Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

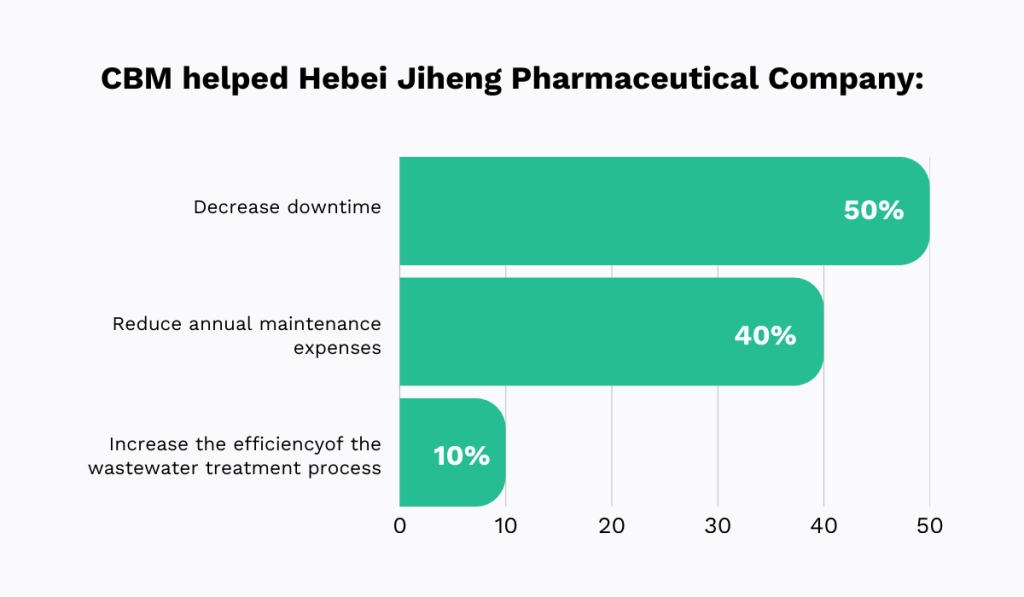

- Hebei Jiheng Pharmaceutical Company used CBM to cut maintenance costs by 40%.

- Companies cannot unlock stable maintenance processes without process mapping.

- Excessive PM can drain time, money, resources, and slow down production.

Have you ever wondered why some maintenance teams are stuck in a reactive, firefighting mode while others run seamlessly, with fewer breakdowns and lower costs?

You might be surprised to learn that the difference isn’t the size of the budget or the sophistication of the tools and technology.

It’s the process behind the work.

In many organizations, maintenance is weighed down by reactive tasks, wasted motion, excess inventory, and unclear priorities.

Downtime eats into productivity, technicians feel stretched thin, and small issues snowball into costly failures.

That’s where lean maintenance comes in.

It focuses on eliminating all kinds of waste, improving flow, and making maintenance a value-driving function rather than a necessary evil.

In this article, you’ll learn how to build a lean process in seven steps, so you can unlock these amazing benefits within your own operation.

1. Communicate the Vision

Before making any changes, ensure that everyone, from leadership to frontline technicians, understands what lean maintenance is and why it matters.

Explain how reducing waste can make their jobs easier, improve equipment reliability, and contribute to the company’s overall success.

People are naturally skeptical of change, so communicating these benefits clearly will increase the likelihood of company-wide buy-in and a successful lean implementation.

Tony Di Tullio, Director of Property Management at Air Canada, Canada’s largest airline, agrees:

Di Tullio explains that the best way to do this is by winning over the naysayers first.

If you can get one or two of them on board, momentum will build quickly.

He also stresses the importance of clearly explaining how the new program will work, what will change, and what employees stand to gain.

A strong presentation should clearly answer questions such as:

- Why are we changing now?

- What problems are we solving?

- What does “better” look like?

- How will this help me in my role?

- How will success be measured and sustained?

Don’t forget to tailor the message to different audiences.

Executives will want to understand ROI, risk reduction, and the overall business impact.

Supervisors will be focused on workload stability, planning efficiency, and execution.

Technicians, on the other hand, will want to know how their day-to-day work will change and how the program will affect safety, downtime, and overall efficiency.

Boeing, a company that achieved significant results through lean, also began by clearly sharing the vision.

Scott Stocker, VP and General Manager of the 787 Program, explains:

By doing this, the vision becomes tangible and believable, helping justify the change and ensuring long-term success.

