Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Equipment failures cost factories 5% to 20% of their productivity annually, translating to millions in losses.

- Preventive maintenance is nearly three times more cost-effective than reactive maintenance.

- Predictive maintenance can reduce planning time by 50% and increase uptime by 20%.

- 65% of companies now use a CMMS to monitor and optimize maintenance operations.

When equipment fails, everything stops. Production lines go dark, costs pile up, and workers face unnecessary risks. The ripple effect can touch every part of your operations.

Managing the risk of equipment failure isn’t about reacting faster when things break. It’s about stopping failures before they happen and building systems that keep critical equipment running.

According to the International Society of Automation, factories lose between 5% and 20% of their productivity due to downtime. For some companies, that translates to thousands or even millions of dollars in losses.

This guide breaks down effective strategies for managing equipment failure risk: from understanding what causes equipment to fail to building a maintenance program that actually prevents problems.

Understanding Equipment Failure Risk

Equipment failure happens when machinery stops working as intended. Sometimes equipment malfunctions completely. Other times, it keeps running but performs below standard.

Risk-based maintenance prioritizes interventions based on the consequences of failure, not just their frequency.

Either way, the consequences are real: unplanned downtime, safety hazards, financial losses, and disrupted operations.

Most equipment failures fall into predictable categories.

- Excessive wear and tear breaks down components over time

- Improper use of machines

- Poor maintenance lets small problems escalate into major breakdowns.

There are many situations that can also lead to failures. Control system failures can shut down entire production lines. Electrical failures pose both operational and safety risks. Mechanical failures in critical systems can cascade through your facility.

The most common types of equipment failure share one thing in common: they can be prevented with the right approach.

The True Cost of Equipment Failure

In most cases, equipment failure costs more than the repair bill. The financial impact can include lost production, emergency repairs, expedited shipping for spare parts, and overtime labor costs.

A 2024 Siemens study found that automotive plants lose approximately $695 million annually due to unplanned downtime. That’s 1.5 times higher than just five years ago.

For heavy machinery operations, the annual cost per plant can reach $59 million.

But the numbers tell only part of the story.

Equipment failure can create safety risks for workers. In addition, production delays damage customer relationships. Non-compliance with regulations can lead to fines and legal exposure.

With a critical asset failure, the effects can spread throughout your entire operation.

Key Strategies to Manage Equipment Failure Risk

The best defense against equipment failure is a combination of several proven approaches. Those approaches include:

Regular Inspections and Monitoring

Necessary inspections catch problems before they cause failures. Pre-use checks verify equipment is safe to operate. Scheduled inspections track wear patterns and identify components nearing the end of their useful life.

The key is making inspections part of a systematic process and not just random.

Equipment-specific checklists ensure technicians look for the right warning signs. Documentation creates a record that helps predict when failures might occur.

Regular inspections also improve workplace safety. Workers spot hazards like frayed cables, leaking fluids, or loose components that could lead to accidents.

One strategy that a lot of companies employ is to implement IoT sensors for continuous monitoring.

Using IoT sensors and AI allows for real-time, data-driven maintenance decisions.

These devices track vibration, temperature, pressure, and other critical parameters in real time. When readings fall outside normal ranges, maintenance teams get immediate alerts.

Digital Twins and AI are increasingly used to analyze incident data for trends and simulate failure scenarios without disrupting live operations.

This approach is most valuable for critical equipment, where unexpected failures have the greatest impact on operations.

Implement Preventive Maintenance

Preventive maintenance is when you service equipment based on a schedule and preferably before breakdowns occur.

Some preventive maintenance tasks include lubrication, filter changes, belt adjustments, and component replacements based on manufacturer recommendations or usage patterns.

