Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Unplanned breakdowns cost farmers approximately $3,348 per season—routine preventive maintenance reduces repair bills by 25%.

- Farm equipment repair costs have spiked 41% since 2020, making proactive maintenance more critical than ever.

- Preventive maintenance delivers a 400% return on investment, with every dollar spent saving an average of $5 in future repair costs.

Your farm equipment represents one of your most significant investments—and how you maintain it directly affects your farming operation’s profitability, efficiency, and long-term success.

When valuable equipment breaks down during critical planting or harvest windows, you’re not just facing costly repairs. You’re dealing with lost productivity, missed deadlines, and potential crop damage that can severely impact your bottom line.

The good news?

Regular maintenance is essential for preventing these disruptions, extending equipment lifespan, and maximizing your return on investment.

In this guide, we’ll explore why regular farm equipment maintenance is so important and show you how to implement a maintenance strategy that keeps your agricultural machinery running smoothly year-round.

Prevent Costly Repairs and Emergency Breakdowns

Regular maintenance ensures your farm equipment stays operational when you need it most, preventing the expensive disruptions that come with unexpected breakdowns.

According to research by AgTech, unplanned equipment failures cost farmers approximately $3,348 per season. These emergency repairs typically occur at the worst possible times—right when you need your machinery most.

Picture this scenario:

It’s harvest season, and your combine breaks down in the middle of the field. The weather forecast calls for rain in 48 hours, and every hour of downtime means potential crop loss.

You’re facing not just the repair costs, but also:

- Lost productivity during peak season

- Rush charges for emergency parts and service

- Potential crop damage from delayed harvesting

- Overtime pay for technicians and operators

- The ripple effect on your entire farming schedule

This is exactly why proactive maintenance tasks matter so much. When you perform regular maintenance, you catch minor issues before they become major problems.

Brett Wilder, a maintenance expert, explains the reality:

“The true cost of equipment breakdowns is often far higher than the dollars spent on parts to get up and running again.”

Regular maintenance activities, such as checking fluid levels, inspecting belts and hoses, and replacing worn parts, help you identify and address problems during scheduled downtime rather than in the middle of critical operations.

According to data from the American Society of Agricultural and Biological Engineers, annual repair costs typically range from 2% to 4% of the original equipment cost when properly maintained.

However, when maintenance is neglected, these costs can skyrocket to 8% or more.

Regular maintenance also helps you avoid the domino effect of equipment failure. When one piece of agricultural equipment goes down, it doesn’t just stop that machine. It can also halt your entire farming operation.

Your well-maintained equipment becomes a reliable asset rather than a liability, ensuring you can maintain your farming schedule and avoid the stress of unexpected breakdowns during crucial periods.

Extend Equipment Lifespan and Maximize ROI

Farm equipment is a significant investment, and regular maintenance is essential to protect it and maximize equipment lifespan.

Modern tractors, combines, and other agricultural machinery can cost hundreds of thousands of dollars. Proper maintenance ensures you get the full value from these expensive assets.

According to Iowa State University research, well-maintained farm equipment can maintain up to 37% of its original value after 10-12 years of use.

Without proper upkeep, that salvage value drops significantly, directly impacting your return on investment.

Regular maintenance tasks extend equipment lifespan in several key ways:

Reducing wear on critical components

When you keep engine oil clean, maintain proper fluid levels, and lubricate moving parts regularly, you prevent the accelerated wear that shortens machinery life. A well-maintained tractor can easily reach 10,000-15,000 hours of operation, while neglected equipment might fail at half that.

Preventing corrosion and deterioration

Farm equipment faces harsh conditions daily. That can include dirt, moisture, chemicals, and extreme temperatures.

Routine maintenance, including cleaning, rust prevention, and protective coatings, helps prevent dirt buildup and corrosion that can permanently damage valuable equipment.

Maintaining peak efficiency

Equipment that’s functioning correctly puts less stress on all components, from the engine to the hydraulic systems. This reduces wear across the board and helps machinery last longer.

While this might seem expensive, it’s far less than replacing the entire machine prematurely.

Store agricultural machinery in covered locations when not in use, and this simple step significantly extends equipment life by protecting it from the elements. Following the manufacturer’s instructions for storage, winterization, and seasonal preparation keeps equipment in top condition between uses.

