Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

• 71% of companies use preventive maintenance as their primary strategy—here’s how to do it right with effective checklists.

• Every $1 spent on preventive maintenance saves $5 in other expenses, making it one of the highest-ROI investments in facilities management.

• Companies with structured PM programs experience 33% less equipment failure and 25% fewer safety incidents compared to reactive approaches.

Picture this: It’s 3 AM, and your production line has ground to a halt. A critical motor just seized up, and your maintenance team is scrambling to find the problem. The emergency repair will cost thousands, your production schedule is shot, and customers will be furious about delayed orders.

Now imagine a different scenario:

Your maintenance technician spotted unusual vibrations during a routine checklist inspection last week. The motor was serviced proactively during a regular scheduled downtime. This was performed at a fraction of the cost of an emergency repair, and production never missed a beat.

That’s the power of preventive maintenance checklists done right.

The numbers tell a compelling story.

Preventive maintenance saves 12-18% in costs compared to reactive maintenance, according to the U.S. Department of Energy. Even more impressive, unplanned downtime costs Fortune Global 500 companies approximately $1.5 trillion annually—losses that comprehensive preventive maintenance checklists can significantly reduce.

But here’s the catch: Not all preventive maintenance checklists are created equal. A poorly designed checklist can actually waste time and resources while still missing critical issues. A practical preventive maintenance checklist, on the other hand, becomes the backbone of your entire maintenance program.

In this guide, we’ll walk you through the best practices for using preventive maintenance checklists that actually work.

From creating customized checklists for different equipment types to implementing digital solutions that maximize efficiency. Whether you’re running a manufacturing plant, managing a facility, or overseeing maintenance operations, you’ll learn how to build a successful preventive maintenance program that reduces downtime, extends equipment lifespan, and saves significant money.

Let’s get started!

What Makes an Effective Preventive Maintenance Checklist

A solid preventive maintenance checklist isn’t just a random list of tasks. It’s a carefully designed tool that guides maintenance technicians through every critical step needed to keep equipment running reliably.

Think of it as a recipe: except instead of baking a cake, you’re preventing costly equipment failures.

Essential Elements Every Checklist Needs

A comprehensive preventive maintenance checklist should include these core components:

1. Asset Identification

Start with the basics: equipment name, unique ID number, precise location, and the date maintenance is being performed. This might seem simple, but clear asset identification prevents confusion when you’re managing dozens or hundreds of pieces of equipment across multiple locations.

2. Clearly Defined Maintenance Tasks

Each task should be specific and actionable.

For example: Instead of writing “check motor,” a practical preventive maintenance checklist specifies “inspect motor bearings for unusual noise or excessive heat” or “measure motor vibration using vibration analyzer.”

The best maintenance activities break complex procedures into individual steps that even a less experienced technician can follow confidently.

3. Maintenance Frequency and Last Completion Date

Document how often each task should be performed—daily, weekly, monthly, quarterly, or annually. Include the date when maintenance was last completed so technicians can verify they’re performing routine maintenance on schedule.

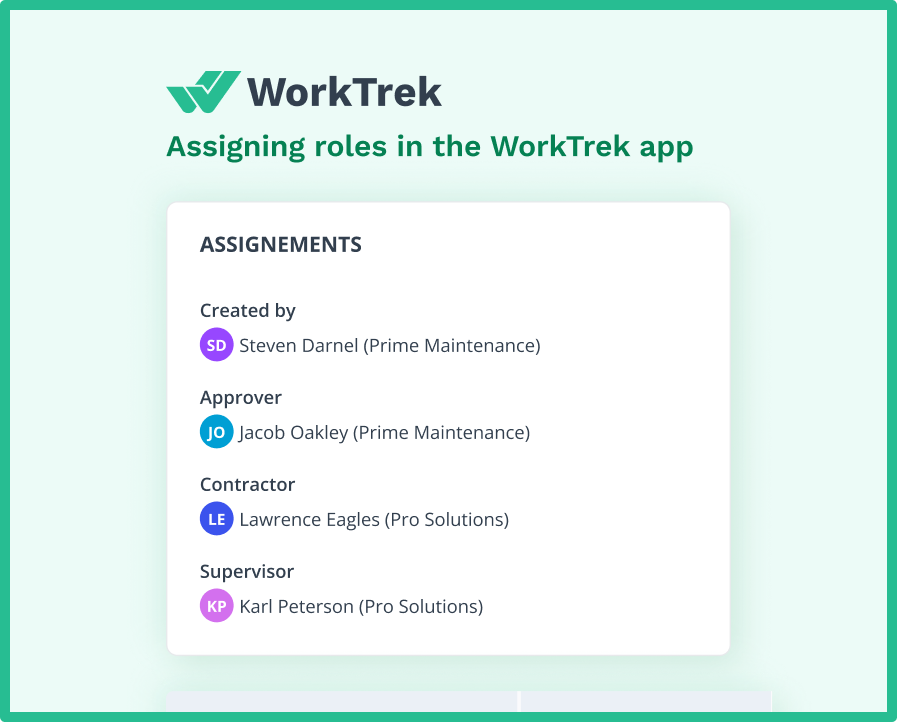

4. Assigned Personnel

Specify which maintenance team members are responsible for each task. Some preventive maintenance tasks require specific certifications or expertise, particularly for electrical systems, HVAC systems, or safety equipment.

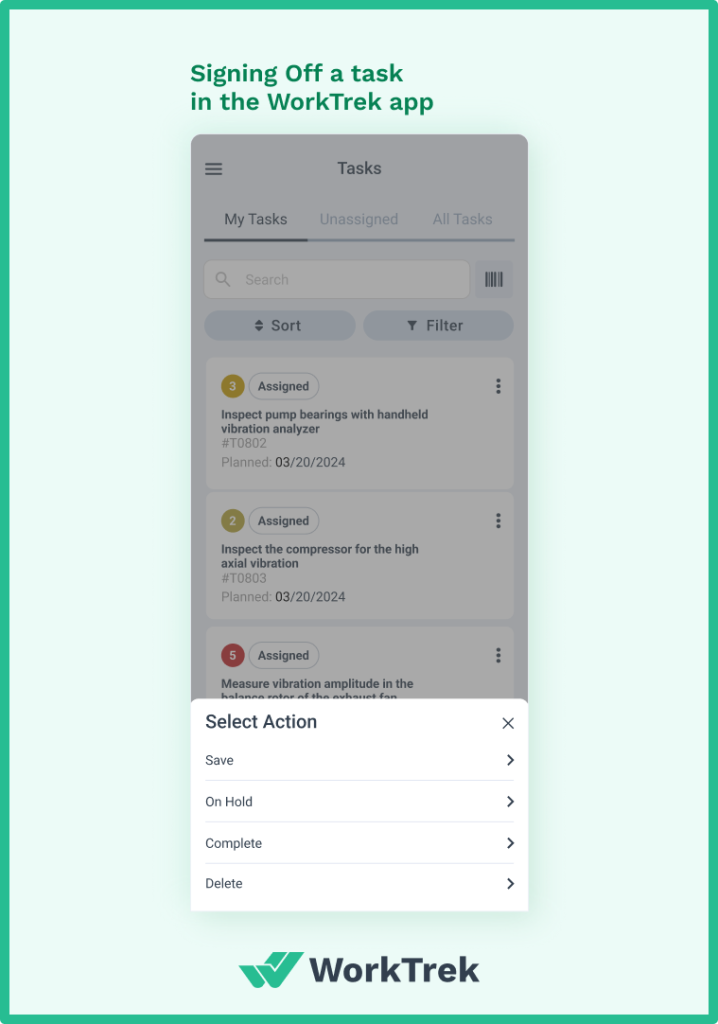

5. Sign-Off Section

Create space for signatures and notes confirming task completion. This accountability measure ensures that maintenance personnel actually perform the work and provides documentation for compliance audits.

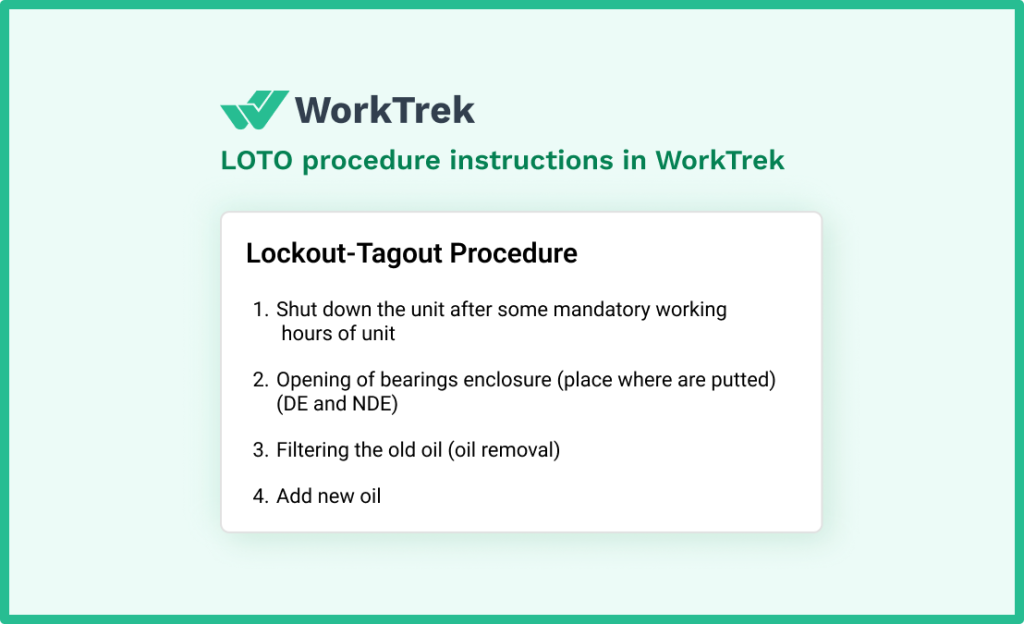

6. Safety Protocols

Include required lockout/tagout (LOTO) procedures and necessary personal protective equipment (PPE). Safety should never be an afterthought in maintenance processes.

7. Required Tools and Parts

List all necessary tools, replacement parts, and materials. This preparation prevents maintenance technicians from wasting time hunting for equipment mid-task.

