Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

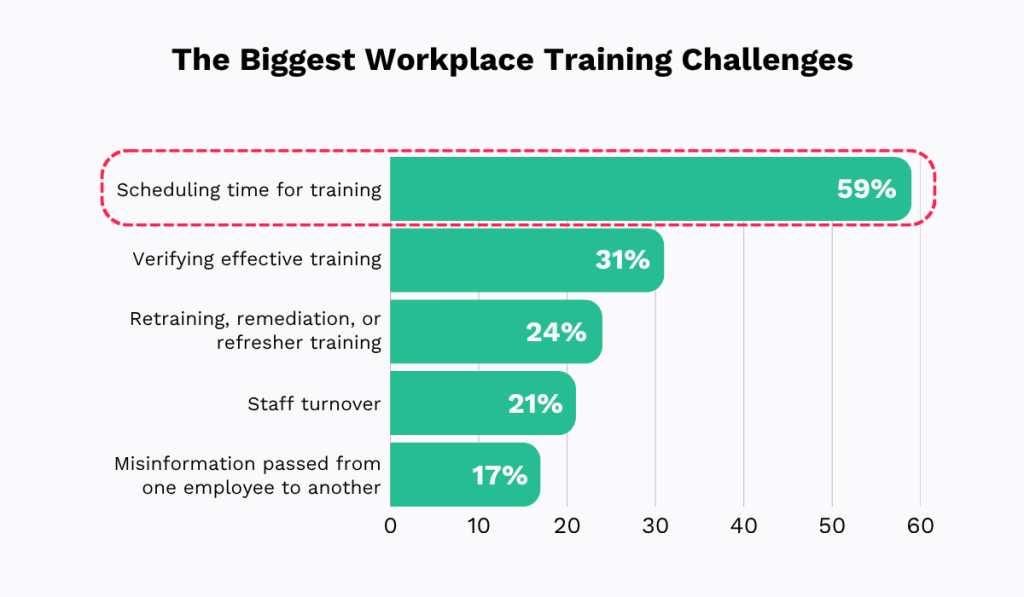

- Scheduling is considered the single biggest barrier to workplace training.

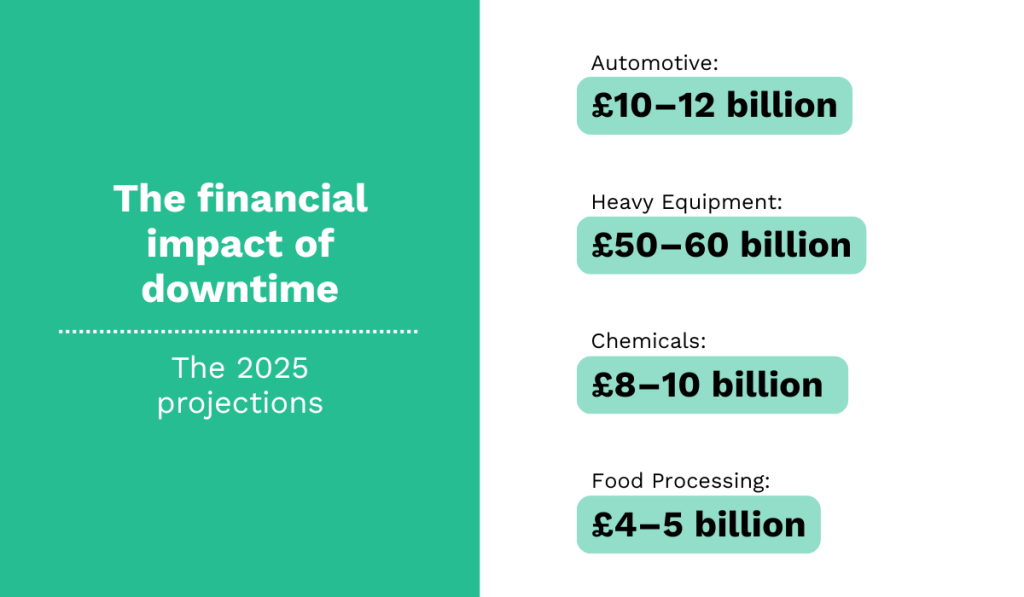

- Heavy equipment and industrial manufacturing lose £60B annually due to downtime.

