Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- A backlog audit reveals the real scope of work and uncovers hidden inefficiencies.

- Prioritizing tasks by criticality ensures resources are focused where they matter most.

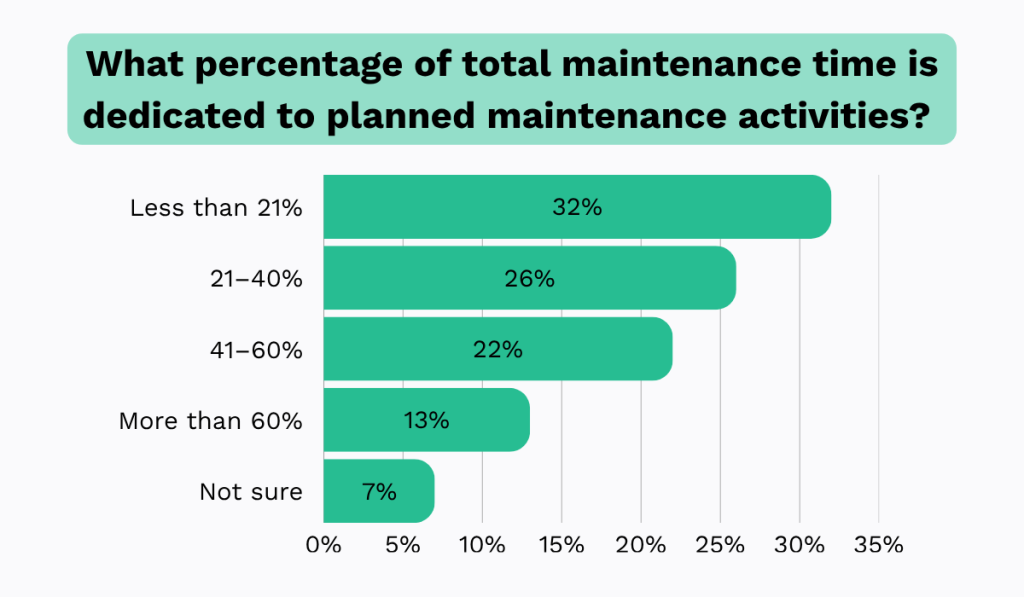

- Only 13% of facilities focus most of their time on preventive maintenance.

As a maintenance manager, you understand the importance of keeping up with maintenance activities and making sure nothing falls through the cracks.

But in reality, things get busy, and it often feels like there’s not enough time to complete everything.

Work orders pile up, urgent breakdowns demand immediate attention, and shifting priorities leave technicians unsure about what to tackle first.

Before you know it, your maintenance backlog is growing out of control, and you start to feel like you’ll never be able to bring it down to an acceptable level.

The good news? That doesn’t have to be the case.

In this article, we’re sharing 5 tips that will help you reduce your maintenance backlog and ensure it remains contained.

Perform a Backlog Audit

Before you start planning how to tackle your maintenance backlog, it’s essential to step back and perform a backlog audit.

This will help you understand how significant your backlog truly is and what factors contributed to its growth in the first place.

For instance, an audit can reveal that your backlog is smaller than it might seem at first glance.

Outdated, completed, and duplicate work orders can clutter the system and distort the true state of affairs.

You might even discover that your backlog is within a healthy range, indicating a well-organized pipeline of planned work.

Preston Ingalls, President Emeritus at the maintenance and reliability consulting firm TBR Strategies, explains that having 3–5 weeks’ worth of backlog is normal.

But what if your backlog has grown beyond that range or is suddenly increasing at an alarming rate?

That is a signal to dig deeper and identify the cause of the buildup.

Is it because your work order approval processes are too complex, or perhaps because of labor shortages?

Do specific assets experience recurring breakdowns, or are your work orders piling up because spare parts aren’t available when needed?

Taking the time to pinpoint all the bottlenecks might seem like a waste of time if you’re anxious to start clearing your backlog.

However, it’s actually beneficial in the long run.

Think of it this way: the sooner you identify and treat the root causes of backlog, the sooner you can end the cycle of piling work orders and constant fire‑fighting.

For instance, a large backlog often stems from incomplete maintenance records.

