Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

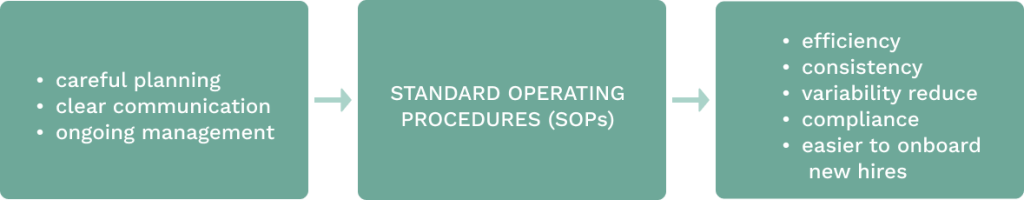

Try for freeOrganizations are establishing Standard Operating Procedures (SOPs) to improve efficiency, ensure consistency, and maintain high-quality outcomes for the overall organization. These are instructions that organizations can document to help employees perform their tasks.

SOP serves as the blueprint for executing tasks and processes, reducing variability, establishing a solid foundation for the organization, and ensuring compliance across the board.

Organizations that implement SOPs generally see an overall increase in quality. However, it does require careful planning, clear communication, and ongoing management.

An established SOP process also helps with onboarding new hires and helps new employees understand the organization’s processes quickly.

This guide looks at the top 10 steps to implement SOPs in your organization effectively.

Source: WorkTrek

Why do you need SOP?

SOPs can help any organization identify areas for improvement, define non-compliance issues, and take the next step in improving efficiency.

Standard Operating Procedures (SOPs) encompass various activities, from everyday operational duties to intricate procedures. They are generally crafted in alignment with industry norms, regulatory mandates, and internal benchmarks of excellence.

Typical instances of SOPs include:

- Directives for managing inventory

- Protocols for customer interaction

- Methodologies for financial reporting

- Documenting repetitive tasks

- Defining task’s complexity

- Streamline decision making

- Keep employees on the same page

- Save time in performing tasks

- Improve company performance reviews

- Improve overall safety considerations

- Develop step-by-step instructions for new employees

- Develop standard operation procedures

- Adhere to industry regulations

- Reduce operational costs

- Document organizational prior knowledge

Steps to implement standard operating procedures

1. Conduct a Comprehensive Process Audit

The first step towards implementing SOPs is to conduct an exhaustive audit of your current processes, routine operations, and documented processes.

During this process, you must identify every process within your organization, document relevant areas, determine important parts of the operation, and provide a clear overview of where SOPs can be most beneficial.

While this process might seem labor-intensive, it can greatly aid in the overall success of implementing SOPs.

This audit should highlight areas that lack consistency, where complex processes face frequent errors or have significant compliance requirements.

Source: Unsplash

2. Prioritize Your Processes

Once the business processes have been mapped out, it is time to prioritize and create the tasks required for SOP. Factors such as the complexity of the task, its impact on business operations, frequency, and risk level should influence this decision.

In this step, focusing initially on routine procedures that, if standardized, could significantly improve operational efficiency and compliance would be helpful. Refining that process will require input from all stakeholders in the organization.

Outlining these simple steps can enhance quality and help allocate resources where the organization needs them most.

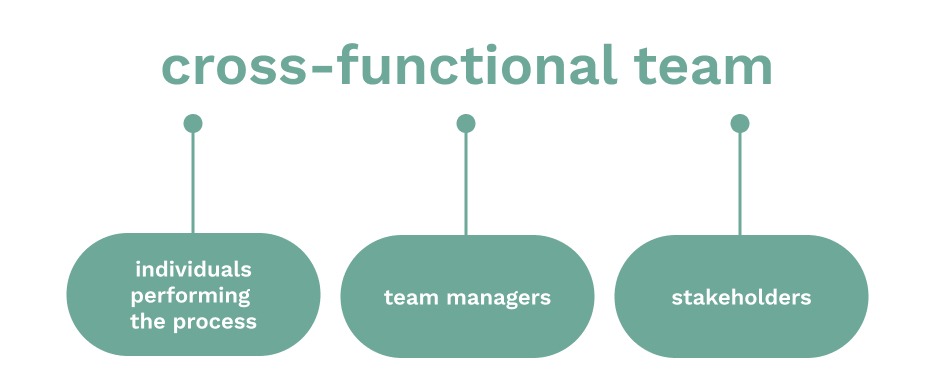

3. Assemble a Diverse Team for Standard Operating Procedure Development

Creating effective SOPs requires insights from a cross-functional team. This team should include individuals who perform the processes, those who manage them, and any other stakeholders with a vested interest in the company’s outcome. Determining employee hierarchical steps in developing a standard operating procedure template is helpful.