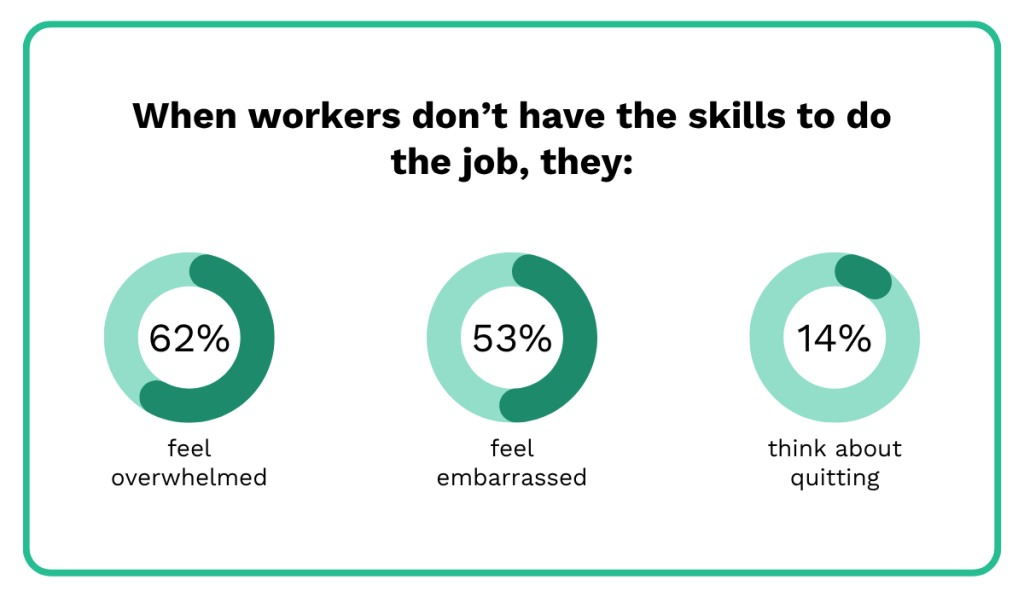

- Employees want to quit their work when they lack the skills to do the job effectively.

When most people think of a CMMS, they picture maintenance scheduling, inventory and asset management, and reporting on maintenance performance.

And they’re right, that’s what it’s best known for.

But here’s something you might not realize: your CMMS can also be a powerful tool for training your technicians.

It’s not a benefit that gets talked about often, but it should be.

A CMMS can make the entire process faster, more effective, and a whole lot less error-prone.

So how exactly does it work?

Keep reading to find out. We’ll break down five ways a CMMS can level up your maintenance training and show you how to put it to work in this often-overlooked role.

Enables Efficient Training Scheduling

A CMMS gives you real-time visibility into work schedules, technician assignments, and equipment availability, making it easier to slot training sessions at optimal times:

With built-in calendar features, you can quickly identify planned downtime windows for training, while also reviewing priority levels to ensure sessions don’t interfere with urgent tasks.

That’s extremely valuable, as nowadays, finding the right time for training seems harder than the training itself.

The 2021 Intertek Alchemy survey backs this up, revealing that scheduling is considered the single biggest barrier to workplace training.

This is especially true in industrial environments, where productivity targets and training hours feel like they’re constantly at war.

In these sectors, many companies still operate under the belief that every minute on the clock should be spent on the line.

After all, downtime is expensive.

For instance, IDS-INDATA projects that in 2025, downtime losses could reach £60 billion in heavy equipment and industrial manufacturing and £12 billion in the automotive sector.

It’s no surprise, then, that companies hesitate to pause operations for training.

However, here’s the paradox: skipping training only makes downtime more likely.

Without well-trained teams, you risk more frequent breakdowns, slower responses, and mounting costs from unplanned outages.

That’s why CMMS tools make such a difference.

By providing full visibility into your operations, they allow you to balance training with the assets’ maintenance needs, ultimately preventing delays, skipped sessions, and conflicts with critical work.

As a result, you can finally have both: a workforce that’s properly trained and a facility that keeps running at peak performance.

Serves as a Centralized Knowledge Base

A CMMS serves as a centralized digital hub for all maintenance-related information.

This can include equipment manuals, SOPs, safety guidelines, troubleshooting guides, and even multimedia resources such as videos or annotated photos.

So, instead of technicians having to search through binders or emails, everything becomes organized, searchable, and instantly accessible on desktop or mobile devices.

This matters because technicians learn faster, gain confidence, and perform better when they can quickly find the information they need.

Yes, this boosts overall efficiency, but it also keeps your team engaged and supported.

In fact, according to the 2025 Axonify survey, when employees lack the skills or resources to do their jobs effectively, they often feel overwhelmed, embarrassed, or even consider quitting.

