Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeAn operations and maintenance Manual is crucial for building owners and facility managers. It provides vital information about a facility’s systems, equipment, and maintenance requirements.

This comprehensive document offers detailed operational guidance and maintenance information, ensuring effective operation and longevity of the assets for various stakeholders, including engineers and maintenance personnel.

These manuals serve as comprehensive guides for managing complex systems efficiently. They contain detailed instructions, diagrams, and schedules necessary for keeping a facility running smoothly.

Creating an O&M Manual is often a requirement after project completion or for contractor handoffs. It compiles all the information on a building’s operation, maintenance, decommissioning, and demolition, making it an invaluable resource throughout a facility’s lifecycle.

Key Takeaways

- O&M Manuals provide essential information for operating and maintaining facility systems

- These documents ensure proper functioning, longevity, and compliance with regulations.

- Regular updates to O&M Manuals are crucial for maintaining their relevance and usefulness.

Defining Operations and Maintenance (O&M) Manuals

An O&M manual is a key document that guides the operation and upkeep of equipment and systems. It contains vital information for proper use, care, and maintenance to keep things running smoothly and safely.

Purpose of O&M Manuals

O&M manuals are essential guides for operating and maintaining a building’s systems. They help extend asset lifespans, reduce costs, and ensure consistent organizational procedures.

O&M manuals provide step-by-step instructions for routine tasks, helping prevent mistakes and improving efficiency.

This valuable resource outlines safety protocols to protect workers and equipment. It can also include electrical, fire safety, and overall equipment handling guides.

O&M manuals offer troubleshooting tips for complex systems. These tips can speed up repairs and minimize downtime. The manuals also act as training tools for new staff.

Components of O&M Manuals

A good O&M manual has several key parts:

- Equipment details and technical specs

- Operating procedures and controls, including machine operating procedures

- Maintenance schedules and checklists

- Safety guidelines and emergency procedures

- Troubleshooting guides

- Parts lists and diagrams

Effective O&M manuals provide maintenance staff with detailed guidance. They include information on proper equipment use and care, and clear instructions help avoid costly mistakes.

Maintenance schedules are essential components. They list required tasks and their frequency, which helps prevent breakdowns and extend equipment life.

Benefits of an O&M Manual

An Operation and Maintenance (O&M) manual offers numerous benefits to organizations, making it an indispensable tool for efficient facility management. Here are some key advantages:

- Improved Operational Efficiency: An O&M manual provides detailed instructions on operating and maintaining equipment, reducing the risk of human error and increasing productivity. Following these guidelines allows staff to perform tasks more effectively, ensuring smooth operations.

- Enhanced Safety Systems: Safety procedures and protocols outlined in an O&M manual help prevent accidents and ensure a safe working environment. This protects employees and minimizes the risk of costly disruptions due to safety incidents.

- Reduced Downtime: Regular maintenance and troubleshooting procedures detailed in an operational manual minimize equipment downtime. By adhering to these guidelines, maintenance personnel can quickly address issues, reducing the impact on operations and revenue.

- Increased Asset Lifespan: Proper maintenance and operation of equipment, as specified in an O&M manual, extend the lifespan of assets and reduce maintenance costs. This reduces the need for costly replacements and ensures that equipment remains in optimal condition for longer periods.