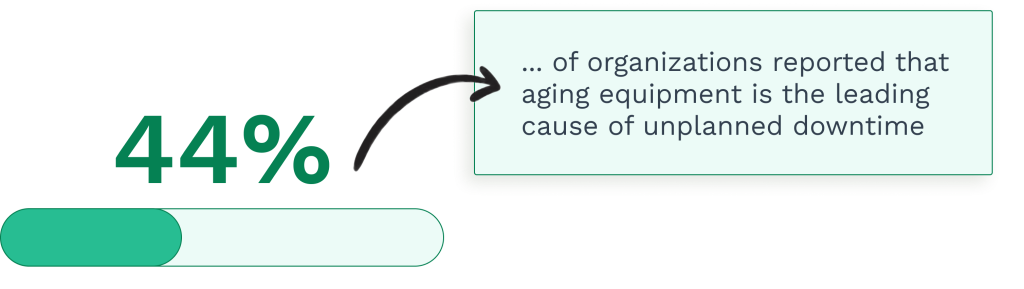

A 2022 survey found that unplanned downtime from equipment failure had the greatest negative impact on plant productivity.

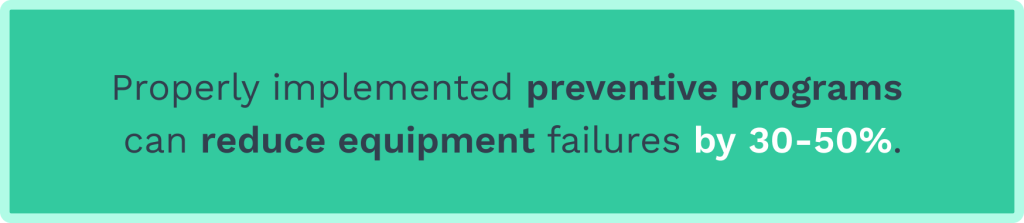

Zach Williams, Engineering Manager at Kito Crosby Australia, explains the business case: “Preventive maintenance is nearly three times more cost-effective than reactive maintenance.”

The approach works because it shifts your focus from emergency repairs to planned interventions.

The goal is to have maintenance happen during scheduled downtime, not in the middle of a production run. Parts arrive through normal ordering, not overnight shipping at premium prices.

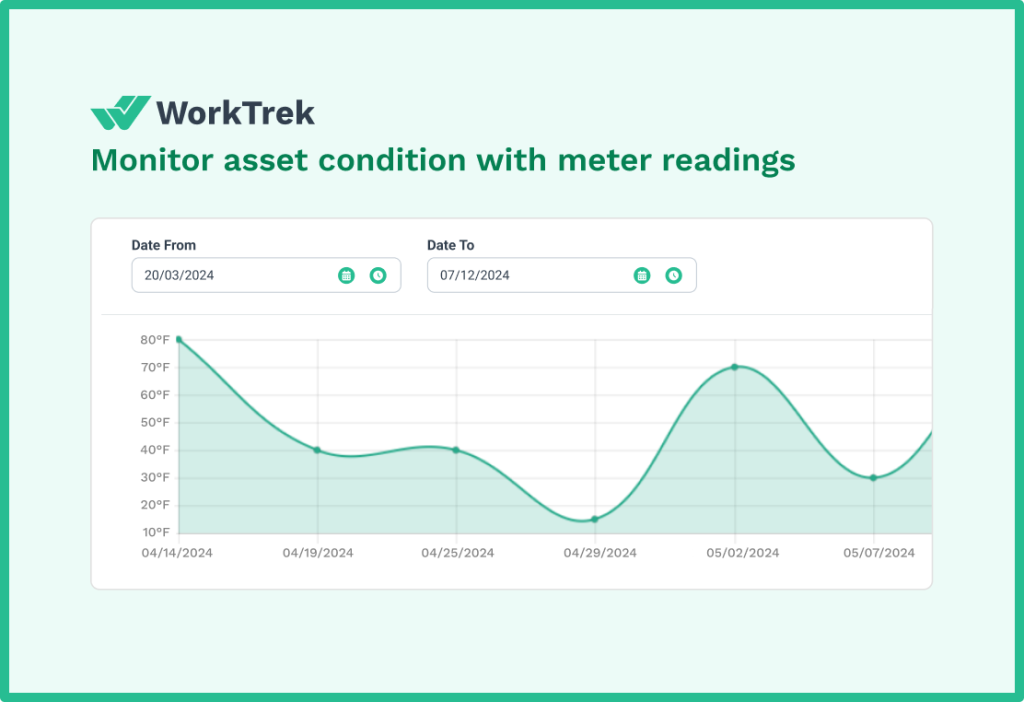

Modern CMMS platforms can simplify and automate preventive maintenance scheduling. WorkTrek can trigger work orders based on time intervals, meter readings, or usage patterns.