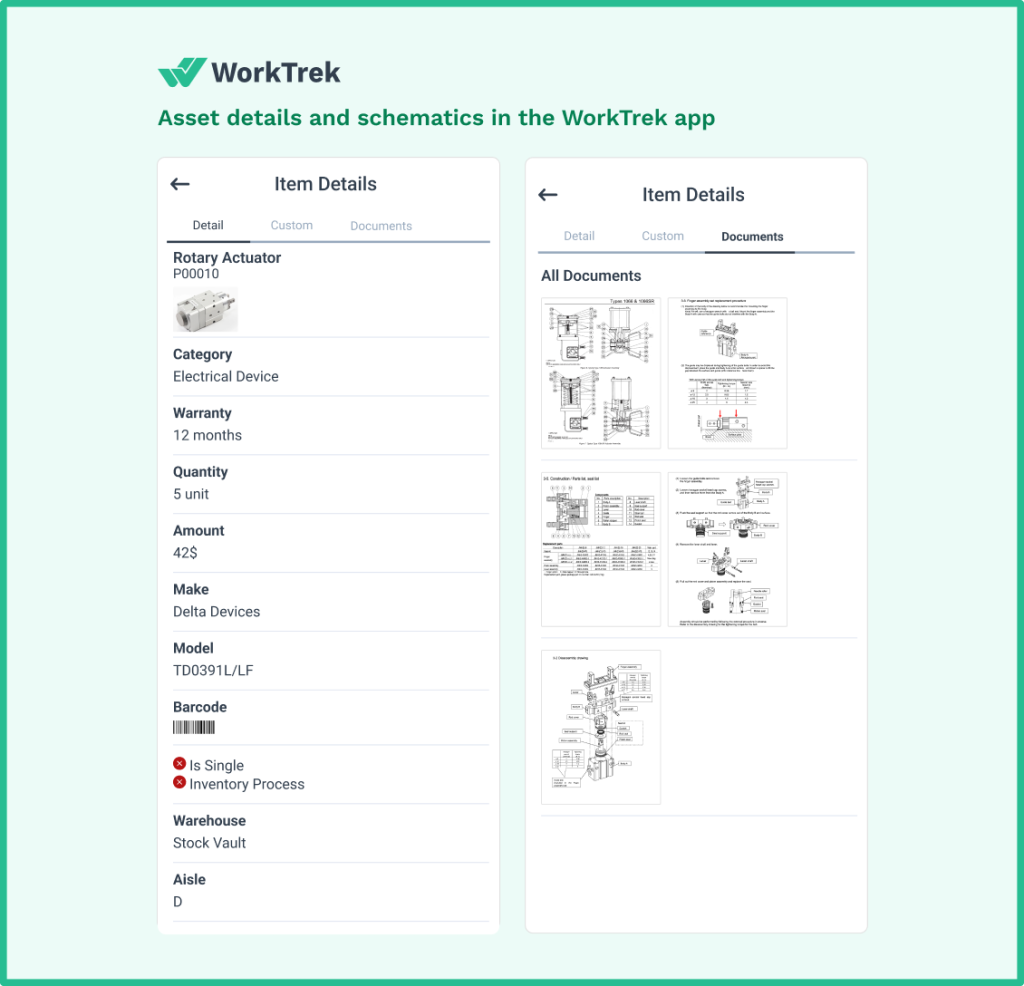

8. Visual Aids

Where appropriate, include photographs, diagrams, or schematics. Visual references are especially valuable for complex equipment or when training new maintenance team members.

9. Time Estimates

Provide realistic duration estimates for planning purposes. Accurate time projections help maintenance managers schedule maintenance effectively without disrupting operations.

Pass/Fail vs. Step-by-Step Format

Your preventive maintenance checklist format should match the task’s complexity.

Pass/Fail Checklists: work best for simple condition monitoring. For example, checking if air filters are clean (pass) or dirty (fail), or whether electrical connections are tight (pass) or loose (fail). These binary inspections enable quick, routine inspections and clear documentation.

Step-by-Step Checklists: are essential for multi-step repairs and complex maintenance procedures. When you’re performing HVAC system maintenance or rebuilding a motor, you need detailed sequential instructions that ensure nothing gets skipped.

The key is to match the format to the task’s complexity. You need to strike a balance where you don’t overcomplicate simple inspections, while avoiding oversimplifying complex preventive maintenance tasks either.

Types of Preventive Maintenance Strategies

Not all preventive maintenance works the same way. Understanding different types of preventive maintenance helps you build more effective checklists and choose the right approach for each asset.

Time-Based Preventive Maintenance

Time-based maintenance schedules work at regular, predetermined calendar intervals regardless of equipment condition or usage.

You’ve probably encountered this approach in your personal life. For example changing your car’s oil every three months or replacing HVAC filters every 90 days, whether you’ve driven much or not.

When time-based preventive maintenance makes sense:

- Equipment with predictable usage patterns

- Components that deteriorate over time regardless of use (fluids, rubber seals, belts)

- Regulatory compliance requirements with specific time commitments

- Failure modes that are clearly age-related

Pros: Highly predictable and easy to schedule. Your maintenance team knows exactly when preventive maintenance tasks are coming.

Cons: Can lead to over-maintenance. You might service equipment that doesn’t actually need attention yet, wasting resources on unnecessary maintenance.

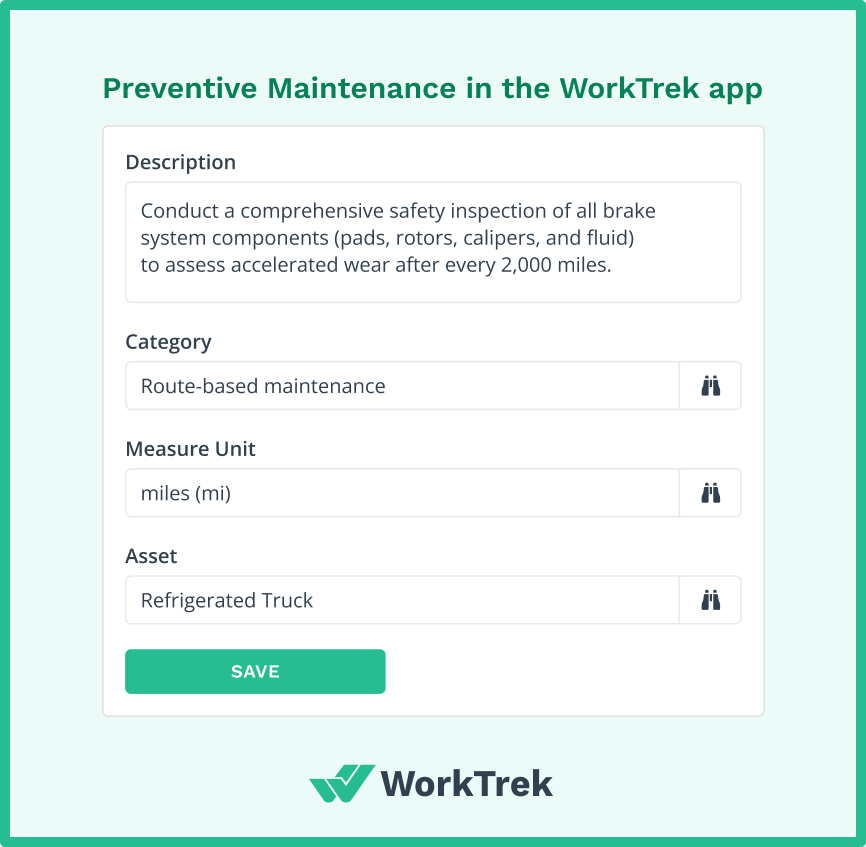

Usage-Based Preventive Maintenance

Usage-based maintenance triggers on equipment usage metrics—operating hours, production cycles, miles traveled, or units produced—rather than calendar dates.

Think of this like aircraft maintenance scheduled after a specific number of flight hours, or forklift inspections performed every 200 operating hours

When usage-based maintenance works best:

- Equipment with irregular or variable usage patterns

- Assets where wear correlates directly with use

- Fleet vehicles and material handling equipment

- Any situation where you can accurately track usage metrics

According to the U.S. Department of Energy, proper maintenance scheduling based on actual equipment usage is a key factor to achieve cost savings in preventive versus reactive maintenance approaches.

Pros: Matches maintenance to actual wear and tear, preventing both over-maintenance and under-maintenance.

Cons: Requires tracking systems to monitor usage metrics accurately.

Condition-Based Maintenance

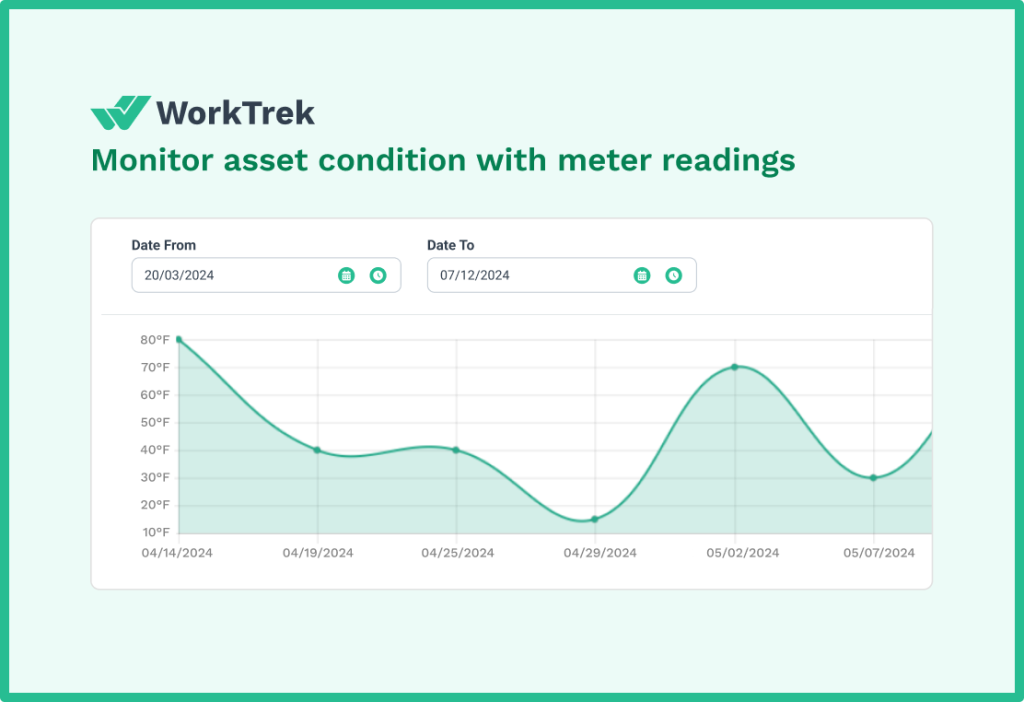

Condition-based maintenance takes a smarter approach: perform maintenance when equipment condition indicates it’s actually needed.

Instead of guessing based on time or usage, you monitor equipment health through sensors, inspections, and diagnostic testing. When measurements exceed preset thresholds, the system triggers maintenance.

Common monitoring methods:

- Vibration analysis for rotating equipment

- Oil analysis for contamination or wear particles

- Thermography to detect overheating

- Ultrasound testing for leaks or electrical issues

- Pressure monitoring for hydraulic and pneumatic systems

Research shows that organizations using condition-based approaches experience significantly fewer unexpected breakdowns than those using purely calendar-based preventive maintenance programs.

Pros: Minimizes unplanned downtime, avoids unnecessary maintenance, and performs service at the exact moment it’s needed.

Cons: Requires investment in sensors, monitoring equipment, and specialized training for maintenance personnel.

Predictive Maintenance: The Evolution of PM

Predictive maintenance represents the cutting edge of maintenance strategies, using machine learning, IoT sensors, and advanced analytics to predict failures before symptoms even appear.

While predictive maintenance adoption decreased slightly from 30% to 27% between 2024 and 2025, this likely reflects organizations realizing it requires more sophisticated infrastructure than they initially anticipated.

Here’s how predictive maintenance connects to your preventive maintenance checklists:

Predictive algorithms analyze data continuously and can trigger checklist-based inspections when they detect concerning patterns. Meanwhile, data collected during routine maintenance tasks feeds back into predictive models, improving their accuracy over time.

The research is compelling: Predictive maintenance can reduce machine downtime by 30-50% and increase equipment life by 20-40%, according to McKinsey & Company.