2. Map Your Current Processes

Next, choose a key maintenance process, such as your work order management workflow or preventive maintenance program, and document its end-to-end flow.

Remember, you cannot improve what you do not understand.

This step helps expose hidden waste, bottlenecks, and variation, and prevents you from “fixing” the wrong problems based on assumptions.

Ricky Smith, VP of World Class Maintenance, a corporate maintenance training provider, stresses the importance of process mapping:

Essentially, mapping your current processes means visually documenting how maintenance work truly flows today, from the moment an issue is identified to the moment the work order is closed.

The goal is not to design the ideal future state yet, but to fully understand the current one, including all delays, rework, handoffs, and variations.

This typically includes mapping:

- How work is requested

- How work is approved, planned, and scheduled

- How parts, tools, permits, and resources are obtained

- How work is executed, documented, and closed

- How feedback and failure data are captured or lost

Be sure to involve technicians and planners in this process to capture the real state of things.

They perform the work every day and know where time, effort, and information are lost.

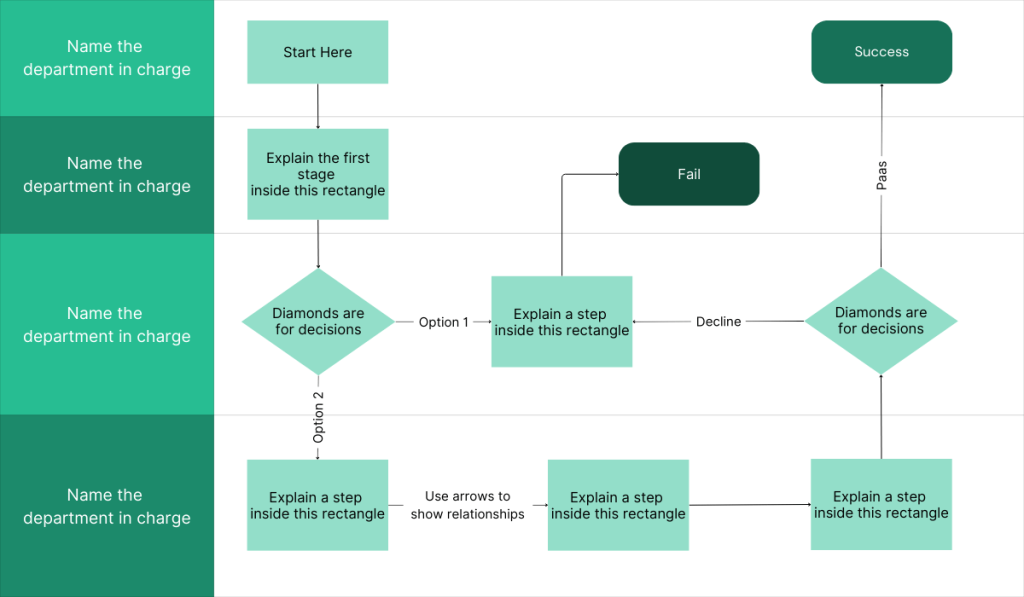

Once you understand all the steps and interactions, depict the process visually.

One commonly used tool is a swimlane diagram, a visual flowchart that maps a process while showing who does what and when, as shown below.

This clarifies roles, handoffs, and responsibilities.

Another option is a Value Stream Map (VSM), a lean management tool that visually maps every step of a process to identify waste and improve efficiency by showing both material and information flow.

Once your processes are fully mapped, you will have a solid baseline for improvement, revealing opportunities for optimization in an objective and structured way.

3. Eliminate Waste

This step is the core of lean maintenance.

It involves identifying and eliminating activities that do not add value to the maintenance process or the organization.

It’s important to remember that waste can take many different forms and affect various aspects of maintenance.

One acronym commonly used to help remember these types of waste is DOWNTIME:

- Defects

- Overproduction

- Waiting

- Non-utilized talent

- Transportation

- Inventory

- Movement

- Excess processing

However, that is just one way to categorize waste in lean maintenance.

