical records to identify patterns and anomalies.

This data-driven approach allows maintenance teams to schedule interventions before breakdowns occur. By setting up automated alerts and work orders, CMMS ensures timely action on potential issues.

Predictive maintenance reduces unexpected downtime, extends equipment lifespan, and optimizes resource allocation. It also minimizes the need for emergency repairs, leading to cost savings and improved operational efficiency.

Source: WorkTrek

Utilizing CMMS Data for Decision-Making

CMMS generates valuable data on asset performance, maintenance history, and resource utilization. This information empowers managers to make informed decisions about maintenance strategies and equipment investments.

Key performance indicators (KPIs) tracked by CMMS include:

- Mean Time Between Failures (MTBF)

- Mean Time To Repair (MTTR)

- Overall Equipment Effectiveness (OEE)

These metrics provide insights into equipment reliability and maintenance effectiveness. By analyzing trends and patterns, organizations can identify areas for improvement and allocate resources more efficiently.

CMMS data also supports lifecycle cost analysis, helping organizations determine the optimal time for equipment replacement or upgrades. This strategic approach to asset management leads to better long-term planning and cost control.

Source: Cooltrack

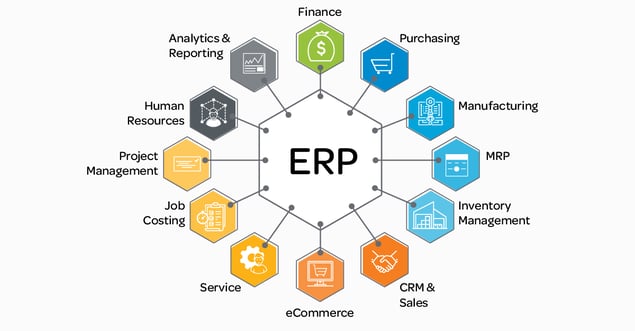

CMMS Integrations and Upgrades

CMMS systems can be enhanced through integrations with other business software and strategic upgrades. These improvements streamline workflows and expand functionality.

CMMS integration with enterprise resource planning (ERP) systems allows for seamless data flow between maintenance and financial modules. This connection enables real-time cost tracking and budget management.

Source: Projectline

Integration with human resources software streamlines workforce management. It simplifies scheduling and ensures proper skill allocation for maintenance tasks.

Connecting CMMS to inventory management systems optimizes the ordering of parts and supplies. This integration prevents stockouts and reduces excess inventory costs.

IoT sensor integration enables predictive maintenance capabilities. Real-time equipment data feeds into the CMMS, triggering alerts and work orders based on asset conditions.

Evaluating CMMS Upgrades and Updates

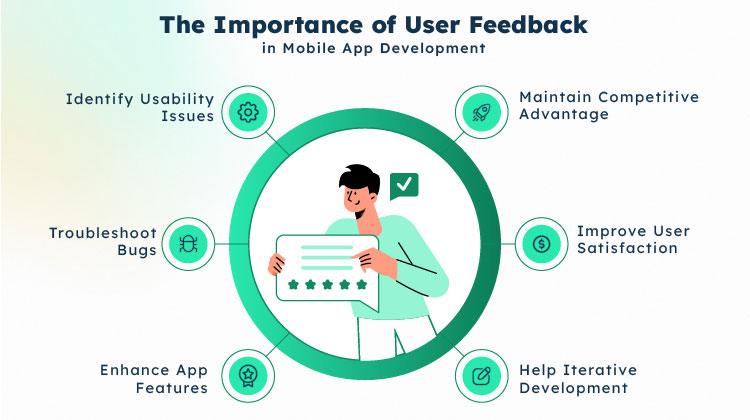

Regular CMMS upgrades improve system performance and add new features. Evaluating upgrade options should focus on addressing current pain points and future needs.

Cloud-based CMMS upgrades often occur automatically, reducing internal IT burden. However, updates to on-premise systems may require more planning and downtime.

Mobile app upgrades enhance field technician productivity. New versions typically offer improved user interfaces and offline capabilities.

Assessing the return on investment for CMMS upgrades is crucial. Organizations should weigh implementation costs against potential efficiency gains and cost savings.