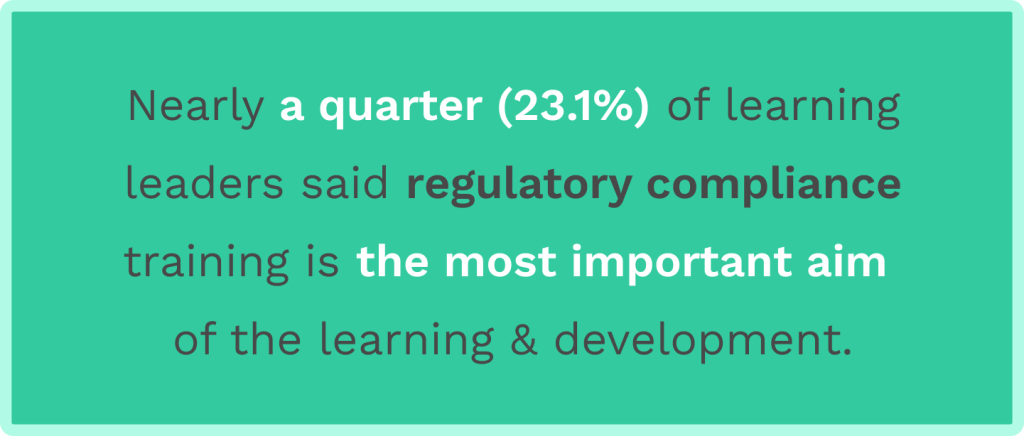

- Compliance with Regulations: An O&M manual ensures compliance with industry regulations and standards, reducing the risk of fines and penalties. Following the documented procedures, organizations can demonstrate due diligence and adherence to legal requirements.

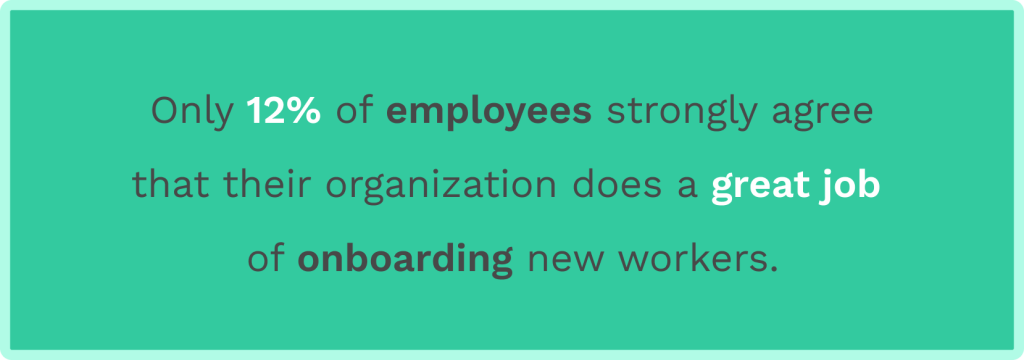

- Improved Training: An operations manual is valuable for training new employees. It provides comprehensive information on equipment operation and maintenance, including visual aids. This reduces the time and operational cost associated with onboarding and ensures that new staff are well-prepared for their roles.

Who Needs an O&M Manual?

An O&M manual is essential for various facility management and operations stakeholders. Here are the key groups that benefit from these comprehensive documents:

- Facility Managers: Responsible for overseeing the maintenance and operation of equipment. They rely on O&M manuals to ensure compliance with regulations and industry standards. These manuals provide the necessary information to manage building systems effectively.

- Maintenance Personnel: Maintenance personnel use O&M manuals to perform routine maintenance, troubleshoot issues, and repair equipment. The detailed instructions and schedules help them carry out their tasks efficiently and accurately.

- Operations Teams: Operations teams rely on O&M manuals to ensure equipment is operated correctly, reducing the risk of accidents and downtime. By following the documented procedures, they can maintain smooth and safe operations.

- Safety Officers: Safety officers use O&M manuals to ensure safety protocols and regulations compliance. These manuals help them identify potential hazards and implement measures to prevent accidents and injuries.

- Regulatory Bodies: Regulatory bodies use O&M manuals to ensure industry regulations and standards compliance. These documents prove that an organization is adhering to legal requirements and maintaining safety standards.

The Importance of O&M Manuals in Project Delivery

O&M manuals play a crucial role in successful project handovers. They ensure smooth transitions, transfer key knowledge and help meet legal requirements.

Ensuring Smooth Handover

O&M manuals are essential for smooth project handovers and are crucial resources for a facility’s maintenance team. They provide detailed instructions on operating and maintaining systems, equipment, and facilities. This information helps new owners or operators quickly understand how to run things effectively.

The manuals include:

- Step-by-step operating procedures

- Maintenance schedules

- Troubleshooting guides

- Safety protocols

These details allow a seamless transition from the construction team to the end-users. They reduce downtime and prevent costly mistakes during the initial operational phase.

