Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Farm equipment repair costs have spiked 41% since 2020, making preventive maintenance more critical than ever.

- Unplanned breakdowns cost farmers an average of $3,348 per season in repair downtime and restrictions.

- Farmers who follow strict preventive maintenance programs see 25% lower repair bills compared to reactive approaches.

When your tractor breaks down during planting season or your combine fails mid-harvest, the financial impact goes far beyond the repair bill.

Between lost productivity, rushed parts orders, and missed weather windows, equipment downtime can transform a profitable season into a financial setback. That’s why understanding farm equipment maintenance isn’t just about keeping machinery running—it’s about protecting your operation’s bottom line.

Modern agricultural equipment represents a massive investment.

A single combine can cost anywhere from $300,000 to $500,000, while tractors and other implements add hundreds of thousands more to your capital expenses. With stakes this high, implementing a comprehensive maintenance program is critical.

Why Farm Equipment Maintenance Matters More Than Ever

The costs of farm machinery are rising at an alarming rate.

According to the Bureau of Labor Statistics, the costs of parts and labor for agricultural machinery and equipment have nearly doubled over the past two decades, with a particularly sharp 41% spike since 2020 alone.

This dramatic increase makes every maintenance decision more consequential. When a hydraulic hose fails or an air filter clogs, you’re not just facing repair costs, you’re dealing with inflated parts prices, expensive labor rates, and the very real possibility of costly breakdowns during critical farming periods.

The financial impact of equipment failures extends well beyond the repair invoice.

Research from the U.S. PIRG Education Fund found that restrictive repair policies and unplanned breakdowns cost farmers about $3,348 per season. This figure accounts for downtime, expedited shipping for emergency parts, overtime labor, and the cascade of expenses that follow when critical equipment sits idle.

During harvest season, timing is everything.

Even a 12-hour breakdown can allow time for a rainstorm, forcing you to wait multiple additional days for harvest or put your crop through a mechanical drying process. According to Iowa State University Extension, just one eight-hour day of downtime can cost growers $2,400 at planting and $900 at harvest when using 12-row equipment.

The good news?

These costs are largely preventable. Farmers who implement strict preventive maintenance programs see approximately 25% lower repair bills compared to those who rely on reactive maintenance.

When you consider that annual repair costs typically run 5-8% of a machine’s purchase price, this reduction represents substantial savings over the life of your equipment.

Important Farm Equipment Maintenance Tasks

Proper maintenance of agricultural equipment requires attention to multiple systems and components. Each piece of equipment on your farm has specific maintenance needs, but certain routine tasks apply across most machinery types.

Oil Changes and Engine Maintenance

Just like your personal vehicle, farm equipment needs regular oil changes to keep engines running smoothly and efficiently.

However, the demanding conditions of agricultural work, which include long hours, heavy loads, and dusty environments, mean your farm machinery may need more frequent service intervals than what you’d expect from a car or truck.

When performing oil changes, always replace engine oil according to the manufacturer’s recommended schedule and use the recommended oil type and weight.

Most modern tractors and combines use hour meters to track usage, making it easier to follow manufacturer guidelines for service intervals.

Consider having a professional oil analysis performed periodically. This simple test can diagnose potential issues before they become major problems, identifying contamination, metal particles, or viscosity breakdown that might indicate wear in critical engine components.

Air Filters and Fuel Filters

Internal combustion engines require the proper mix of fuel and air to run efficiently. Clogged air and fuel filters interfere with combustion efficiency, reducing power output and increasing fuel consumption.

Under dusty field conditions, air filters may need to be replaced more frequently than the standard maintenance schedule suggests.

Black smoke from the exhaust is often a sign of over-fueling and may indicate you need to clean injectors or replace fuel filters.

Don’t wait for visible symptoms. Check and replace filters at regular intervals based on operating hours and field conditions. Keep spare filters on hand so you can quickly swap them out as necessary without waiting for parts delivery.

Lubrication and Greasing

Farm machinery handles tremendous stress from regular use, making proper lubrication critical for preventing premature wear. All moving parts, from chains and bearings to hydraulic systems, need regular greasing to reduce friction and maintain smooth operation.

Create a lubrication schedule based on the operator’s manual for each piece of equipment. Factors such as your local climate and the manufacturer’s recommendations will affect how often you complete this task.