The most successful maintenance programs combine these approaches strategically.

Use time-based maintenance for components with predictable wear, usage-based maintenance for variable-use equipment, and condition-based or predictive maintenance for critical assets where the investment in monitoring technology pays off.

How to Create Customized PM Checklists

Generic, one-size-fits-all checklists don’t work. The most effective preventive maintenance checklists are tailored to specific equipment, operating conditions, and organizational needs.

Here’s how to build preventive maintenance checklists that actually prevent failures.

Start with Manufacturer Guidelines

Your first resource should always be original equipment manufacturer (OEM) documentation. Manufacturers know their equipment best and provide baseline recommendations for maintenance frequencies and procedures.

Ignoring OEM recommendations can void warranties, leaving you financially exposed when equipment fails.

Assess Equipment Criticality

Not all assets deserve equal attention. A production-critical machine that would halt operations if it failed needs more frequent and thorough maintenance than a backup compressor that rarely runs.

Create a criticality matrix based on:

- Impact on production if equipment fails

- Safety consequences of failure

- Customer satisfaction effects

- Repair costs and complexity

- Availability of backup equipment

Your most critical assets should have the most comprehensive preventive maintenance checklists with shorter inspection intervals.

Review Maintenance History and Failure Patterns

Your maintenance records contain valuable insights about what actually goes wrong with your equipment.

Pull historical data and look for patterns:

- Which components fail most frequently?

- What warning signs appeared before past failures?

- Are failures clustered at specific intervals or usage levels?

- What could routine inspections have caught earlier?

Add inspection points to your preventive maintenance checklist that specifically target these recurring issues.

Gather Frontline Knowledge from Technicians

Your maintenance technicians work with equipment daily and often know things that never make it into formal documentation.

Talk to the people actually performing maintenance tasks. They’ll tell you:

- Which steps in existing checklists waste time

- What warning signs they’ve learned to watch for

- Which tools or information would make their jobs easier

- Where unclear instructions cause confusion

This collaboration ensures your checklists reflect real-world conditions, not just theory.

Consider Your Operating Environment

Equipment operating in harsh conditions, such as extreme temperatures, dusty environments, high humidity, or corrosive atmospheres, deteriorates faster than manufacturer specifications might assume.

A conveyor in a clean office environment and one in a dusty manufacturing plant need different maintenance schedules. Adjust your preventive maintenance checklist frequencies to match actual operating conditions.

Determine the Right Maintenance Frequency

Setting appropriate maintenance intervals is crucial. Too frequent and you waste resources; too infrequent and you miss developing problems.

Key factors for determining frequency:

1. Failure Developing Period (FDP): The time between when you can first detect a problem and when equipment actually fails. Best practice: inspect at FDP/2 (half this period) to catch issues with a safety margin.

2. Mean Time Between Failures (MTBF): Historical data showing average operating time before repair is needed. Use this to establish baseline inspection frequencies.

3. Equipment Usage Intensity: High-utilization equipment needs more frequent attention than occasionally-used assets.

4. Criticality Level: Your most critical assets warrant more frequent inspections, even if failure data doesn’t strongly support it.

Pro tip: Start conservatively with shorter intervals, then extend them as you gather performance data showing equipment remains reliable. Target completing preventive maintenance tasks within 10% of planned intervals for optimal scheduling.

Document Everything Clearly

The best checklist in the world fails if technicians can’t understand it.

Write instructions clearly enough that a relatively new maintenance team member could follow them with minimal supervision. Avoid jargon where possible, define technical terms when necessary, and break complex procedures into logical sequential steps.

Keep individual steps brief. Don’t combine multiple actions into a single checklist item. “Inspect and clean motor bearings, check alignment, and verify lubrication” should be three separate steps, each with its own sign-off.

Equipment-Specific Checklist Best Practices

Different equipment types require different maintenance approaches. Here’s what your preventive maintenance checklists should include for common critical systems.

HVAC Systems

HVAC system maintenance directly impacts energy efficiency, occupant comfort, and indoor air quality. According to ENERGY STAR, proper maintenance also ensures your system operates as efficiently as intended.

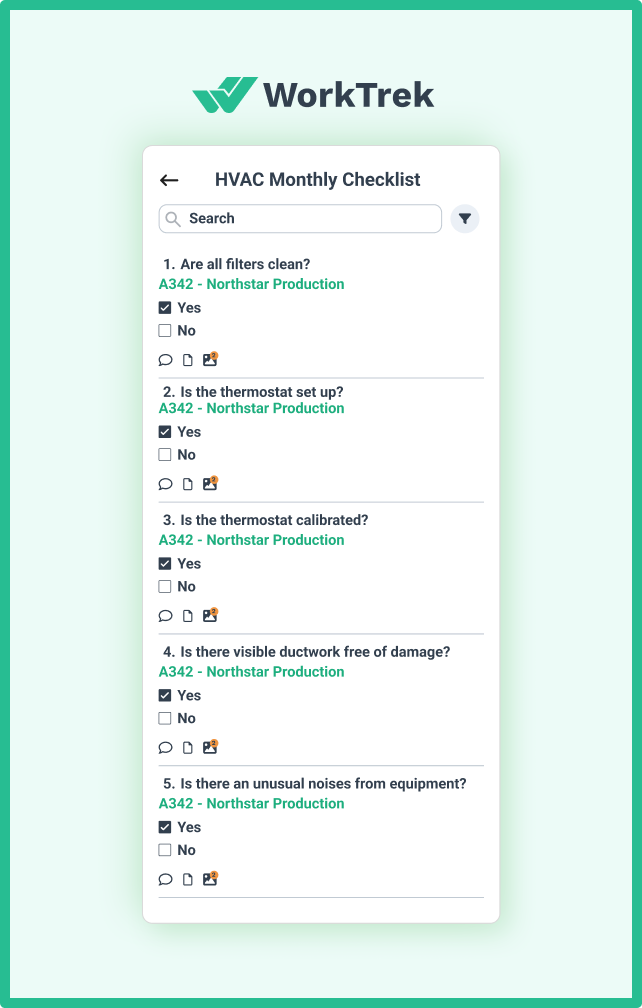

Essential HVAC maintenance tasks:

Monthly or Quarterly:

- Clean or replace air filters (every 30-90 days, depending on the environment)

- Check thermostat settings and calibration

- Inspect visible ductwork for damage or disconnection

- Listen for unusual noises from equipment

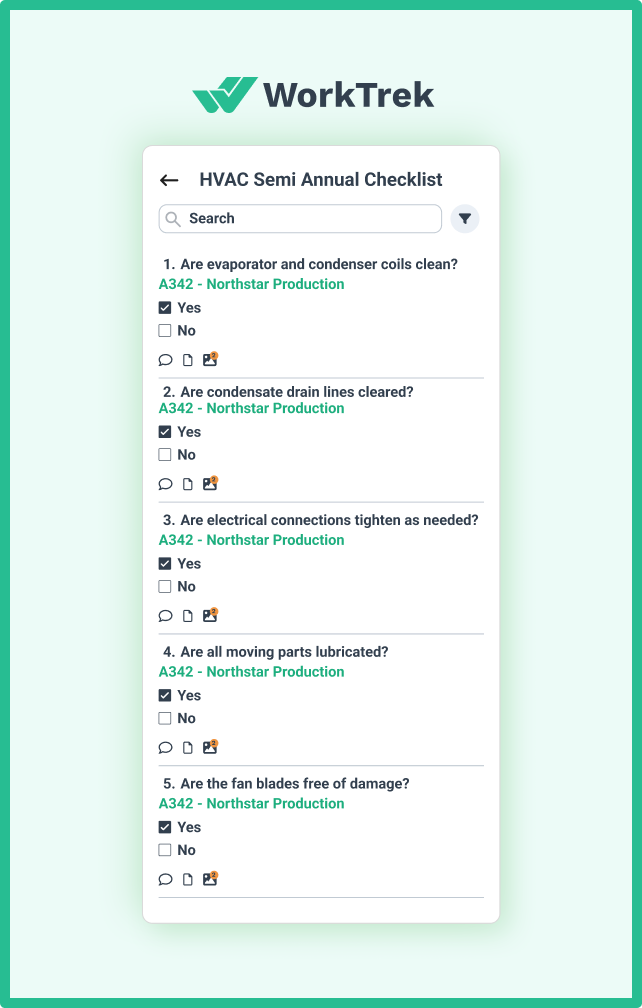

Semi-Annually (Spring and Fall):

- Clean evaporator and condenser coils

- Check and clear condensate drain lines

- Inspect electrical connections and tighten as needed

- Measure voltage and current on motors

- Lubricate all moving parts per manufacturer specifications

- Check refrigerant levels (requires certified technician)

- Inspect fan blades for damage and clean if dirty

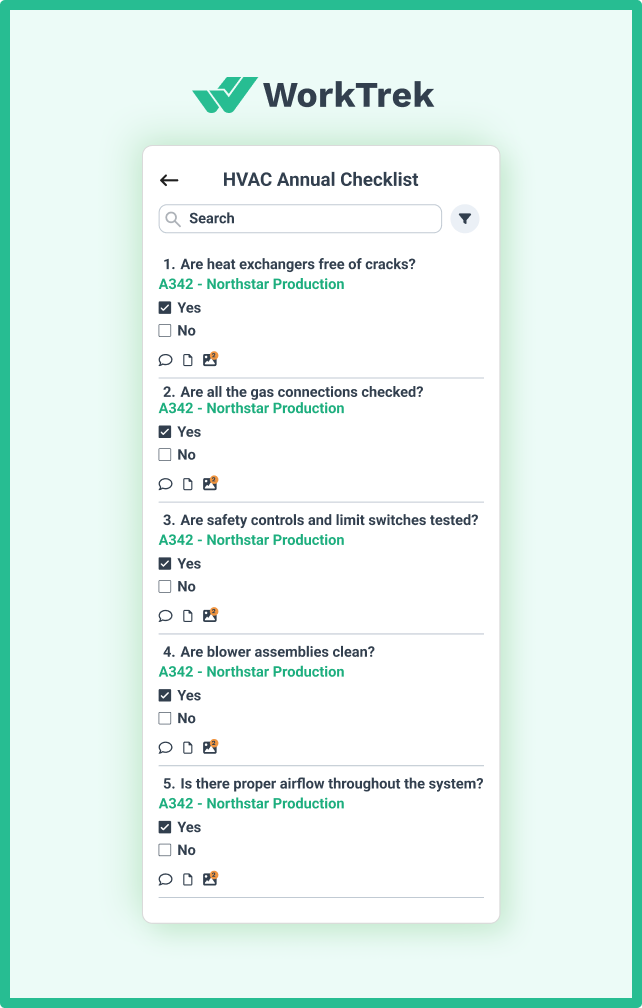

Annually:

- Comprehensive inspection of heat exchangers (critical for safety—cracks can leak carbon monoxide)

- Check gas connections, pressure, and burner combustion

- Test safety controls and limit switches

- Inspect and clean blower assemblies

- Verify proper airflow throughout system

Seasonal considerations matter: Prep your cooling system in spring before demand peaks, and tune up heating equipment in fall before cold weather arrives. This proactive maintenance prevents failures during periods when you need equipment most.

Electrical Systems

Electrical maintenance carries serious safety implications. Always follow lockout/tagout (LOTO) procedures, and ensure only qualified personnel perform electrical work.