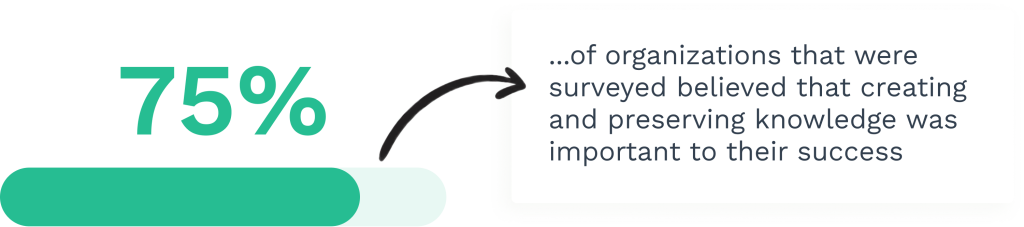

Facilitating Knowledge Transfer

O&M manuals serve as a comprehensive knowledge base. They capture the expertise of various project stakeholders, including:

- Engineers

- Contractors

- Equipment manufacturers

- Safety specialists

This collected wisdom ensures that critical information is not lost when the project team moves on. New staff can refer to the manual for guidance, reducing the learning curve and minimizing errors.

The manuals also provide a single source of truth for all operational aspects. This helps resolve disputes and keeps everyone on the same page.

Compliance and Legal Obligations

O&M manuals are often required for legal and regulatory compliance. They demonstrate that a project meets industry standards and safety requirements.

Key compliance aspects include:

- Environmental regulations

- Health and safety guidelines

- Building codes

- Warranty conditions

O&M manuals protect owners from legal issues by documenting compliance. They also serve as evidence of due diligence in audits or inspections.

Proper manuals can help secure insurance coverage and may be necessary for obtaining occupancy permits. They show that the facility is ready for safe and efficient operation.

Best Practices for Developing O&M Manuals

Creating an effective Operations and Maintenance (O&M) manual requires careful planning and execution. The following practices help ensure the manual serves its purpose well.

Inclusiveness and Detailing for Maintenance Personnel

An O&M manual should cover all equipment operation and maintenance aspects and include detailed descriptions of systems, components, and procedures.

A maintenance manual template ensures the documentation is thorough and a reliable resource for building operators and maintenance personnel.

The manual should provide step-by-step instructions for routine tasks, troubleshooting guides, and safety protocols. Diagrams, flowcharts, and photos can clarify complex information.

Including a table of contents and index makes finding specific information easier. Technical specifications, warranty details, and contact information for support should also be included.

User-Friendly Formats

The manual’s format plays a key role in its usefulness. A well-organized structure with clear headings and subheadings improves navigation.

Using plain language and avoiding jargon makes the content accessible to all users. Short paragraphs and bullet points help break up text and highlight important information.

Digital formats allow for easy updates and searchability. Interactive elements like hyperlinks and pop-up definitions can enhance the user experience.

Keeping Information Up-to-Date

Regular updates are crucial for maintaining the manual’s relevance and accuracy. A schedule for reviewing and revising the manual should be established.

Changes in equipment, procedures, or regulations must be promptly reflected in the manual. Involving multiple departments in the update process ensures comprehensive revisions.

A version control system helps track changes and ensures users have access to the most current information. It can also notify relevant staff members of updates.

Utilizing O&M Manuals for Maintenance and Operations

O&M manuals serve as vital tools for facilities teams. They guide daily tasks, help handle emergencies, and support ongoing improvements. Proper use of these manuals ensures smooth operations and extends equipment life.

Routine Maintenance Procedures

O&M manuals provide detailed instructions for regular upkeep of systems and equipment. They outline step-by-step processes for tasks like:

- Daily checks and inspections

- Weekly or monthly cleaning routines

- Scheduled part replacements

- Lubrication and calibration procedures

These guides help staff perform maintenance correctly and on time. This prevents breakdowns and extends equipment lifespan.

Manuals often include checklists and logs. These tools help track completed work and spot potential issues early. By following the manual’s procedures, teams can reduce unexpected downtime and repair costs.

