What is Emergency Maintenance?

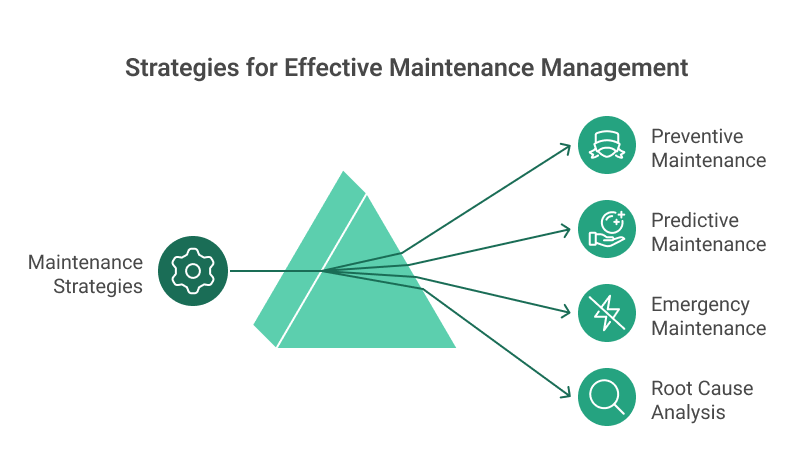

Emergency maintenance is an unplanned, urgent repair or service performed when equipment unexpectedly fails or presents a safety hazard. Unlike preventive or predictive maintenance, which is scheduled in advance, emergency maintenance occurs in response to an immediate breakdown, malfunction, or dangerous situation that needs to be addressed to prevent further damage or operational shutdowns.

Because emergency maintenance is reactive, it often comes with high costs, including labor overtime, expedited parts procurement, and extended equipment downtime.

Emergency repairs may disrupt production schedules, causing lost productivity and revenue.

Minimizing emergency maintenance is a priority in industries where equipment uptime is critical, such as manufacturing, power generation, and healthcare.

Organizations aim to reduce emergency maintenance by implementing preventive and predictive maintenance strategies, which focus on addressing issues before they escalate into critical failures.

However, emergency maintenance is inevitable, especially in systems where certain shortcomings cannot be predicted or prevented.

Emergency maintenance should be handled efficiently, and root cause analysis should be conducted afterward to avoid similar issues from reoccurring.

Industry Examples of Emergency Maintenance

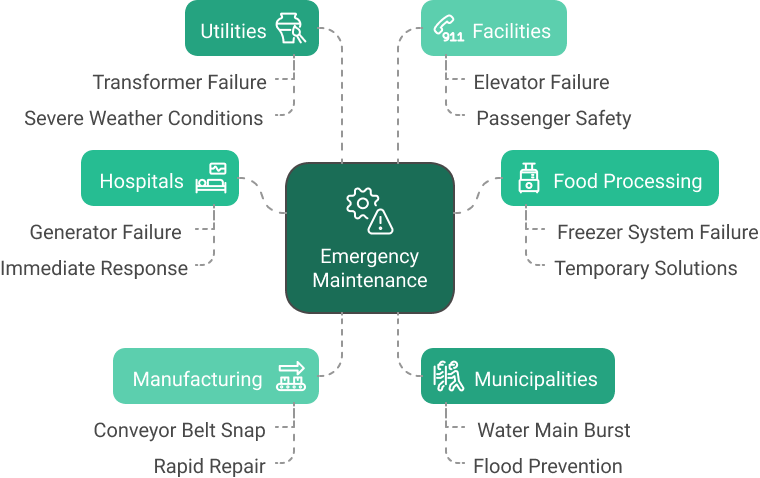

Emergency maintenance becomes critical when unexpected equipment failure poses immediate risks to safety, production, or essential services.

Hospitals

Consider a hospital’s backup generator suddenly failing during a power outage. This requires immediate emergency maintenance since patients’ lives could depend on continuous power for critical medical equipment. The maintenance team must respond instantly, regardless of time or cost.

Food Processing

Another compelling example occurs in food processing facilities. Imagine a critical freezer system failing during peak production hours. Without immediate emergency maintenance, thousands of dollars worth of perishable products could spoil, and the entire production line might need to halt.

The maintenance team must work quickly to repair the system or implement temporary cooling solutions to prevent product loss.

Manufacturing

In manufacturing settings, emergency maintenance often involves production-critical equipment. Picture a central conveyor belt suddenly snapping in an automotive assembly plant. This single point of failure could stop the entire production line, costing thousands of dollars per minute in lost productivity.

Emergency maintenance teams must respond immediately to replace or repair the belt, often working under intense pressure to minimize downtime.

Municipalities

Municipal infrastructure provides another important example. A burst water main in a city center requires emergency maintenance regardless of the time or weather conditions.

The maintenance team must respond swiftly to prevent flooding damage to surrounding buildings, maintain water service to critical facilities like hospitals, and prevent potential contamination of the water supply.

Utilities

Power distribution systems frequently require emergency maintenance during severe weather events. When a transformer fails during a winter storm, maintenance crews must work in challenging conditions to restore power to affected areas, mainly when the outage affects vulnerable populations or critical infrastructure.

Facilities

In commercial buildings, elevator failures with trapped passengers represent classic emergency maintenance scenarios. These situations require immediate response not just for passenger safety but also to maintain building functionality and comply with safety regulations.

The success of emergency maintenance often depends on having well-prepared response plans and easily accessible spare parts for critical systems.

Organizations that handle emergency maintenance effectively maintain emergency contact lists, stock critical spare parts, and conduct regular training for rapid response scenarios.

These examples demonstrate why organizations need robust emergency maintenance protocols and dedicated teams ready to respond anytime.

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free