During peak operating seasons, you may need to grease fittings daily or even multiple times per day on heavily used equipment.

Hydraulic Fluid and Systems

Hydraulic systems power critical functions on modern farm equipment, from implements and loaders to steering and braking systems. Maintain proper hydraulic fluid levels and regularly check for leaks, as low fluid levels or contamination can cause system failures.

Examine hydraulic hoses for signs of wear, cracking, or deterioration. A failed hydraulic hose during operation can halt work immediately and create safety hazards. Replace any questionable hoses before they fail in the field, and keep standard sizes in your spare parts inventory for emergency replacements.

Tire Pressure and Condition

Proper tire pressure affects everything from fuel efficiency to equipment performance and soil compaction.

For every ten PSI a tire is underinflated, vehicles lose approximately 1% of their fuel economy. This adds up quickly across a large fleet of farm equipment.

Check tire pressure regularly using a reliable gauge and adjust as needed for your specific application. Additionally, inspect the tread condition for signs of wear or damage. Uneven wear patterns can indicate alignment issues or improper inflation that needs correction before more serious problems develop.

Belts, Chains, and Moving Parts

Inspect belts and chains for wear, proper tension, and alignment during your regular maintenance schedule.

These components are under constant stress and can wear down over time, particularly during heavy use.

When replacing a belt or chain, also inspect and replace related components, such as sprockets and pulleys, if they show wear. If you only have the broken part, it is a temporary fix that often leads to repeat failures.

Creating a Farm Equipment Maintenance Schedule

Good maintenance practice requires organization and consistency. Rather than relying on memory or hoping someone remembers to complete tasks, establish a structured maintenance schedule that tracks all service activities across your entire fleet of agricultural equipment.

Daily Maintenance Checks

Before startup each day, perform basic inspections to catch potential problems early. Walk around equipment looking for obvious damage, loose fasteners, fluid leaks on the ground beneath machinery, or unusual sounds when starting engines.

Check that all safety guards are in place and functioning properly before the operation begins.

These daily maintenance tasks take only a few minutes but can prevent hours of downtime by identifying issues before equipment fails in the field. Train all operators to complete these basic checks and report any concerns immediately.

Weekly and Monthly Tasks

Weekly maintenance tasks focus on deeper inspections and routine service. Examine belts, hoses, and connectors for any signs of wear, cracks, or deterioration. Apply grease to fittings as recommended by the manufacturer. Check battery terminals for corrosion and ensure secure connections to prevent starting issues.

Monthly maintenance now includes oil changes, fuel filter replacements, and more comprehensive system checks.

This is when you’ll want to thoroughly inspect hydraulic systems, test battery voltage, and address any minor issues identified during weekly checks before they escalate into major problems.

Seasonal Maintenance Programs

Farm maintenance needs change with the seasons, making it essential to adapt your approach throughout the year. A mid-season maintenance checklist helps you prepare equipment for upcoming demands, while off-season maintenance ensures machinery is properly stored and protected during downtime.

Before planting season, conduct thorough inspections of all equipment that will see heavy use. Clean machines thoroughly, inspect for winter damage, lubricate all fittings and bearings, and top off all fluids.

Test lights, signals, and hazards to ensure they’re in working order. This comprehensive pre-season preparation can prevent breakdowns during critical planting windows.

Prior to harvest, sharpen or replace cutting blades on combines and balers to ensure clean cuts that protect crop quality.

Inspect and replace worn belts and chains that might fail under the heavy workload of harvest. Having these components in optimal condition prevents mid-harvest failures that could cost thousands in lost time and damaged crops.

During the off-season, perform extensive preventive maintenance that’s difficult to complete during busy farming periods.

Change engine oil, transmission fluid, and coolant. Empty fuel tanks or use fuel stabilizers to prevent fuel degradation while the equipment is not in use. Clean equipment thoroughly to remove debris and prevent corrosion, paying particular attention to areas like engine bays, undercarriages, and storage areas.

Proper Storage Prevents Damage

Preventative maintenance of farm tools and equipment extends beyond mechanical service. It includes proper storage, which is important to your investment.

Equipment stored outside faces constant assault from the weather, leading to rust, deteriorated seals, and sun-damaged components that shorten equipment lifespan.

