Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- O&M costs for wind turbines represent 20-35% of the total levelized cost per kWh over a turbine’s lifetime

- Wind turbines experience an average of 2-4 failures per turbine per year, with gearbox failures causing the longest downtimes

- Proper maintenance can extend turbine lifespan to 20-30 years, maximizing renewable energy production

- The global wind turbine maintenance market is valued at over $20 billion annually

Wind turbines are among the world’s most vital renewable energy sources, converting wind power into clean electricity across wind farms worldwide. However, maintaining these massive structures requires specialized knowledge, careful planning, and consistent execution.

Without proper maintenance, wind turbines face costly repairs, extended turbine downtime, and reduced energy production. That’s why understanding the fundamentals of wind turbine maintenance is essential for wind farm operators and wind turbine technicians alike.

In this guide, we’ll explore everything you need to know about keeping wind turbines running at peak performance, from routine maintenance tasks to advanced predictive maintenance strategies.

Understanding Wind Turbine Maintenance

Wind turbine maintenance involves inspecting, servicing, and repairing components to ensure optimal performance and longevity.

It includes:

- Routine inspections

- Turbine cleaning

- Proper lubrication

- Addressing both minor and major repairs in a timely manner

According to industry data, maintenance costs typically range from 1.2 to 1.5 eurocents per kWh of wind power produced over the turbine’s lifespan. For a new turbine, these costs may initially constitute 10-15% of total expenses, but can increase to 20-35% by the end of the turbine’s lifespan.

The importance of proactive maintenance cannot be overstated. Most wind turbines are designed to operate for 20-30 years, but achieving this lifespan requires consistent care and attention to critical components.

Research shows that wind turbines typically experience 2-4 failures per turbine per year, with offshore turbines facing even higher failure rates due to extreme weather conditions and environmental factors.

Regular maintenance ensures:

- Consistent energy production without unexpected breakdowns

- Prevention of costly repairs through early detection

- Extended component life and overall turbine lifespan

- Enhanced safety for wind turbine technicians and surrounding communities

- Optimal performance under varying wind speed conditions

Essential Wind Turbine Components Requiring Maintenance

To effectively maintain wind turbines, it’s crucial to understand the key components that require regular attention. Each plays a vital role in turbine operation and energy production.

Wind Turbine Blades and Rotor System

The rotor blades are perhaps the most visible turbine components, capturing kinetic energy from the wind. These massive structures face constant exposure to harsh environmental conditions, from lightning strikes to extreme temperatures.

Common issues include:

- Leading-edge erosion from rain, hail, and debris impact

- Surface cracks due to fatigue and UV exposure

- Lightning damage requiring immediate repairs

- Ice accumulation affecting aerodynamic efficiency

Studies indicate that approximately 10-15% of wind turbines experience blade cracking during their lifetime, with blade failures causing an average downtime of 15-30 days per incident.

Gearbox and Drive Train

The gearbox converts the low-speed rotation of the rotor blades into the high-speed rotation required by the generator. It’s one of the most maintenance-intensive components in a wind turbine operation.

Research from multiple databases identifies the gearbox as particularly critical because downtime per failure is high compared to other turbine components.

Gearbox failures account for approximately 10-15% of all wind turbine failures, with an average downtime of around 15 days per incident.

Generator and Electrical Systems

The generator converts mechanical energy into electrical energy. According to IRENA statistics, generators account for about 30% of total maintenance costs and 5.5% of downtime.

Generator failures represent roughly 15% of all turbine failure causes, with older turbines (over 10 years) experiencing failure rates of 7-10% annually.

The electrical systems, including cables, control panels, and electrical connections, require regular inspection to prevent electrical faults that could lead to system failures.

Yaw System and Tower Structure

The yaw system positions the turbine nacelle to face the wind, optimizing energy capture. Yaw system failures are among the most common causes of turbine shutdowns, accounting for approximately 12% of total failures.

The tower structure and foundation bear enormous static and dynamic loads.

Regular inspection of structural integrity, including bolts, welds, and the foundation, is essential to prevent catastrophic failures. Tower failures, while representing only about 4% of all failures, can have severe consequences.