This is because, without accurate documentation, tasks can be duplicated, overlooked, or delayed.

Research shows this is a problem many facilities face.

Ultimately, this creates inefficiencies that lead to work orders accumulating.

If you take the time to conduct a backlog audit, you can uncover these issues and put systems in place to ensure all maintenance activities are documented consistently going forward.

Remember: auditing your backlog isn’t just about cleaning up data, but about creating an accurate picture of what truly needs attention and why.

Prioritize Tasks by Criticality

Once you’ve eliminated all of the already completed and no longer relevant tasks from your backlog, you’ll probably end up with a leaner list of tasks that still need to be taken care of.

But that doesn’t mean you can start clearing them in random order, because not all of them carry the same weight.

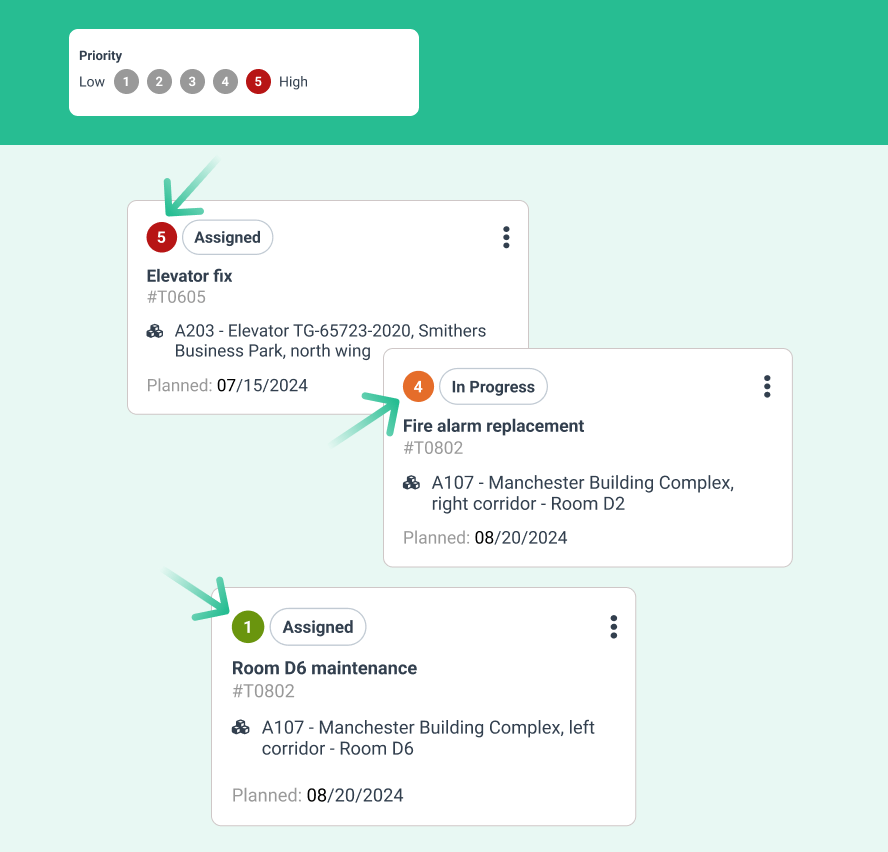

Instead, you want to rank them by criticality.

That way, you can focus your time and resources on the most essential tasks first.

However, according to Augury’s 2024 “Machine Health Is Business Health” report, 64% of the surveyed organizations say that they can’t visualize the real-time condition of critical assets across all sites.

Not knowing what is happening with your machinery makes it difficult to accurately assess which tasks are urgent and which can wait.

The solution?

Implementing condition monitoring tools and a centralized maintenance management system that can provide real-time insight into the performance of assets.

Such tools will help you collect and visualize the asset data, but to make sense of it, you need to employ a prioritization method.

This can be as simple as sorting maintenance tasks into high-, medium-, and low-priority categories.

| Priority Level | Example Task |

|---|---|

| High | Repairing a failed production line motor, replacing a malfunctioning pressure valve, or addressing an electrical fault that poses a safety hazard. |

| Medium | Performing scheduled preventive maintenance on pumps or conveyors, replacing worn belts or bearings, or recalibrating sensors. |

| Low | Repainting floor markings, fixing minor lighting issues in non-production areas, or organizing spare parts storage. |

With a method like this in place, you’ll ensure critical tasks are taken care of first, while less urgent work can be scheduled strategically later.