If you have a garage or barn for your equipment, use it.

Indoor storage is the best option for proper maintenance when machinery is not in use. If you don’t have room to store all the equipment inside, consider installing an overhang that keeps rain and snow off your most valuable machinery.

For equipment that must stay outside, use tarps or fitted covers to offer some protection from the elements.

The Role of Maintenance Logs and Record Keeping

Comprehensive maintenance records provide the foundation for an effective equipment management program. Without accurate service records, you’re forced to rely on memory or guesswork about when maintenance was last performed—an approach that leads to both over-maintenance and under-maintenance, neither of which is cost-effective.

Maintain a logbook or digital system for each tractor, implement, and piece of equipment. Record dates, hours, or odometer readings, tasks completed, parts replaced, and any issues identified. This practice ensures you follow through on needed maintenance tasks rather than hoping someone “just remembers” what needs to be done.

Beyond tracking routine maintenance intervals, detailed maintenance logs help identify patterns. If a particular component fails repeatedly, your service notes will reveal this trend, allowing you to investigate root causes rather than simply replacing parts. These records also prove invaluable when selling equipment, as buyers pay premium prices for well-maintained machines with documented service histories.

Common Farm Equipment Maintenance Mistakes to Avoid

Even experienced farmers can fall into maintenance traps that increase costs and reduce equipment reliability. Understanding these common pitfalls helps you avoid expensive mistakes.

Ignoring the Operator’s Manual

Many farmers never open the owner’s manual, relying instead on experience or assumptions about how equipment should be maintained.

However, manufacturer guidelines are developed specifically for each piece of equipment, and ignoring them can void warranties, cause premature failures, and create safety risks.

The operator’s manual specifies upkeep activities, recommended lubricants, proper adjustment procedures, and troubleshooting guides. Following these recommendations maintains warranty coverage and ensures you’re caring for the equipment as its designers intended.

Delaying Preventive Maintenance

When schedules get tight, it’s tempting to skip routine maintenance and “just get the crop in.” However, this shortsighted approach inevitably leads to emergency repairs at the worst possible times. Equipment that misses scheduled oil changes, filter replacements, or adjustments will fail—usually during peak demand when downtime is most expensive.

According to industry research, 65% of harvest failures could have been prevented with proper pre-harvest inspection and routine tasks completed on schedule. The time invested in preventive maintenance is minimal compared to the hours lost when equipment breaks down in the field.

Incomplete Repairs

When a part breaks, some farmers replace only that specific component without investigating the cause of the failure.

This approach creates a cycle of repeated breakdowns. For example, replacing a drive chain when the sprocket is damaged or swapping a belt when the pulley is worn sets you up for another failure in the near future.

When making repairs, inspect related components and replace anything that shows significant wear. This comprehensive approach may cost more initially, but it prevents the frustration and expense of addressing the same system multiple times.

Pushing Equipment Beyond Design Limits

Constantly running machines at maximum performance or forcing them to do things they weren’t designed for strains joints and causes premature equipment failure. While it might save time in the short term, this practice significantly shortens equipment lifespan and increases maintenance costs.

Run machines just under their intended maximum performance level most of the time to avoid undue stress. Understanding and respecting equipment limitations—whether it’s speed, load capacity, or operating conditions—prevents the kind of abuse that leads to costly breakdowns.

Poor Spare Parts Inventory Management

Running out of critical spare parts during peak season can turn a 30-minute repair into a multi-day disaster while you wait for expedited shipping.

Maintain an inventory of essential components based on your equipment’s common failure points and usage patterns.

Stock items like belts, hoses, bearings, filters, and hydraulic fittings are appropriate for your equipment. Having these parts on hand allows for quick replacements, reducing downtime and keeping operations running smoothly. However, avoid excessive inventory that ties up capital.

How Farm Equipment Maintenance Software Streamlines Operations

Managing maintenance across multiple pieces of farm equipment can quickly become overwhelming, especially when relying on paper logs or spreadsheets, or when trying to track everything in your head.

