Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Despite acknowledging the risk of knowledge loss, only 22% of organizations have formal processes for documenting maintenance training.

- Using a CMMS helps turn maintenance documentation into a living knowledge base.

- Investing in staff training reduces reliance on costly outsourced repairs.

More often than not, facility maintenance comes with a lot of unavoidable costs: from machinery repairs to staffing needs and equipment upgrades.

The last thing that maintenance managers want to add to that list is training.

But training is not just another line item that you can skip or postpone, especially in regulation-heavy industries.

It’s essential for keeping your operations running smoothly, minimizing downtime, and ensuring the safety of your people and equipment.

In this guide, we’re sharing what your maintenance training program should include, what benefits it brings, and what types of training you should consider.

What Should a Maintenance Training Program Include?

The exact definition of a good maintenance training program will vary across industries, organizations, and even specific technical roles.

For instance, maintenance training in a chemical plant should extensively cover the handling and storage of hazardous waste.

The same wouldn’t be considered highly relevant for commercial property maintenance.

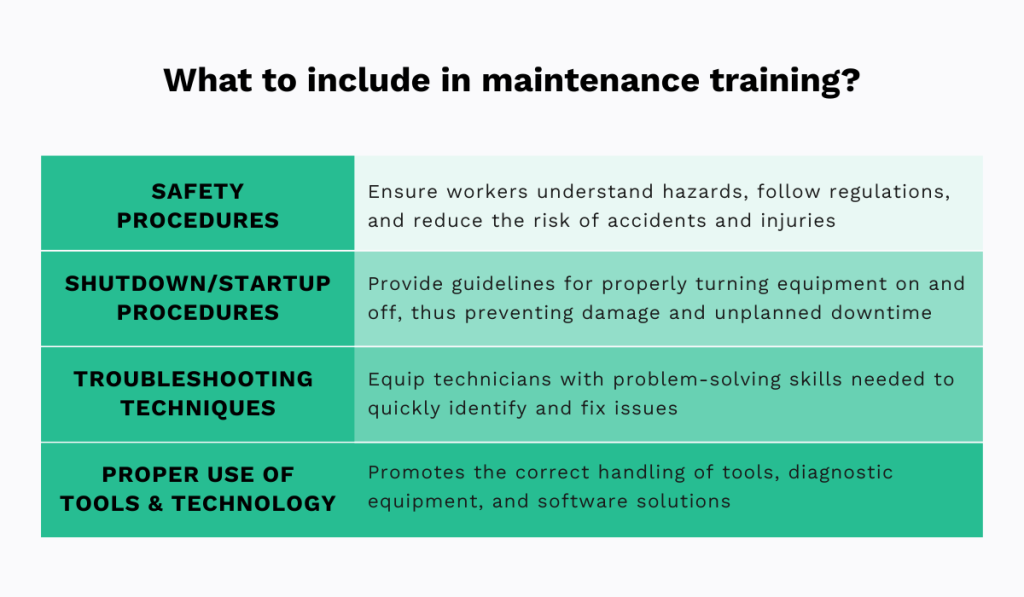

However, certain key topics should be covered in every training program:

Identifying these key topics and training your maintenance staff on them is the first (and the biggest) step.

But even the most thorough, well-planned training won’t mean much if your maintenance processes aren’t systematically documented and easily repeatable.

Let’s explore that in more detail.

How to Document Maintenance Training Activities?

The goal of training is not just to transfer knowledge, but also to ensure that it can be applied consistently by all maintenance staff, regardless of their experience level.

Yet, many organizations are struggling with the concept of documenting training activities.

In the UK, for instance, industrial organizations lose an average of £240,000 in productivity per retiring maintenance specialist solely due to undocumented knowledge.

Although the majority of them think that knowledge loss is a business risk, only 22% follow organized knowledge documentation processes.

To make matters worse, manually documenting proper maintenance procedures is still all too common.

Yes, using spreadsheets and paper logs might seem easier and more affordable at first glance.