Hydraulic and Lubrication Systems

Proper lubrication is vital for reducing friction and extending component life. The hydraulic system controls blade pitch and braking mechanisms, making it critical for turbine safety and performance.

Research indicates that up to 25% of wind turbines fail prematurely due to inadequate lubrication in gearboxes. Oil leaks and contamination can lead to bearing damage and eventual system failure.

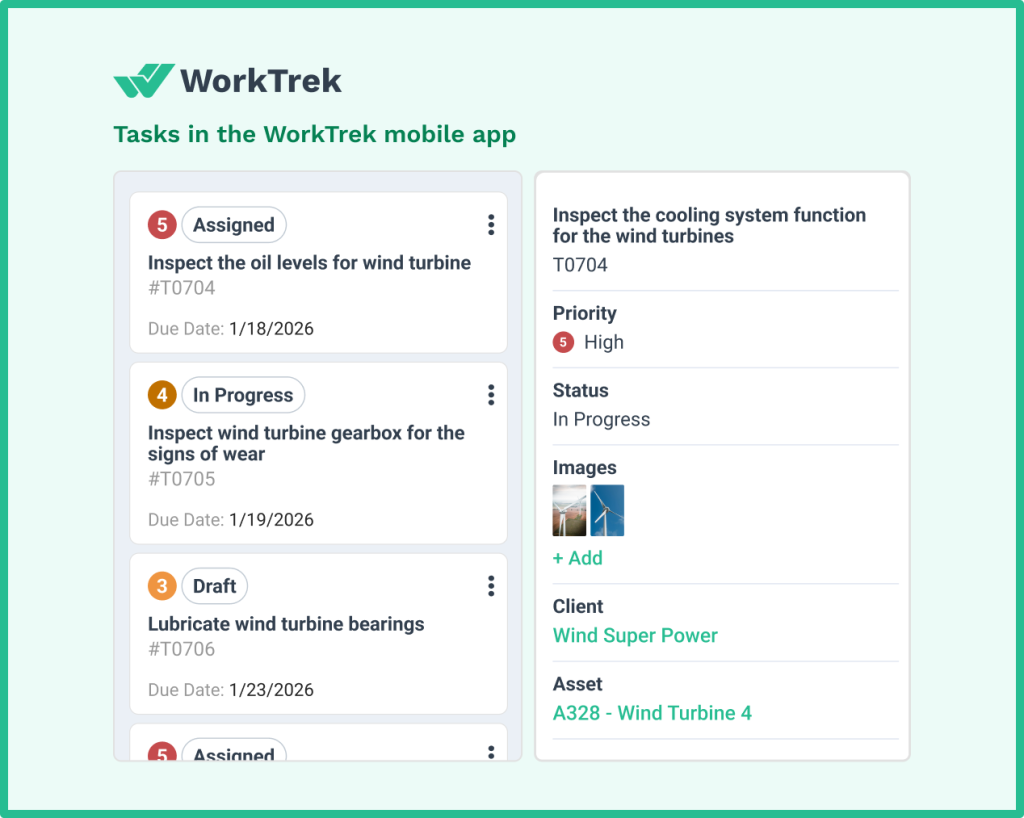

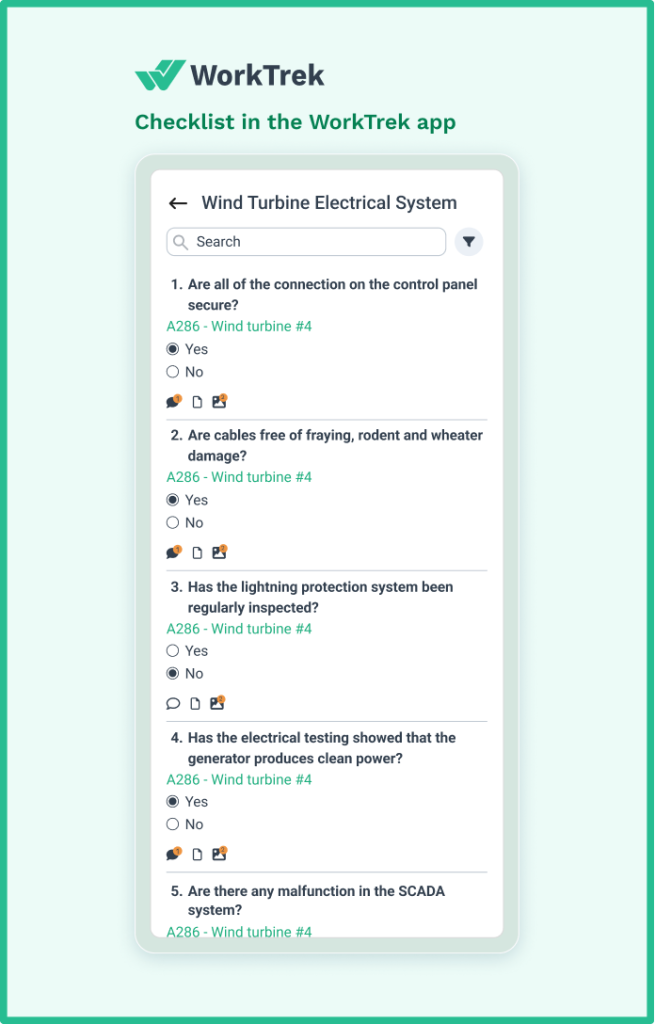

Wind Turbine Maintenance Checklist: Essential Tasks

A comprehensive wind turbine maintenance checklist should systematically address all critical components. Here are the essential maintenance tasks that wind farm operators need to incorporate into their maintenance schedule.

Routine Inspections

Visual inspections form the foundation of any maintenance program. Wind turbine technicians should regularly inspect:

- Rotor blades for cracks, erosion, and surface damage

- Tower and foundation for structural issues

- Electrical components, including cables and connectors

- Oil levels and quality in the gearbox and hydraulic systems

- Control systems and sensors for accurate operation

Most turbines need servicing at least once every two years, though some models require more frequent maintenance depending on turbine age, location, and operating conditions.

Turbine Cleaning and Lubrication

Turbine cleaning involves removing dirt, debris, and contaminants from critical areas. The nacelle, blades, and generator all accumulate dust that can impact performance and create safety hazards.

Lubrication schedules should address:

- Yaw and pitch bearings for smooth rotation

- Main shaft bearings to prevent premature wear

- Gearbox components according to the original equipment manufacturer’s specifications

- Generator bearings for continuous operation

Electrical System Maintenance