Another commonly used approach is the 5 Ms framework:

| Man (Workforce) | Waste related to human resources, including underutilized skills, lack of training, inefficient movement, safety hazards, and poor communication |

| Machine (Equipment) | Waste associated with equipment, such as downtime due to breakdowns, inefficient operation, underutilization, and inadequate maintenance |

| Material (Spare Parts & Supplies) | Waste related to materials, including excess inventory, stockouts, obsolete parts, inefficient procurement processes, and poor storage practices |

| Method (Maintenance Processes & Procedures) | Waste is embedded in how maintenance work is performed, such as inefficient workflows, lack of standardization, unnecessary steps, and inadequate documentation |

| Measurement (Data & Analysis) | Waste caused by poor data-driven decision-making, inaccurate performance metrics, and the inability to identify, measure, and track improvement efforts |

It doesn’t really matter which framework you choose for your operations, as they are all very similar and focus on the same underlying issues.

What does matter, however, is avoiding the mistake of trying to tackle all waste at once.

Instead, work with your team to identify the single largest source of waste and address that first.

For many organizations, this is often the planned maintenance program, due to a common misconception that more maintenance automatically leads to better results.

In reality, excessive maintenance can be a significant source of waste, says Charles Rogers, Senior Implementation Consultant at Fiix Software:

Preventive maintenance can indeed drain time, money, resources, and even slow down production.

So, here’s what to do instead.

4. Introduce Condition-Based Maintenance

Lean maintenance is less about time-based schedules and more about using real asset condition data to trigger work.

This approach, known as condition-based maintenance (CBM), relies on monitoring key indicators of asset health, such as vibration or oil quality, to determine when maintenance is actually needed.

Martin Thomson, Senior Manager of Digital Services at Schneider Electric, a French multinational specializing in digital automation and energy management, explains it well:

“Think of [CBM] like keeping a ship on track. If you wait until you’re way off course, […], and then try to correct, that’s inefficient. But if you’re constantly checking your course from day one, you get there faster, and you make your equipment last longer.”

In other words, the goal is not to follow a fixed, static schedule, but to continuously fine-tune maintenance plans based on an asset’s real condition and usage, which change constantly.

By doing so, companies prevent both under-maintenance, which can lead to major failures, and over-maintenance, which wastes time and resources.

The result is significantly improved asset reliability and availability.

Take it from Hebei Jiheng Pharmaceutical Company, which used CBM to cut downtime by 50% and maintenance costs by 40%.

Thanks to this strategy, the factory can now operate at full capacity, maximizing revenue without adding extra assets, personnel, or other resources.

For organizations just starting with condition-based maintenance, it’s best to begin gradually.

There’s no need to monitor every asset or invest immediately in the most advanced technology.

Instead, focus on a small number of critical assets and use user-friendly, cost-effective IoT sensors.

As your team gains experience and the benefits of CBM become evident, you can scale the program over time.

5. Standardize Work

Next, it’s time to define and document the best-known method for performing each maintenance task, so it can be executed consistently, safely, and efficiently every time.

This includes not only the task itself, but also all supporting elements, such as tools, parts, safety precautions, approvals, and documentation.

So, when developing your SOPs, consider including the following elements:

| Purpose & Scope | Why the SOP exists and which specific equipment or tasks it covers |

| Roles & Responsibilities | Who performs the task, who supervises it, and who provides approval |

| Required Resources | A complete list of tools, parts, software, and personal protective equipment |

| Step-by-Step Procedures | Clear, sequential instructions, ideally supported by visuals such as diagrams or photos |

| Safety Precautions | Critical warnings, PPE requirements, lockout/tagout steps, and hazard identification |

| Quality Control | Acceptance criteria or checkpoints to confirm the work has been completed correctly |

| Documentation & Reporting | Instructions for recording task completion, findings, or issues (for example, in a CMMS) |

| Troubleshooting & Emergency Actions | Guidance for handling unexpected issues or breakdowns |

This may seem like a lot of information, but when it comes to process standardization, being thorough matters.

It reduces variation, one of the biggest contributors to defects, safety risks, and rework, and creates a stable foundation for continuous improvement.

Ultimately, when work is standardized, maintenance is performed correctly and consistently, thereby minimizing unexpected downtime and wasted effort.

However, even the best SOPs are ineffective if they are difficult to find or access.

If procedures are scattered across paper documents in an office, technicians, particularly those who work in the field, are unlikely to take the time to search for them.

Abid Sulayman, Business Process Improvement and Automation Specialist at Autotek.io, a provider of digital solutions for the automotive industry, suggests a better approach:

Put simply, digitize your SOPs.