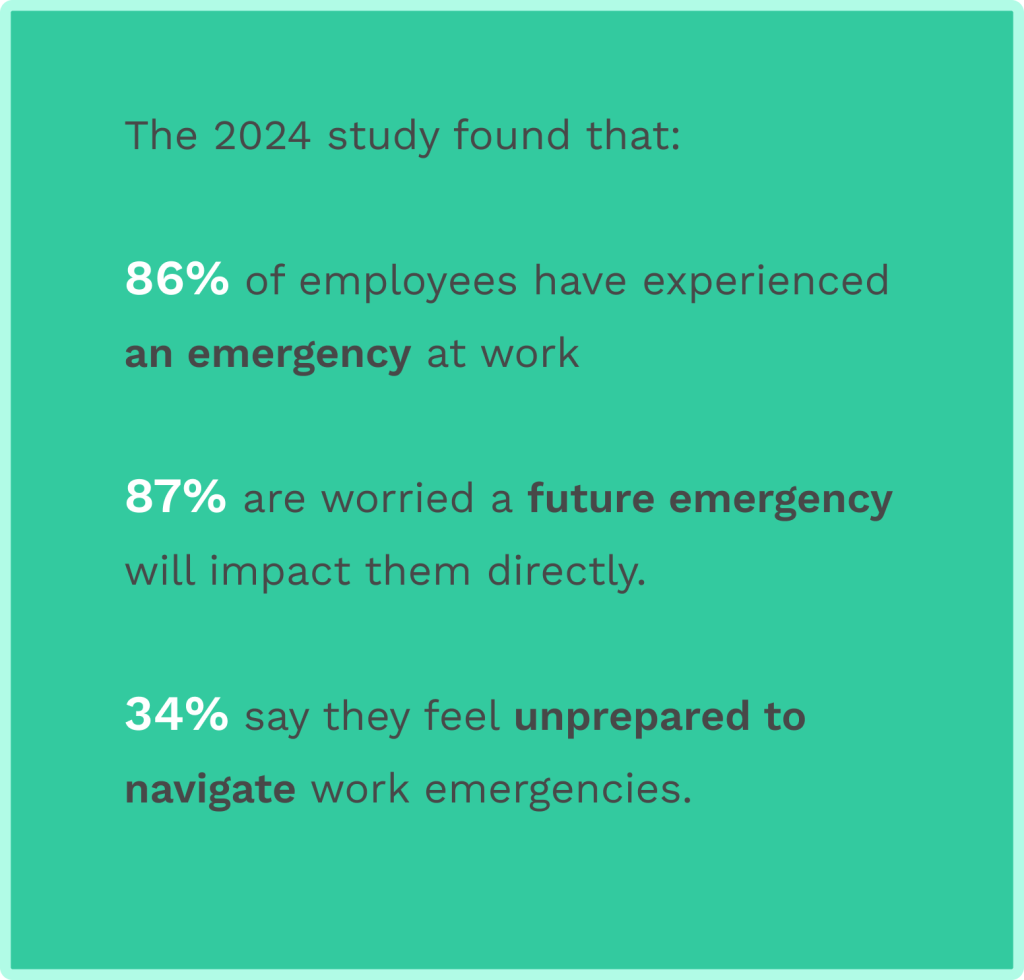

Emergency Response and Safety Procedures

O&M manuals contain crucial info for handling urgent situations. They list common emergencies and steps to address them quickly.

Key elements often include:

- Emergency shutdown procedures

- Safety information and equipment locations

- Contact lists for specialized technicians or vendors

- Detailed information, including diagrams showing critical system components

- Maintenance guidelines

- Operation instructions

- Maintenance of fire safety systems

Clear protocols help staff react swiftly and safely during crises. This can prevent injuries, limit damage, and reduce recovery time.

Manuals may also outline steps for system restarts after emergencies. This ensures a smooth return to normal operations.

Performance Monitoring and Improvements

O&M manuals support ongoing system optimization. They provide benchmarks and methods for tracking performance over time.

Important aspects include:

- Key performance indicators (KPIs) to monitor

- Acceptable ranges for various metrics

- Troubleshooting guides for common issues

- Preventive maintenance guides

Regular monitoring helps identify inefficiencies or declining performance early. This allows for timely adjustments or repairs.

Manuals may suggest upgrade paths or optimizations as systems age.

They can guide decisions on when to repair versus replace equipment. This info helps facilities teams plan budgets and improve long-term efficiency.

O&M Manuals as Living Documents

O&M manuals need regular updates to stay functional. They should reflect the latest changes and improvements in building systems and operations.

Importance of Updates and Revisions

O&M manuals must be kept up-to-date to remain valuable. As buildings and equipment change over time, the manual must also change.