Critical electrical inspection points:

- Main breaker and distribution panels

- Circuit breakers for proper operation

- Electrical connections for tightness (loose connections cause fires)

- Wiring for fraying, damage, or deterioration

- Grounding systems for continuity

- GFCI outlets for proper trip function

- Emergency lighting and exit signs

Testing requirements:

- Insulation resistance testing is performed annually

- Infrared thermography scanning is performed quarterly to detect hot spots

- Ground fault testing

- Circuit breaker exercise testing every 1-3 years

Safety note: OSHA regulations require specific maintenance and inspection protocols for electrical systems. Your preventive maintenance checklist should incorporate these compliance requirements.

Material Handling Equipment (Forklifts and Powered Industrial Trucks)

OSHA regulation 29 CFR 1910.178 mandates specific inspection requirements for material handling equipment.

OSHA requires forklifts be examined:

- At least daily before being placed in service

- After each shift for round-the-clock operations

- Defects must be immediately reported and corrected

- Never operate unsafe equipment

Your forklift daily preventive maintenance checklist should include:

Pre-operation walk-around:

- Visual check for damage, leaks, or abnormalities

- Tire inspection: proper inflation, wear, damage

- Fork and mast: bends, cracks, excessive wear

- Load backrest extension secure and undamaged

Fluid level checks:

- Engine oil

- Hydraulic oil

- Coolant

- Brake fluid

- Battery electrolyte (if applicable)

Functional tests:

- Brakes (service and parking)

- Steering responsiveness

- Horn and backup alarm

- Lights (headlights, taillights, warning lights)

- Hydraulic controls (lift, tilt, side shift)

- Seatbelt condition and operation

- Fire extinguisher present and charged

Weekly or monthly deeper inspections should cover:

- Battery terminals and connections

- Hydraulic hoses for wear or damage

- Chain tension and lubrication

- Overhead guard condition

- Load capacity plate legibility

Manufacturing Equipment

Manufacturing equipment represents a significant capital investment and directly impacts production capacity. Equipment failure in a manufacturing plant creates costly production disruptions.

CNC machines require particularly careful maintenance:

Daily preventive maintenance tasks:

- Clean machine bed and remove metal chips

- Check coolant level and condition

- Inspect cutting tools for wear

- Verify automatic lubrication system operation

- Check hydraulic pressure gauges

Weekly tasks:

- Clean way covers and linear guides

- Check and clean air filters

- Inspect the pneumatic system for leaks

- Verify program backup procedures

Monthly maintenance activities:

- Test hydraulic oil quality

- Clean coolant tank filters

- Grease the chuck and rotary components

- Check safety interlocks and emergency stops

- Inspect cable carriers and cable condition

Quarterly preventive maintenance:

- Deep clean coolant system

- Clean chuck jaws thoroughly

- Check machine leveling

- Inspect ball screws for backlash

Annual comprehensive inspection:

- Complete accuracy verification by certified engineers

- Replace hydraulic oil and filters

- Full electrical system inspection

- Replace worn way covers

- Update control software if needed

According to equipment maintenance research, proper CNC maintenance significantly extends machine lifespan and maintains precision tolerances essential for quality production.

Safety Equipment

Safety equipment maintenance isn’t optional—it’s a legal and moral obligation to protect your workforce.

Fire extinguishers (OSHA 29 CFR 1910.157):

- Monthly: Visual inspection checking location, pressure gauge, seal integrity, and physical condition

- Annually: Professional maintenance by certified inspector

- 6-year: Internal inspection for stored pressure dry chemical extinguishers

- 12-year: Hydrostatic pressure testing

Emergency eyewash stations and safety showers (ANSI Z358.1-2014):

- Weekly activation: ANSI standards require all units be activated weekly to verify operation and flush stagnant water

- Annual: Full compliance inspection

- Location requirement: Within 10-second travel distance (approximately 55 feet) from hazard areas

- Water temperature: Must provide tepid water (60-100°F) to prevent thermal shock

First aid kits and AEDs:

- Monthly inspection of contents and expiration dates

- Immediate replacement of used supplies

- Regular training refreshers for designated responders

Safety equipment must be 100% reliable when needed. Don’t cut corners on these critical systems.

Digital vs. Paper: Choosing the Right Approach

One of the most impactful decisions you’ll make about your preventive maintenance program is whether to use paper checklists or go digital.

Let’s be honest about the trade-offs.

The Paper Checklist Reality

Paper preventive maintenance checklists have served organizations for decades. They’re simple, require no technology, and work anywhere without batteries or internet connectivity.

But paper checklists have serious limitations:

Time-consuming and error-prone: Handwritten notes can be illegible. Technicians sometimes check boxes without actually performing work. Data entry from paper to computer doubles workload.

Risk of loss or destruction: That clipboard with three months of maintenance records? It’s sitting in a puddle after yesterday’s rainstorm. Critical documentation is gone forever.

Difficult to track and monitor: You can’t see overall program compliance without manually reviewing every paper checklist. Patterns and trends remain invisible.

No real-time feedback: When a technician discovers a critical issue at 2 AM, notifying management means finding a phone and making calls, not instantly alerting everyone who needs to know.

Can’t easily retrieve history: Finding past maintenance records means digging through filing cabinets. “What did we find during the August inspection three years ago?” is a multi-hour research project.

Digital Checklist Advantages

Modern computerized maintenance management systems transform preventive maintenance checklists from static paper documents into dynamic, intelligent tools.

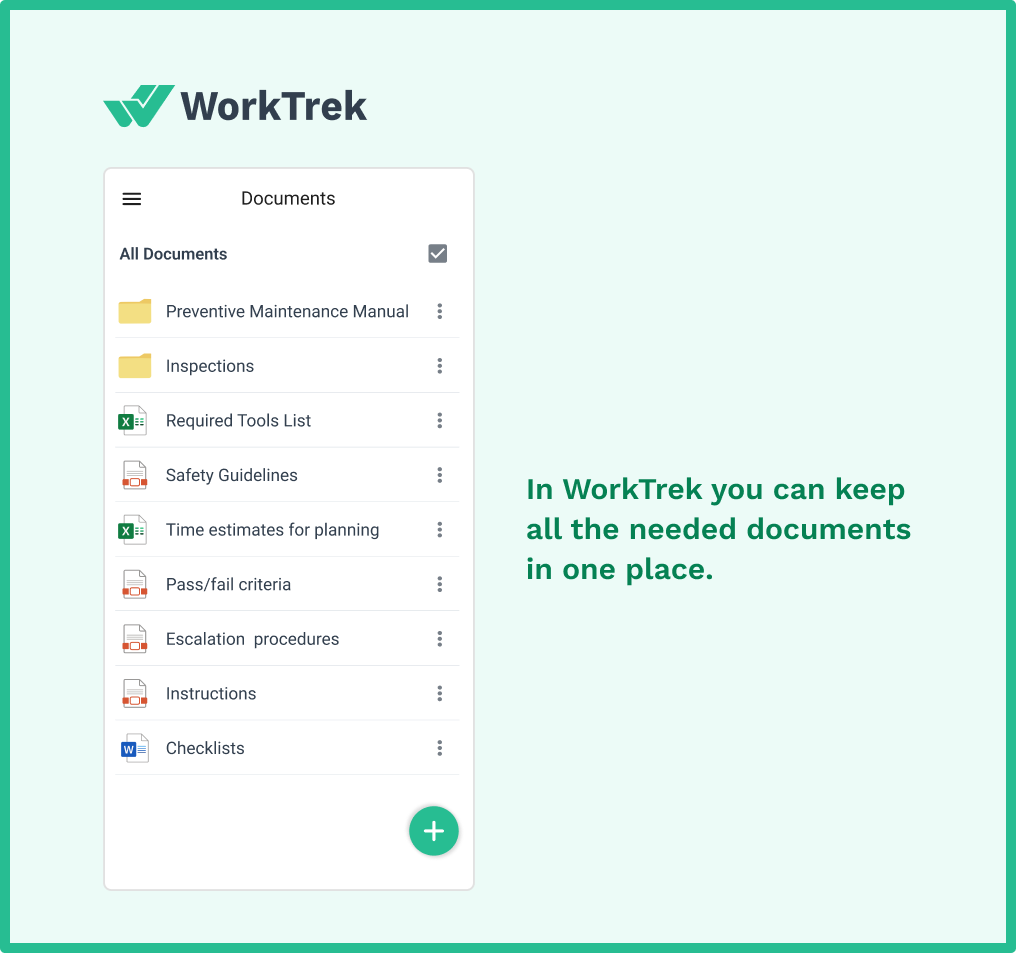

Accessible anywhere, anytime: Mobile apps put comprehensive preventive maintenance checklists directly in technicians’ hands. Access asset history, reference manuals, and submit completed inspections from the shop floor.

Real-time data capture and updates: Record observations instantly. Take photos documenting conditions. Updates appear immediately in the central system, where managers can see them.

Automatic notifications and reminders: No more missed inspections because someone forgot to check the schedule. The system automatically notifies maintenance personnel when preventive maintenance tasks are due.

Centralized documentation: Everything lives in one searchable database. Finding historical data takes seconds, not hours.

Multimedia support: Embed photographs, videos, and equipment diagrams directly in checklists. Visual references make complex procedures clearer.

Better compliance documentation: Digital systems create automatic audit trails. Timestamp verification proves work was completed on schedule, satisfying compliance requirements.

Analytics and reporting: Track completion rates, identify recurring problems, measure technician productivity, and optimize maintenance schedules based on actual data rather than guesswork.

The impact is significant: Organizations using digital checklists see 20% improvement in maintenance team productivity compared to paper-based workflows.

When Paper Still Makes Sense

Despite digital advantages, paper checklists remain appropriate in specific situations:

- Very small operations with just a few pieces of equipment

- Environments where electronics aren’t practical (extreme temperatures, water exposure, explosive atmospheres)

- Simple single-asset checks where digital overhead isn’t justified

- Emergency backup when technology fails

For most modern operations, though, digital wins decisively.

Making the Transition

If you’re currently using paper and considering going digital, approach the transition strategically:

Start with pilot programs: Choose a few high-value assets and convert their checklists first. Learn lessons on a small scale before rolling out organization-wide.

Involve technicians in design: The people who use checklists daily should help design digital workflows. This buy-in is crucial for adoption.

Provide thorough training: Don’t assume everyone is tech-savvy. Some maintenance personnel may need significant support during the transition.

Maintain paper backup temporarily: Keep paper checklists available for the first few months as a safety net while users gain confidence with digital systems.

Measure results: Track completion rates, downtime reduction, and time savings to quantify the return on your digital investment.

How CMMS Software Transforms Checklist Management

A computerized maintenance management system takes preventive maintenance checklists from good to exceptional by automating workflows, centralizing information, and providing powerful analytics.

Let’s look at how CMMS transforms every aspect of checklist management.