Embrace Predictive Maintenance

Predictive maintenance takes prevention a step further. Instead of maintaining equipment on a fixed schedule or following OEM recommendations, you service it based on actual condition.

Strict adherence to OEM guidelines for workloads and service intervals helps avoid overworking machinery.

This strategy uses sensor data and historical performance to predict when equipment will fail. Maintenance happens just before problems occur, not too early or too late.

Research by Deloitte shows predictive maintenance can reduce planning time by up to 50% and increase uptime by 20%.

BMW’s Regensburg plant uses AI-powered predictive maintenance on its conveyor systems. Project manager Oliver Mrasek reports that they avoid around 500 minutes of production disruption per year by detecting potential faults before they cause failures.

The investment in sensors and analytics platforms pays off through fewer emergency repairs and longer equipment life. For companies with critical assets where downtime costs are high, predictive maintenance delivers strong returns.

Train Your Team Properly

Operational errors can be the cause of a lot of equipment failures. For example, overloading machines, skipping safety procedures, or operating without proper training puts unnecessary stress on equipment.

With additional employee training, these risks can be reduced.

Training should focus on equipment specifications, proper operating procedures, and early warning signs of problems. The process should teach technicians how to use machinery within design parameters and what to do when something seems wrong.

Regular review of risk assessments is essential in risk-based maintenance to adapt to evolving conditions.

Training should cover more than basic operation. Maintenance teams need expertise in troubleshooting, repair procedures, and safety protocols. Cross-training creates flexibility when specialists aren’t available.

According to research on equipment longevity, properly trained users operate equipment more efficiently, reducing wear and tear while minimizing energy consumption.

Regular training keeps knowledge current, especially when equipment is upgraded or procedures change.

Maintain Proper Spare Parts Inventory

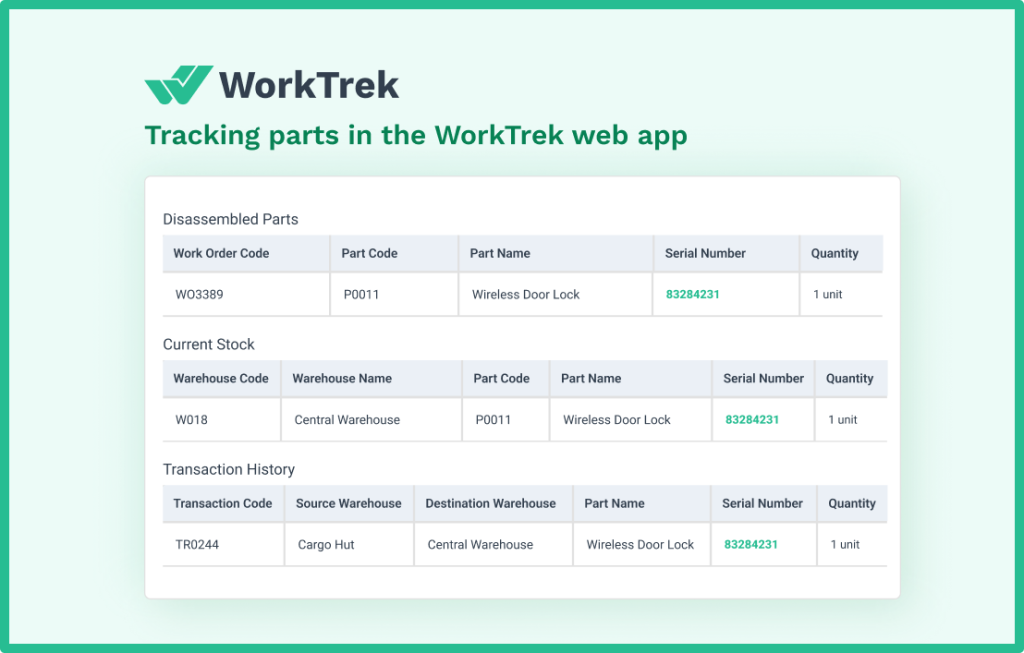

Having the right spare parts available prevents small issues from becoming extended downtime events. When a component fails, you can replace it immediately instead of waiting days or weeks for delivery.