In other words, failure to provide essential data can directly affect your employee retention rates.

Luckily, with a CMMS, employees get the knowledge they need in seconds, whether they are in the office or in the field.

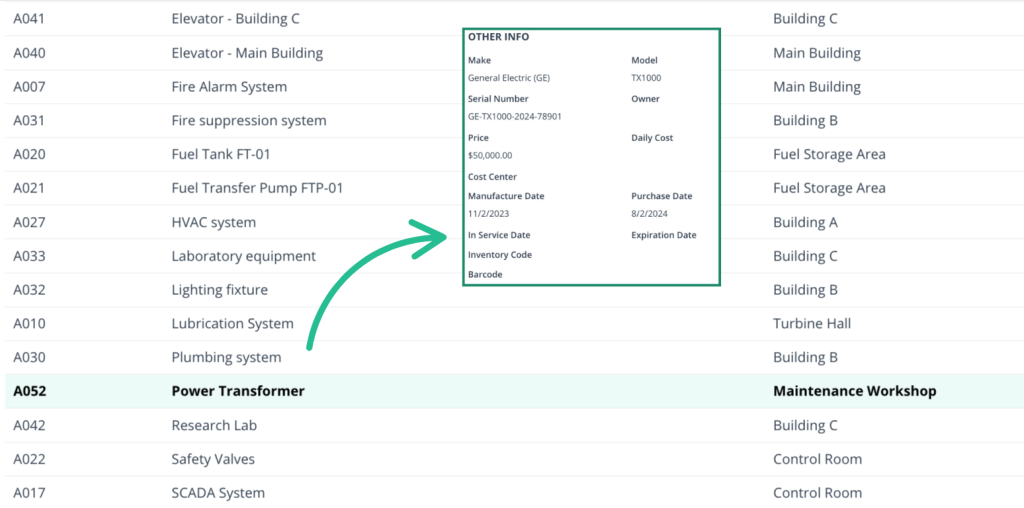

Take our own solution, WorkTrek, as an example.

With our tool, you can access complete asset data, including location, warranty details, maintenance history, and more, all within one platform available across desktop, tablet, and mobile devices.

You can also integrate hazard and risk information, required PPE, and lockout/tagout procedures for each asset to ensure safety and compliance.

Additionally, customizable forms and checklists can be attached to preventive maintenance, work orders, or logs.

That way, trainees can access consistent, up-to-date instructions anytime, which reinforces learning and builds independence.

Why waste time with scattered, disorganized training materials when you can make everything centralized and accessible, whenever and wherever it’s needed?

With a CMMS like WorkTrek, your people can finally spend less time searching for information and more time putting that information to work.

Enables Learning from Past Successes and Failures

A CMMS doesn’t just display current data. It also preserves valuable historical information.

It maintains detailed records for each asset, including when issues occurred, what caused them, how they were resolved, and which solutions proved most effective.

Such historical data forms a rich library of real-world case studies that trainers can use to highlight both best practices and mistakes to avoid.