Regular maintenance ensures your farming operation gets the maximum lifespan from every piece of equipment, turning what could be a 5-7 year investment into reliable machinery that serves you for a decade or more. That’s the difference between frequent, costly part replacements and a well-planned maintenance strategy.

Improve Efficiency and Performance

Well-maintained equipment operates at peak efficiency, delivering better performance, higher productivity, and more reliable results across your farming operation.

When agricultural machinery is functioning correctly, every system works in harmony. The engine runs smoothly, hydraulic fluid flows properly, fuel consumption stays optimized, and all moving parts operate without friction or resistance.

According to maintenance research from Brightly, regular maintenance optimizes energy efficiency and ensures equipment operates at peak levels. This translates directly into fuel cost savings and improved productivity.

Here’s how regular maintenance improves efficiency:

Optimal fuel consumption

Clean air filters, properly tuned engines, and maintained fuel systems ensure your equipment uses fuel efficiently.

BusinessDojo research shows that implementing proper maintenance practices can reduce fuel consumption by 10-20%.

When you perform regular maintenance on fuel systems, you prevent inefficiency caused by clogged filters, dirty injectors, or poorly tuned engines, all of which waste costly diesel fuel.

Maximum power delivery

A well-maintained tractor delivers full power to the ground, allowing you to complete tasks faster and with less fuel.

Low fluid levels, worn belts, or neglected hydraulics rob power, forcing equipment to work harder to accomplish the same tasks.

Consistent performance

Regular maintenance ensures your equipment performs reliably day after day. You’re not dealing with inconsistent operation, unexpected slowdowns, or equipment that needs constant adjustment to function properly.

Reduced downtime

When you stay on top of maintenance tasks, you avoid the unscheduled downtime that disrupts your farming schedule. Your machinery is available when you need it, running smoothly without interruption.

Beyond the immediate efficiency gains, proper maintenance also prevents the gradual performance degradation that occurs when minor issues go unaddressed.

A small problem, such as slightly low hydraulic fluid levels or a partially clogged filter, might not stop your equipment immediately, but it reduces efficiency over time.

Your farming operation depends on equipment working at peak efficiency during critical windows. Regular maintenance ensures you don’t lose productivity to preventable performance issues that slow you down when every hour counts.

Reduce Operating Costs

Strategic maintenance planning significantly lowers your total operating costs by preventing expensive problems and optimizing resource use across your farming operation.

The cost savings from regular maintenance extend far beyond avoiding major repairs. When you implement a comprehensive maintenance program, you reduce expenses in multiple areas simultaneously.

Research data show that preventive maintenance can reduce costs by 12-18% compared to reactive approaches.

Even more impressive, every dollar invested in preventive maintenance saves an average of $5 in future repair costs, which translates to a 400% return on investment.

Let’s break down the key areas where regular maintenance reduces your operating costs:

Lower repair bills

Studies show that farmers who improve their maintenance procedures reduce maintenance costs by 25%. By catching and addressing equipment deterioration early, you pay for minor fixes instead of major overhauls.

Reduced fuel costs

Properly maintained engines run more efficiently on fuel, saving you money on every gallon of diesel. With fuel representing a significant portion of operating costs, these savings add up quickly across your entire fleet.

Fewer emergency service calls

Emergency repairs cost more than planned maintenance work. You pay premium prices for rush parts, after-hours labor, and expedited shipping. Regular maintenance eliminates most of these expensive emergency situations.

Optimal parts inventory

When you follow a planned maintenance schedule, you can stock spare parts strategically and purchase them at regular prices rather than paying premium costs for rush orders.

Extended replacement cycles.

Well-maintained equipment lasts longer, allowing you to delay costly part replacements and maximize the useful life of expensive machinery.

According to BusinessDojo, annual maintenance and repair costs typically run 5-8% of machinery’s purchase price when properly managed.

However, if you employ reactive maintenance, it can significantly increase costs.

Consider the total cost picture.

Data from Investigate Midwest shows that farm equipment repair costs spiked 41% between 2020 and 2024. In this environment of rising costs, the predictability and savings from regular maintenance become even more valuable.

Regular maintenance also reduces the hidden costs of poor equipment performance. Inefficient equipment uses more fuel, takes longer to complete tasks, and requires more operator attention, draining resources from your farming operation.