When determining which tasks are high-priority, their impact on productivity and safety should be the primary deciding factor.

Yes, it’s important to resolve issues that can stop production, but even more so, address those that could compromise safety in your facility.

Andrew Gager, COO of AMG International Consulting, agrees.

The bottom line is that, by focusing on the most critical work first, you ensure that your resources are used where they have the biggest impact on productivity and safety.

Once those major issues are resolved, your backlog will become more manageable, and your overall maintenance program stronger.

Streamline Your Work Order System

Another issue that heavily contributes to backlog buildup is a disorganized work order process.

When your maintenance staff doesn’t know what needs to be done and when, or which tasks take priority, a mounting pile of unresolved issues becomes inevitable.

As a manager, you also don’t know who is doing what, and you worry about whether a critical task has been completely forgotten.

This was the reality for Ben Tucker, equipment manager for Barriere Construction, before the company implemented a work order system:

“Before we implemented a work-order system, I knew 30 percent of the time what my people were doing. After we started using work orders, I knew what my people were doing 99 percent of the time, and knowing what’s going on is critical. Scheduling your work orders daily and knowing where your labor is going each day are essential to good management.”

A work order system enables technicians to stay on top of tasks without chasing paperwork and gives managers full visibility into ongoing work.

Ultimately, this makes it easier to shrink the maintenance backlog and saves valuable time.

Christopher Wilcox, maintenance manager at Univar Solutions, puts it this way:

He goes on to explain that using a CMMS to streamline work order management enables organizations to make better decisions and optimize their maintenance operations.

Simply put, it is the best way to standardize your workflows, simplify approvals, and centralize all relevant maintenance information.