But they’re not going to ensure the data’s accuracy, consistency, and accessibility, which are essential for knowledge transfer.

Joel Tesdall, President of MAPCON Technologies Inc., agrees:

“If you don’t have software to do that, you’re doing everything on paper. That might work out to start with, but it’s not going to make you very efficient.”

That is why he suggests using software tools, such as CMMS, to support the documentation process.

Take our own solution, WorkTrek, as an example.

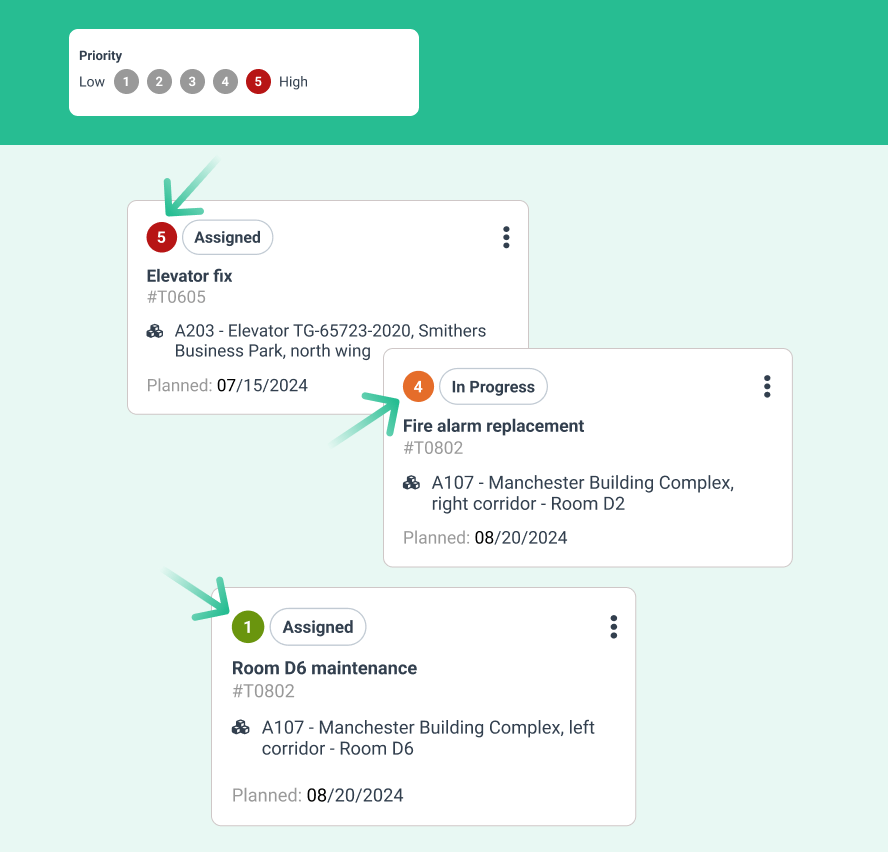

WorkTrek provides a central platform to organize, schedule, and track all maintenance-related activities.

It allows maintenance managers to assign tasks, monitor completion rates, and ensure employees have the skills needed for specific equipment or procedures.