By investing in routine maintenance, you gain control over your operating costs and avoid the financial unpredictability that comes with running poorly maintained equipment.

Enhance Safety for Operators

Maintaining agricultural equipment in proper working condition is vital for operator safety, protecting your workers from accidents, and creating a safer farming environment.

Farm equipment poses inherent risks, and malfunctioning machinery significantly increases the danger.

According to the U.S. Bureau of Labor Statistics’ maintenance data, up to 30% of manufacturing deaths are related to maintenance activities, underscoring the critical importance of proper equipment upkeep.

Regular maintenance enhances safety in several crucial ways:

Preventing mechanical failures.

Well-maintained equipment experiences fewer sudden failures that could endanger operators. Brake systems that are properly serviced, steering mechanisms that function correctly, and safety features that work as designed all protect the people operating your machinery.

Ensuring safety systems function

Agricultural equipment comes with important safety features—rollover protection, emergency shutoffs, guards on moving parts, and warning systems. Regular maintenance ensures these vital components work when needed.

Maintaining visibility and control

Keeping equipment in good repair means lights work properly for early-morning or late-evening operations, mirrors are intact, and controls respond predictably. These factors prevent accidents caused by reduced visibility or unexpected equipment behavior.

Reducing fire hazards

Proper maintenance prevents fuel leaks, manages heat buildup, and keeps electrical systems in good condition—all critical for preventing equipment fires that endanger operators and threaten your entire farming operation.

Minimizing exposure to breakdowns

When equipment breaks down in the field, operators often resort to quick fixes under less-than-ideal conditions, increasing the risk of injury. Regular maintenance prevents these dangerous situations.

One farm equipment dealer explains the safety impact:

“A piece of malfunctioning farming equipment can be dangerous. They can pose a threat to the person operating the machine.”

Beyond protecting individual operators, well-maintained equipment creates a safer work environment overall. When machinery operates reliably, operators can focus on their work rather than compensating for equipment problems, reducing the risk of accidents caused by distraction or workarounds.

Regular inspections also identify safety issues before they cause injuries.

Checking for worn belts that could snap, frayed hydraulic hoses under pressure, or loose components that could come free during operation helps prevent accidents in the first place.

Your workers are your most valuable asset.

Regular maintenance protects them from preventable injuries while demonstrating your commitment to their safety—something that pays dividends in morale, retention, and peace of mind.