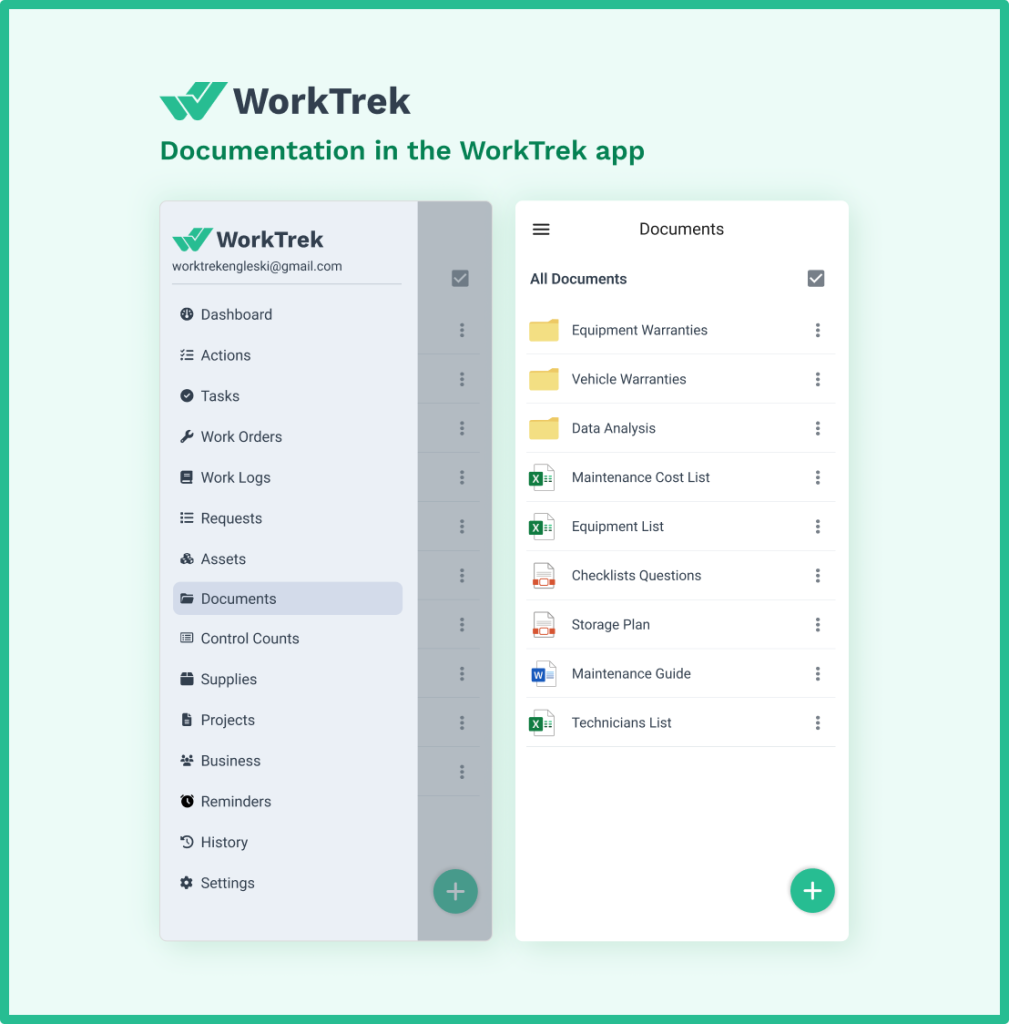

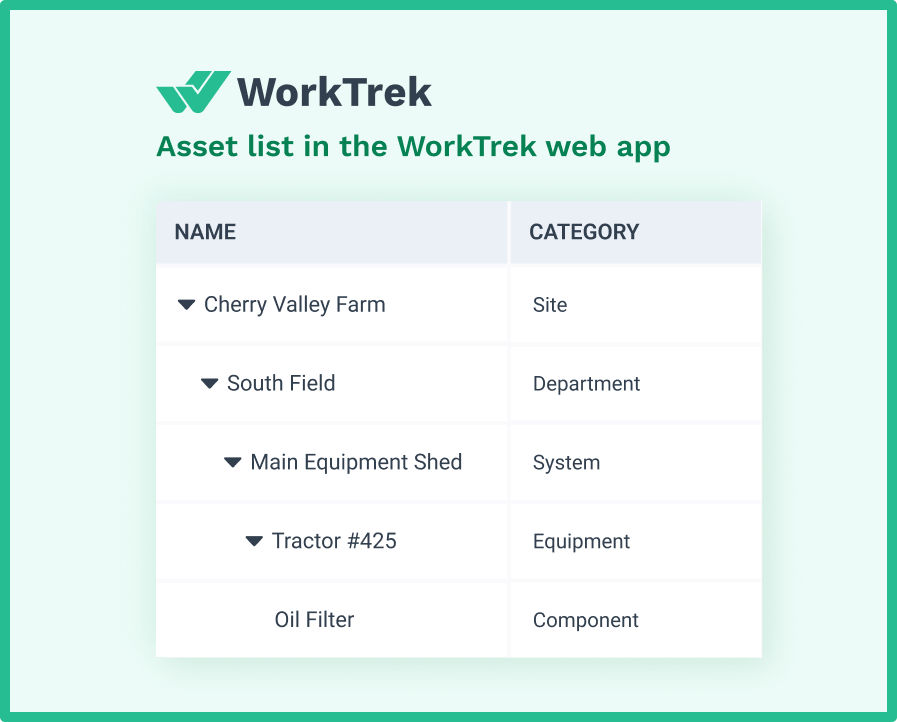

Modern maintenance software solutions like WorkTrek provide centralized systems that automate scheduling, track service history, and ensure nothing falls through the cracks.

Digital tools eliminate the guesswork of equipment maintenance by providing automated reminders at set intervals or on calendar dates.

When a tractor reaches its scheduled service interval, the system sends notifications to ensure maintenance occurs at the optimal time, not when someone remembers or after a breakdown forces the issue.