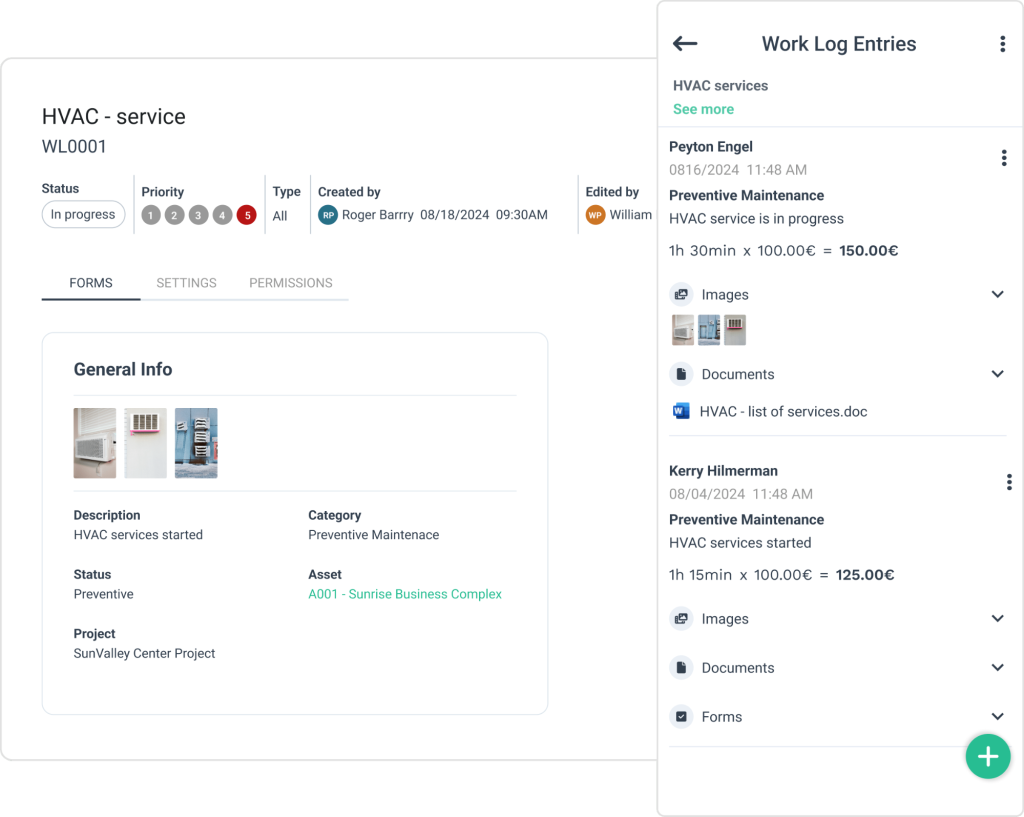

But CMMS doesn’t just improve operational efficiency. It also serves as a knowledge base.

Every task, procedure, and workflow that you enter into WorkTrek can later be referenced for training purposes.

In other words, new hires can get insight into your facility’s procedures through real-life examples.

In short, ensuring that all procedures are documented creates the foundation for efficient and safe maintenance operations at your facility.

Benefits of Maintenance Training

Now that we’ve covered what maintenance training should focus on, you might be wondering, “How do we convince the decision-makers that it’s worth the money?”

That can be a challenge, as training is often viewed as a budget drain rather than a core strategic investment.

With that in mind, let’s explore some of the biggest benefits of maintenance training.

Increased Maintenance Staff Retention

Maintenance training is meant to equip your staff with the technical skills they need to perform their jobs well.

But its impact extends beyond just technical competence.

Knowing which tools to use, how different systems work, and which procedures to follow, because someone took the time to educate them, instills a sense of confidence in your staff.

And when they feel capable, they also experience higher job satisfaction.

