Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- 43% of companies struggle to recruit maintenance staff.

- Preventive maintenance costs 2-5 times less than reactive maintenance.

- CMMS solutions improve visibility, reduce downtime, and strengthen communication.

By now, most companies understand the value of an effective preventive maintenance (PM) program.

They recognize that it can deliver significant cost savings, improve operational efficiency, and reduce unplanned downtime, ultimately enhancing customer experience and brand reputation.

Yet despite these benefits, many organizations still struggle to implement preventive maintenance effectively, whether due to limited knowledge, inadequate tools, or poorly defined processes.

This is where Planned Maintenance Optimization (PMO) comes in.

PMO is designed to improve your existing PM programs by leveraging asset failure history and current maintenance workflows.

Compared to more resource-intensive methodologies such as Reliability-Centered Maintenance (RCM), PMO requires less time to develop while still delivering measurable, high-impact results.

Read on to learn more.

What is Planned Maintenance Optimization

In the simplest terms, planned maintenance optimization is a structured framework for improving your existing maintenance program.

It analyzes asset failure history along with current workflows and routines to determine which tasks to eliminate, what to improve, and what’s already working well.

The ultimate goal is to strike the right balance between over-maintaining, which wastes time and resources, and under-maintaining, which increases the risk of unexpected failures.

It’s all about doing the right maintenance at the right time.

While improving operational efficiency and extending equipment lifespan are always core objectives of PMO, there are several approaches used to achieve them:

| Judgment-based PMO | Leverages the deep experience of frontline technicians, combined with operational data and asset criticality, to refine maintenance tasks and schedules |

| Reliability-centered maintenance–derived PMO | Applies core RCM principles, such as failure modes and effects analysis, but focuses only on the most critical assets or the most common failure types |

| Failure Reporting, Analysis, and Corrective Action System (FRACAS) | Requires teams to report and analyze every failure to identify root causes, then use those insights to create or modify preventive maintenance tasks |

In practice, the most effective PMO programs integrate all three methods, combining RCM principles, FRACAS data, and the practical knowledge of experienced personnel.

Benefits of Planned Maintenance Optimization

When all these elements come together, the PMO program starts unlocking significant value.

Let’s go over some of its benefits.

Improved Maintenance Efficiency

With PMO, maintenance work is completed faster, with fewer errors, less rework, and more efficient use of labor and materials.

This is because PMO moves organizations away from reactive or rigid time-based maintenance and instead prioritizes work based on asset criticality, condition, and failure history.

India Gibson, Launch Leader at Schneider Electric, a French multinational specializing in digital automation and energy management, explains why that matters:

“Rather than spending time and money and having downtime to do a reactive approach or check the box on a typical maintenance protocol, we can respond quicker to changes that require immediate attention.”

The biggest issue with traditional methods is that they fail to reflect how equipment performs in real-world conditions.

Time-based maintenance often leads to over-servicing assets that are still operating well, wasting labor and resources.

Reactive maintenance, on the other hand, allows early warning signs to go unnoticed, resulting in unplanned downtime and rushed repairs.

Conversely, PMO directs your focus and effort where they’re needed most, preventing disruptions while keeping assets in optimal condition without unnecessary waste.

As a result, work quality improves, repeat failures decline, and maintenance teams can manage more assets using the same resources.

It’s a much smarter way of working.

And for many maintenance teams today, working smarter is the only path forward.

A recent ABB survey found that 43% of companies struggle to recruit maintenance staff, as experienced workers retire and fewer young professionals enter the field.

On top of that, maintenance work is becoming more complex, material and tool costs continue to rise, and budgets seem to only be shrinking.

In other words, the pressure is high, and there’s little room for error.

PMO provides modern maintenance teams with a solution that allows them to maximize their existing resources, reduce operational disruptions, and maintain reliability without burning out the workforce.

Increased Asset Uptime

PMO also tackles the biggest enemy of any asset-heavy operation: unplanned downtime.

It does this by analyzing each asset and identifying which potential failures have the greatest impact on uptime.

This enables you to focus resources where disruptions would be most severe and harmful to the operation.

