Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeWhat is System FMEA (SFMEA)? It is a key tool for improving product and system reliability. It helps teams find and fix problems before they cause issues.

In short, System Failure Mode and Effects Analysis (SFMEA) is a systematic approach to evaluating potential failures within a system, understanding their impacts, and prioritizing actions to mitigate these risks.

Illustration: WorkTrek / Data: TWI

SFMEA takes a holistic view and examines how different system parts work together. It checks for ways the system might fail and what could happen if it does. This systematic approach helps make products and processes safer and more reliable.

Companies use SFMEA to catch problems early. Fixing issues before they become big problems saves time and money. SFMEA is helpful in many fields, such as car making, healthcare, and software design. It helps teams build better, safer products that customers can trust.

Understanding SFMEA

System Failure Mode and Effects Analysis (SFMEA) is a powerful tool for improving system reliability. It helps identify and prevent potential failures before they occur, enhancing safety and performance across industries.

Definition and Importance

As described above, SFMEA can help evaluate and reduce potential system failures. It examines how these failures impact the system and prioritizes actions to minimize risks. The main goal of SFMEA is to boost system reliability, safety, and performance—something all maintenance managers want.

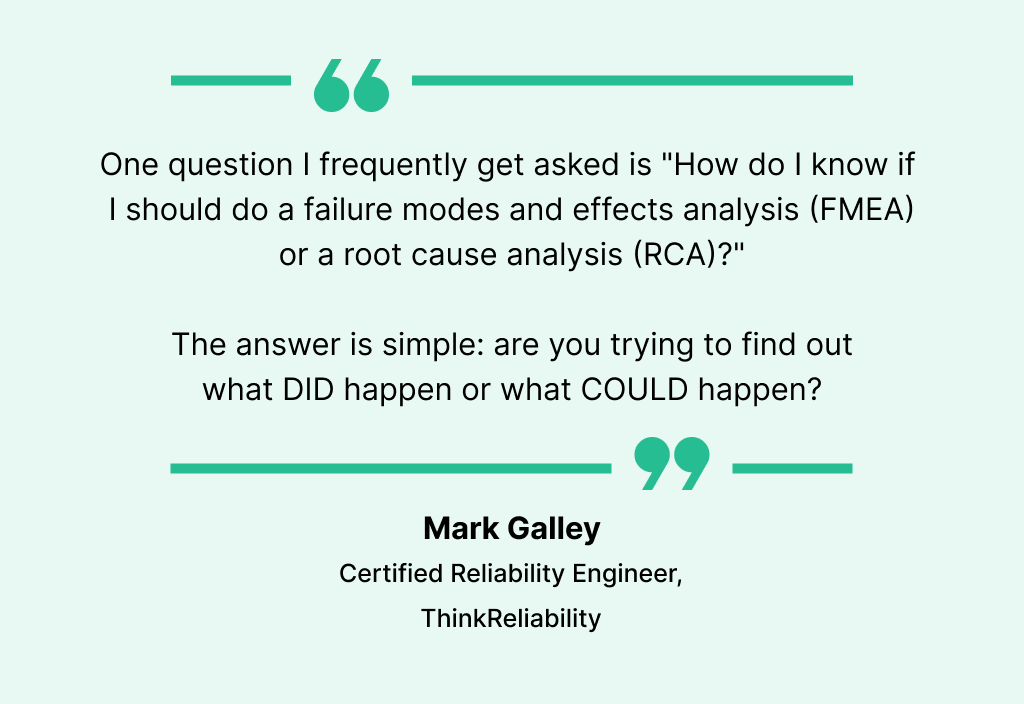

Illustration: WorkTrek / Quote: ThinkReliability

This technique is useful for complex systems where failures can have serious consequences. It allows teams to spot weak points early in the design process, allowing them to make changes before problems arise in real-world use.

SFMEA helps companies save time and money. It reduces the need for costly fixes after a product is released and improves customer satisfaction by delivering more reliable products.