How CMMS Solutions Transform Farm Equipment Maintenance

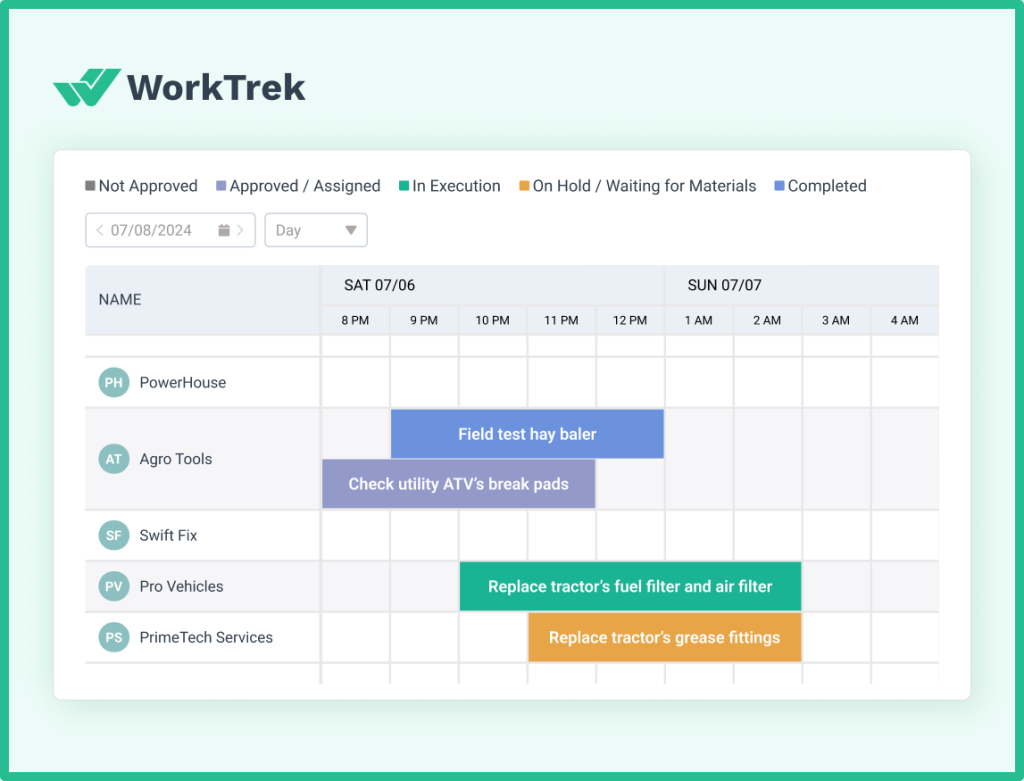

A computerized maintenance management like WorkTrek streamlines your entire maintenance program, making it easier to keep equipment in top condition while reducing costs and improving reliability.

Managing maintenance manually, with spreadsheets, paper logs, or memory, becomes increasingly difficult as your farming operation grows. Important maintenance tasks get overlooked, service histories are incomplete, and valuable equipment doesn’t receive the attention it needs.

This is where modern CMMS platforms like WorkTrek transform how you approach farm equipment maintenance.

According to recent industry data, 65% of companies now use a CMMS to monitor and optimize maintenance operations. This is with good reason.

These systems deliver measurable improvements across all aspects of maintenance management.

Here’s how a CMMS enhances your maintenance program:

Automated scheduling prevents missed maintenance

WorkTrek automatically schedules preventive maintenance based on calendar intervals, operating hours, or both. You’ll never miss an oil change, filter replacement, or inspection because the system tracks everything and alerts you when service is due.

Complete service histories improve decision-making

Every maintenance activity is documented in one central system, creating detailed records for each piece of equipment. When you need to decide between repairs and replacement, you have all the data you need.

Parts inventory management eliminates delays

Track spare parts inventory, set reorder points, and ensure critical components are always available. WorkTrek automatically deducts parts from inventory when work orders are completed, giving you real-time visibility into stock levels.

Mobile access supports field operations

Technicians can access work orders, view service instructions, and update maintenance records directly from their mobile devices—even while working in remote fields or equipment storage areas.

Data analytics optimize maintenance strategies

WorkTrek provides over 50 pre-built reports and more than 20 KPIs that help you analyze maintenance costs, identify problematic equipment, and continuously improve your maintenance program.

Streamlined workflows save time

Automate work order creation, approval processes, and completion tracking. What used to require multiple phone calls, emails, or trips to the office now happens automatically within the system.

The impact is substantial.

According to maintenance industry research, 65% of organizations point to more proactive maintenance practices as the key factor in reducing unplanned downtime.

WorkTrek makes this proactive approach practical by:

- Creating automatic work orders when maintenance is due

- Sending notifications before service deadlines

- Providing checklists that guide technicians through complex procedures

- Tracking maintenance completion rates and identifying overdue tasks

- Analyzing cost trends to optimize your maintenance budget

For farming operations managing multiple tractors, combines, planters, and implements across different locations, this centralized visibility is invaluable. You can see at a glance which equipment needs attention, what maintenance is scheduled, and where potential problems are developing.

The platform also supports continuous improvement. As you build service histories and track costs over time, you identify patterns—which equipment has the highest repair costs, which maintenance tasks deliver the best results, and where you should focus resources for maximum impact.

Conclusion

Regular farm equipment maintenance is important for running a successful, profitable farming operation in today’s challenging agricultural environment.

When you invest in proper maintenance, you’re not just avoiding costly repairs; you’re protecting valuable equipment, improving efficiency, reducing operating costs, and ensuring the safety of everyone who operates your machinery.

The data is clear:

Farmers who implement comprehensive maintenance programs reduce repair costs by 25%, experience fewer unexpected breakdowns, and achieve significantly better ROI on their equipment investments.

In an industry where margins are tight and equipment costs continue rising, these improvements directly impact your bottom line.

Start by evaluating your current maintenance practices, identifying areas for improvement, and implementing CMMS systems like WorkTrek to keep equipment in top condition.