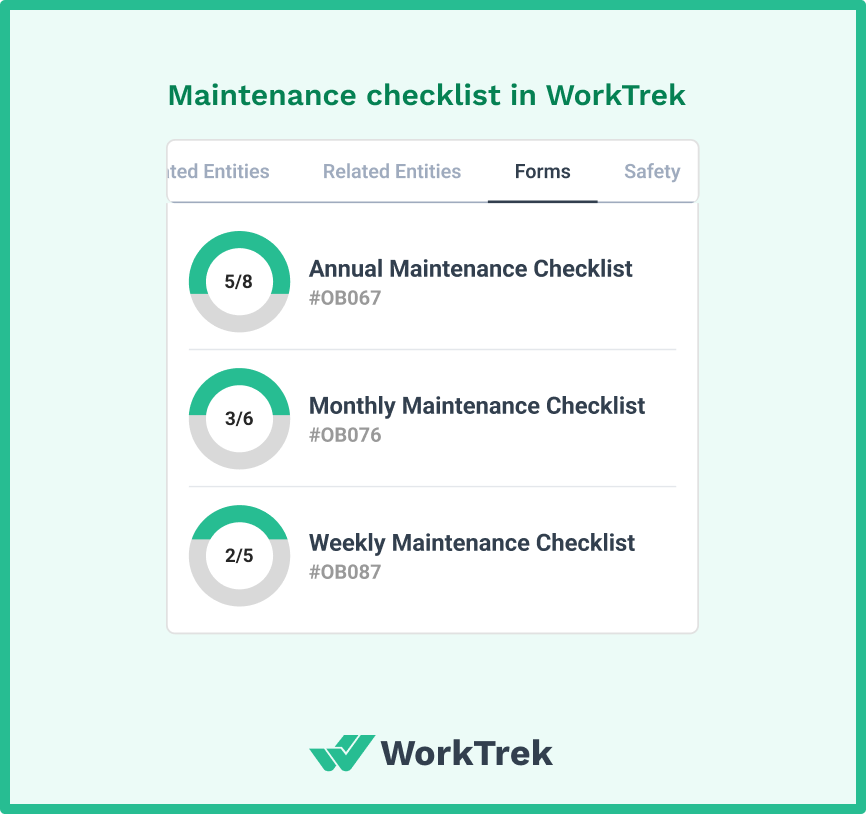

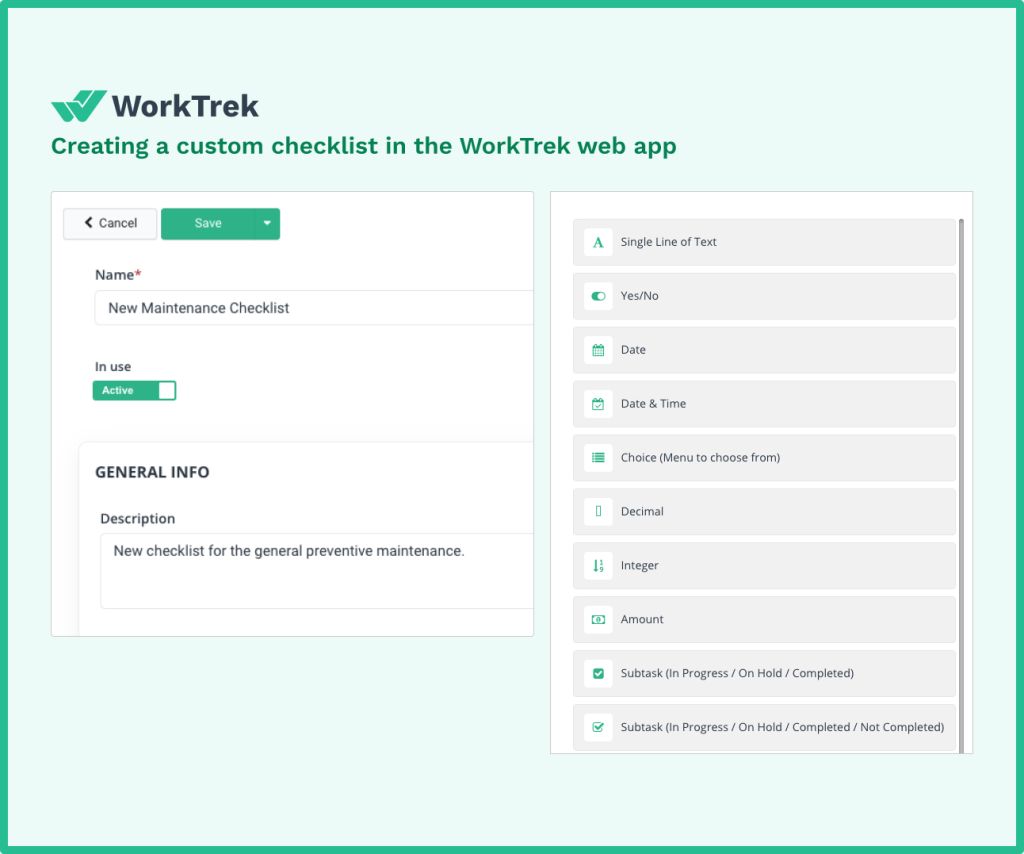

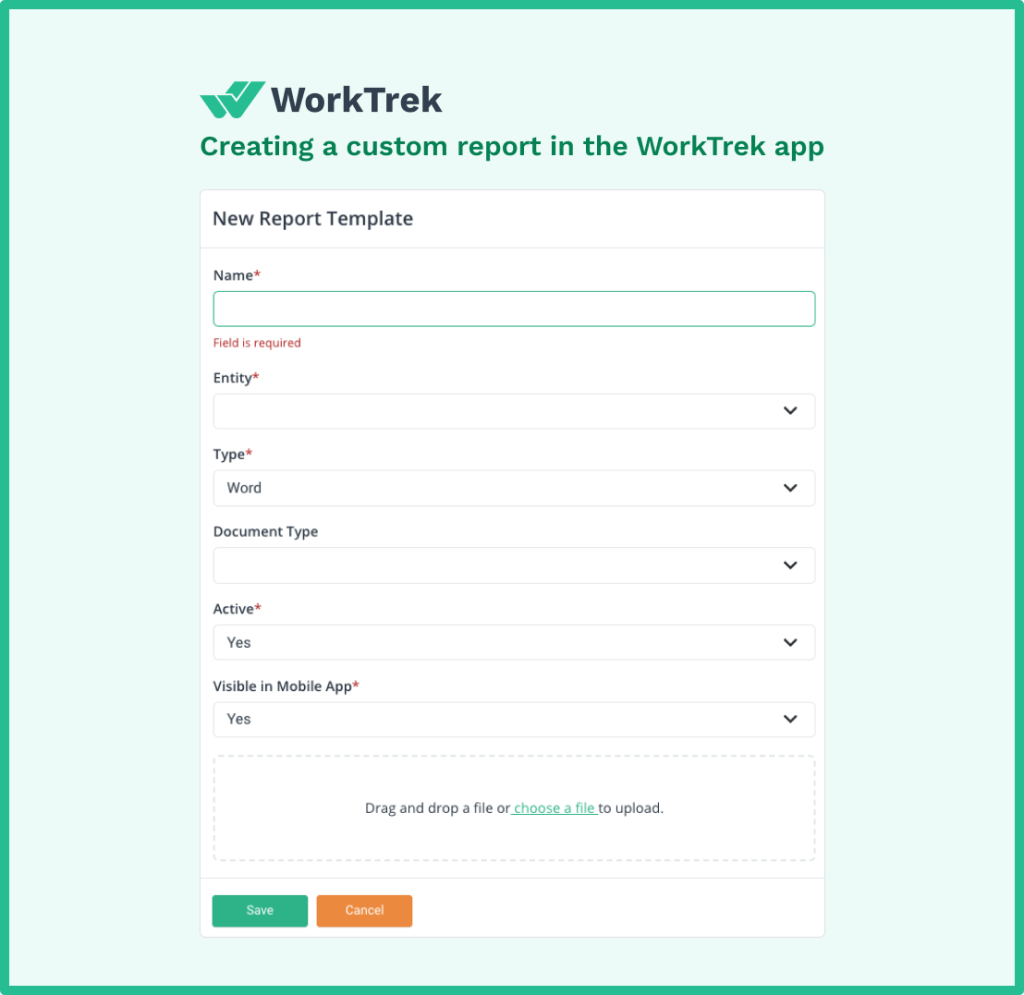

Standardized Templates That Ensure Consistency

CMMS platforms let you create master preventive maintenance checklist templates for each equipment type. When you add a new asset, you attach the appropriate template—ensuring every similar piece of equipment receives identical maintenance procedures.

This standardization eliminates variation that can arise when technicians cut corners or forget steps with paper checklists. Everyone follows the same comprehensive maintenance plan.