By centralizing and making them accessible anytime and anywhere, you significantly increase the likelihood of compliance.

Instead of wasting time searching for instructions, technicians can pull them up on their phones, see exactly how to perform the task, and get to work immediately.

6. Streamline Workflows with Automation

Following all the steps outlined in this guide without automation would be difficult, if not downright impossible.

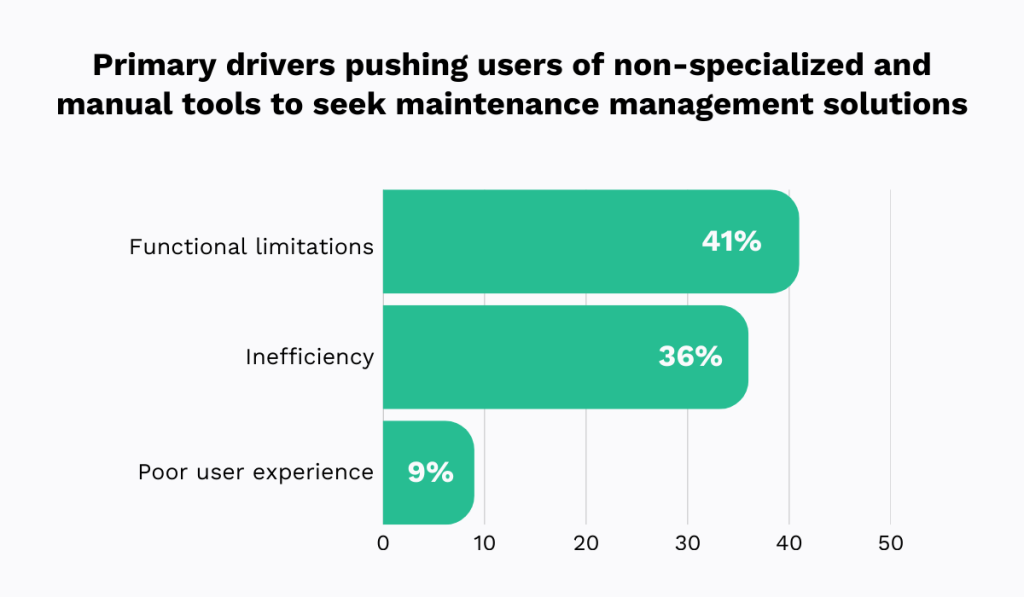

After all, manual processes are extremely time-consuming, prone to errors, and hard to scale.

In fact, research shows that most people abandon manual maintenance management due to functional limitations, inefficiency, and poor user experience.

Lean maintenance is all about minimizing waste and inefficiency, which makes automation a logical step in implementing a successful lean program.

To better understand how lean and automation go hand in hand, take a look at WorkTrek.

This CMMS centralizes all maintenance data, reduces repetitive tasks, and improves visibility across operations through its core features:

| Work Order Management | Create, assign, track, and prioritize WOs from anywhere. Capture key details with customizable required fields. |

| Work Request Management | Submit requests through multiple channels: app, email, or request portal. Automatically notify stakeholders of updates, and collect feedback once work is completed. |

| Asset Management | Record and update all asset information, including physical location, performance history, warranties, maintenance logs, and costs. |

| Inventory Management | Track parts using barcodes or QR codes to reduce manual entry. Receive automated low-stock alerts to avoid delays. |

| Invoicing | Generate invoices from work orders in just a few clicks. Minimize errors by pulling accurate data directly from completed tasks. |

| Analytics | Unlock insights into your business with reports, KPIs, metrics, and customizable dashboards |