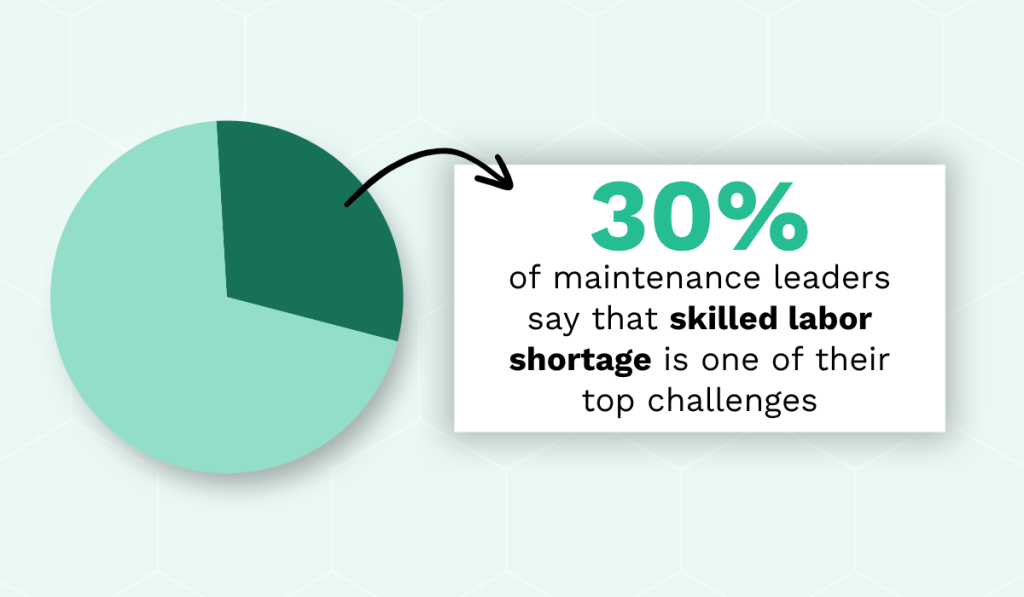

According to the 2025 State of Industrial Maintenance Report, skilled labor shortage is one of the top challenges facing maintenance leaders.

With labor shortage being such a serious problem, ensuring that your staff feel happy and supported is critical for retaining them.

Training plays a huge role in achieving that, and it makes sense why that is the case.

Mastering the skills maintenance technicians need for day-to-day operations is bound to reduce frustration, and continuous learning helps keep the job engaging.

But most of all, knowing that the organization invests in their growth fosters loyalty among employees.

Pablo Paz, national service training manager with over a decade of experience, thinks so, too.

However, forums like Reddit are teeming with threads in which maintenance technicians admit that formal training is more often an exception, rather than a rule.

The “no training needed” approach seems to be the norm, and it contributes to skills gaps and difficulties in retaining staff.

However, if structured maintenance training becomes the new normal, facilities can strengthen not just the expertise of their staff but also their loyalty.

Fewer Safety Incidents

Another important benefit of maintenance training is its impact on fostering safety awareness in your facility.

It emphasizes safe operating procedures and emergency protocols.

Ultimately, this builds a culture of safety where employees are less likely to make mistakes that are not just costly but also dangerous.

According to research conducted by Watco, 26% of facilities managers say that slips, trips, and falls have impacted them.

The same study estimates that non-fatal workplace injuries cost companies over £500 million each year.

This includes not just injury and insurance payouts, but also hidden costs such as administration, production delays, equipment damage, and even reputational damage.

Despite all this, safety awareness remains a low priority for many.

Why?

Tim Roback, Engineering Manager at Rockwell Automation, offers an explanation.

“Number one, in many cases, people aren’t comfortable interpreting and applying the safety standards. Number two, they don’t see the opportunity for increased productivity with safety improvements, so it’s always an educational process to explain that safety can add value. It’s not just a cost.”

Simply put, too much emphasis is placed on productivity and cost savings, while not enough is given to the benefits that safety improvements can offer.

To make matters worse, ignoring safety will only end up costing you more.

The solution?

Make safety awareness a core part of your maintenance training.

The sooner you start seeing education on safety procedures as an investment, the sooner you’ll reap the benefits: fewer injuries and incidents, and fewer costs that come with them.

Reduced Downtime

Well-trained staff can detect and address maintenance issues before they escalate into costly breakdowns.

As a result, unplanned downtime is minimized and production schedules remain on track.

Things don’t always run that smoothly, though.

In reality, unexpected equipment breakdowns continue to be the most reported challenge in 2025, with 41% of maintenance teams mentioning them.

This is yet another issue that maintenance training can help overcome.