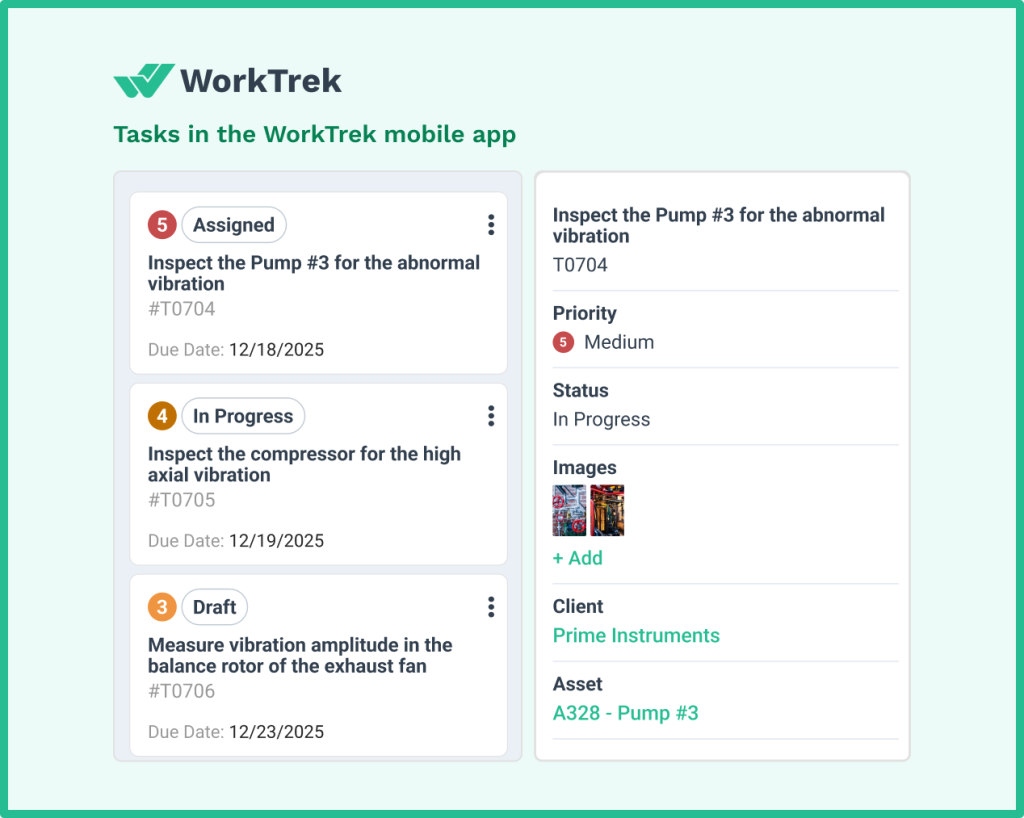

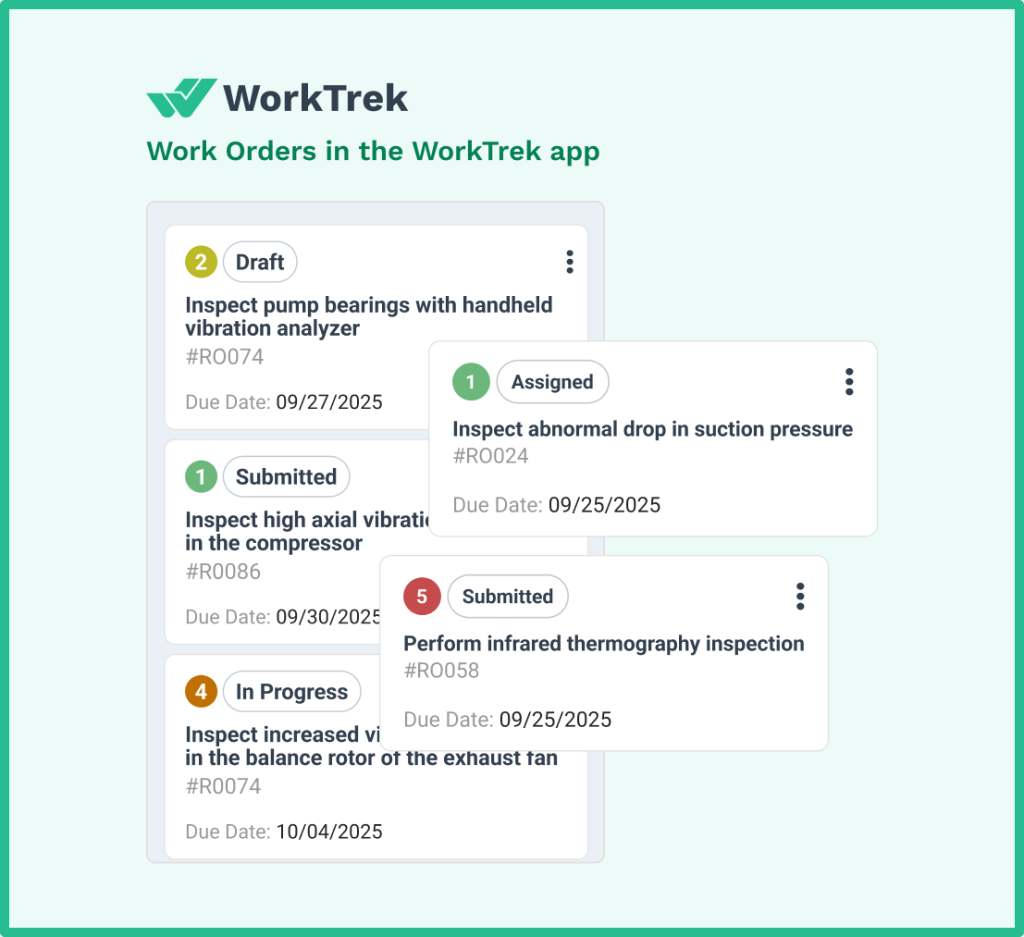

Automated Work Order Generation

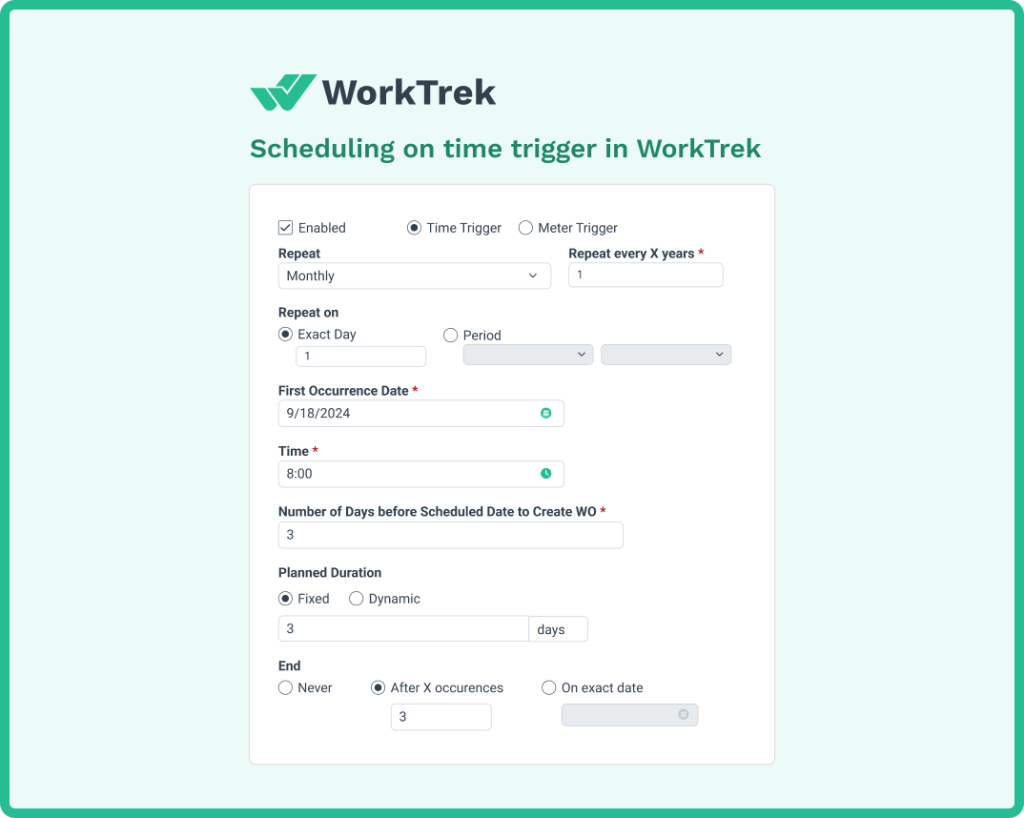

Instead of manually creating work orders for each scheduled maintenance task, your CMMS automatically generates them based on your preventive maintenance schedule.

The system can trigger work orders based on:

- Calendar dates for time-based preventive maintenance

- Meter readings for usage-based maintenance

- Sensor thresholds for condition-based maintenance

Maintenance team members receive automatic notifications when preventive maintenance tasks are assigned, eliminating the excuse “I didn’t know it was due.”