Typically, Failure Modes and Effects Analysis (FMEA) is used for this kind of evaluation.

Below is an example of an FMEA worksheet with its core terms, giving you a clearer idea of how the method works:

| Item | A broken asset in question |

|---|---|

| Potential failure mode | The specific manner or way by which a failure could occur |

| Potential cause | The underlying cause or sequence of causes that lead to a failure mode |

| Local effects of failure | The failure consequences as it applies to the item under analysis. |

| Next higher level effect | The failure effect as it applies at the next higher indenture level. |

| Probability | The likelihood of the failure occurring. |

| Severity | The consequences of a failure mode. Severity considers the worst potential consequence of a failure |

| Detection | The means of detection of the failure mode by the maintainer |

| Risk level | Severity (of the event) × probability (of the event occurring) × detection (probability that the event would not be detected before the user was aware of it) |

| Mitigation | Proposed mitigation or actions used to lower a risk or justify a risk level or scenario |

As you can see, FMEA involves a detailed analysis of components, assemblies, and subsystems to identify possible failure modes, their causes, and their effects.

It may seem slightly complex, but it’s highly effective.

The method clearly highlights where the greatest risks lie, so you can be confident your decisions are data-driven and not based on guesswork.

Now, this isn’t to say that PMO neglects less-critical assets.

Instead, it applies the most appropriate maintenance strategy to each, based on risk, failure type, and cost.

For example:

| Reactive Maintenance | For low-cost, non-critical assets where downtime is acceptable (e.g., lightbulbs, garden tools) |

| Time-Based Maintenance | For assets with predictable wear patterns (e.g., HVAC filters, vehicle oil changes) |

| Usage-Based Maintenance | For assets with variable workloads (e.g., forklifts, production robots) |

| Condition-Based Maintenance | For high-value or complex assets where monitoring is feasible (e.g., turbines, elevators) |

Ultimately, when each asset receives the care it needs, when it needs it, the risk of unplanned stoppages drops significantly.

According to the businesses surveyed by Cheqroom, this is the key to high productivity, improved reputation, and increased customer satisfaction.

That’s why PMO is so valuable.

It ensures assets are maintained proactively, available when needed, and perform reliably, helping companies meet their production goals.

Reduced Maintenance Costs

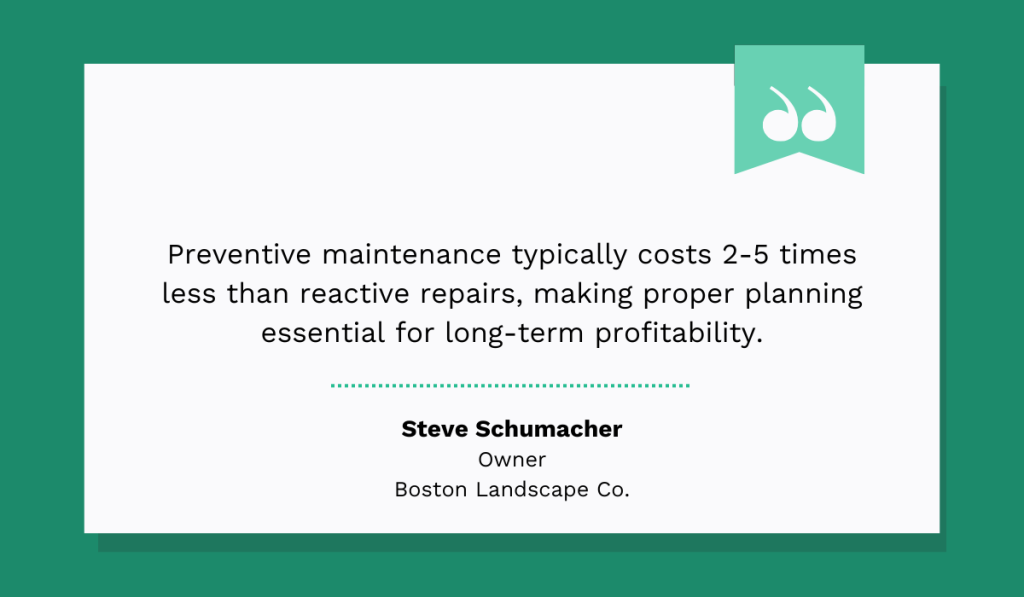

When maintenance is efficient, strategic, and data-driven, cost savings follow naturally.