The electrical systems require specialized attention to prevent failures. Regular tasks include:

- Testing and cleaning electrical connections

- Inspecting control panels for signs of overheating or damage

- Verifying proper operation of lightning protection systems

- Checking sensor calibration and control system functionality

- Monitoring transformer and converter performance

Blade Inspection and Repair

Given the critical role of turbine blades in energy production, blade maintenance deserves special attention. Advanced inspection techniques include:

- Ultrasonic testing for internal damage detection

- Thermal imaging to identify delamination

- Visual inspection using drones or rope access

- Leading-edge protection system verification

Industry statistics indicate that blade fatigue accounts for approximately 20-25% of blade-related failures, underscoring the importance of proactive inspection and repair.

Predictive Maintenance Technologies

Modern wind farms increasingly employ predictive maintenance approaches using condition monitoring systems. These technologies include:

- Vibration analysis to detect bearing and gearbox issues

- Motor current analysis for electric motor fault detection

- Oil analysis for contamination and wear particle detection

- Thermal monitoring for electrical component health

- SCADA system data analysis for performance trends

According to recent studies, predictive maintenance using advanced oil analysis and condition monitoring can reduce the median levelized cost of energy by 1-2% across the U.S. fleet, with cumulative savings estimated at approximately $6 billion by 2050.

Wind Turbine Maintenance Schedule and Frequency

A good maintenance schedule can balance thoroughness with cost efficiency.

Maintenance frequency varies based on several factors. Those include turbine type, environmental conditions, and manufacturer recommendations.