The challenge is always balancing inventory costs with availability.

Stockpiling every possible part ties up capital and warehouse space. But running too lean means critical repairs get delayed.

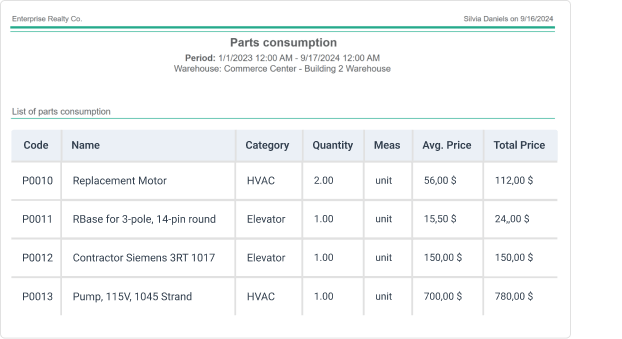

Smart inventory management focuses on critical components—parts that fail predictably or have long lead times. Historical data shows which items need to be on hand and which can be ordered as needed.

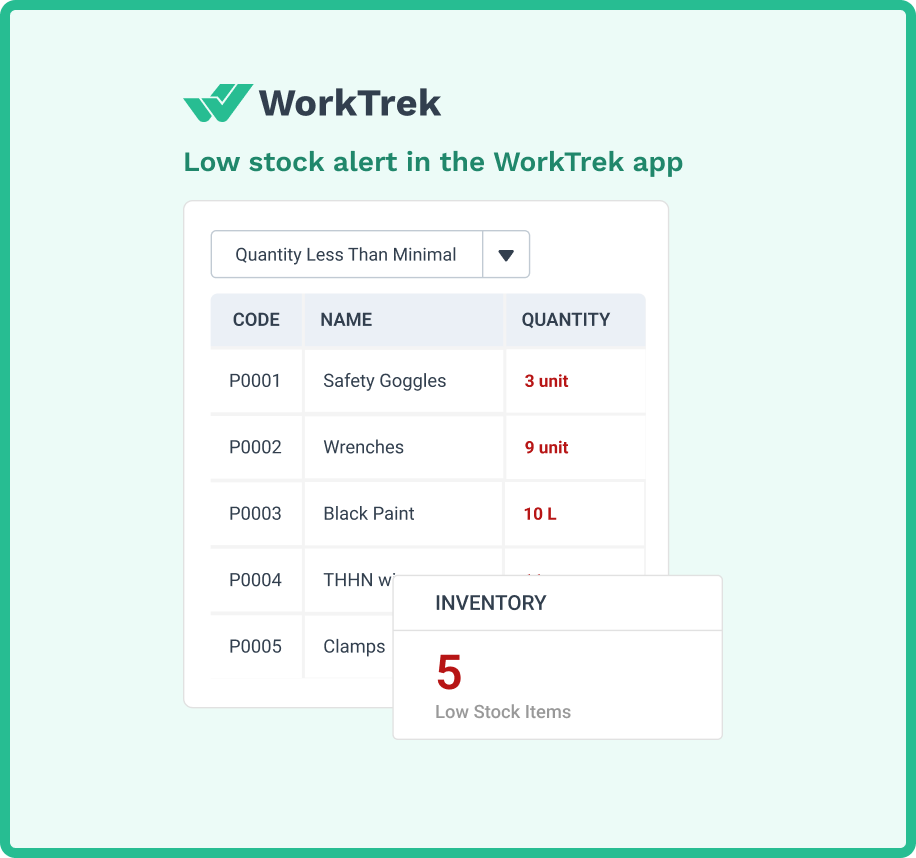

Proper inventory management means tracking usage patterns, setting reorder points, and maintaining relationships with reliable suppliers. A CMMS helps by automatically tracking parts usage and triggering reorder alerts when stock falls below minimum levels.

Follow Manufacturer Guidelines

Something as simple as an equipment manual can contain essential information on maintenance requirements, operating limits, and troubleshooting procedures. Manufacturers are experts and understand how their equipment works and what it needs to stay reliable.

Following recommended maintenance schedules helps maintain warranties and ensures equipment performs as designed.