Mobile Access at Point of Service

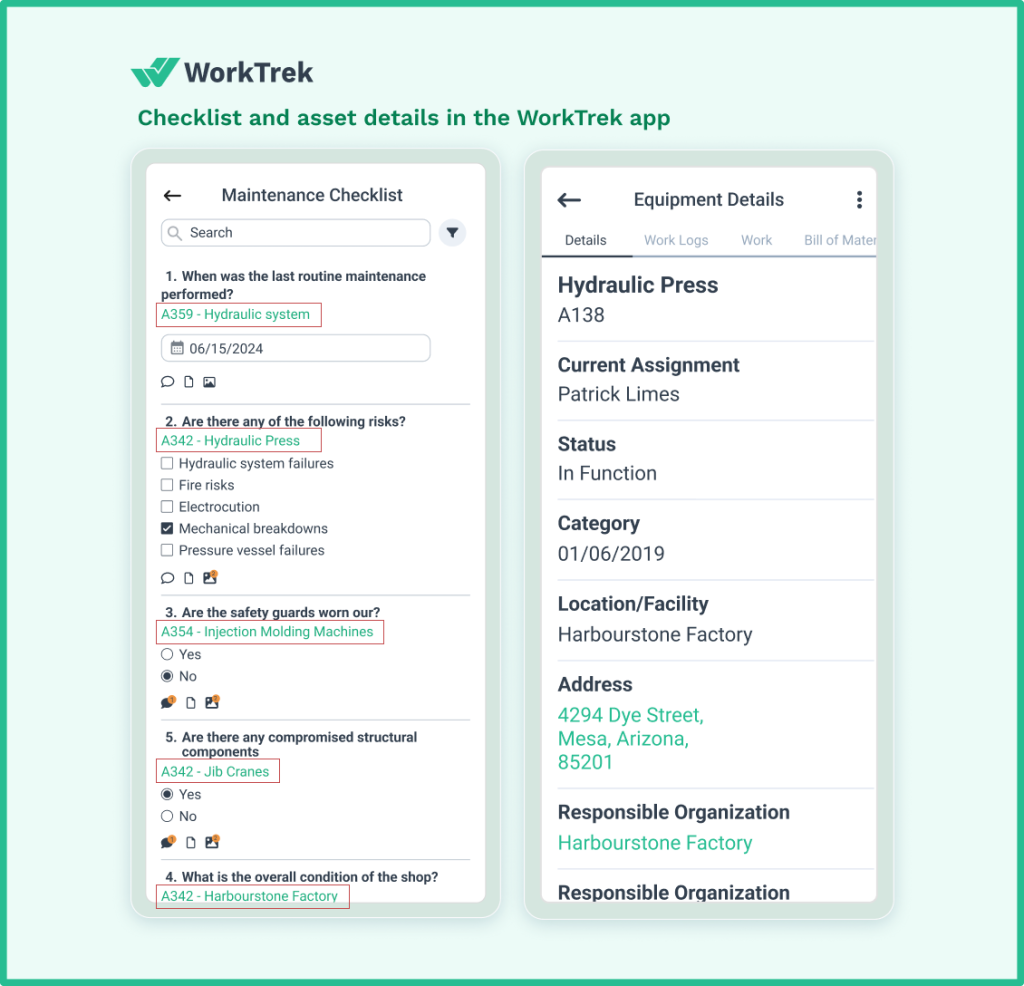

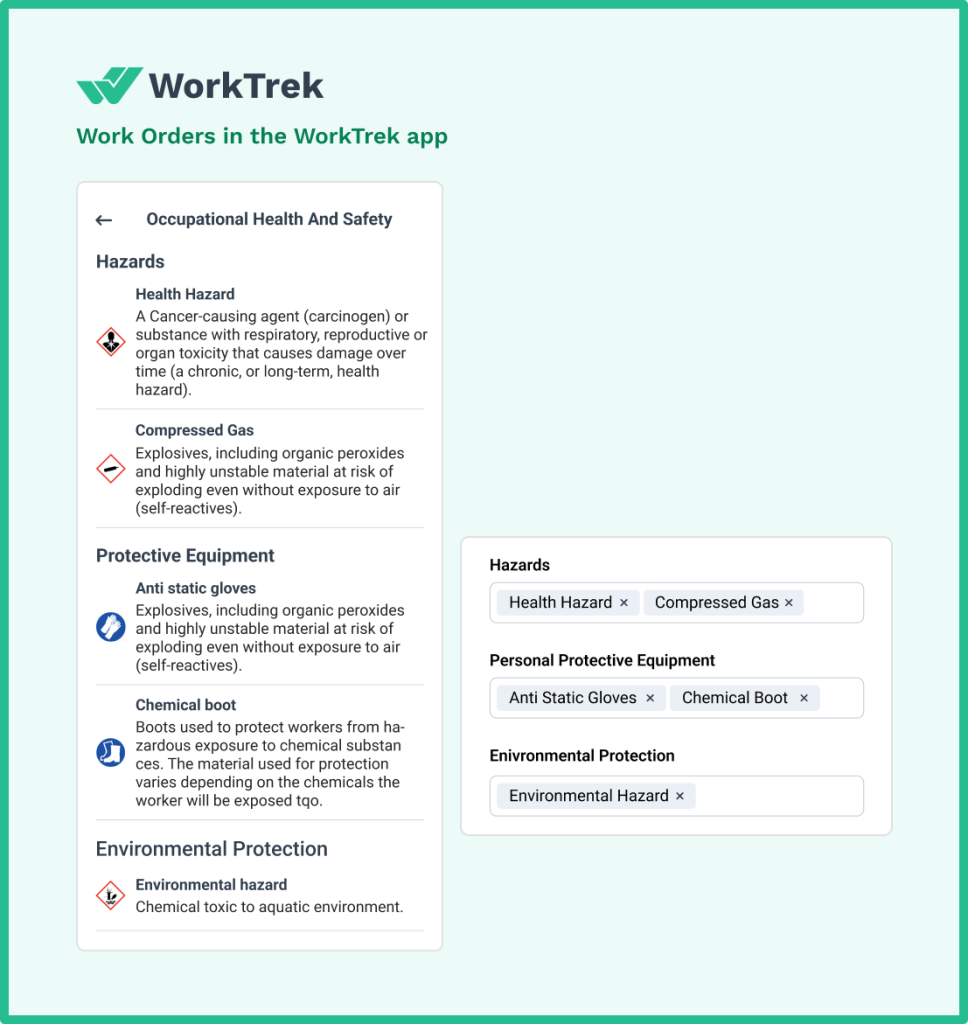

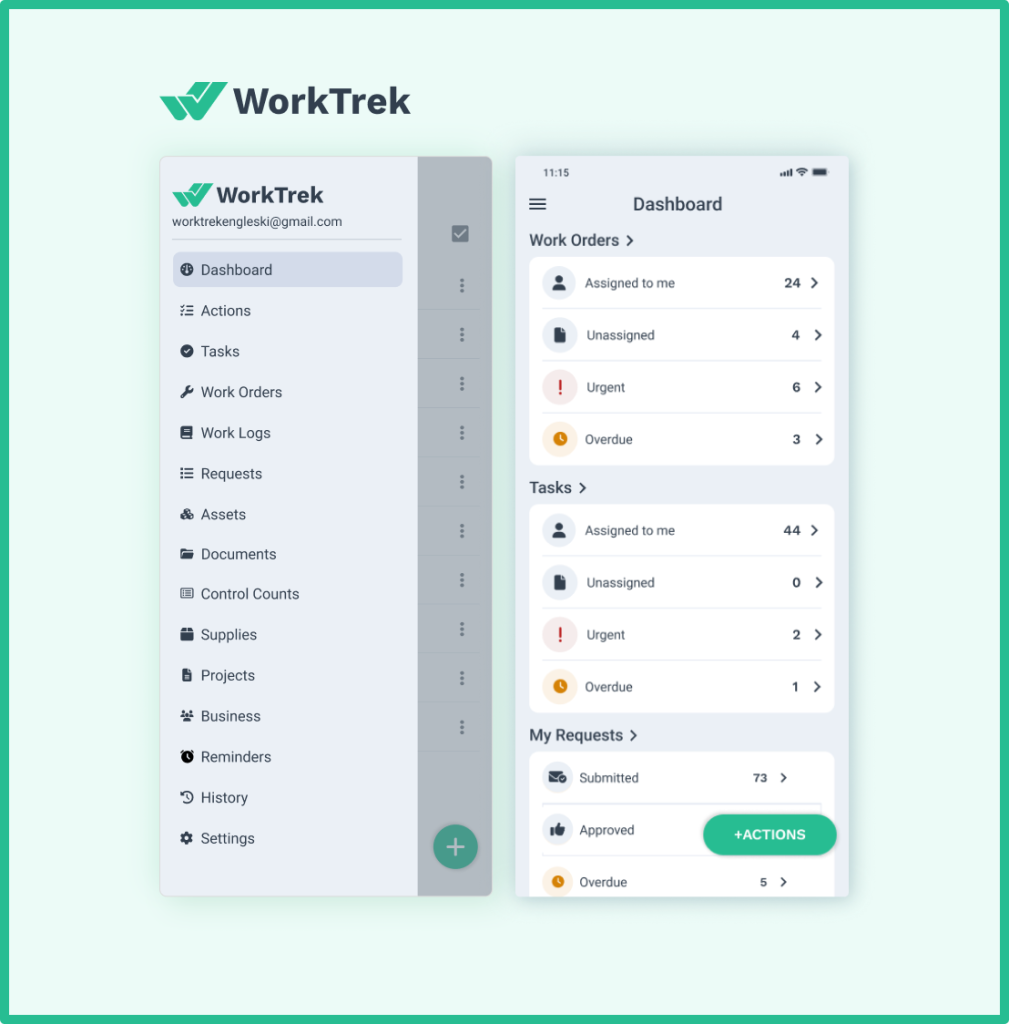

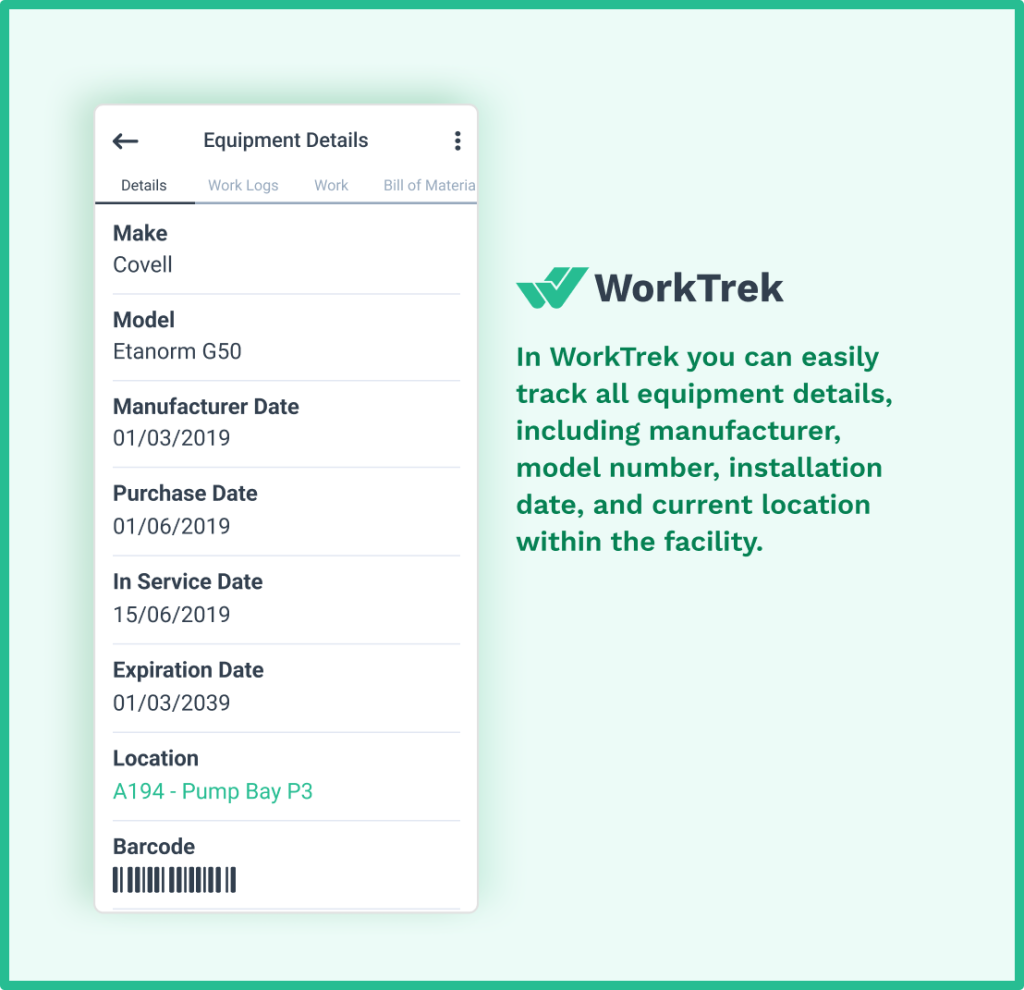

Modern CMMS platforms like WorkTrek include mobile apps that put full system capabilities in technicians’ pockets.

When a technician arrives at equipment needing maintenance, they can:

- Scan a QR code to pull up the asset record instantly

- Access complete maintenance history

- View equipment manuals and technical documentation

- See photos from previous inspections for comparison

- Follow the step-by-step checklist instructions

- Record findings and measurements directly into the system

- Take photos documenting current conditions

- Mark work orders complete with digital signatures

Research shows 37% average productivity increases in the first year after implementing mobile CMMS capabilities.

Comprehensive Data Tracking and Analytics

Digital systems automatically capture vast amounts of data that were previously untrackable with paper checklists.

Key metrics CMMS tracks automatically:

- Mean Time Between Failures (MTBF): Average operating time before equipment needs repair

- Mean Time to Repair (MTTR): Average time to restore equipment to service

- PM Compliance Rate: Percentage of scheduled maintenance completed on time

- Work Order Completion Rate: Percentage of assigned tasks actually finished

- Planned vs. Unplanned Maintenance Ratio: How much time you spend preventing problems versus fighting fires

- Overall Equipment Effectiveness (OEE): Comprehensive measure of manufacturing productivity

These metrics reveal patterns invisible with paper checklists, enabling data-driven optimization of your entire maintenance program.

Integration with Other Maintenance Operations

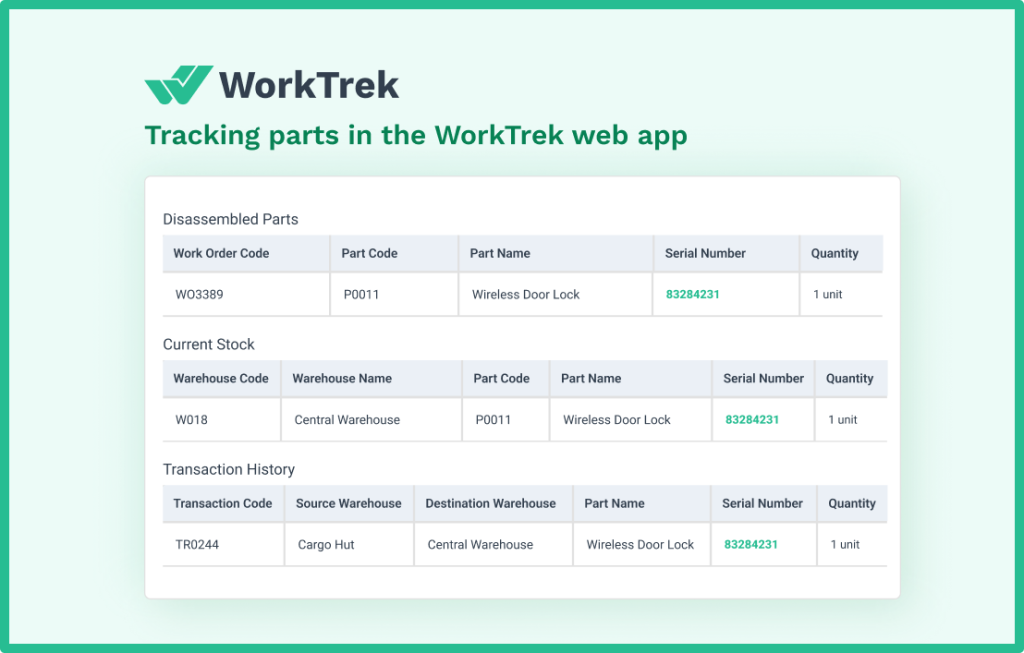

Standalone checklists exist in isolation. CMMS integrates preventive maintenance checklists with every other aspect of maintenance management:

Work order management: Preventive maintenance checklists automatically generate work orders with all necessary instructions, parts lists, and labor estimates embedded.