Source: WorkTrek

4. Draft Clear and Concise SOPs

Drafting standard operating procedures involves detailing each step of the process in a clear, concise manner. The language should be simple, avoiding industry jargon that could confuse or alienate staff.

You can start with a simple SOP template and refine the document as you learn more about the organization.

This phase may also involve deciding on the format of your SOPs, including written documents, flowcharts, or video tutorials, depending on what best suits your organization’s needs.

5. Review and Test the SOPs

Before finalizing your company’s SOPs, review and test them to ensure they effectively achieve their intended purpose. This might involve a pilot run of the SOPs with a small group or department, allowing for real-world feedback and identifying gaps or inaccuracies.

This process is highly iterative, and incorporating feedback will likely increase the output quality and the overall program’s success.

6. Formalize and Document the SOPs

After thorough testing and review, formalizing your SOPs is next. This includes finalizing the document format, ensuring accurate and up-to-date information, and making the SOPs accessible to all relevant employees.

Distribute the document among the organization and receive, evaluate, and implement feedback.

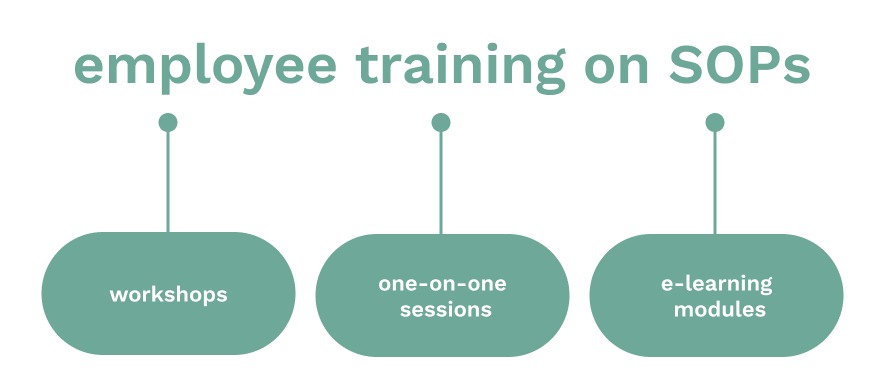

7. Train Employees on SOPs

Successfully implementing a standard operating procedure in your organization without a training program will be very difficult.

Effective training ensures everyone understands their roles and responsibilities within the SOPs, reducing errors and improving compliance.

Training can be conducted through workshops, one-on-one sessions, or e-learning modules, depending on the size and structure of your organization. There are several SOP writing guide training tools online that you can also implement in your process.

Source: WorkTrek

8. Implement the SOPs Across the Organization

With training complete, it’s time to roll out the SOP across your organization. This step requires a careful and systematic process that the organization can monitor closely. At this point, you’ve spent a lot of time and energy developing the organization’s standardized procedures, and it is important to ensure that the implementation step is handled with care.

9. Monitor Compliance and Assess Effectiveness

Ongoing monitoring of SOP is necessary to ensure the procedures are being followed and to gauge their effectiveness in improving operations.

This quality output may also involve regular audits, feedback sessions, and performance metrics to identify areas for improvement. These steps are critical in ensuring your SOP process is managed as designed across the organization.

10. Regularly Review and Update SOPs

The final step in the SOP lifecycle is regularly reviewing and updating your procedures. As your organization evolves, so too will your processes and operational needs.

Regular reviews ensure your SOPs remain relevant and effective, supporting continuous organizational improvement. As you learn more about the process, it is important to continue updating SOPs to reflect the organization better. This constant improvement of the SOP process will ensure its success in the long term.