Standard Maintenance Intervals

Industry best practices recommend the following general schedule:

- Semi-annual inspections (every 6 months): Basic visual checks, oil level verification, minor adjustments

- Annual maintenance (every 12 months): Comprehensive inspection, lubrication service, minor component replacement

- Major service (every 5 years): Extensive inspection, major component overhaul, complete system testing

Offshore turbines typically require more careful maintenance planning due to limited accessibility during extreme weather conditions.

Weather windows for offshore maintenance work must be carefully planned to ensure safe working conditions.

Condition-Based Scheduling

Rather than following a strictly time-based schedule, many operators now implement condition-based maintenance. This approach uses real-time monitoring data to schedule maintenance only when performance indicators suggest the need.

Advantages include:

- Reduced unnecessary maintenance activities

- Prevention of unexpected breakdowns through early warning

- Optimized maintenance crew deployment

- Lower overall maintenance costs while maintaining reliability

Seasonal Considerations

Environmental factors play a significant role in maintenance scheduling:

- Winter maintenance: Ice detection systems monitoring, blade de-icing, cold-weather lubrication

- Spring/Fall: Ideal for comprehensive inspections and major repairs

- Summer: Lightning protection system verification, cooling system maintenance

- Storm season: Pre and post-storm inspections, emergency preparedness

Common Wind Turbine Maintenance Costs and Challenges

Understanding the cost structure and challenges of wind turbine maintenance helps operators plan budgets and resources effectively.

Maintenance Cost Breakdown

According to Thunder Said Energy analysis, wind power operating costs average $40/kW-year, with approximately $25/kW dedicated to maintenance activities. This translates to a global maintenance market worth over $20 billion annually.

Costs typically include:

- Labor costs for scheduled and unscheduled maintenance

- Spare parts and replacement components

- Equipment rental (cranes, specialized tools)

- Transportation and logistics

- Insurance and safety equipment

- Emergency repairs and expedited services

The average cost of wind turbine repair after failure is approximately $150,000, though this varies significantly based on failure type and component complexity.

Common Maintenance Challenges

Wind farm operators face several persistent challenges:

Accessibility Issues

Offshore turbines and remote onshore locations create logistical difficulties. Weather conditions can prevent access for extended periods, delaying critical maintenance and extending turbine downtime.

Component Lead Times

Many turbine components require long procurement cycles. When major components fail, obtaining replacements can take weeks or months, particularly for older turbine models.

Skilled Technician Shortage

The specialized nature of wind turbine maintenance creates demand for highly trained technicians. The industry faces ongoing challenges in recruiting and retaining qualified personnel.

Unpredictable Failures

Data show that approximately 70% of wind turbine failures occur within the first 10 years of operation. These early-life failures often result from manufacturing defects or installation issues that aren’t always predictable.

Environmental Stressors

Continuous improvement in turbine design hasn’t eliminated vulnerability to environmental factors:

- Lightning strikes, causing electrical and blade damage

- Extreme temperatures affect lubrication and component expansion

- High wind speeds create excessive loads on structural components

- Salt exposure in offshore and coastal environments causes corrosion

Cost Management Strategies

Cost management requires a balanced approach:

- Implementing preventive maintenance to avoid emergency repairs

- Maintaining adequate spare parts inventory for critical components

- Using quality components from original equipment manufacturers – don’t skimp

- Training in-house maintenance teams to reduce contractor dependency

- Leveraging data analytics to optimize maintenance schedules

Conclusion

Wind turbines represent a significant investment in renewable energy infrastructure. This makes proper maintenance an essential investment to protect wind turbines.

The challenges are real.

From the physical demands of working at extreme heights to managing complex maintenance schedules across distributed assets. Environmental factors, component complexity, and the critical importance of minimizing downtime all demand sophisticated approaches to maintenance management.

However, modern CMMS platforms like WorkTrek provide the tools needed to overcome these challenges.

By centralizing asset information, automating preventive maintenance, enabling mobile access, and delivering data-driven insights, these systems transform maintenance from a reactive cost center into a strategic advantage.

The future of wind energy depends on well-maintained turbines operating at peak efficiency. With the right approach to maintenance and the support of advanced CMMS platforms, wind farm operators can confidently meet this challenge while contributing to a sustainable energy future.