Many farm equipment maintenance software platforms tie maintenance activities to parts inventory and accounting systems. When you replace an air filter, the system can automatically deduct one filter from inventory and log the expense.

Work orders and purchase orders link together so you always know which replacement parts are on hand and which need ordering, avoiding surprises that could ground equipment during critical periods.

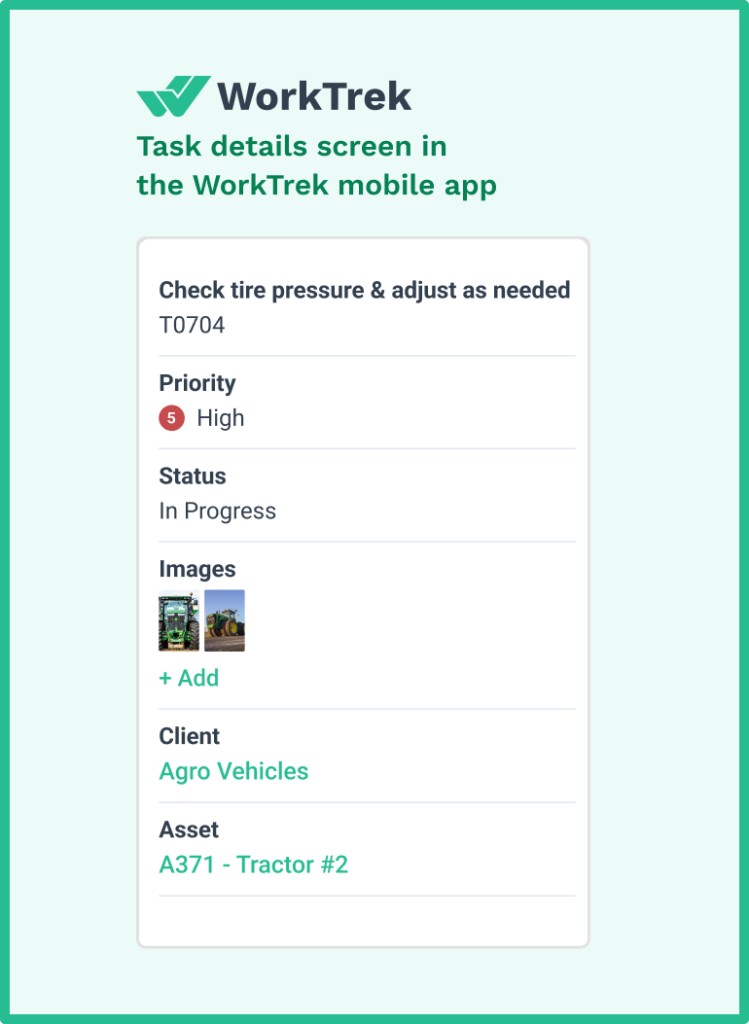

Advanced maintenance software can include digital equipment inspections with customizable checklists. Rather than pencil-whipping paper forms, operators complete inspections in a mobile app with just a few clicks, documenting issues immediately and creating service records that inform future maintenance decisions.