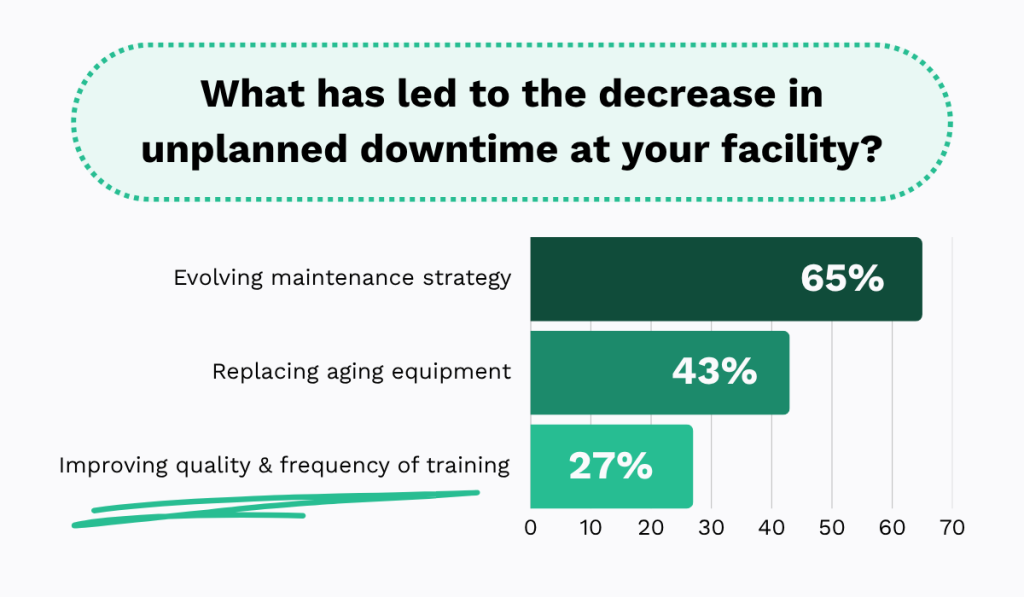

In fact, according to 27% of maintenance professionals, improving the quality and frequency of training is the most effective way to reduce unplanned downtime incidents.

The other two approaches reported by the respondents—maintenance strategy improvements and replacing old equipment—play a significant role in reducing downtime, too.

However, these might not be as easy to implement.

Overhauling your entire maintenance strategy takes significant planning, time, and financial resources.

Likewise, replacing outdated equipment requires substantial financial investment and carries the risk of production downtime.

In comparison, improving your maintenance training program is much more manageable.

You don’t have to transform everything overnight. Start with the basics, and build momentum from there.

Doing this will help you create a culture of continuous improvement, reduce unnecessary downtime, and save you money in the process.

Lower Repair Costs

You might think that putting money towards the newest machinery and automation solutions is the smartest investment.

After all, they promise increased productivity and seamless performance, so spending on maintenance training may seem unnecessary.

But the reality is that, even with the most advanced equipment, breakdowns and malfunctions are inevitable.

No machine will work perfectly 100% of the time, so having employees who know how to identify early warning signs and perform proper upkeep is priceless.

Otherwise, you’ll be forced to outsource repairs at a premium.

Greg Wortman, Operations Manager at Redimix Companies, says that investing in your own people is undoubtedly the more affordable option.

As Wortman explains, relying on subcontractors to fix your equipment often doesn’t just result in additional expenses.

It also puts you at risk of repairs being done incorrectly.

This can lead to recurring issues with the equipment, reduced equipment lifespan, and more serious consequences.