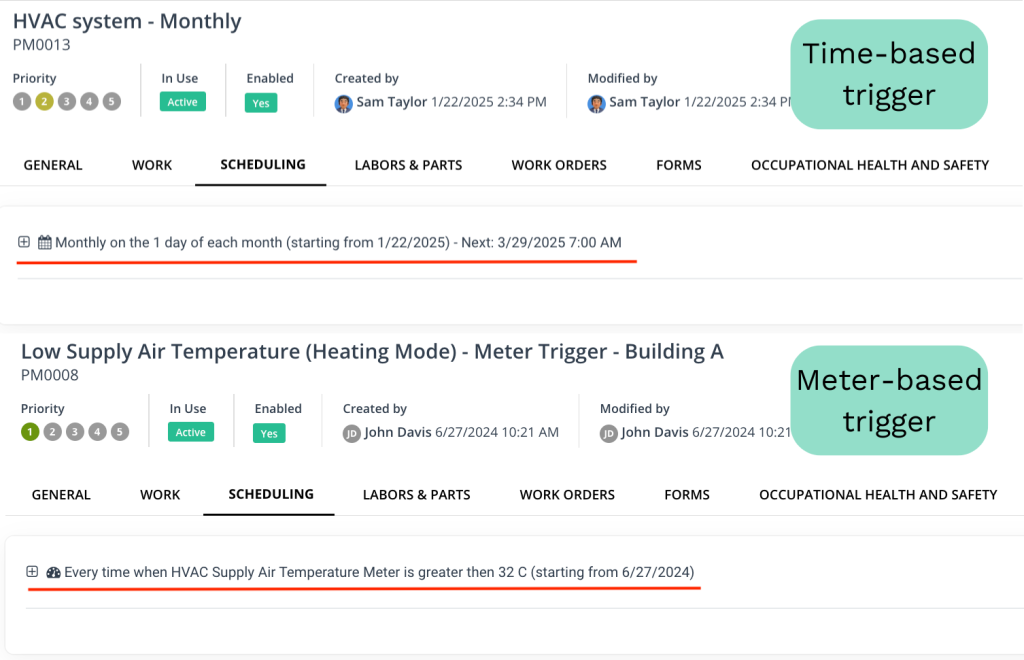

Most importantly, WorkTrek automates preventive maintenance (PM) scheduling.

You can set up recurring work orders with assigned personnel, priority levels, SOPs, checklists, photos, and instructions.

Scheduling can be based on time (daily, monthly, etc.) or usage metrics such as mileage, hours, temperature, or pressure.

This allows you to maintain assets proactively, ensuring they receive the care they need, when they need it.

Additionally, WorkTrek automatically generates follow-up work orders after failed inspections, keeping assets in peak condition with minimal downtime.

Overall, automation makes maintenance work easier, faster, data-driven, and strategic.

This aligns perfectly with lean principles, which prioritize waste reduction and help workers focus more on value-added activities.

7. Create a Continuous Improvement Loop

In lean maintenance, work is never truly complete.

Performance must be continuously reviewed, failures should be treated as learning opportunities, and incremental improvements should be made consistently.

That’s how you prevent stagnation.

Assets, technology, and business conditions are constantly evolving. Continuous improvement ensures the maintenance program evolves along with them.

Scott Stocker from Boeing implemented this mindset, too, and offers this advice:

“Promote Lean thinking as an ongoing process rather than a one-time initiative. […] Establish regular performance review and feedback mechanisms to track progress and make step-by-step improvements.”

Before conducting performance reviews, however, start by outlining clear KPIs to measure success.

Without them, you risk trying to track everything at once, which can be overwhelming and provide little actionable insight.

Clear, predefined KPIs, on the other hand, help maintain focus and consistency over time.

Begin with just a few relevant metrics, such as:

| Mean Time Between Failures (MTBF) | Measures how often equipment fails, highlighting areas needing reliability improvements |

| Mean Time to Repair (MTTR) | Tracks the average time taken to fix an asset, indicating maintenance efficiency |

| Planned Maintenance Percentage (PMP) | The proportion of scheduled versus reactive maintenance; higher PMP reflects a proactive approach |

| Maintenance Cost as a Percentage of Revenue | Ensures maintenance spending aligns with business goals and is not excessive |

As your program matures, you can add more KPIs as needed.

Additionally, if you use a CMMS or similar solution, remember that the system automatically tracks and analyzes many of these metrics.

Often, accessing these reports is just a few clicks.

Then it’s all about putting what you’ve learned into action.

Conclusion

When implementing lean maintenance, don’t expect everyone to get everything right the first time.

You will almost certainly encounter skepticism, misunderstandings about new roles or processes, and mistakes or inconsistent execution.

That’s completely normal. Lean takes time to fully take hold.

In fact, when people are asking questions and pointing out what isn’t working, it’s a sign they’re engaging with the process rather than ignoring it, which is exactly what you want.

So, expect variability early on and normalize mistakes.

Treat errors as opportunities for improvement, not as evidence that the implementation is failing.

Over time, this way of working will become the new normal, delivering the benefits you’ve been working toward.