How WorkTrek Transforms Farm Equipment Maintenance

While many farmers still track maintenance using notebooks, whiteboards, or spreadsheets, these manual methods leave too much room for error and make it nearly impossible to gain comprehensive visibility into your fleet’s health.

WorkTrek offers a purpose-built CMMS solution designed to eliminate these challenges and bring efficiency to every aspect of farm maintenance.

Centralized Equipment Management

WorkTrek creates a complete digital asset inventory of all your farm equipment in one centralized system. Every tractor, combine, implement, and piece of machinery has its own record containing specifications, purchase information, service history, and current condition data. This asset inventory provides the foundation for all maintenance planning and helps you make informed decisions about repair-versus-replace scenarios.

Unlike scattered paper records or multiple spreadsheets, WorkTrek’s centralized system means everyone on your team works from the same information. When a technician needs service notes from the last hydraulic repair or the shop manager wants to review parts consumption across all equipment, that data is instantly accessible from any device.

Automated Maintenance Scheduling

One of WorkTrek’s most powerful features is automated preventive maintenance scheduling based on time intervals, hour meters, or custom triggers. The system tracks equipment usage and automatically generates work orders when service is due, sending service reminders to the appropriate personnel.

This automation ensures that routine tasks like oil changes, filter replacements, and inspections happen on schedule rather than being forgotten during busy periods. By staying ahead of maintenance intervals, you avoid the costly emergency repairs that result from neglected equipment.

WorkTrek also allows you to create custom maintenance schedules tailored to your specific equipment and operating conditions. If certain machinery works in particularly dusty or demanding environments, you can adjust service frequencies without affecting other assets.

Mobile Access for Field Teams

Farm maintenance doesn’t happen in an office. It often happens in barns, shops, and fields across your operation. WorkTrek’s mobile app puts complete maintenance information in the hands of operators and technicians wherever they are.

They can view upcoming tasks, access step-by-step instructions, record completed work, and update equipment status in real-time.

This mobile accessibility dramatically improves efficiency. When an operator notices a potential issue during daily checks, they can document it immediately with photos and notes, creating a work order that alerts the maintenance team. No more trying to remember details later or losing critical information because it wasn’t written down.