The biggest benefit of PMO is that it puts proactive maintenance front and center.

This ensures maintenance is performed regularly and consistently, enabling you to detect early signs of degradation and intervene before costly emergency repairs or complete asset replacement occur.

This alone can lead to significant cost reductions.

Steve Schumacher, Owner of Boston Landscape Co., agrees:

However, we’ve already noted that PMO goes beyond simply following a rigid maintenance schedule.

In other words, it doesn’t mandate maintenance at fixed intervals without paying attention to an asset’s condition.

Instead, it leverages historical data and reliability models to determine the optimal timing for each task, ensuring maintenance is performed only when needed, thus avoiding wasted labor, parts, and downtime.

In the end, there is such a thing as too much maintenance, and it can be just as costly as too little.

Tien Ha, Associate Expert at Hanwha Corporation, a major South Korean conglomerate spanning industries from explosives and energy to aerospace and finance, warns:

PMO helps you avoid both extremes.

It customizes maintenance schedules to each asset’s unique needs, maximizing reliability while preventing overspending on unnecessary work or spare parts.

The result: well-maintained assets, smoother operations, and, ultimately, lower costs.

Planned Maintenance Optimization Best Practices

To unlock the above-mentioned advantages, follow these best practices.

They’ll ensure you identify any mistakes in your program early and implement PMO without additional stress on your team.

Reduce Reactive Maintenance

Although some reactive maintenance is inevitable in any upkeep strategy, your goal should be to reduce it as much as possible if you want your PMO program to succeed.

Reactive maintenance is often the most expensive and least efficient type of upkeep, frequently causing downtime, secondary damage, and unnecessary costs.

Don’t risk it.

Reduce reactive work and improve asset reliability, labor efficiency, safety, and budget predictability through a more proactive approach.

Anna Waters, Director of Asset Management at EDP Renewables, a company that develops and operates wind farms, solar parks, and more, perfectly summarizes the value of preventive maintenance:

Before you start cutting reactive maintenance in favor of preventive measures, you need to decide exactly how much you need to cut.

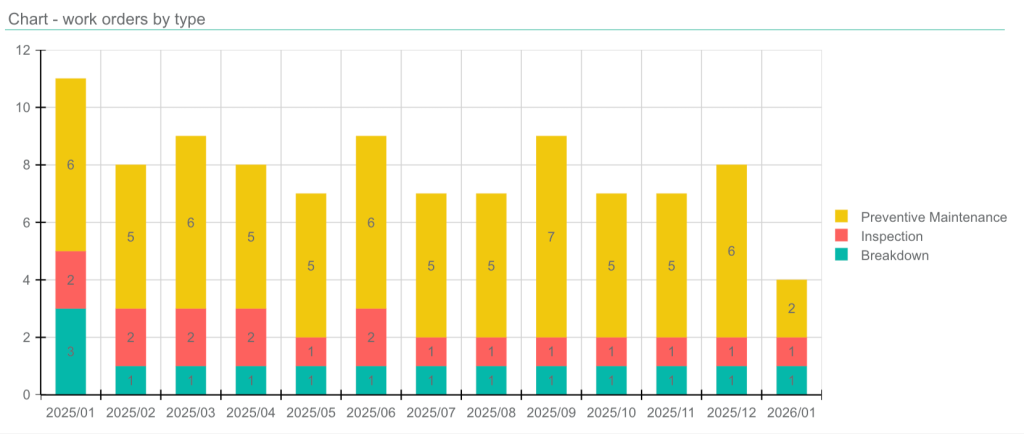

Start by tracking the percentage of reactive versus planned work.

You’ll find the data needed for your calculations in your maintenance log, where you can see total hours spent on each type of activity.