Deviating from these guidelines often leads to premature wear, unexpected failures, and voided warranties.

Manuals also provide critical safety information and proper repair procedures. They specify which parts to use, how to test components, and when to replace items.

As an example, Haas Automation’s lathe manuals include detailed maintenance schedules showing exactly when to service each component. This level of specificity takes guesswork out of maintenance planning.

Keep manuals accessible to maintenance teams, whether in paper form or digital format. Consider storing them in your CMMS so technicians can access procedures while working on equipment.

Building a Risk Management Culture

To effectively address equipment failure, you need more than just good procedures. The organization needs a top-down commitment.

Leadership sets the tone.

When senior management prioritizes maintenance and invests in proper tools, teams take equipment reliability seriously.

However, when budgets get cut and maintenance gets deferred, failures increase.

Communication matters too.

Operators need clear channels to report issues. Maintenance teams need to share findings about equipment condition. Managers need visibility into maintenance metrics and failure trends.

Regular reviews of maintenance data help identify patterns. Are certain assets failing repeatedly? Do failures cluster around specific times or conditions? This analysis reveals where to focus improvement efforts.

Creating a culture of reliability means celebrating prevention, not just fast repairs. Teams should be recognized for catching problems early, not praised for heroic emergency fixes.

How CMMS Technology Reduces Equipment Failure Risk

A Computerized Maintenance Management System centralizes all maintenance activities in one platform.

Instead of depending on scattered spreadsheets and paper records, everything lives in a single system that tracks assets, schedules work, and analyzes performance.

According to UpKeep, 65% of companies now use a CMMS to monitor and optimize maintenance operations. Teams using these platforms report better visibility into completed work, reduced unplanned downtime, and enhanced collaboration.

