Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeIf your maintenance team is battling inefficiency and excessive downtime, there are several steps you can take to improve team productivity.

It involves developing a systematic strategy to boost its collective output, implementing a Computerized Management System (CMMS) like Worktrek, and creating a preventive maintenance plan.

In this article, we will explore seven steps designed to augment the productivity and dependability of your maintenance crew.

Define Clear Goals and Objectives for your Maintenance Teams

The first step in the process is defining clear maintenance goals and objectives. These goals should align with your company’s strategic goals and the values of the maintenance department, providing a sense of purpose and direction.

Aligning with the executive team on the company’s mission and top priorities can effectively set objectives for maintenance improvements.

SMART goals—Specific, Measurable, Achievable, Relevant, and Time-bound—play a critical role in this process. SMART goals help make informed decisions and set realistic, attainable objectives for the maintenance team.

For instance, instead of setting a vague goal like “improve maintenance,” a SMART goal would be:

- Specific: Reduce equipment downtime

- Measurable: By 10%

- Achievable: Within the next six months

- Relevant: To improve maintenance.

- Time-bound: Set a specific timeframe.

By setting SMART goals, you can effectively track progress and ensure your objectives are clear and achievable.

Source: Fossil Consulting Services

Setting measurable goals enables maintenance technicians to:

- Track progress

- Pinpoint remaining tasks with step-by-step instructions

- Evaluate performance

- Uncover improvement areas and set production goals

- Improve overall business operations

- Reduce reactive maintenance

- Improve productivity and asset reliability

- Improve maintenance metrics

Time-specific goals encourage technicians to focus on each step rather than worrying about the entire process.

This structured approach boosts efficiency and morale, as team members can see their progress and celebrate short-term successes.

Implement a Computerized Maintenance Management System (CMMS)

Once you establish your objectives, the next step is to implement a Computerized Maintenance Management System (CMMS).

Modern maintenance management has evolved from tedious manual methods to utilizing advanced CMMS software for greater efficiency.

A CMMS streamlines work orders, tracks maintenance tasks, and controls inventory. All of these ar key elements in transforming maintenance operations. With the expertise of a seasoned maintenance manager, these processes are optimized for maximum effectiveness.