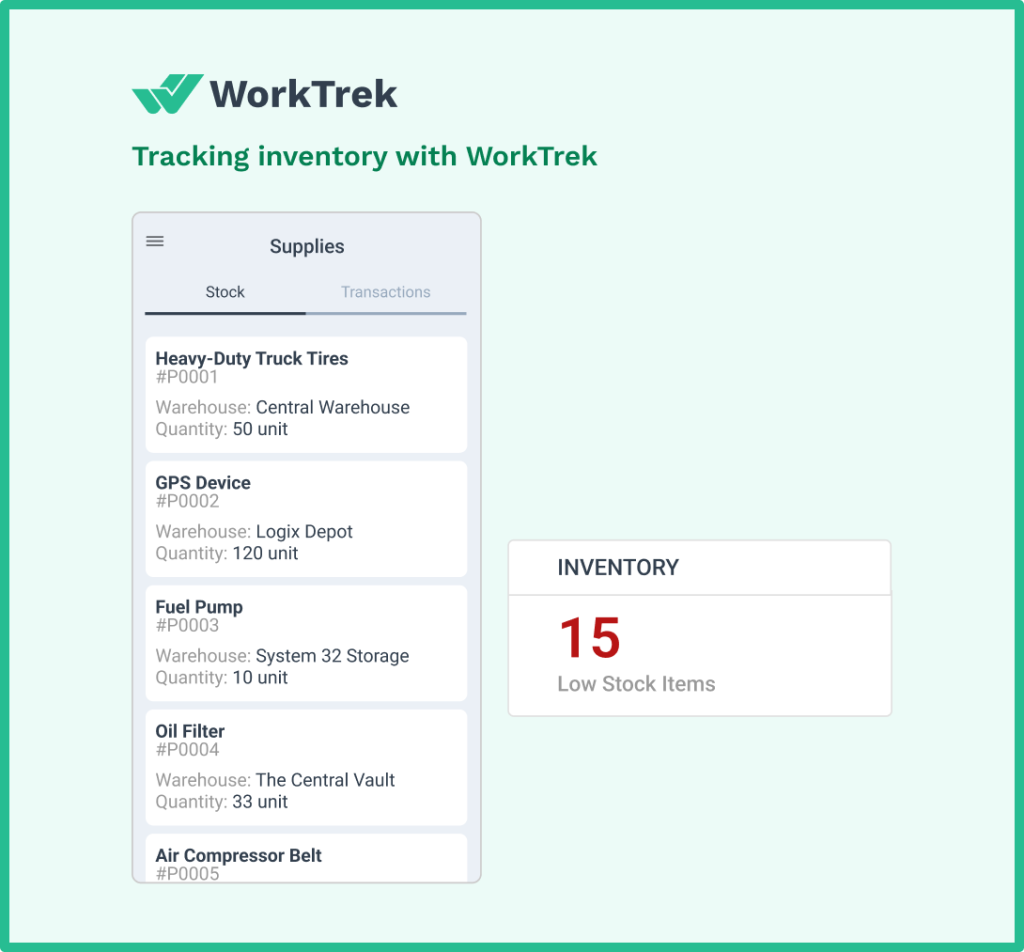

Inventory management: The system tracks parts used during maintenance activities and automatically flags inventory levels requiring replenishment, reducing carrying costs by 15-25%.

Asset management: Complete equipment hierarchies link checklists to specific assets, tracking maintenance history, warranty information, and lifecycle costs in one place.

Scheduling optimization: The system balances preventive maintenance tasks with corrective work, production schedules, and maintenance personnel availability.

WorkTrek: Built for Modern Maintenance Teams

A CMMS like WorkTrek brings all these capabilities together in an intuitive platform explicitly designed for maintenance operations.

WorkTrek’s preventive maintenance features include:

Flexible scheduling options: Set up time-based, meter-based, or condition-based triggers for automatically generating work orders. The system accommodates the full range of preventive maintenance strategies.

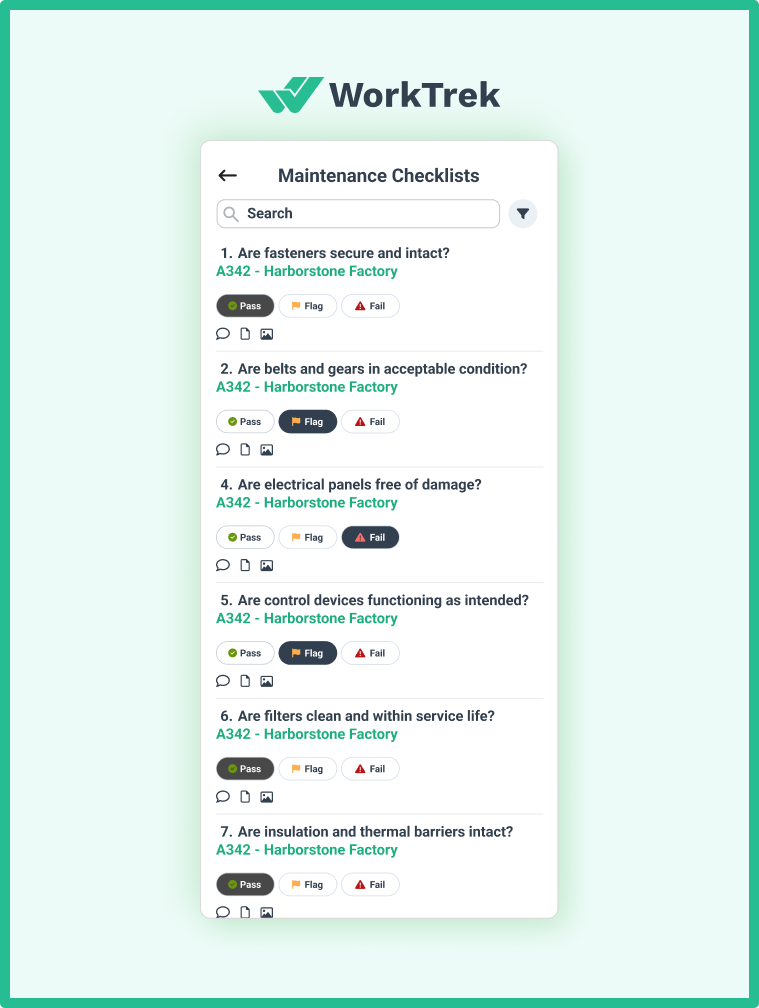

Customizable checklists: Build detailed checklists with pass/fail items, measurements, text descriptions, and photo documentation. Include equipment-specific instructions and safety procedures.

Mobile-first design: Native iOS and Android apps give maintenance technicians full functionality in the field, including offline capability for areas without connectivity.

Comprehensive analytics: Pre-built reports and customizable dashboards track over 30 maintenance KPIs, giving you complete visibility into program effectiveness.

Easy integration: WorkTrek connects with existing ERP systems, IoT sensor platforms, and other business software to create a unified maintenance ecosystem.

Organizations implementing WorkTrek report better visibility, control, and organization of maintenance activities, with regulatory audits becoming significantly easier thanks to comprehensive digital documentation.

Measuring and Improving Your PM Program

Creating an effective preventive maintenance checklist is an ongoing process, not a one-time project. The best maintenance programs continuously measure performance and refine approaches based on data.

Key Performance Indicators to Track

Focus on these critical metrics to evaluate preventive maintenance effectiveness:

1. Preventive Maintenance Compliance (PMC)

Formula: (Completed PMs ÷ Scheduled PMs) × 100

Target: 70-90%

This metric shows the percentage of scheduled preventive maintenance that is completed. A score below 70% indicates serious problems. It means that either you’re planning too much maintenance, or execution discipline is lacking.

2. Planned Maintenance Percentage (PMP)

Formula: (Planned maintenance hours ÷ Total maintenance hours) × 100

Target: 80-90%

World-class organizations spend most of their maintenance time on planned activities rather than on emergency firefighting. Low PMP means you’re stuck in reactive mode.

3. Mean Time Between Failures (MTBF)

Formula: Total operating time ÷ Number of failures

Tracks reliability. Rising MTBF means your preventive maintenance program is working—equipment runs longer between failures.

4. Mean Time to Repair (MTTR)

Formula: Total repair time ÷ Number of repairs

Measures maintenance efficiency. Falling MTTR indicates improving technician skills, better parts availability, or more effective maintenance procedures.

5. Overall Equipment Effectiveness (OEE)

Combines availability, performance, and quality into a single metric.

World-class benchmark: 85% Average: 60% Low performers: 40%

Research shows that 90% of organizations practicing preventive maintenance see improved OEE compared to reactive approaches.

6. Maintenance Cost per Unit Produced

Tracks whether maintenance expenses are appropriate relative to output. Rising costs may indicate aging equipment or ineffective maintenance approaches.

Review and Update Process

Effective preventive maintenance checklists evolve based on experience and changing conditions.

Establish regular review cycles:

Quarterly reviews: Look at completion rates, recurring issues, and technician feedback for each major equipment category. Make minor adjustments to frequencies or procedures.

Annual comprehensive reviews: Deep dive into all checklists systematically. Compare predicted failure modes against actual failures. Update based on a full year’s operational data.

Event-triggered reviews: Any unexpected equipment failure should trigger an immediate checklist review. What could have been detected earlier? What inspection points are missing?

Change-triggered reviews: Whenever you modify equipment, change operating parameters, or alter production processes, review related preventive maintenance checklists.

Continuous Improvement Actions

Don’t just collect data—act on insights:

Optimize task frequencies: If equipment consistently shows no issues during inspections, consider extending intervals. If you’re catching problems late, increase frequency.

Add or remove tasks: Include new inspection points targeting recurring failure modes. Eliminate tasks that never reveal issues and provide no value.

Improve instructions: When technicians consistently ask questions about checklist steps, clarify the instructions. Add photos or diagrams where procedures remain unclear.

Update acceptance criteria: Refine pass/fail thresholds based on what actually predicts failures versus false alarms.

Pilot test changes: Before implementing major modifications organization-wide, test with a small group. Confirm improvements before full rollout.

Share lessons learned: When one team improves a checklist, extend successful changes to similar equipment across your organization.

Conclusion: Building a Preventive Maintenance Program That Actually Works

The data clearly demonstrates the value of a solid preventive maintenance checklist. Organizations with structured preventive maintenance programs experience 33% less equipment failure, 25% fewer safety incidents, and significant cost savings compared to reactive maintenance approaches. Every dollar invested in preventive maintenance typically returns five dollars in avoided costs.

But these benefits only materialize when you apply best practices consistently:

Comprehensive preventive maintenance checklists should be tailored to specific equipment and operating conditions.

Choose the right maintenance strategy for each asset type. Time-based, usage-based, condition-based, and predictive maintenance each have appropriate applications.

Leverage technology strategically. For most modern operations, computerized maintenance management systems dramatically improve compliance, efficiency, and visibility compared to paper-based approaches.

The alternative to preventive maintenance is reactive firefighting costs. Manufacturing facilities face average downtime costs of $260,000 per hour. Those losses are preventable through proper preventive measures.