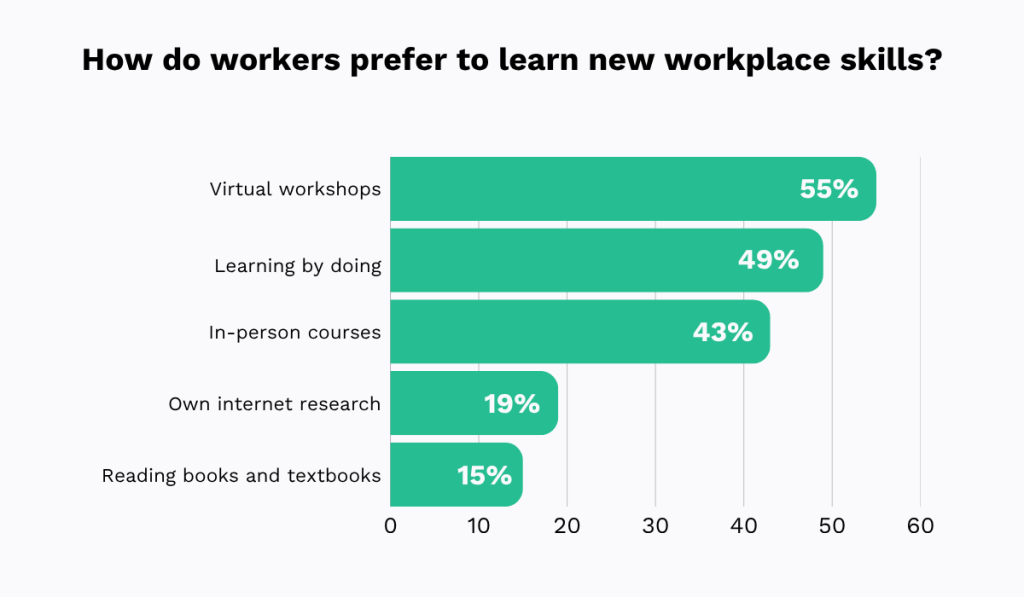

A KPMG study has shown that trainees prefer a blend of learning approaches, from virtual workshops and hands-on learning to digital resources.

Historical maintenance data fits into this by allowing trainees to see the real-world impact of good and poor maintenance practices.

It teaches them not only the “how,” but also the “why” behind procedures, but without any of the risks of real-world errors.

Ultimately, by reviewing past decisions and their outcomes, trainees can better understand the consequences of their own actions.

Without this insight, they might repeat mistakes, miss warning signs, or underestimate the importance of preventive measures.

As Sarah Ischer, Senior Director, Expertise at What Works Institute, a research-to-practice think tank and learning community for environmental, health, safety & sustainability, points out:

Although she’s speaking about safety training here, the same principle applies to maintenance.

Workers need to understand the real consequences of poor practices for the lessons to resonate truly.

Since it isn’t always feasible to let mistakes play out in real life, historical data becomes a powerful training tool, helping teams learn from the past and become more engaged.

Streamlines Communication Between Trainers and Trainees

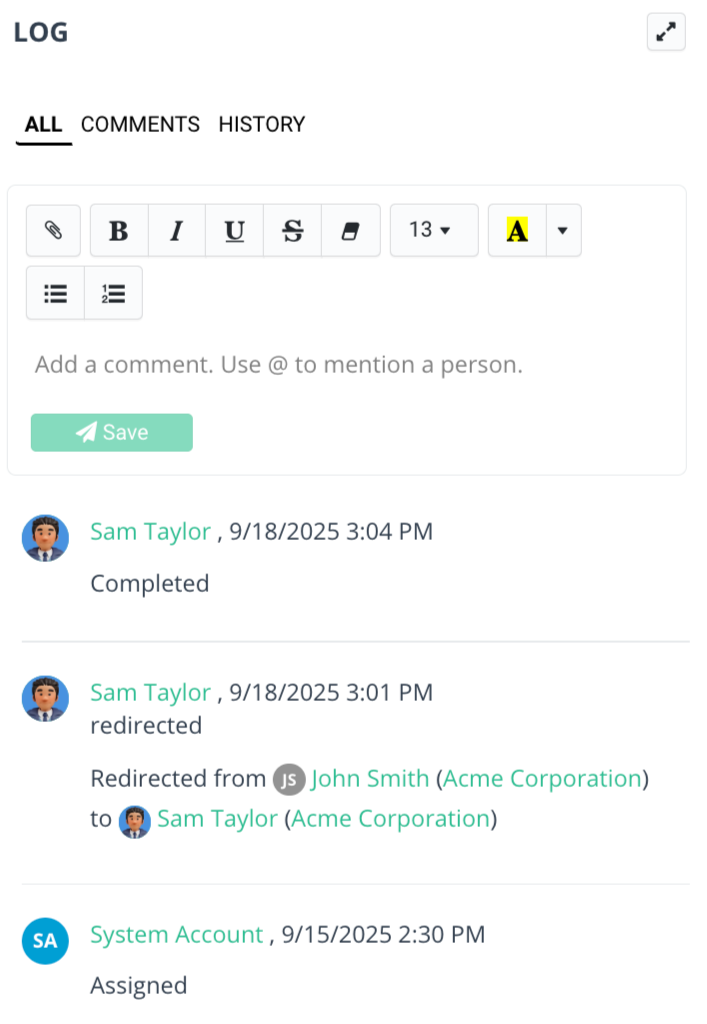

A CMMS provides built-in communication tools that enable trainers and trainees to interact directly within the system.