User feedback is valuable when considering upgrades. Maintenance teams can provide insights into which new features would be most beneficial.

Source: Taazaa

Training and Change Management

Implementing a CMMS requires effective training and change management strategies. These elements are crucial for successful adoption and maximizing the system’s benefits.

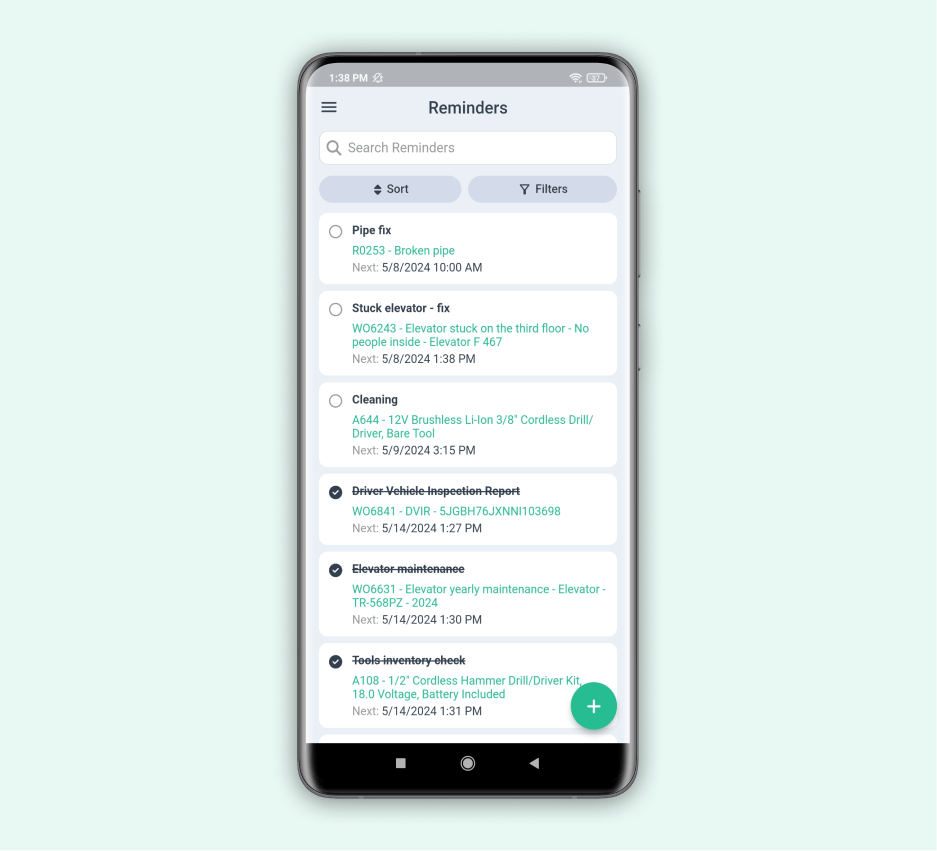

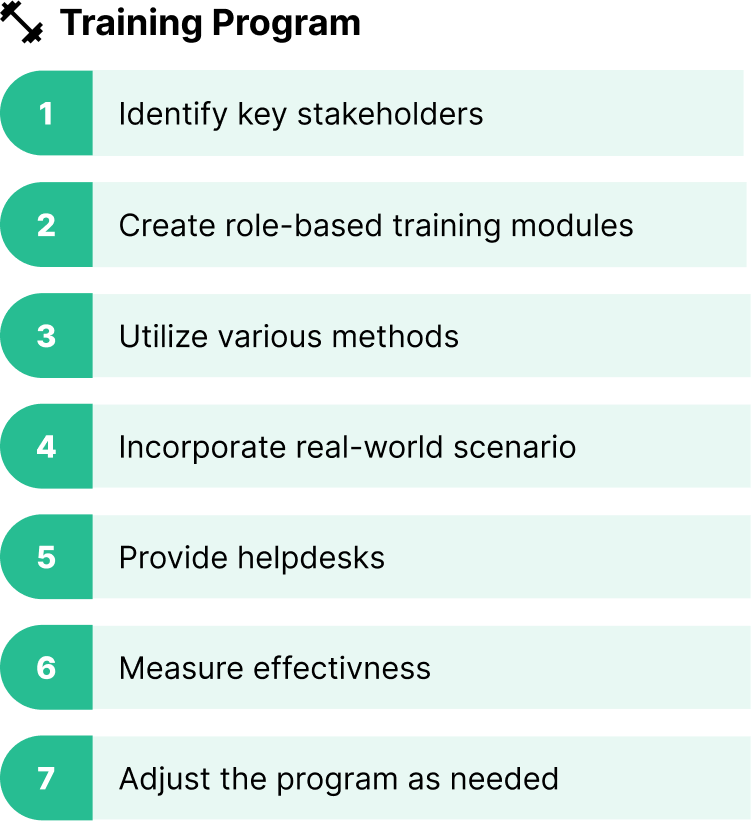

Developing a Training Program for CMMS Users

A comprehensive CMMS training program should cater to user roles and skill levels. Start by identifying key stakeholders and their specific needs. Create role-based training modules that focus on relevant features and workflows.

Utilize various training methods, such as hands-on workshops, online tutorials, and documentation. Incorporate real-world scenarios and practice exercises to reinforce learning. Provide ongoing support through helpdesks and refresher courses.

Measure training effectiveness through assessments and user feedback. Adjust the program as needed to address gaps and evolving requirements.

Source: WorkTrek

Managing Organizational Change with CMMS Implementation

Successful CMMS implementation requires a well-planned change management approach. Begin by clearly communicating the benefits and reasons for adopting the new system to all stakeholders.

Identify and address potential resistance points early in the process. Involve key users in the implementation to foster a sense of ownership and commitment.

Create a transition plan that outlines steps for moving from old processes to new CMMS-driven workflows. Set realistic timelines and milestones to track progress.

Designate change champions within the organization to promote adoption and provide peer support. Regularly collect feedback and address concerns to ensure smooth integration of the CMMS into daily operations.

Monitoring and Adjusting Goals

Regular evaluation and refinement of maintenance goals are essential for optimizing asset performance and operational efficiency. A CMMS provides valuable data and insights to support this ongoing process.

Analyzing Performance Data

CMMS software collects and organizes maintenance data, enabling teams to track key performance indicators (KPIs). These metrics may include equipment uptime, mean time between failures, and maintenance costs.