Digital maintenance management systems go a step further, often automatically calculating these percentages for you, like so:

Once you understand the current state of your operations, you can work with the entire maintenance team to set a realistic target for minimizing reactive work, expressed as a percentage.

Defining your goal clearly and numerically not only keeps the team focused but also makes it easy to track progress month over month to ensure you’re on the right path.

Measure the Effectiveness of the Program

You can’t truly know whether your PMO program is delivering real value if you aren’t actively tracking its progress and outcomes.

Without objective measurement, results become subjective and anecdotal rather than grounded in reality.

This ultimately renders the entire effort ineffective, especially in the eyes of senior leadership, who are primarily interested in concrete benefits and measurable results.

When you diligently monitor your program’s progress, on the other hand, there’s no room for opinions or guesswork.

If the program is working, it becomes clear how and where it’s delivering value.

And if it isn’t, the data quickly shows where to focus your efforts to course-correct.

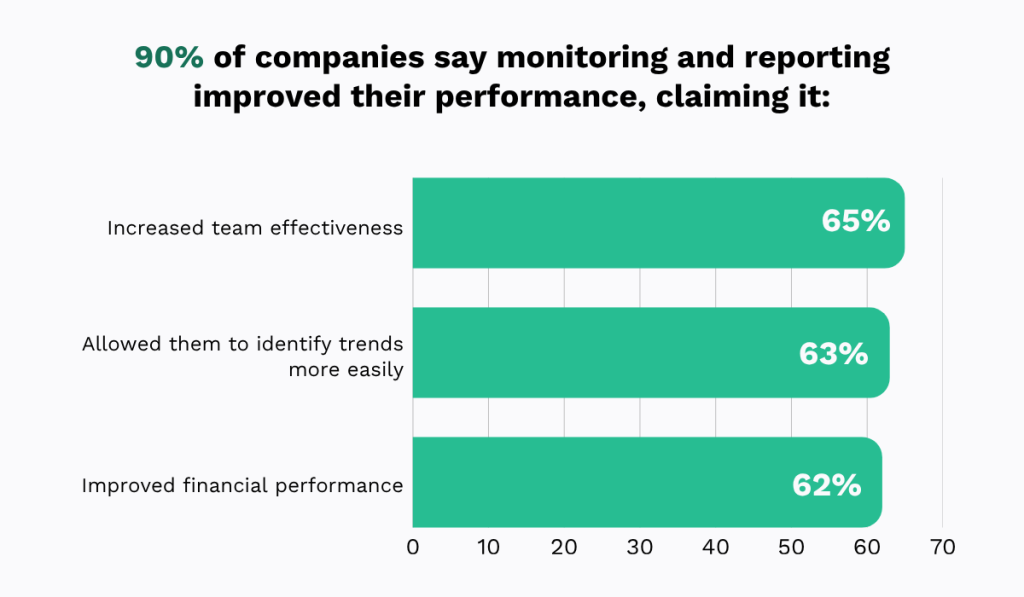

This is supported by a 2023 Databox survey, which found that the majority of companies report improved performance through consistent monitoring and reporting.

“What gets measured, gets improved” may be an overused phrase, but it endures for a reason.

When launching your PMO program, ensure you also define clear, easy-to-measure KPIs that allow you to track progress effectively.

Start with a small, but relevant set of metrics. This should provide meaningful insight without overwhelming your team.

Consider including some of the following:

| Percentage of Subjective Tasks | The proportion of tasks performed without clearly defined standards. A high percentage signals the need for better task definition and standardization. |

| Percentage of Condition Monitoring | The share of maintenance activities based on monitoring techniques such as vibration analysis or oil analysis. A higher percentage reflects a shift toward proactive, advanced maintenance practices. |

| Unplanned Downtime Hours | The total hours of unexpected equipment downtime. A reduction in this metric indicates that PMO efforts are effectively improving equipment reliability. |

| Manpower Hours Required | The total labor hours spent on maintenance activities. Tracking this helps ensure work is optimized and resources are focused on value-added tasks. |

Over time, you can refine these KPIs or introduce new ones as your program matures.

It’s only natural that your PMO objectives and needs change over time. Just make sure your KPIs reflect that.