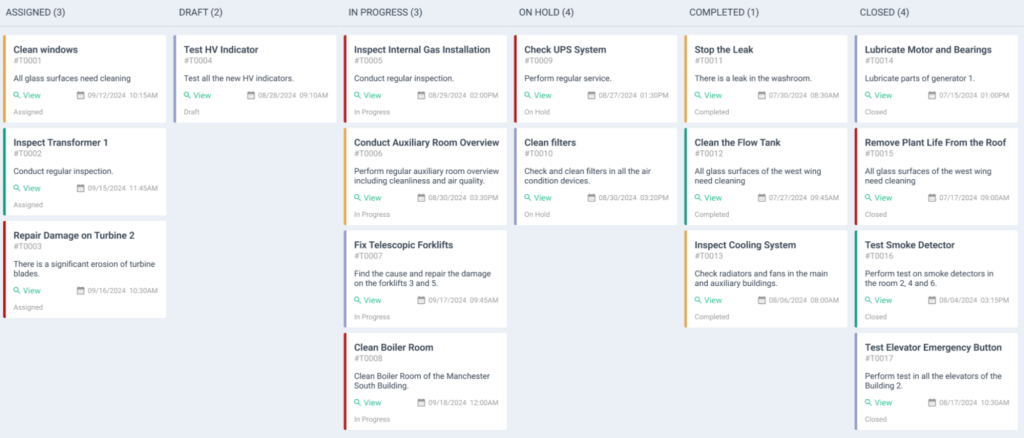

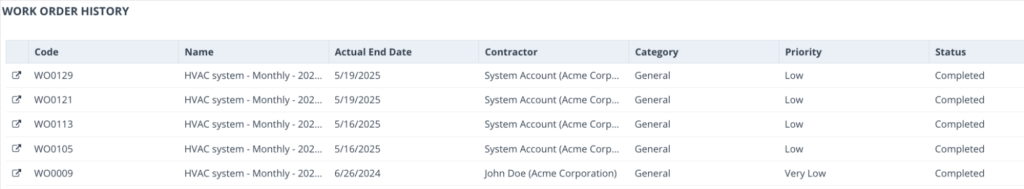

Trainers can leave comments on work orders (shown below), provide step-by-step guidance, attach instructional materials, and send reminders about upcoming tasks or deadlines.

Many CMMS platforms also support mobile notifications and messaging, ensuring feedback and updates reach trainees in real time, no matter where they are.

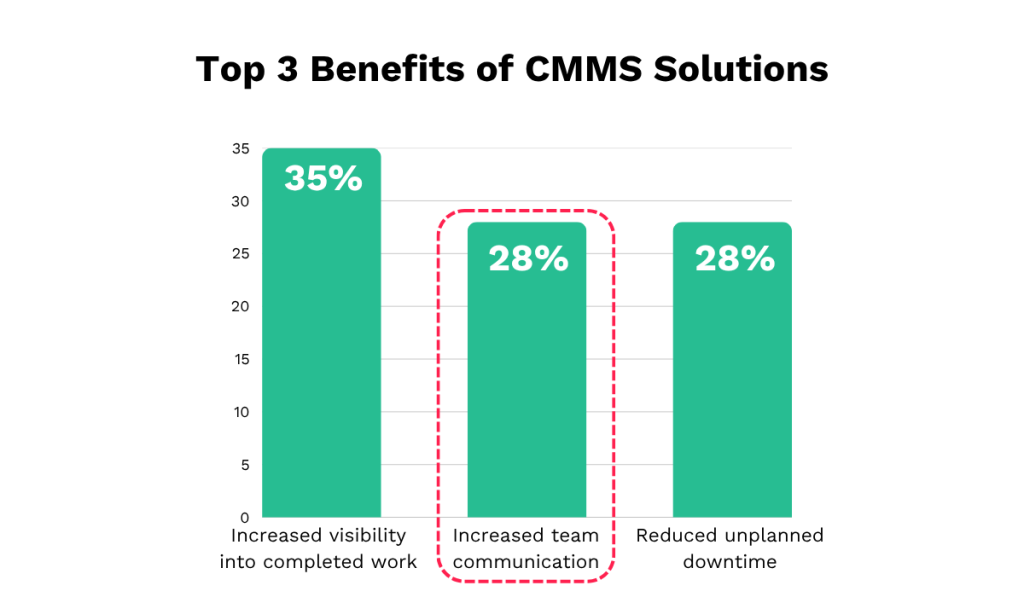

This significantly improves communication between trainers and trainees, and some recent studies even back this up.

This is extremely important because clear communication is the foundation of effective skill development.

Without it, trainees may misunderstand instructions, make errors, or hesitate to ask questions.