Regular review of these KPIs helps identify trends and areas for improvement. Teams can compare actual performance against established goals to gauge progress.

Data visualization tools in CMMS platforms often present information in easy-to-understand formats like charts and graphs. This visual representation aids in the quick identification of patterns or anomalies.

Source: WorkTrek

Continuous Improvement in Maintenance Operations

Performance analysis insights drive continuous improvement efforts. Maintenance teams can use this information to refine strategies and set new, more challenging goals.

CMMS systems often include features for documenting and sharing best practices. This knowledge base helps teams learn from successes and avoid repeating mistakes.

Periodic review meetings allow stakeholders to discuss findings and propose adjustments to maintenance procedures. These sessions may lead to updates in preventive maintenance schedules or changes in resource allocation.

Automated alerts in CMMS platforms can notify managers when KPIs deviate from target ranges. This real-time feedback enables prompt corrective action and goal adjustment as needed.

Conclusion

Setting smart maintenance goals with a CMMS empowers organizations to optimize maintenance operations. By leveraging data-driven insights and automation, companies can enhance equipment reliability and extend asset lifespans.

Implementing a CMMS facilitates proactive maintenance strategies, reducing unexpected breakdowns and minimizing downtime. This approach leads to improved productivity and cost savings across the organization.

Regular goal evaluation and adjustment ensure continuous improvement in maintenance practices. As teams become more proficient with CMMS tools, they can refine their objectives and achieve higher operational excellence.

Effective use of a CMMS for goal setting fosters better communication between maintenance teams and management. This alignment of objectives contributes to overall business success and long-term sustainability.

Organizations that embrace CMMS-driven goal-setting position themselves for greater competitiveness in their industries. The resulting efficiency gains and cost reductions provide a significant advantage in today’s fast-paced business environment.

Illustration: WorkTrek / Quote: smartsheet