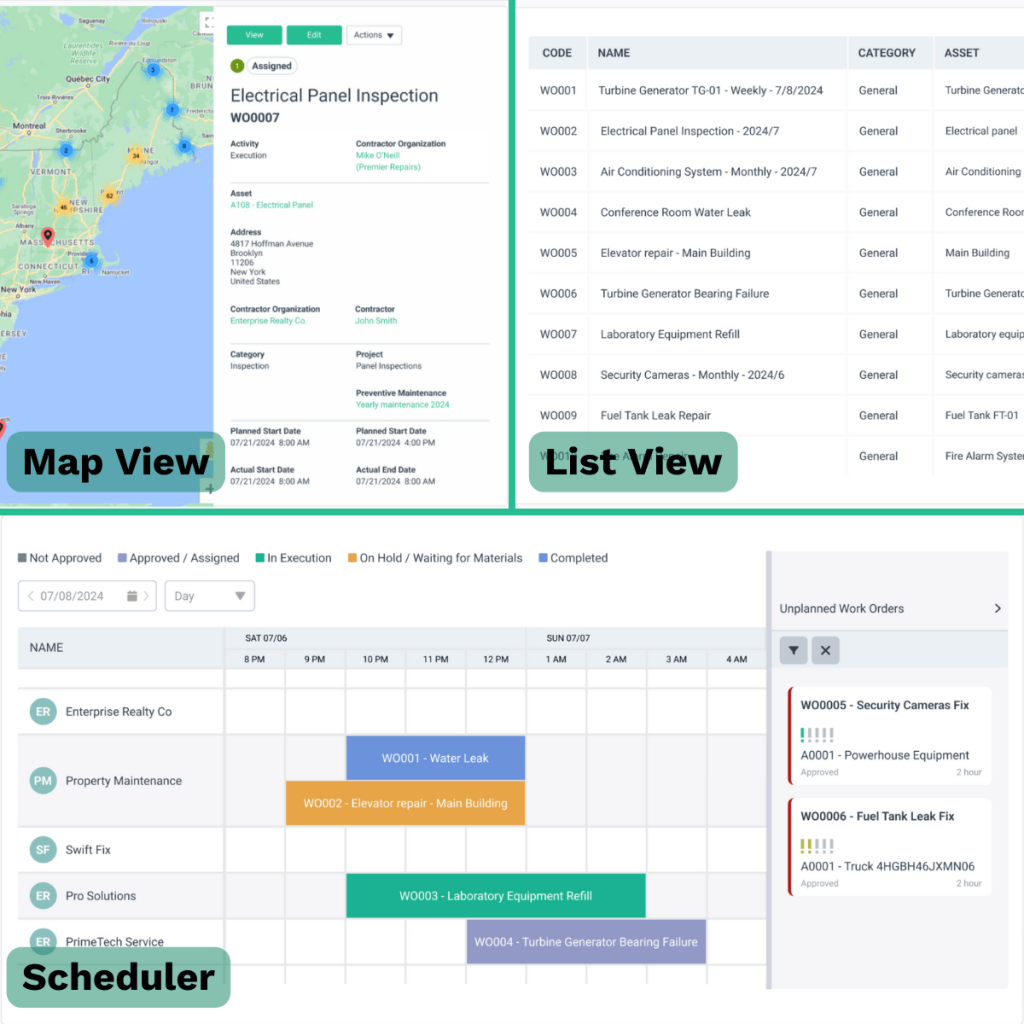

Take WorkTrek as an example.

Our intuitive work order management feature enables you to create, schedule, assign, and track work orders in real time.

You can also assign a priority level to each work order you create, which is especially important when you’re dealing with a substantial backlog and need your technicians to focus on the most critical tasks first.

To help ensure that all your maintenance records remain accurate and up to date, WorkTrek also offers a mobile app.

With it, your technicians can:

- Receive real-time mobile notifications on assigned work orders

- Fill out checklists and complete work orders while in the field

- Create comprehensive records of work and site history

By keeping everything documented in real time, you eliminate delays in reporting and reduce the chances of missed or duplicated tasks.

As a maintenance manager, keeping track of dozens of work orders at once can quickly become overwhelming.

That is where the different ways to view all the maintenance activities come into play.

WorkTrek’s Scheduler view can be very helpful in this regard, offering a bird’s-eye view of all ongoing, upcoming, and completed work orders.

This makes it easy to spot workload imbalances, identify potential scheduling conflicts, and allocate resources more effectively to keep your backlog under control.

Overall, a CMMS like WorkTrek makes work order management a breeze, helping maintenance teams stay organized, prioritize activities effectively, and steadily reduce their backlog.

Cross-Train Your Team

The size of your maintenance backlog can quickly get out of control if your technicians are trained to perform only one type of task.

Imagine an equipment failure at your facility needs to be addressed immediately, and the only person who knows how to fix it happens to be off that day.

The rest of the team scrambles to troubleshoot the issue without the right expertise, wasting valuable time while other work orders continue to pile up.

That is a scenario you don’t want to end up in, and one you can avoid through cross-training your maintenance team.

Mike Greany, service manager at All Pro Plumbing, Heating, and Air Conditioning, understands this, which is why everyone at his company is cross-trained.

“Our installation crews are being cross-trained and brought up to do performance tests on residential calls when they are not doing installs. We are cross-training everyone in the company. All our HVAC guys are learning plumbing, and our plumbing folks are learning HVAC.”

By investing in cross-training your team, you not only increase flexibility but also ensure work keeps moving, even when unexpected challenges arise.

In other words, the better equipped your technicians are to handle various maintenance tasks across your facility, the more likely you are to prevent your backlog from growing.

And the good news is, workers are eager to learn.

According to the 2022 Career Optimism Index Study by the University of Phoenix, the majority of American workers are seeking opportunities to expand their skill sets.

When you invest in your technician training, you show them that you recognize their potential and want to see them grow, which in turn makes them feel appreciated and empowered.

It also prepares them for future advancement, explains Cate Deane, director of training at Ruppert Landscape:

Deane goes on to explain that having multiple team members who know how to perform key tasks reduces reliance on any one individual.

This, in turn, reduces disruptions during emergencies or staff transitions.

Although she is talking about the landscaping industry, the same applies to maintenance.

The more skilled your technicians are across different maintenance tasks, the better equipped they are to handle a variety of challenges.