Traditional methods, such as paper notes or verbal instructions, can be inconsistent and easily lost, but a CMMS centralizes guidance, documents it, and makes it accessible when it’s needed.

This fosters an environment that accelerates skill acquisition, improves retention, and builds confidence in new technicians.

The 2024 Grammarly survey supports this, showing that the majority of business leaders observed increased employee productivity and confidence due to effective communication.

With a CMMS, communication becomes more effective than ever.

Trainees receive prompt feedback, are able to clarify any doubts right away, and their learning process becomes much smoother and more streamlined.

Helps Monitor Training Outcomes

Simply providing training to your team isn’t enough.

To build a strong maintenance culture, you need to continuously monitor, analyze, and refine your training efforts.

A CMMS makes this possible with powerful reporting capabilities that track technician performance over time across multiple metrics, such as:

| Task Completion Accuracy | The percentage of maintenance tasks or work orders completed correctly without errors |

| Time to Competency | How long does it take a trainee to reach a predefined level of skill or independence |

| Work Order Rework or Repeat Maintenance | The number or percentage of work orders that must be redone due to errors |

| Equipment Downtime Post-Training | Reduction in downtime caused by human error or improper maintenance |

| Maintenance Response Time | How quickly a trained technician responds to and resolves a maintenance issue |

Armed with this objective and detailed data, you can compare performance against benchmarks or senior technicians’ standards and determine whether new skills are being applied effectively.

This reveals the areas where your training program needs improvement, allowing you to provide personalized feedback and adjust the training plan dynamically.

Relying solely on observation or manual reporting makes this nearly impossible.

A CMMS and its analytics capabilities, however, ensure training is measurable, consistent, and directly aligned with actual performance needs.

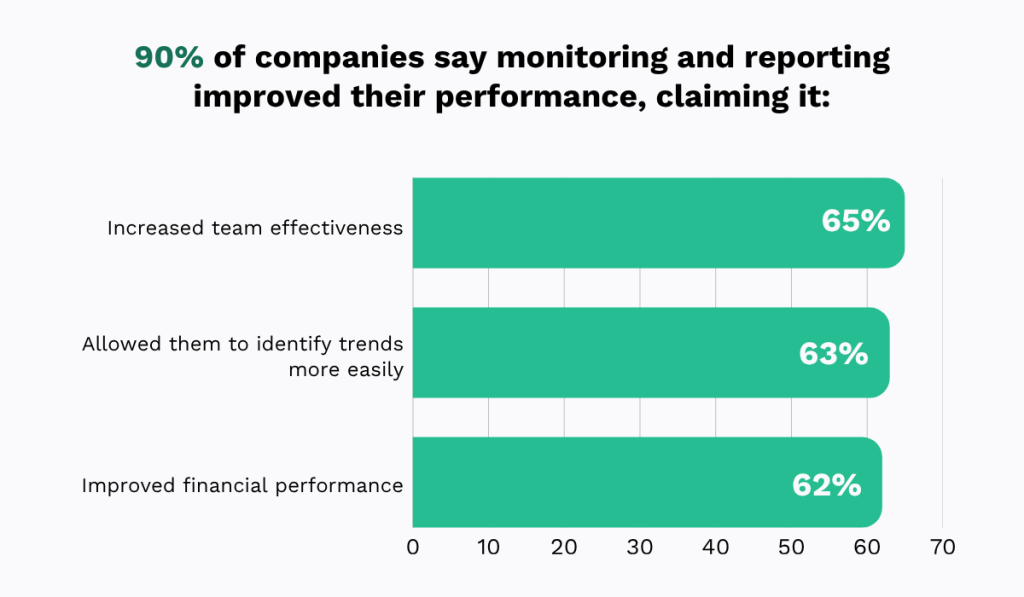

The 2023 Databox survey supports this, showing that the majority of companies report improved performance through monitoring and reporting.

Specifically, they highlighted benefits such as increased effectiveness, easier trend identification, and even improved financial outcomes.

The lesson is quite clear: to improve anything, you must track it over time.

Maintenance training is no different.

By monitoring trainees’ progress with accurate, up-to-date data, you can see what works, what doesn’t, and take action to enhance your program.

After all, what good is training if it doesn’t deliver the results you need?

Conclusion

Your CMMS is more than just a tool for maintaining assets.

When used to its fullest potential, it empowers your people, giving them everything they need to work efficiently, safely, and with confidence.

That’s a real game-changer.

With a well-trained maintenance team, your entire operation becomes stronger and more resilient, especially if downtime is typically a big issue for you.