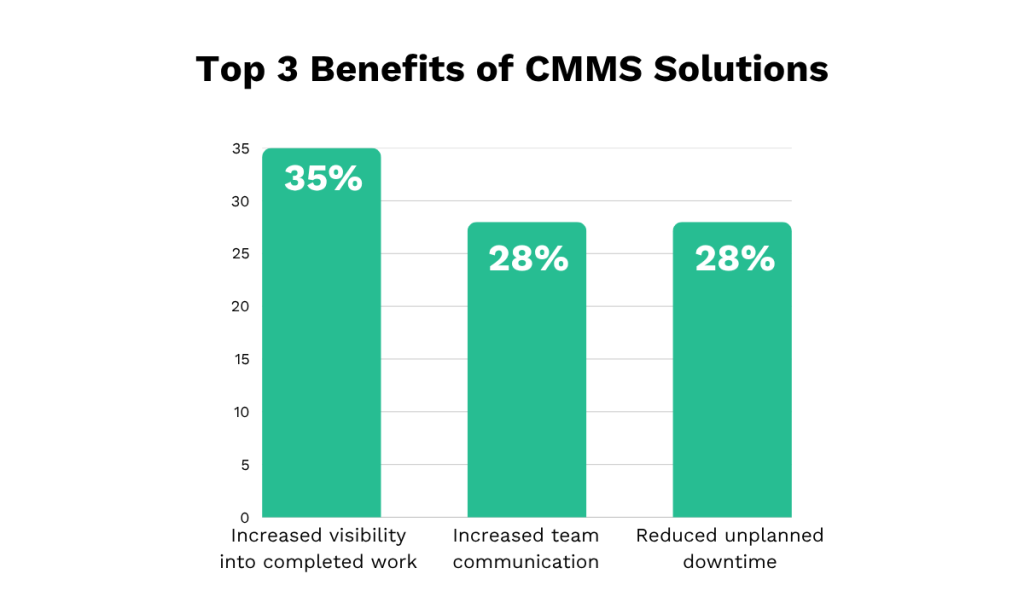

Use CMMS

A PMO relies on accurate data, repeatable processes, and continuous improvement, all of which a CMMS directly enables.

These systems serve as central hubs for all maintenance-related tasks, from work orders and spare parts to PM schedules and asset profiles.

It’s no surprise, then, that research shows CMMS platforms deliver significant improvements, including better visibility into completed work, reduced unplanned downtime, and stronger team communication.

When you have clear insight and control over every aspect of your operations, it becomes much easier to identify inefficiencies and determine the best course of action for optimization.

Our CMMS, WorkTrek, was built with this exact philosophy in mind: better visibility, better control, and better outcomes.