Regular updates ensure staff have the correct information to operate and maintain systems safely and effectively.

This helps prevent errors and keeps the building running smoothly.

Outdated manuals can lead to mistakes, inefficiency, and even safety risks. By updating the manual, facility managers can:

- Fix errors or unclear instructions

- Add new equipment or systems

- Remove info about retired equipment

- Include improved procedures

- Define emergency protocols

- Define quality control procedures

Incorporating Feedback and Lessons Learned

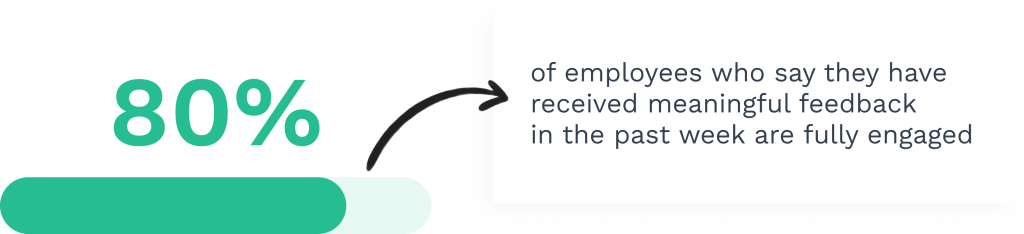

O&M manuals get better when they include real-world experience. Staff feedback and lessons from daily operations make the manual more useful.

Managers should set up a system to collect input from maintenance teams and building users. This could be through regular meetings or a simple form.

Key areas to focus on:

- Common issues faced by staff

- Suggestions for better procedures

- Notes on equipment quirks or special needs

- Safety concerns or near-misses

By adding this info to the manual, future staff can benefit from experience.

This leads to smoother operations and fewer repeated mistakes.

Regular reviews help spot trends and recurring problems. These insights can guide training, upgrades, and process improvements.

Technological Advancements in O&M Manual Management

New digital tools and smart systems are changing how O&M manuals are created and used. These innovations make manuals more useful and easier to access.

Digital Documentation

Digital O&M manuals are replacing paper versions. They can be updated quickly and accessed from anywhere, and cloud storage keeps the latest information available to all users.

Digital manuals often use searchable text, which helps workers find what they need. Some systems also let teams add notes or flag issues in the manual.

Many companies now use special software to create digital manuals. These tools can pull data from other systems and make it easy to add photos and videos.

Interactive and Smart Manuals

Modern O&M manuals are becoming interactive. They may include:

- 3D models of equipment

- Step-by-step videos for tasks

- Virtual reality training modules

Smart manuals can link to live data from machines. This helps workers see real-time info as they work.

Some manuals now use AI to suggest fixes based on symptoms. They can also learn from past issues to give better advice over time.

Mobile apps for O&M manuals let workers access information on their phones, which is handy for field work or quick checks.

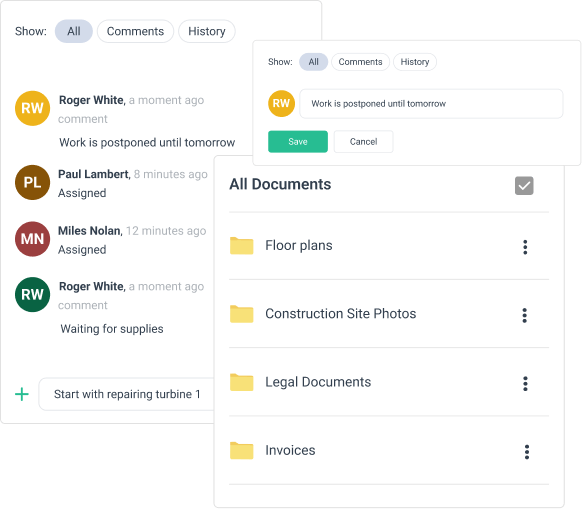

Integrating with a Connected CMMS

Integrating an O&M manual with a Computerized Maintenance Management System (CMMS) like WorkTrek offers numerous benefits, enhancing maintenance operations’ overall efficiency and effectiveness.

Here are some key advantages:

- Centralized Repository: CMMS provides a centralized repository for all O&M manuals, ensuring easy access and reducing the risk of lost or outdated documents. This centralized approach streamlines information management and improves accessibility for maintenance personnel.

