Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeAccurate and timely data is important for facility management and equipment maintenance reporting. Even more important is the way managers present this important data. A good maintenance report is very helpful to businesses and companies, as accurate and reliable maintenance history records can prevent mistakes while increasing equipment maintenance awareness.

When your maintenance reports are complete and accurate, they can provide critical information to grow or expand your business at breakneck speed while improving your company’s bottom line.

A maintenance report, is a document that contains important information about each repair and maintenance task or work performed on an asset or equipment. Keeping equipment and assets in top operating condition minimizes the risk of unplanned downtime. Even when repairs are required, you should keep comprehensive and detailed records. Maintenance reports track asset failures and repairs.

Definition And Importance Of Maintenance Management

Maintenance management is an essential part of good production. It helps companies manage their resources while controlling time and costs to ensure maximum efficiency of manufacturing processes, utilities and related facilities. It is a tool that helps ensure reliable and satisfactory production quality, employee safety and environmental protection. Maintenance management is also referred to as CMMS, namely Computerized Maintenance Management System.

Maintenance is an important factor in quality assurance and in some cases determines the long-term success of a company. Poorly maintained resources can cause instability and interrupt production partially or completely. Machine failure or complete failure can be a costly process for most companies.

During downtime, the labor cost per unit increases over time until the machine returns to normal. When this happens, there are unexpected costs to addressing these issues, including additional costs for repair facilities, technicians/repairers, preventive maintenance checks, and replacement parts. These are some examples of what can happen to a company over time without a solid maintenance management solution – even for companies with new machines on the production line.

Maintenance Management Objectives

While there are many different software programs that can help maintain a healthy manufacturing process, the common goal of all maintenance management programs is to analyze production and find best practices in specific areas. Through thorough analysis and accurate reporting, the goal is to control costs, plan work correctly and efficiently, ensure that the company complies with all regulations, while preventing and minimizing breakdowns.

What Is The Maintenance Report?

Maintenance reports are used by upper management, including managers, as they inform them about the performance of assets and equipment. You examine the time spent on maintenance and analyze it against previous performance.

In addition, costs, time required to perform maintenance, and key performance indicators in the process were analyzed. The purpose of equipment maintenance is to find abnormalities and handle them properly.

As you continue this practice, you will see increased machine efficiency and improved plant performance, as well as less time spent on maintenance. Maintenance reports also help reduce downtime and minimize equipment failure.

The Importance Of Maintenance Reports

No matter what maintenance strategy you follow, the insights gained from maintenance data can only help you if they are accurate, complete, reliable and detailed. It is important to maintain accurate and complete maintenance records, including information about every asset, machine or piece of equipment your organization or business owns.

These reports contain information such as when the asset was last maintained or when the asset was purchased. The good news is that maintenance software can now notify maintenance managers of upcoming maintenance activities.

If your goal is to increase the reliability of your equipment, you should keep your equipment and assets in working order. You should also consider different sources of information for different sectors, such as:

- Assets or types of assets, including expensive assets, critical assets, low-priority assets, and assets or assets that may fail periodically;

- Number of equipment service technicians, eg veteran, expert and novice;

- Activities related to the equipment or asset, such as work performed on the asset, downtime, warranty, depreciation, and spare parts inventory; and,

- Compliance, including validation, inspections, permits, policies and regulations.

Improve your business and optimize it with WorkTrek!

Report maintenance accurately so nothing goes wrong!

Try for freeRemember that because these factors are interdependent, you need to link data from one variable to another. This will help you gain a clear and comprehensive view of maintenance operations.

For example, you can view your team’s response time (average) and resolution time in the team performance report. You can also find the total hours worked by each user for a given time period. This is important information to help you determine when to schedule preventive maintenance and work orders based on technician availability. This can also help you determine if you are understaffed.

Quality maintenance records and reports are important because they help avoid costly repairs. As you probably know and understand, some equipment and assets are relatively inexpensive to maintain, while others are prohibitively expensive. Repair or repair costs are the sum required to restore equipment and assets to working condition.