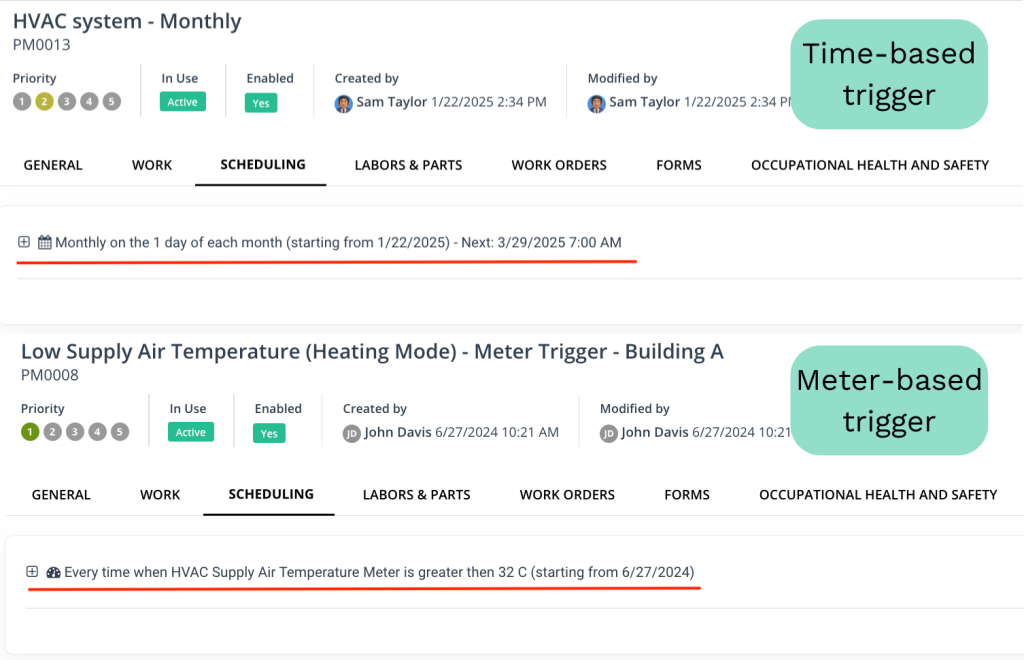

Our PM scheduling feature, for example, helps standardize and control PM execution by allowing you to create recurring maintenance work orders based on different trigger types.

You can define planned durations, set end rules, assign work to specific personnel, and include all relevant details, such as instructions, descriptions, hazard warnings, and task reminders.

This ensures planned work is never overlooked and is performed consistently every time, thereby eliminating unnecessary rework or errors.

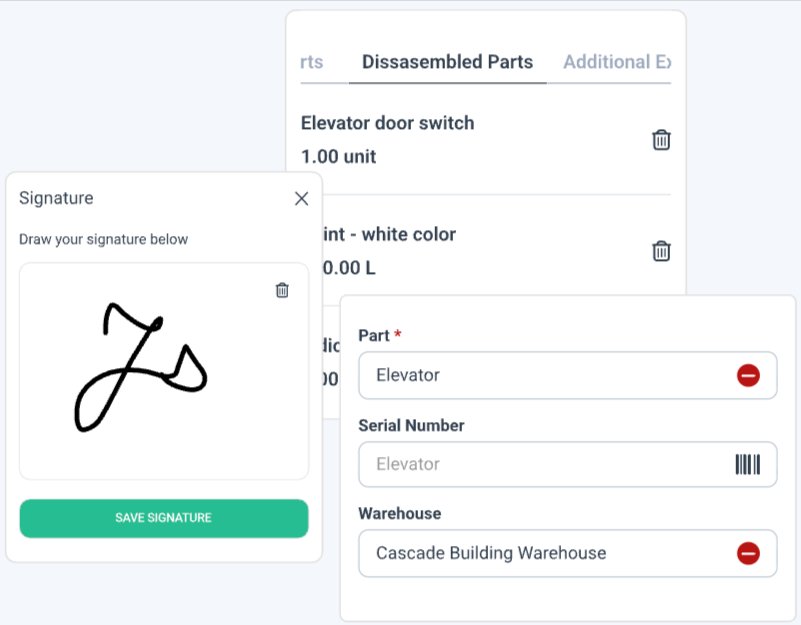

Once the work is completed, technicians can capture signatures, upload photos, log labor hours, record spare parts used, and close out work orders directly from their mobile devices.

All of this data is stored in the system and can later be analyzed to measure the effectiveness of your program.

WorkTrek takes care of this part of the process, too.

Its reporting capabilities include more than 50 pre-built reports and over 20 pre-built KPIs, enabling you to monitor your entire maintenance operation and pinpoint areas for improvement.

For instance, you may track planned vs actual maintenance expenses, reactive vs preventive work, overdue WOs, and so much more.

The bottom line is this: a CMMS like WorkTrek provides the structure, data, and control required to design, execute, measure, and continuously improve your PMO.

Attempting to implement a PMO program without a tool like this would be a significant missed opportunity.

Conclusion

In the end, the most important thing to know about PMO is that it relies heavily on data.

You need a clear picture of your failure histories, current workflows, routines, and the details of each asset, to analyze and compare.

What does this mean for you right now?

If you decide to move forward with this program, the first step is to evaluate your data.

Review your logs for accuracy, completeness, and consistency, and ask yourself whether they tell the whole story.

Only once you’re confident in your data will you have a solid foundation for a successful PMO implementation.