Implement CMMS Software

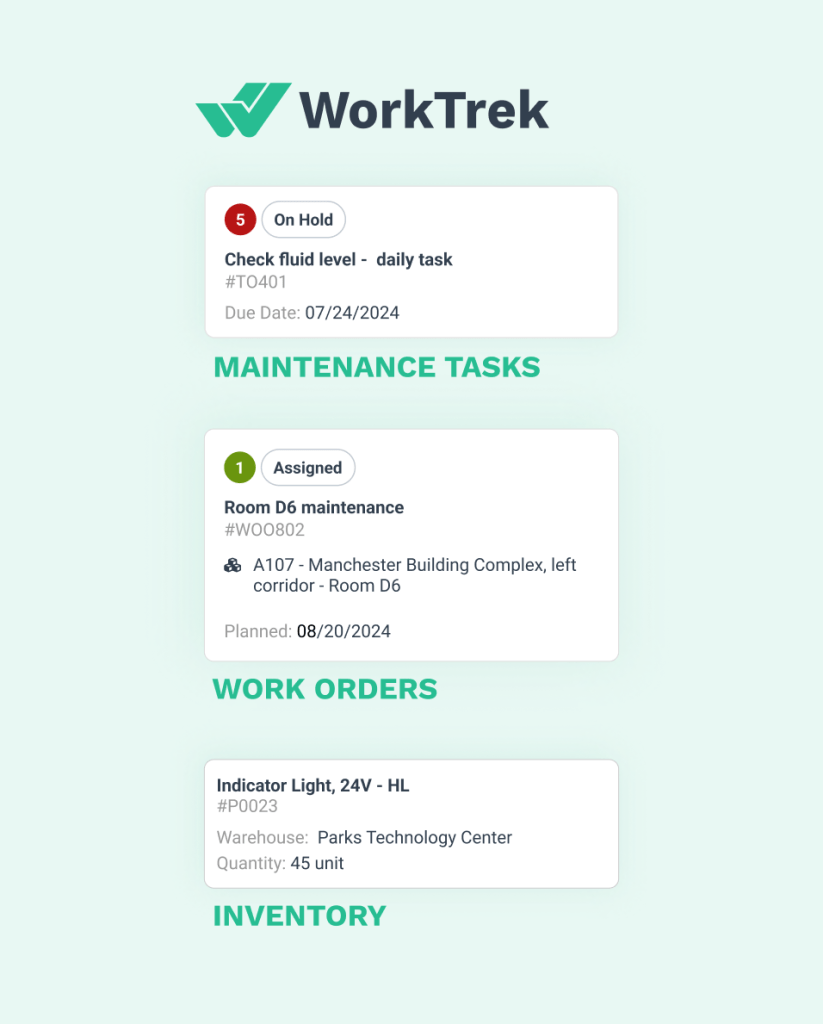

Introducing CMMS solutions like WorkTrek represents a substantial shift in managing maintenance activities.

These platforms enhance our oversight of maintenance tasks by simplifying work order management and providing real-time data on assets. CMMS tools categorize work requests, enable workforce submissions, and allow managers to oversee task allocation.

This can reduce equipment downtime and ensure that all maintenance aspects operate precisely.

Source: WorkTrek

Team Calendar View

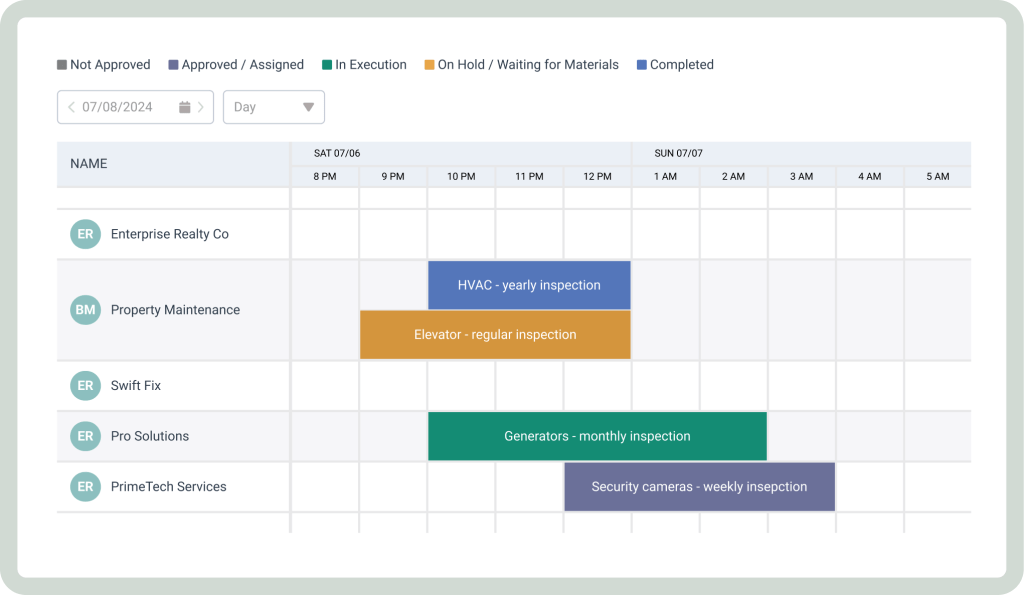

CMMS offers intuitive calendar views tailored to various approaches to improve procedural workflows within an organization’s routine check-ups and minimize the likelihood of unexpected reactive maintenance events.

Another benefit is the centralization of all relevant documentation in a single platform. This can avoid delays commonly associated with traditional paper-based systems.

The manual work order approach often suffers from poor organizational practices, hindering quick reference during critical moments when timely resolution is crucial for overall success.

Source: WorkTrek

Develop a Preventive Maintenance Plan

The next step in the process is developing a preventive maintenance plan, which is in addition to implementing CMMS in your organization. This is part of the industry best practices.