How WorkTrek Helps Manage Equipment Failure Risk

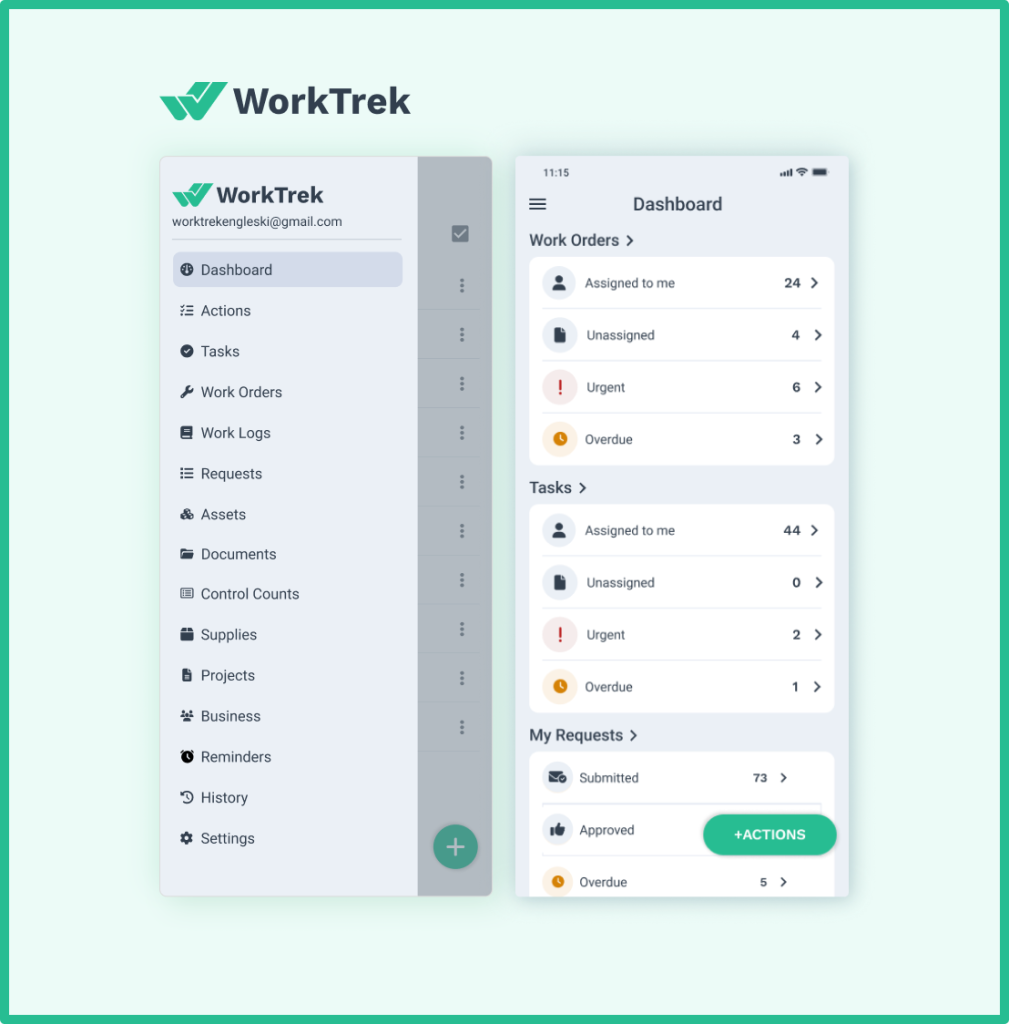

WorkTrek provides the tools maintenance teams need to prevent failures and minimize downtime.

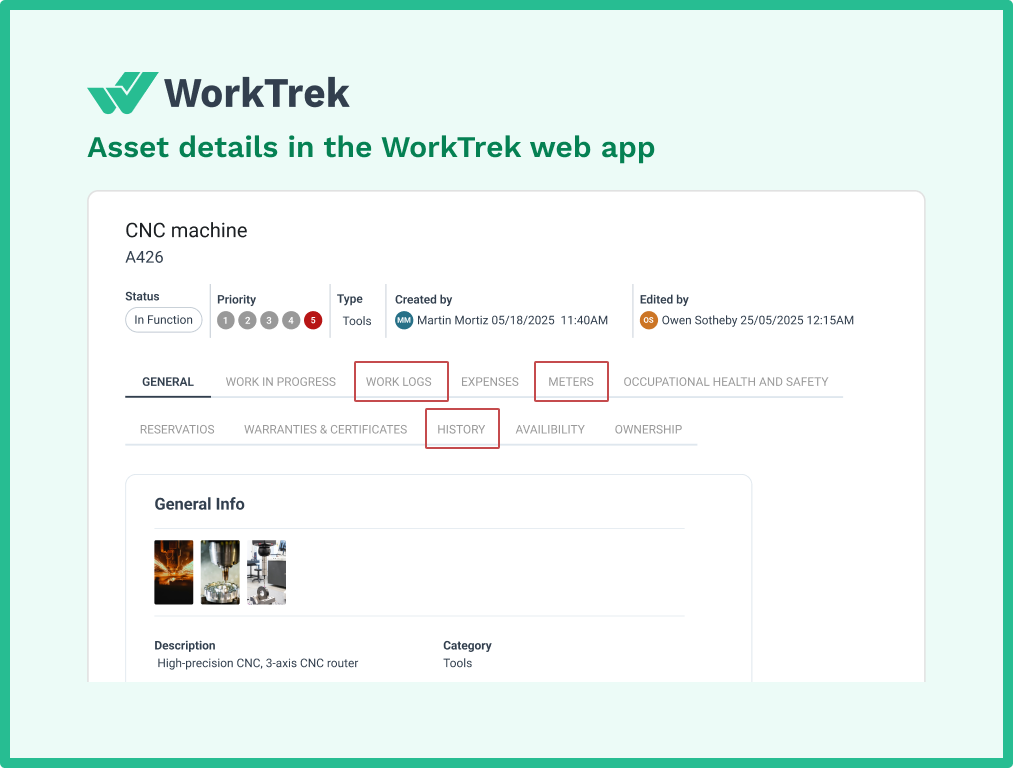

The platform automates preventive maintenance scheduling based on time, usage, or condition triggers. Work orders are automatically created and assigned to the right technicians. No manual scheduling, no forgotten tasks.