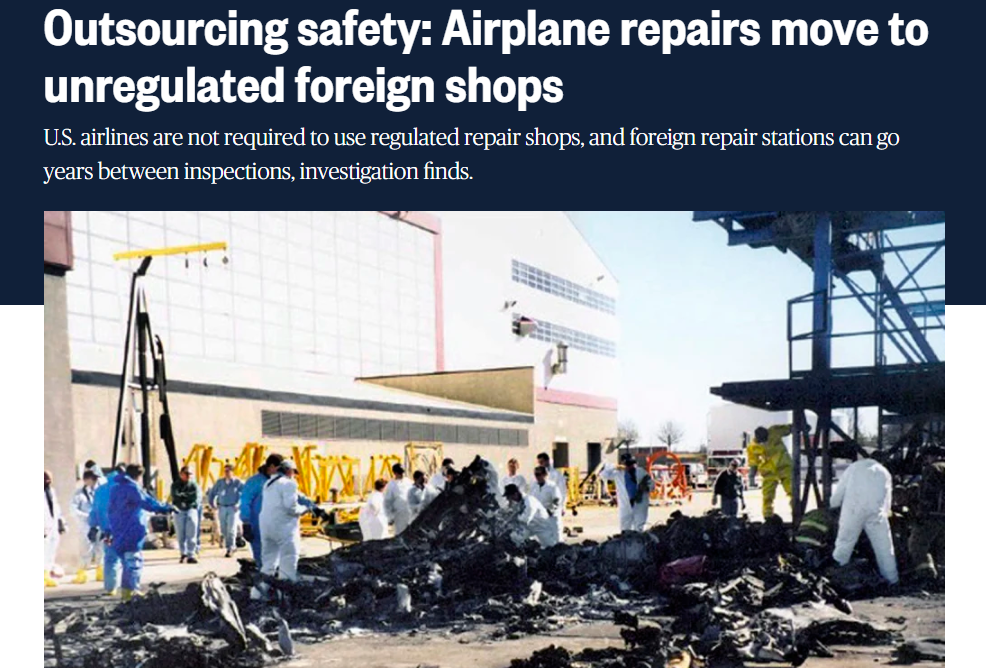

The case of the Air Midwest Flight 5481 from 2003 demonstrates just how dangerous maintenance outsourcing can be.

Negligent repairs to the tail section of the plane caused the pilot to lose control, causing him to crash into a hangar at Charlotte-Douglas International Airport and killing 21 people.

As it turns out, the airline had outsourced its maintenance checks to a company in West Virginia, which then subcontracted the work to another company.

Tragic stories like this teach an important lesson: when maintenance is outsourced, especially without proper oversight, the risks far outweigh the benefits.

That is why investing in training your in-house maintenance staff is both a smart financial decision and the best way to safeguard your people and equipment.

Types of Maintenance Training Programs

There are various types of maintenance programs, each serving a different purpose depending on your team’s needs and goals.

We’ll explore three key types: skill-based, cross-functional, and industry-specific.

Skill-Level Based

Maintenance training programs are designed based on skill level, considering the worker’s career stage and level of responsibility.

This type of training can further be divided into entry-level, advanced, and management-level training.

Entry-level training focuses on educating your maintenance staff on basic technical skills and safety procedures.

This type of training is supposed to get them comfortable with performing routine maintenance tasks, but it also sets the foundation for further training as they gain more experience.

It may be tempting to dismiss entry-level skills as too simple, but in a labor market that is short on expertise, they provide the stepping stone to career growth.

In other words, once a maintenance technician has these basic skills under their belt, they can be trained up further.

As JD Solomon, Senior Consultant at J.D. Solomon, Inc., explains, that is exactly what many employers are relying on today.

That is where advanced training comes in.

It teaches maintenance technicians about specialized techniques and diagnostics, and exposes them to more complex systems.

At this stage, they learn to handle troubleshooting, predictive technologies, and preventive maintenance strategies.

This ultimately prepares them to solve higher-level problems and support more efficient operations.

Finally, there’s management training, such as IFMA’s Leadership and Strategy Course.

This type of training is geared toward maintenance leaders, supervisors, and managers who are responsible for overseeing teams and budgets.

Its goal is to help managers learn how to balance resources, improve uptime, and align maintenance with business goals.

Cross-Functional

With the aforementioned shortages of skilled labor, cross-functional maintenance training is becoming increasingly popular.