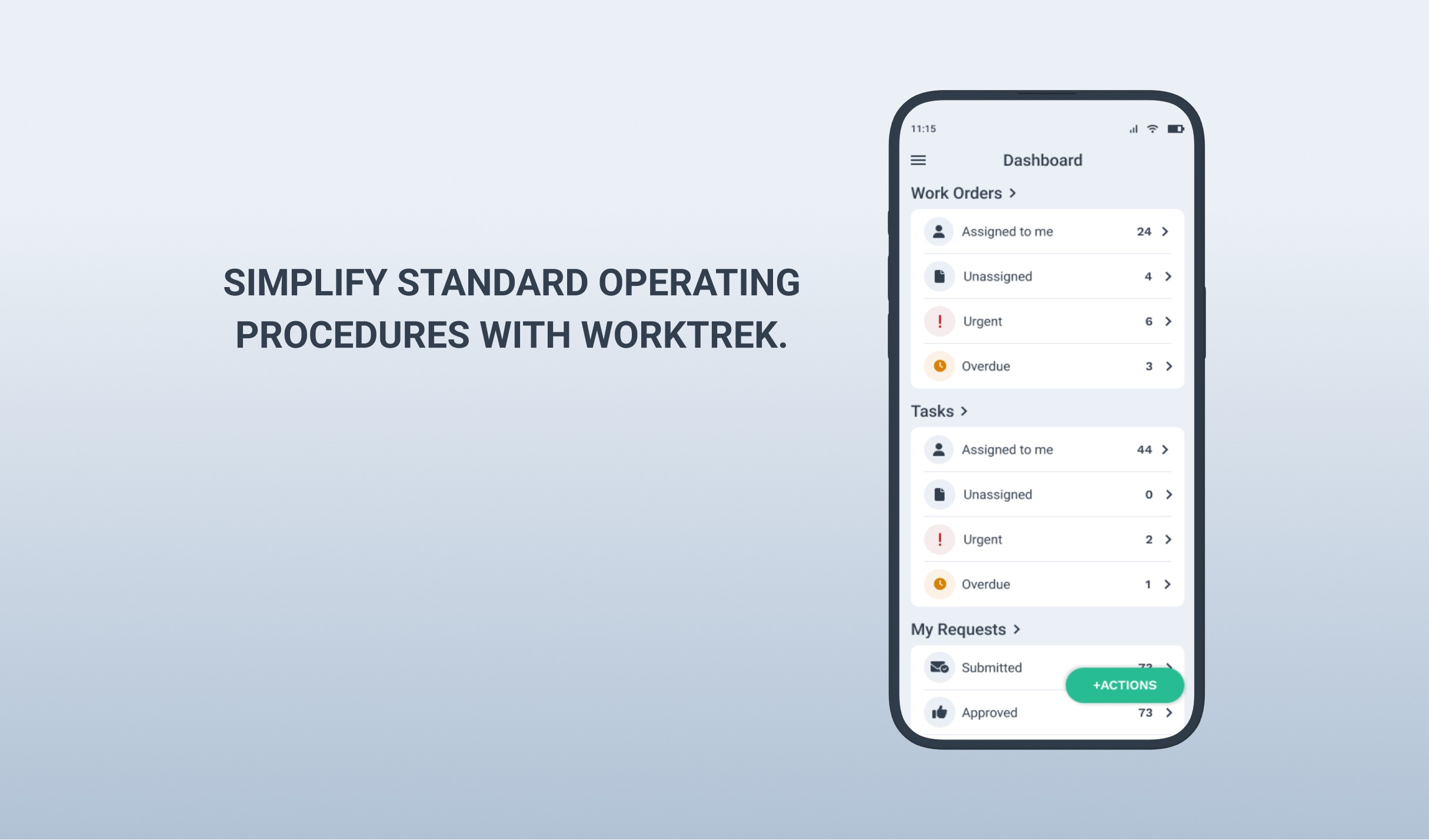

How can a CMMS or Work Order Management Software Simplify SOP?

Suppose your company continues to depend on manual work orders to manage maintenance and facilities. In that case, implementing a Work Order Management system will greatly improve your organizational efficiency and allow your team to better adhere to the entire process of SOP.

Work Order management systems can automate much of the manual effort required for equipment maintenance. This helps standardize processes, help staff members access detailed instructions, and provide digital written instructions on how to manage all equipment.

Source: WorkTrek

Conclusion

Implementing Standard Operating Procedures is a vital strategy for any organization aiming to streamline operations, enhance consistency, and uphold quality standards.

Following a standard operating procedure in these ten steps, from conducting audits to reviewing and testing, can help any organization streamline processes.