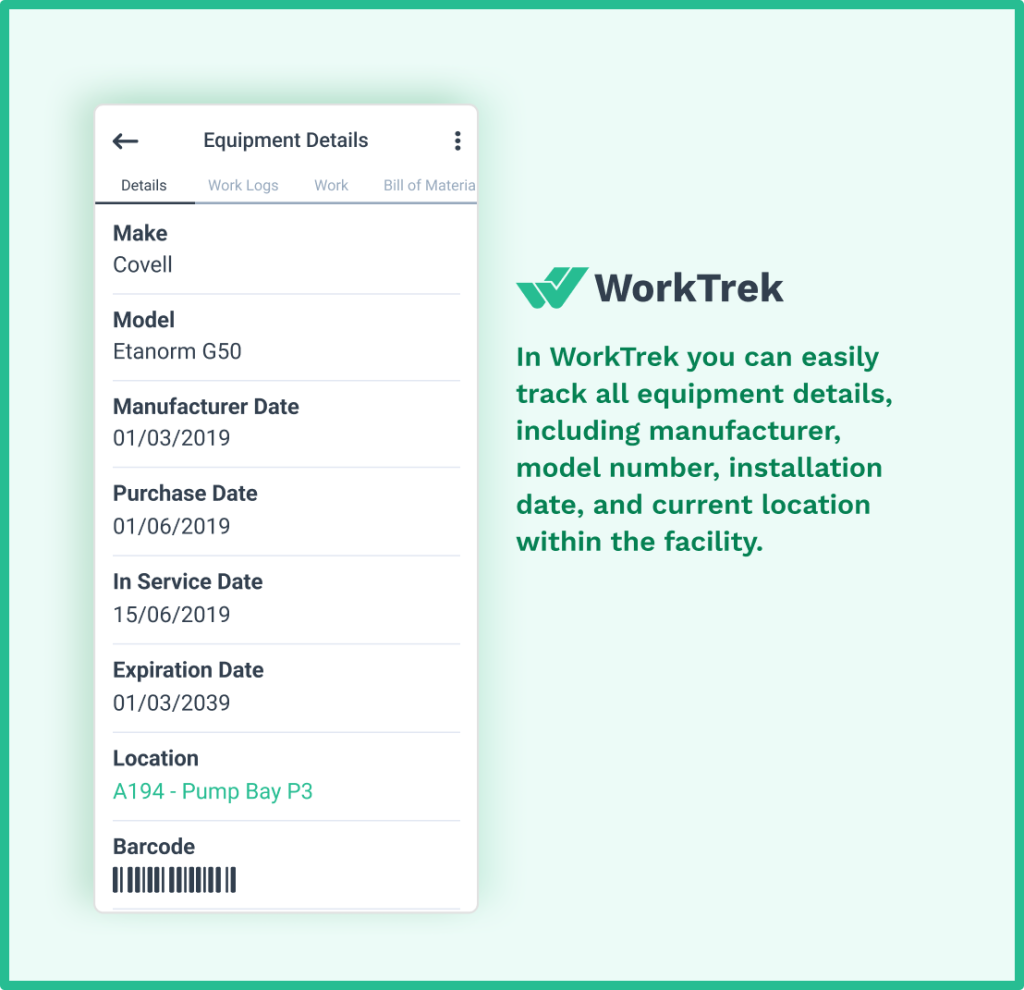

Asset management features track equipment history, maintenance records, and failure patterns. When equipment fails, technicians can review past issues and solutions. This knowledge prevents recurring problems and speeds up repairs.

Real-time alerts notify teams when equipment parameters fall outside normal ranges or when scheduled maintenance is due. Issues get addressed before they become failures.

The mobile app gives technicians instant access to work orders, equipment manuals, safety procedures, and maintenance histories. Everything they need is available at the point of work, reducing errors and improving efficiency.

Parts inventory management tracks spare parts automatically. When technicians complete work orders, the system deducts used parts from inventory. Low stock triggers reorder alerts, so critical components stay available.

Detailed analytics show which assets consume the most maintenance resources, where failures occur most often, and how actual costs compare to budgets. This visibility helps managers optimize maintenance strategies and justify investments in equipment reliability.

WorkTrek integrates with condition monitoring systems, creating a complete picture of equipment health. Sensor data flows into the platform, triggering maintenance actions when thresholds are exceeded.

For companies serious about reducing equipment failure risk, WorkTrek delivers the automation, visibility, and control that modern maintenance operations require.