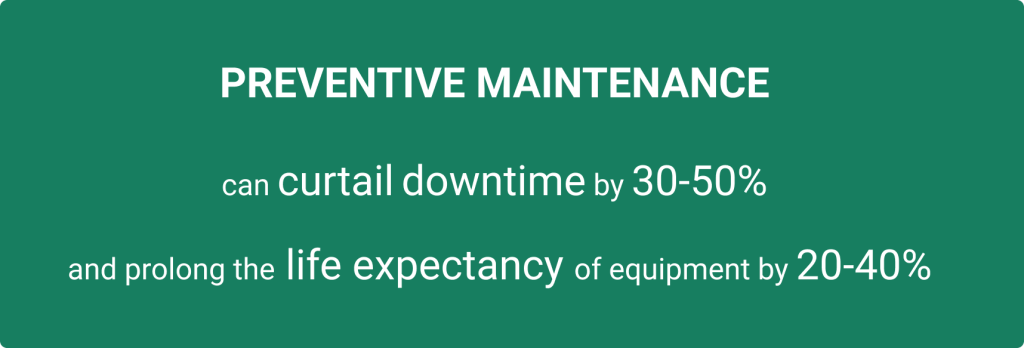

Preventive maintenance helps improve the lifespan of assets by ensuring equipment is kept in good condition. This can reduce unexpected breakdowns, improve resource allocation, optimize resource allocation, and improve overall maintenance performance.

Scheduling maintenance in advance can significantly reduce unplanned downtime, crucial for maintaining high equipment efficiency.

Benefits of Preventive Maintenance

A preventive maintenance plan offers several benefits.

- Reduce maintenance costs by eliminating emergency repairs and unplanned maintenance.

- Improve health and safety practices by including clear instructions in each PM Checklist.

- Maintains a safe working environment, contributing to overall team productivity.

- Boosts customer satisfaction by maintaining equipment efficiency and avoiding service or product quality disruptions.

Source: WorkTrek / Data: Maintworld

Pairing CMMS with Preventive Maintenance

Using a CMMS to organize and manage preventive maintenance schedules can help reduce waste and costs associated with poor planning and neglected maintenance. A CMMS can:

- Automate preventive maintenance schedules

- Create customized PM Checklists

- Assist the maintenance team in managing routine tasks

- Improve compliance

- Implement an easy-to-use reporting tool

- Quickly identify areas for continuous improvement

- Give maintenance managers a singular view of all work being performed

Train and Support Maintenance Team Members

A well-equipped and motivated maintenance team is the foundation of any successful maintenance department.

Evaluating each member’s capabilities and proficiencies helps pinpoint educational needs, allowing for targeted training that improves their ability to perform various tasks within the field of maintenance.

By doing so, every individual in the team, including those at a supervisor level, gains proficiency in handling complex maintenance jobs with greater competence.

Illustration: WorkTrek / Data: eLearning Industry

Benefits of Cross-Training

Implementing cross-training for different maintenance tasks, such as preventive and predictive maintenance, enhances versatility and broadens skill sets across various functions.

This approach fosters agility and adaptability when encountering new challenges. Setting up mentoring programs where experienced workers pass on their knowledge to less experienced colleagues offers valuable on-the-job learning and promotes a culture of teamwork and collaboration.

Involving the workforce in practical assignments also increases hands-on experience, advancing professional development and expertise.

Source: AIHR

Continuous Feedback and Reviews

Regular feedback with the maintenance team can inspire team members to stay engaged.

Implementing a certification program improves retention and gives talented maintenance team members an upward career path.

Measure and Analyze Maintenance Performance

There are several methods you can use to track performance:

Key Performance Indicators (KPIs)

Key Performance Indicators (KPIs) are measurable values that help assess an organization’s or specific activities’ success in reaching key business goals. In maintenance performance, KPIs track and evaluate equipment reliability, repair efficiency, and maintenance expenditures.