- Automated Workflows: CMMS automates workflows, ensuring maintenance personnel receive notifications and assignments promptly. This reduces the risk of missed maintenance tasks and ensures all necessary activities are completed on time.

- Real-Time Updates: A connected CMMS enables real-time updates to O&M manuals, ensuring that maintenance personnel can access the most up-to-date information. This is crucial for maintaining accuracy and relevance in maintenance procedures.

- Data Analysis: CMMS provides data analysis capabilities, enabling organizations to track maintenance activities, identify trends, and optimize operations. This data-driven approach helps make informed decisions and improve overall maintenance efficiency.

- Improved Compliance: CMMS ensures compliance with industry regulations and standards, reducing the risk of fines and penalties. By maintaining accurate and up-to-date O&M manuals, organizations can demonstrate adherence to legal requirements and safety protocols.

By integrating O&M manuals with a connected CMMS, organizations can enhance their maintenance operations, improve compliance, and ensure the longevity and efficiency of their equipment and systems.

Case Studies and Examples of Effective O&M Manuals

The O&M manual for a low-carbon building demonstrates how these documents can bridge the gap between design and operation.

This case study highlights the manual’s role in maintaining energy efficiency and reducing carbon emissions.

A manufacturing plant implemented interactive checklists in their O&M manual. These checklists were integrated into work orders, ensuring precise task execution and improving maintenance efficiency.

A hospital used a cloud-based platform to create and manage its O&M manual. This approach allowed for real-time updates and easy access for staff, leading to better equipment upkeep and reduced downtime.

An office building’s O&M manual included detailed energy management procedures.

This resulted in a 15% reduction in energy consumption over two years.

A water treatment plant’s O&M manual featured:

- Clear equipment diagrams

- Step-by-step maintenance guides

- Troubleshooting flowcharts

These elements led to faster issue resolution and improved plant performance.

A school district’s O&M manual incorporated QR codes linking to instructional videos.

This innovative approach improved staff training and reduced maintenance errors by 30%.

Challenges and Pitfalls in O&M Manual Preparation

Creating a practical O&M manual can be tricky. Common issues include missing key information and making the content difficult to use. However, there are ways to avoid these problems and create a better manual.

Common Mistakes and Overlooked Aspects

Many O&M manuals lack clear instructions, which can confuse users. Some manuals also miss essential details about equipment maintenance.

Another issue is outdated information. The manual also needs updating as systems change, but this step is often forgotten.

Poor organization is a frequent problem. The manual loses value if users can’t quickly find what they need.

Some manuals use too much technical language. This makes it hard for all staff to understand.

Ignoring user feedback is a big mistake. The people using the manual daily often have the best input for improvements.dugita

Mitigating Risks in O&M Manual Creation

To avoid mistakes, start with a clear plan. Outline what the manual needs to cover before writing begins.

Use a team approach. Get input from engineers, operators, and maintenance staff to ensure that all important information is included.

Regular reviews are key. Set up a schedule to check and update the manual, keeping the content current and useful.

Make the manual easy to use. Use clear headings, tables, and diagrams. A good layout helps users find information quickly.

Test the manual with actual users. Their feedback can point out areas that need improvement.

Consider using digital formats. Electronic manuals can be easier to update and search than paper versions.

Summary

An Operations and Maintenance (O&M) Manual is a critical document for facility management that provides comprehensive guidance on operating and maintaining building systems and equipment.

These manuals are essential resources for facility managers, maintenance personnel, operations teams, and safety officers. They contain detailed instructions, diagrams, and schedules for proper facility operation.

The key benefits of O&M manuals include improved operational efficiency, enhanced safety systems, reduced downtime, increased asset lifespan, regulatory compliance, and better staff training.

They play a crucial role in project handovers by ensuring smooth transitions and knowledge transfer.

Best practices for developing O&M manuals include maintaining comprehensive detail, using user-friendly formats, and keeping information current. Modern O&M manuals are increasingly digital, featuring interactive elements and integration with Computerized Maintenance Management Systems (CMMS).

Regular updates are essential to reflect changes in equipment, procedures, or regulations, making them effective “living documents” that evolve with the facility’s needs.