This supports their career growth, enables your maintenance activities to run smoothly, and keeps your backlog under control.

So, don’t let skill gaps slow down your backlog reduction efforts.

Instead, invest in cross-training your team, broaden their capabilities, and create an adaptable workforce that can tackle any challenge without bottlenecks.

Implement a PM Program

Even if you implement all the advice we’ve shared so far, it won’t amount to much if your overall maintenance approach is reactive.

A reactive approach means that maintenance is driven by unexpected breakdowns, rather than planned upkeep.

This results in a constant influx of work orders, most of which will likely be deemed urgent.

Before you know it, you’ll end up with a backlog that feels impossible to clear.

You might think that the preventive approach is the cornerstone of most maintenance programs anyway, and that very few facilities choose to operate reactively.

Even research says so: 71% of maintenance leaders claim that preventive maintenance is a foundational aspect of their maintenance programs.

But that is only part of the story.

In reality, only 13% of facilities allocate the majority of their time to it, and unplanned work dominates most maintenance schedules.

These numbers show that preventive maintenance still isn’t as prevalent as it could be.

So, instead of wasting time on constant reactive repairs, it’s important to invest in a structured PM program.

This will help you address issues at the root and early on, ultimately reducing emergency work, keeping your assets reliable, and managing your backlog.

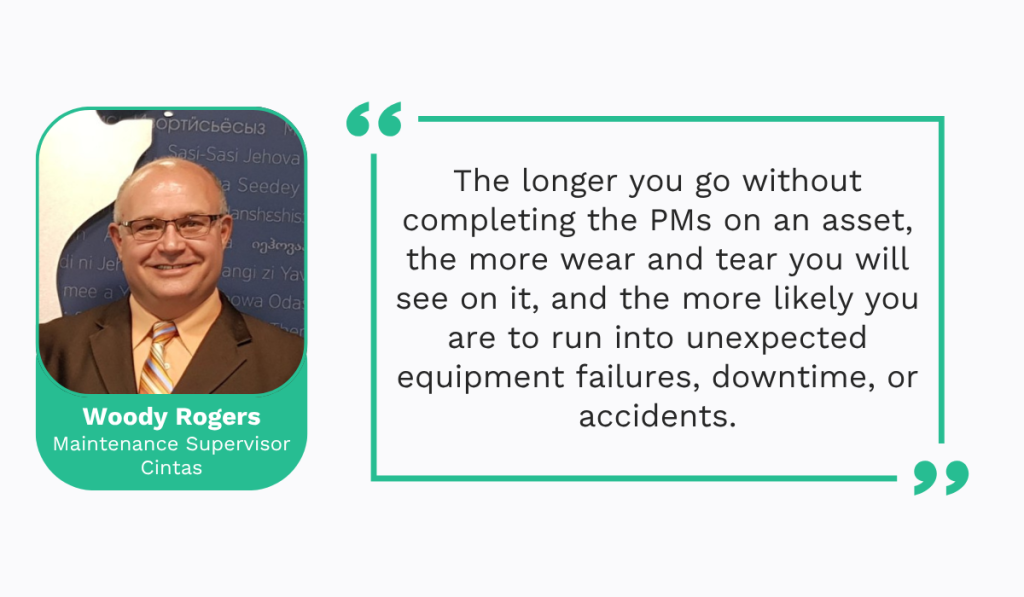

If you don’t make preventive maintenance the foundation of your maintenance program, you’re putting your equipment and operations at risk, explains maintenance supervisor Woody Rogers.

The bottom line is that, although preventive maintenance requires more planning and upfront effort, it pays off in the long run.

Not only does it keep your equipment running smoothly, but it also helps shrink the maintenance backlog and prevents it from getting out of control.

Conclusion

Even though tackling your maintenance backlog can feel overwhelming, if not impossible at times, we hope this article has shown you that it doesn’t have to be.

By following the advice we shared, you can do more than just keep your backlog under control.

You can build a stronger, more agile maintenance program that keeps your assets healthy and your facility running.

And remember: having a few weeks’ worth of backlog is normal and even desirable, so don’t chase the idea of clearing it completely.

Instead, focus on following the strategies that will keep it in check.