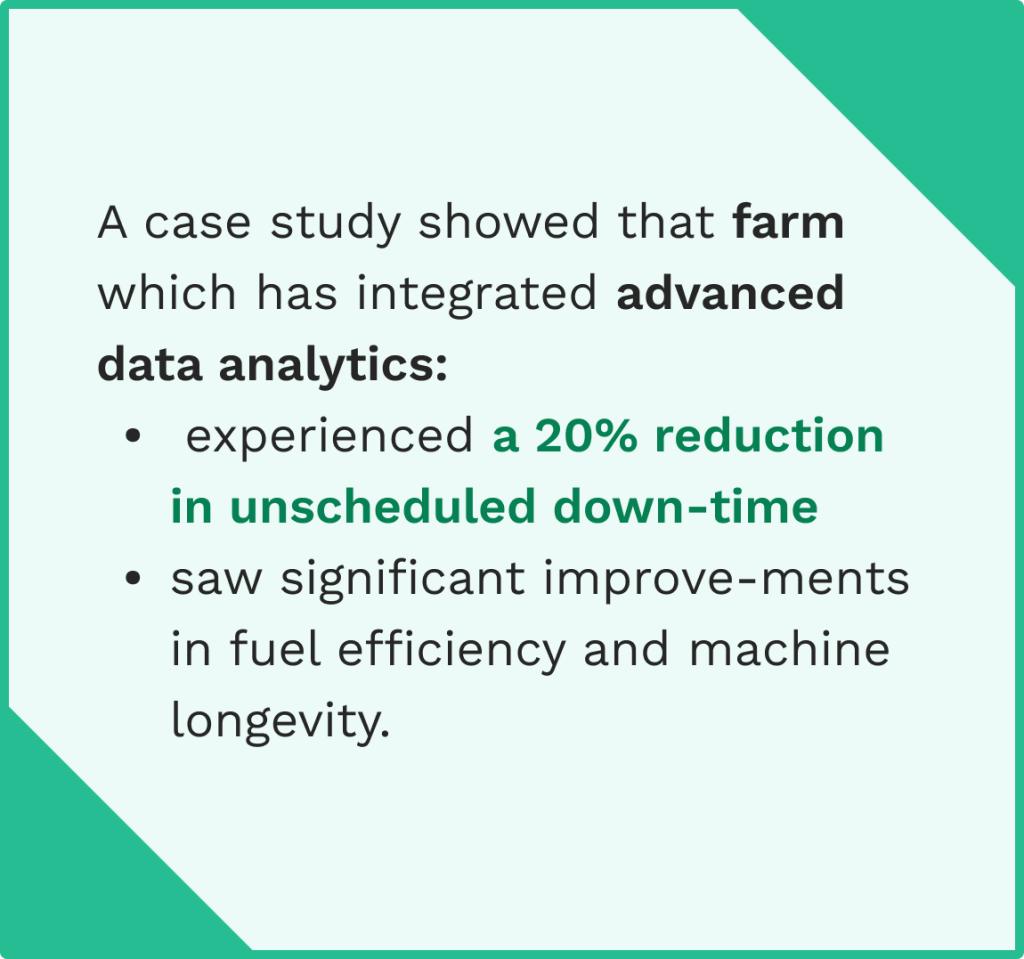

Comprehensive Maintenance Data and Analytics

WorkTrek captures detailed maintenance data across all service activities and transforms it into actionable insights through built-in reporting and analytics. Track maintenance costs per asset, monitor equipment downtime, analyze failure patterns, and measure the effectiveness of your preventive maintenance program.

These insights help you make data-driven decisions about equipment management. If maintenance costs for a particular piece of machinery are consistently high, the data support decisions about whether to perform major repairs or replace it. When you can see which assets require frequent service, you can adjust inspection frequencies or investigate underlying issues causing excessive wear.

Streamlined Parts Inventory Management

Managing spare parts inventory is a constant challenge.

Stock too little and you face downtime waiting for deliveries; stock too much and you tie up capital in unused parts.

WorkTrek’s inventory management features help you find the right balance by tracking parts consumption, monitoring stock levels, and automating reordering.

When technicians complete maintenance tasks, they assign spare parts to work orders. The system automatically deducts used parts from inventory totals, keeping accurate real-time counts.

You can set minimum thresholds for critical items, and WorkTrek will notify you when parts need reordering, preventing stockouts of essential components.

Improved Communication and Collaboration

WorkTrek enhances team communication by ensuring everyone stays informed about equipment status and maintenance needs.

When a work order is created, assigned technicians receive notifications. As work progresses, status updates keep supervisors informed. Comments and notes attached to work orders create a running record of issues and resolutions.

This transparency prevents duplicate efforts, missed communications, and confusion about who’s responsible for what. Everyone from operators to shop managers to farm owners can see the same information, fostering collaboration and accountability.

By bringing all these capabilities together on a single platform, WorkTrek transforms farm equipment maintenance from a reactive, paper-intensive process into a proactive, data-driven program.

The result is reduced equipment downtime, lower maintenance costs, extended machinery lifespan, and the peace of mind that comes from knowing your equipment will be ready when you need it most.

Conclusion

Farm equipment maintenance is more than just preventing breakdowns.

It’s about protecting one of your operation’s largest investments and ensuring you can execute critical farming tasks when weather and market conditions demand it. With repair costs climbing 41% in recent years and downtime expenses measured in thousands of dollars per day, the cost of poor maintenance has never been higher.

The good news is that effective maintenance doesn’t require expensive overhauls or complicated programs.

Start with the fundamentals: follow manufacturer guidelines, establish regular service intervals, maintain detailed records, and address small issues before they become major problems.

These basic practices alone can reduce your repair costs by 25% while significantly extending equipment lifespan.

As your maintenance program matures, consider implementing digital tools like WorkTrek to automate scheduling, centralize information, and gain visibility into maintenance operations.

The efficiency gains and cost savings these systems deliver quickly justify the investment, particularly for operations managing multiple pieces of equipment across diverse farming activities.