Asset Management

Stay in control of your assets – organize, track, and manage them while having detailed insights into all asset information at your fingertips.

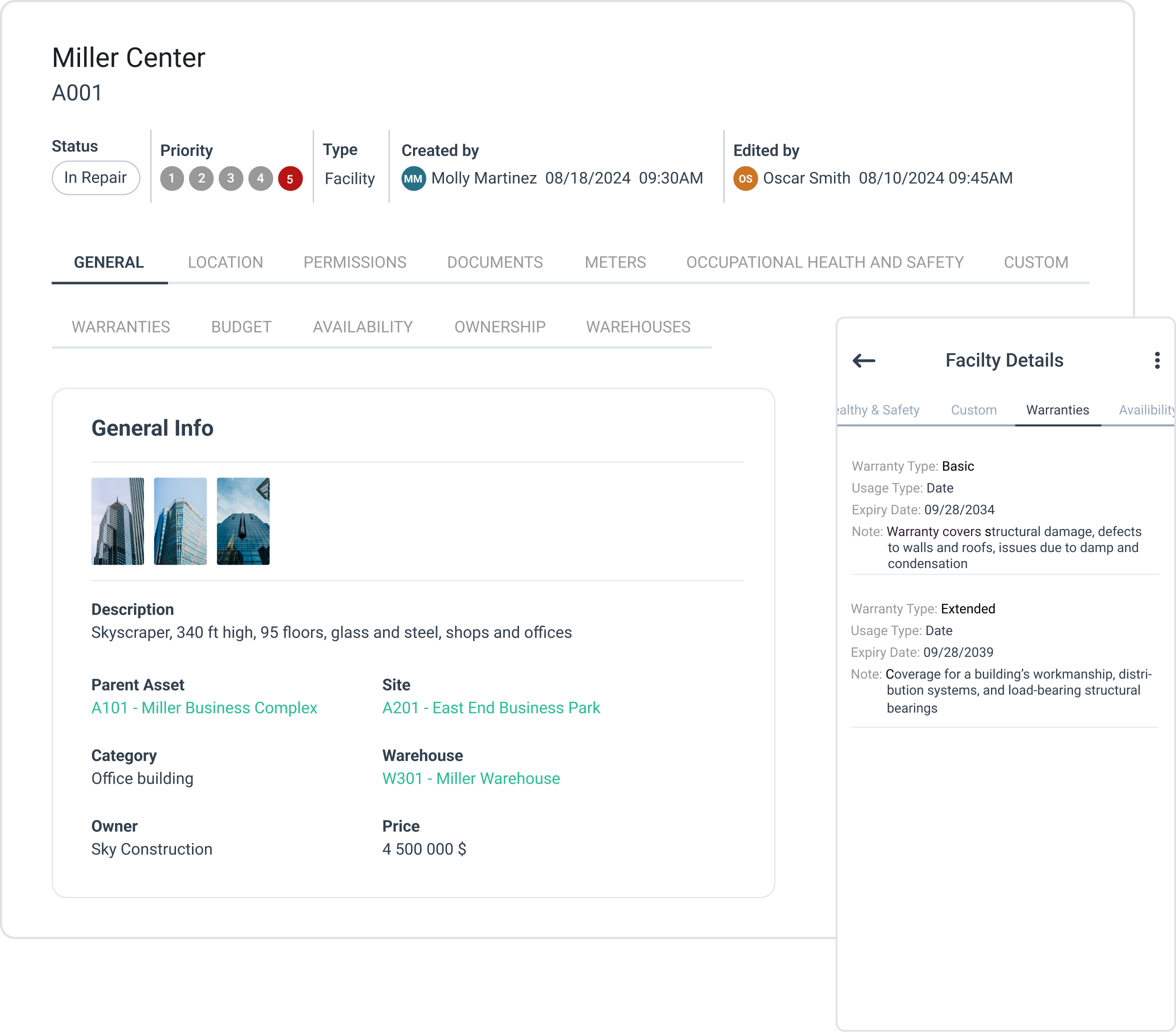

Access asset information and history anytime, anywhere

Enable all parties to access complete asset metadata, including physical location, custom fields, warranty, maintenance history, and expenses, through a single platform available on desktop, tablet, and mobile devices. Utilize barcode or QR code labels for easier asset identification.