Characteristics of Effective Maintenance Reports

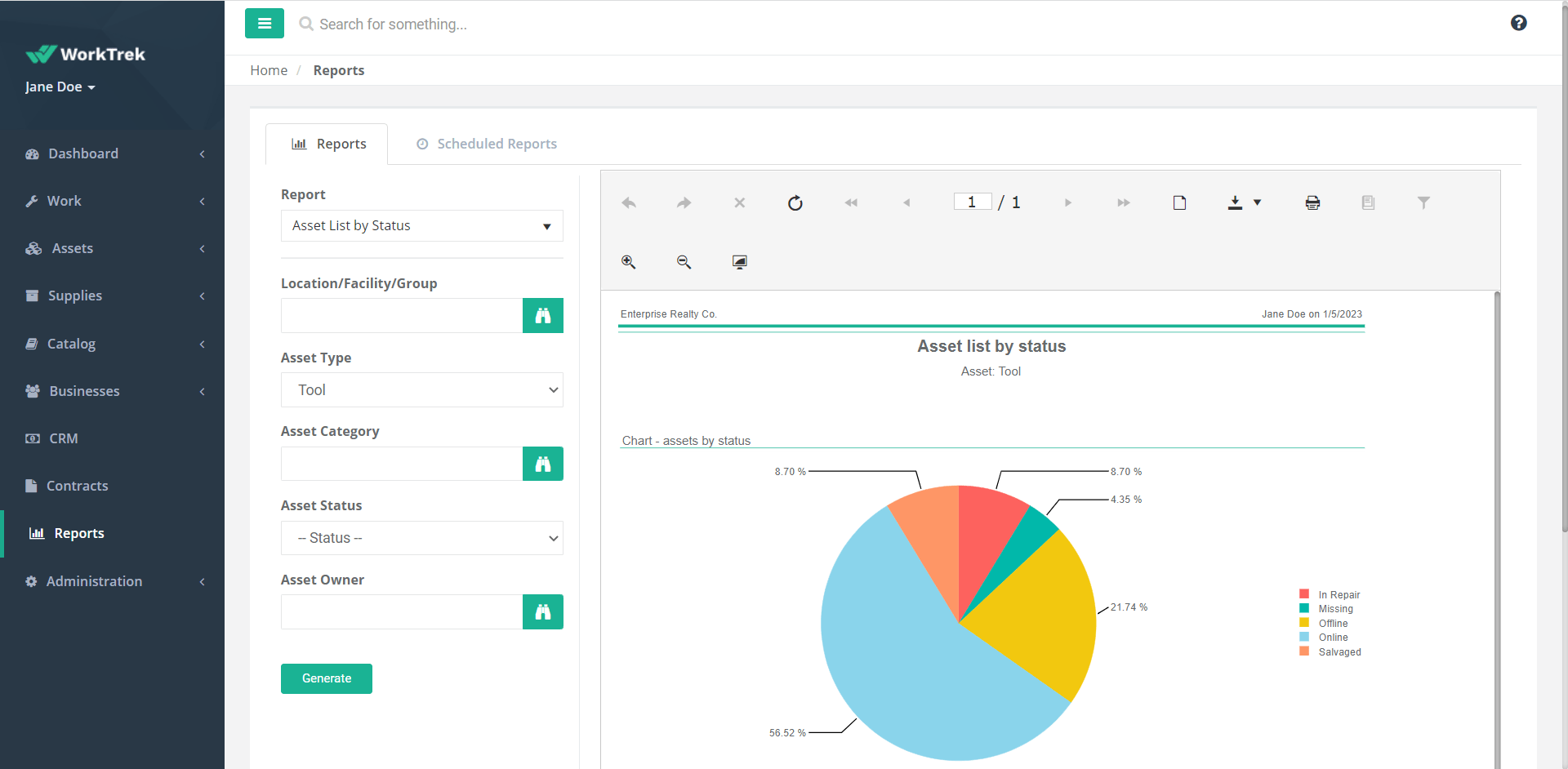

There are a number of reports you can run to gain insight or detailed insight into how your settings are performing. Maintenance reports can include asset costs, personnel performance, asset trends, planned work orders, and more. You intuitively know which data and information to monitor. But how do you know if your reports are actually delivering the insights you need?

A valid maintenance report would be:

- Accurate

- Related

- Simply

- On time

Accuracy is key to using data to make informed decisions. Inaccurate information can have devastating consequences such as: unforeseen equipment failure or safety risk that could have been avoided. Any reports you create should be factual and contain enough data to give you a complete, clear picture of what’s going on.