The goal of such training programs is to broaden employees’ skill sets beyond their primary role.

So, if a technician is trained in mechanical repairs, providing them with basic electrical diagnostics training could be beneficial.

That way, they can address a broader range of issues within the facility, meaning that you don’t have to outsource a specialist to solve them.

This type of training is a win for both the technician and your facility:

They get to expand their skillset, and your facility experiences less downtime due to a reduced dependency on outside specialists.

Woody Rogers, Maintenance Supervisor at the facilities services company Cintas, understands this well.

That is why they found a creative solution for cross-training their staff: training videos.

Training videos are a great way to share knowledge and cross-train.

They show technicians exactly how to perform a task, instead of just telling them, which makes it easier to understand and retain the process.

But there’s more to it: they’re also more accessible and easily revisited, which eliminates the need for repeat in-person training.

Overall, they are a less costly way to cross-train your maintenance staff, which makes skill-building more consistent and scalable.

Industry-Specific

Different industries have different equipment, compliance requirements, and safety standards, so industry-specific training is often non-negotiable.

For instance, maintenance in healthcare facilities can be especially demanding.

It impacts patient safety and infection control, but also requires compliance with strict regulations.

Key training areas for healthcare maintenance professionals include:

| Medical Equipment Maintenance | Servicing, calibrating, and repairing specialized devices like MRI machines, infusion pumps, sterilizers, and ventilators. |

| Infection Control Procedures | Cleaning, disinfecting, and maintaining equipment to meet healthcare hygiene standards. |

| Life Safety Systems | Training on fire alarms, emergency lighting, HVAC, and backup power systems. |

| Regulatory Compliance | Understanding OSHA standards and state or country-specific codes. |

So, how can aspiring maintenance professionals in the healthcare industry obtain this knowledge?

There is a variety of formal training programs they can pursue, along with a mix of certifications and on-the-job training.

Many healthcare facilities require certifications such as Certified Healthcare Facility Manager (CHFM) or training through organizations like the American Society for Healthcare Engineering (ASHE).

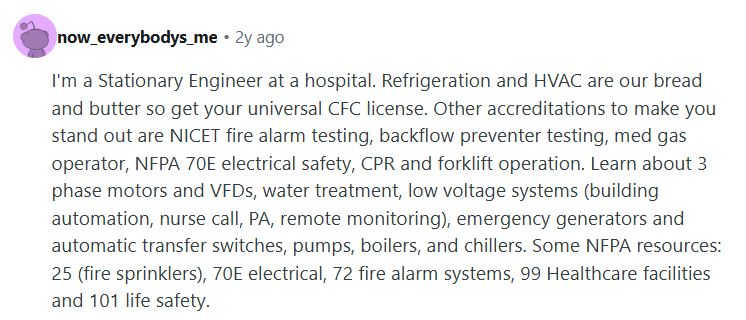

One Reddit user also recommends additional helpful resources and accreditations to consider:

But healthcare isn’t the only industry that requires specialized maintenance training.

For instance, in chemical manufacturing, maintenance technicians need to be trained in hazardous materials handling and leak detection, and they must also comply with OSHA and EPA regulations.

Those who want to work in maintenance in nuclear plants, on the other hand, require specialized training in radiation safety and advanced diagnostic skills.

The bottom line is, industry-specific training builds on the foundation of basic maintenance skills and takes them to a whole new level.

So, technicians who have the ambition to grow will benefit from mastering these specialized areas.

Conclusion

If you used to think that maintenance training was a necessary evil that might as well be skipped, we hope that this article changed your mind.

Because the truth is, maintenance training isn’t an unnecessary cost.

It’s a long-term, strategic investment in the safety and efficiency of your facility.

Of course, if training hasn’t been a priority so far, don’t feel the pressure to overhaul everything at once.

Start by focusing on the most critical skills and documenting key procedures, and build on them over time.

That way, training will slowly become a sustainable, ongoing part of your maintenance culture.