Different perspectives on your assets

Track your assets in detail

Model all your locations, plants, facilities and complex equipment and machinery with unlimited level asset hierarchy.

Find and search all asset details

List view provide easy access to asset information you need and export to Excel and PDF functionality.

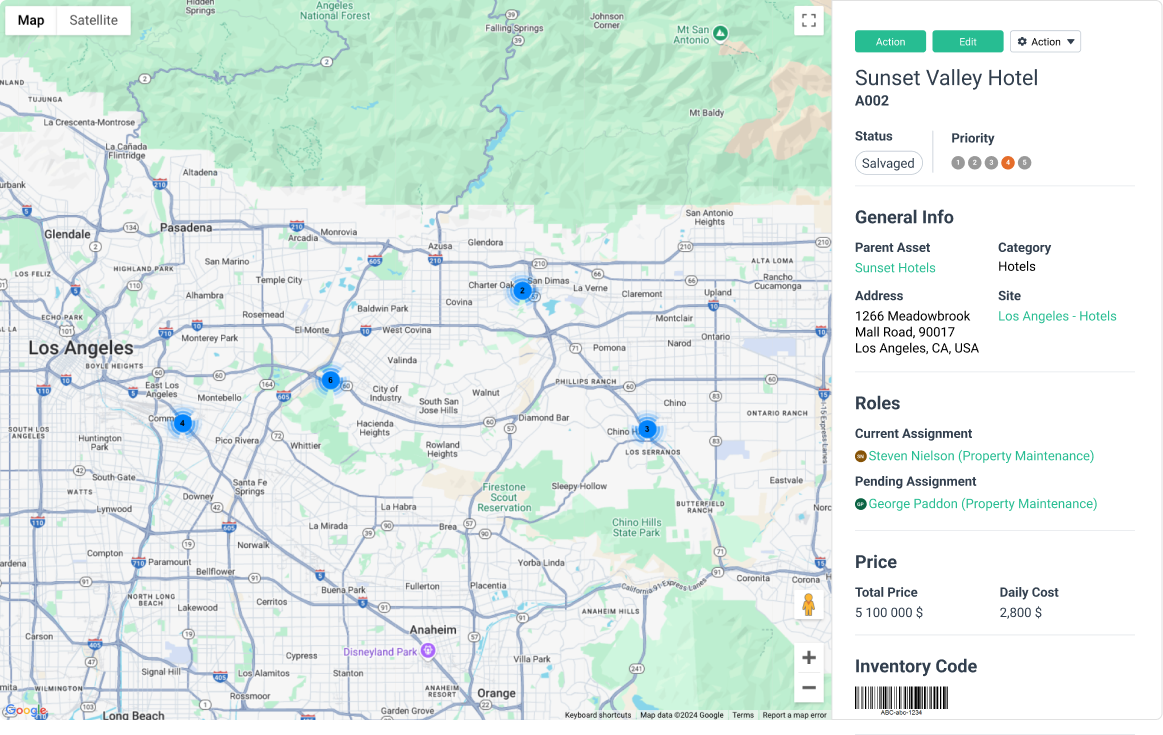

Visualize Asset Locations

Map view provides a clear, visual overview of the physical locations of assets, making it easier to track and manage geographically dispersed assets.

Advanced permissions for asset and location-based access

Ensure that users access only the relevant information, improving data security and operational efficiency. Assign specific roles and responsibilities, reduce errors and streamline asset management processes across different sites.

Monitor asset condition with meter readings

Track assets over time using meter readings such as working hours, and mileage. Instantly view historical performance by scanning barcodes and QR codes to access the relevant asset information in the field.

Provide detailed downtime tracking

Track equipment status, downtime history, and production loss. Use reminders to prevent missing downtime reports. Capture detailed information for each event, including category, cause, production loss, required repairs, related work orders, and more.

Reduce costs by identifying expensive assets

Make budget decisions by identifying your most costly assets. Get insights into total expenses for each asset, including labor & parts and expenses related to planned & unplanned shutdowns.