What It Means To Collect Data Correctly?

Without accurate data (in CMMS), using a database to manage plant performance is extremely difficult. In it, you can only use ticket records to capture text in the form of “action taken” for bug history – some don’t even have that.

It’s hard to turn back the clock if actionable error data isn’t captured after a work order is completed. You might be able to interview people for work done 3-4 weeks ago, but certainly not 3-4 years ago. While textual error comments are useful for reading individual work orders, they do not allow the SQL aggregate commands required for Pareto-style error analysis. In conclusion, it can be said that this is (faulty) data that can never be recovered.

The extent to which a CMMS contributes to profitability is directly related to data quality, analytical reporting, and roles assigned to analysis.

Why Should Maintenance Data Be Accurate And Complete?

Maintaining the accuracy of your data is very important because if it is inaccurate, you cannot rely on it. Data efficiency is reduced and decisions based on that data are ineffective. As a result, the output is not as expected.

The maintenance information must be complete, no matter how boring the time is! However, you must ensure that the data is correct and complete. If any data fields are blank, you may be missing some information that may be important when making a decision.

Maintenance reports play a vital role in several aspects such as in terms of maintenance planning, forecasting and maintenance budgeting. Now it also affects all of these types when reporting is incorrect or incomplete. This is why accuracy and complete data are so important.

What Are The Benefits Of Maintenance Reports?

In Maintenance Reports, you take all the collected data and turn it into actionable insights into your operations, helping you coordinate everything from suppliers and providing visibility into the types and timing of preventive maintenance checks and tasks schedule. Maintenance reports give you the business intelligence you need to make smart, data-driven decisions.

Part of that is how they help you combine large amounts of data into maintenance metrics and KPIs. You can think of data as letters, metrics and KPIs as words, and then the sentences you create from the letters, enabling you to effectively “read” and understand your operations.

Another benefit of maintaining reports is that they tell you where to look and take a closer look at the raw data. For example, this month’s report may show an increase in missed PMs. You know, if you keep this trend going for a long time, you’re going to see more reactive work orders because the teams can’t find and fix small issues before they become big ones. Now that you see the problem, you can drill down into the data to find the root cause. It can happen that you have too many PMs scheduled for your team, you wait too long to order necessary parts and materials, or you switch suppliers when you should have stuck with a slightly more expensive but more reliable supplier.

You can’t fix a problem until you know the cause. Maintenance reports help you determine what went wrong, which can then answer the critical “why?” question.

How Can You Improve Maintenance Reporting?

Now that we know what they are and how they can help you, we have a solid idea of what we want and why we want it. The question is, “How do we get it?”

Remember, reporting is about collecting data and turning it into actionable information that can be used to improve overall operations. This means you need to start looking for ways to acquire and store high-quality data. Back to our food analogy. Getting a good maintenance report is like cooking a good meal. First, you need quality ingredients.

Easy, standardized data collection – However, the problem faced by many maintenance departments is that it is not easy to get good data. When you’re working with pen and paper, things tend to go wrong. From the technician writing the wrong number in the wrong place to losing all your paperwork. And because everything is manual, people tend to finish their work before going back and trying to enter data from memory.

The only accessible source of truth – Even if you manage to get good data, sticking with it is another challenge. It’s hard to keep everything up to date when everything is paper or spreadsheets. Remember that changes you make in one place will not be reflected. Once someone on the team updates the file, everyone else’s copy is now out of date.

Simple automatic number calculation – But we can imagine that we live in an almost perfect world where you can use manual methods or a weakly glued combination of different software to acquire and preserve reliable data. Even if we have perfect data and can keep it, does it do us any good?

Possibly, but without an efficient way to process this data, you’re facing a lot of extra work. So much so, in fact, that you’re now destroying any possible return on investment you could have gained from collecting and storing all this data.

In Conclusion

All advanced businesses depend on the accuracy of information. Without it, any cutting-edge technique is meaningless, because the results you get depend on the type of data you feed it.

Data is the key to growth, and Report Maintenance provides just that! The organization is struggling, especially with maintenance.

Maintenance reports are records that contain clear data about your past maintenance activities and their impact on costs, resources and assets.

Without a doubt, to improve your business and optimize it, you need CMMS (Computerized Maintenance Management System) software. It can be an icebreaker for your business and take your business to another level.