Common Equipment Failure Patterns to Watch

Understanding how equipment typically fails can help you intervene before breakdowns occur.

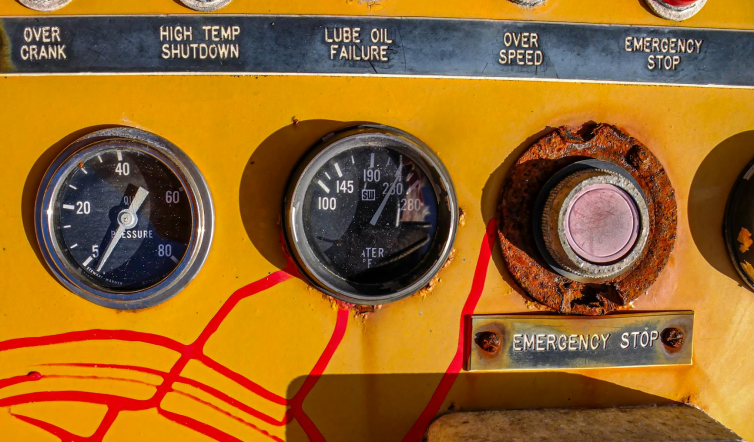

Aging equipment shows increasing failure rates as components near the end of life. Bearings wear out, seals deteriorate, and electrical insulation breaks down. The solution is condition-based replacement before complete failure.

Wear and tear from normal use gradually degrades performance. Regular inspections catch this early. Preventive maintenance replaces worn components before they fail.

Environmental factors accelerate equipment degradation.

Extreme temperatures, humidity, dust, and vibration all contribute to premature failure. Controlling operating conditions and matching equipment to the environment reduces this risk.

Inadequate lubrication causes friction and heat buildup. Following lubrication schedules and using correct lubricants prevents this common failure mode.

Electrical issues often start with minor problems—loose connections, dirty contacts, or voltage fluctuations. Regular electrical system checks catch these before they cause complete failures.

Measuring Your Equipment Failure Management Success

You can’t improve what you don’t measure. Track these metrics to evaluate how well you’re managing equipment failure risk:

Mean Time Between Failures (MTBF) shows how long equipment typically runs before failing. Higher numbers mean more reliable equipment.

Mean Time to Repair (MTTR) measures how quickly you restore equipment to service. Lower numbers indicate efficient repair processes.

Planned vs. Unplanned Maintenance Ratio reveals how proactive your maintenance is. More planned work means better control.

Maintenance Cost as Percentage of Replacement Value helps identify over-maintained or under-maintained assets.

Overall Equipment Effectiveness (OEE) combines availability, performance, and quality into a single metric showing how well equipment performs.

Downtime Hours tracks lost production time. Breaking this down by equipment and failure type shows where to focus improvement efforts.

Regular review of these metrics identifies trends and guides resource allocation. Most CMMS platforms generate these reports automatically.

The Path Forward

Managing equipment failure risk requires commitment with substantial payoffs.

Less unplanned downtime means higher productivity. Fewer emergency repairs reduce costs. Safer equipment protects workers. Better reliability improves customer satisfaction.

Start by assessing your current maintenance practices.

- Where do most failures occur?

- Which assets are most critical?

- How much downtime costs your operation?

Use the information that you gather to prioritize improvements.

Implement preventive maintenance for critical equipment first.

Add condition monitoring where it delivers the highest return. Train teams on proper operating procedures.

Invest in tools that support your maintenance strategy.

A modern CMMS eliminates manual work, improves data accuracy, and provides visibility that helps you make better decisions.

Conclusion

Companies that treat maintenance as a strategic investment rather than a cost center see real results: less downtime, lower costs, safer workplaces, and higher productivity.

The strategies covered here are proven and work.

- Regular inspections catch problems early

- Preventive maintenance stops failures before they happen

- Predictive maintenance optimizes when you service equipment

- Proper training reduces operational errors

- Smart inventory management keeps repairs fast.

But none of this works without the right tools and commitment.

Modern CMMS platforms like WorkTrek automate the heavy lifting, giving you visibility and control over your maintenance operations. They turn data into action and help teams work smarter.

Start small if you need to.

Pick your most critical assets and implement better maintenance practices there first. Track your results. Build on what works.