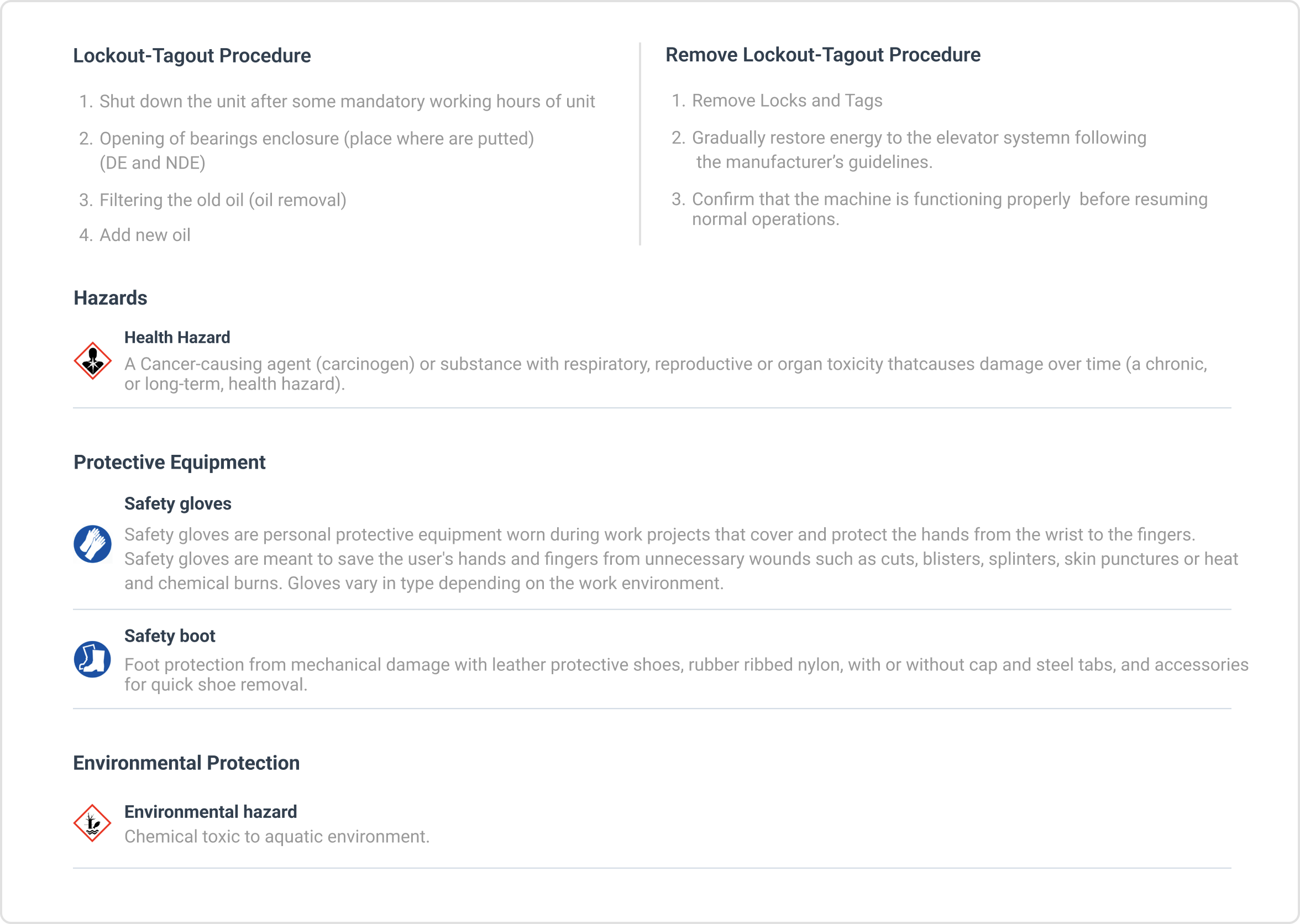

Enhance health and safety standards

Predefine hazards and risks, necessary personal protective equipment, and lockout tagout procedures for each piece of equipment to document processes and prevent potential accidents.

Track tools and equipment

Maintain a clear record of the tools and equipment you possess, their locations, and who is using them. Eliminate the problem of lost or missing items. Reserve essential tools and equipment in advance. Conduct regular inventory cycle counts to verify your equipment.