By analyzing metrics like Mean Time to Repair (MTTR), Mean Time Between Failures (MTBF), and Overall Equipment Effectiveness (OEE), KPIs offer valuable insights into the effectiveness of maintenance strategies. This data-driven approach allows maintenance managers to pinpoint areas needing improvement, optimize resource allocation, and ensure maintenance activities are aligned with organizational objectives, ultimately leading to enhanced productivity and minimized downtime.

Overall Equipment Effectiveness (OEE)

The key metric, Overall Equipment Effectiveness (OEE), gauges how efficiently machinery is used by considering availability, operational efficiency, and quality output. Compliance with Preventive Maintenance measures the proportion of preventive maintenance tasks completed on time against those scheduled. Meanwhile, the Planned Maintenance Percentage compares planned versus actual maintenance work hours.

Illustration: WorkTrek / Quote: dynaway

CMMS

With a Computerized Maintenance Management System (CMMS), one can streamline the process by producing automated reports that offer deep dives into performance metrics related to KPIs and overall productivity in your facilities.

By routinely analyzing these data-driven reports aligned with their departmental objectives during transitions or periods of change, managers overseeing maintenance can track progress dynamically and adjust strategies.

Accordingly, this continual refinement aligns with the goals laid out previously. This systematic evaluation enables maintenance teams to adhere closely to targets and pinpoint prospective improvement avenues proactively.

Foster Open Communication and Collaboration

The success of a maintenance department and the creation of a supportive work atmosphere depend heavily on the practice of open dialogue and collective effort among team members.

Maintaining transparent communication within the team enhances information exchange, paving the way for easy collaboration. It also cultivates a setting where individuals are comfortable proposing new ideas or expressing concerns, fostering inclusivity.

Initiating regular morning meetings ensures that all team members are well-informed about any updates and share a common understanding of daily objectives.

Encouraging maintenance professionals to participate in making decisions instills a sense of worth and boosts their involvement. Brainstorming sessions allow them to contribute creative solutions to intricate issues, thus promoting an ethos centered around continuous improvement within the team.

Illustration: WorkTrek / Data: Blink

Recognize and Reward Team’s Success

Maintaining a motivated and enthusiastic maintenance team hinges on recognizing their accomplishments and offering suitable rewards.

Acknowledging their hard work can create a positive atmosphere, boosting morale and motivation. Celebrating the team’s successes instills a sense of pride, encouraging members to strive for collaborative excellence.

The success of maintenance staff can be celebrated through different gestures like providing accolades during company-wide announcements or organizing recreational events outside work premises. Offering days off is another significant gesture demonstrating gratitude for the team’s exemplary dedication and effort. Public commendation of individual milestones within group settings also acts as an incentive, prompting others towards meritorious performances deserving similar praise.

Giving time off to maintenance personnel in recognition of their labor shows appreciation and is instrumental in curtailing staff burnout. This strategy contributes significantly to maintaining sustained high performance across your maintenance operations.

Source: WorkTrek

Embrace Continuous Improvement

Maintenance teams that adopt a continuous improvement strategy and integrate new technologies, tools, and best practices can optimize their operations.

Fostering a continuous improvement culture supports skill development and keeps the maintenance team motivated and engaged.

Performing a cost analysis for targeted improvement areas, especially for critical and expensive equipment, is vital for effective continuous improvement.

Implementing changes in one area and using a control group to measure the outcomes ensures the effectiveness of continuous improvement efforts before broader application. By identifying and addressing problems, maintenance teams can conserve time and resources, increasing uptime and greater productivity.

Source: WorkTrek

Summary

Improving maintenance team efficiency involves setting clear goals, implementing a CMMS, developing a preventive maintenance plan, training and supporting team members, measuring performance, fostering communication, and embracing continuous improvement. Maintenance teams can achieve higher productivity, reduced downtime, and cost savings by following these steps.

Implementing these strategies requires commitment and effort, but the rewards are worth it. A motivated and efficient maintenance team is an invaluable asset to any organization. Embrace these steps today and watch your maintenance team transform into a high-performing unit.