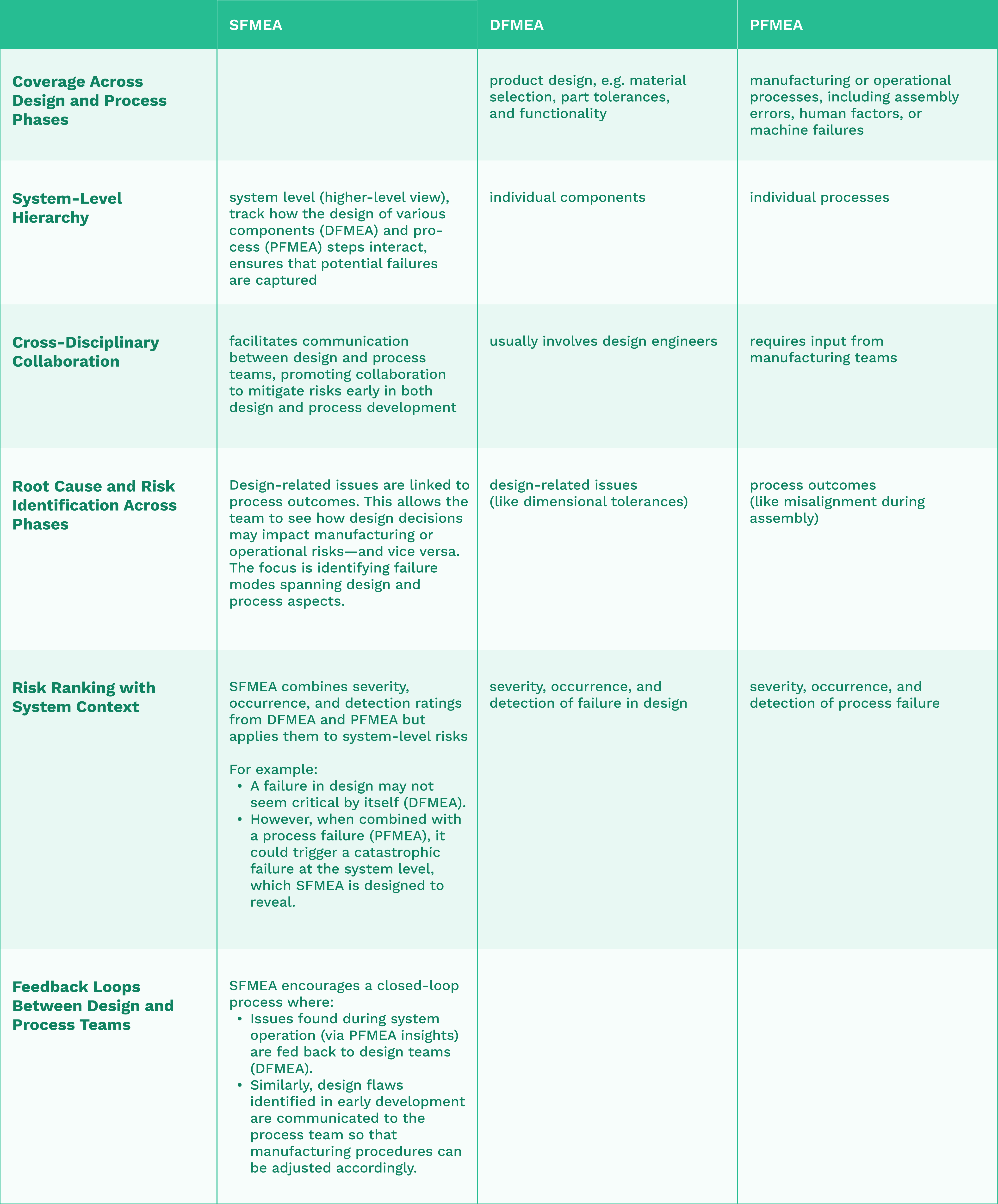

Comparison with DFMEA and PFMEA

SFMEA is part of a family of failure analysis techniques. It works alongside Design FMEA (DFMEA) and Process FMEA (PFMEA). Each type focuses on different aspects of product development.

- SFMEA: Looks at the entire system and how parts interact

- DFMEA: Focuses on product design

- PFMEA: Examines manufacturing processes

SFMEA takes a broader view than DFMEA or PFMEA. It considers how failures in one part might affect others, making it ideal for complex systems with many components.

SFMEA often combines elements of DFMEA and PFMEA, creating a more complete picture of potential risks across the system.

Source: WorkTrek

Scope and Applications

SFMEA is used in many industries. It’s valuable in fields where system failures can be dangerous or costly. Some key areas include:

- Automotive: Ensuring the safety and reliability of vehicle systems

- Healthcare: Improving patient safety in medical devices and procedures

- Manufacturing: Enhancing production line efficiency and product quality

- Aerospace: Ensuring the safety and performance of aircraft systems

The scope of SFMEA covers the entire system and its interfaces with other systems. It looks at how different parts work together and what might go wrong.

SFMEA is often used early in product development. This allows teams to catch and fix issues before they become expensive problems. It’s also helpful in improving existing systems and processes.

Executing SFMEA

Executing System Failure Mode and Effects Analysis (SFMEA) involves a structured approach to identify and address potential system failures. This process boosts system reliability and safety through careful risk assessment and mitigation strategies.

Cross-Functional Teams

SFMEA requires a cross-functional team to analyze system failures effectively and to reduce process failure modes. These teams bring together experts from various disciplines, including engineering, quality control, and operations.

The team’s diverse knowledge helps spot potential issues a single department might miss. Members collaborate to identify failure modes, their effects, and possible causes.

This multidisciplinary approach ensures a thorough examination of the system from different angles. It leads to more robust solutions and a deeper understanding of system interactions.

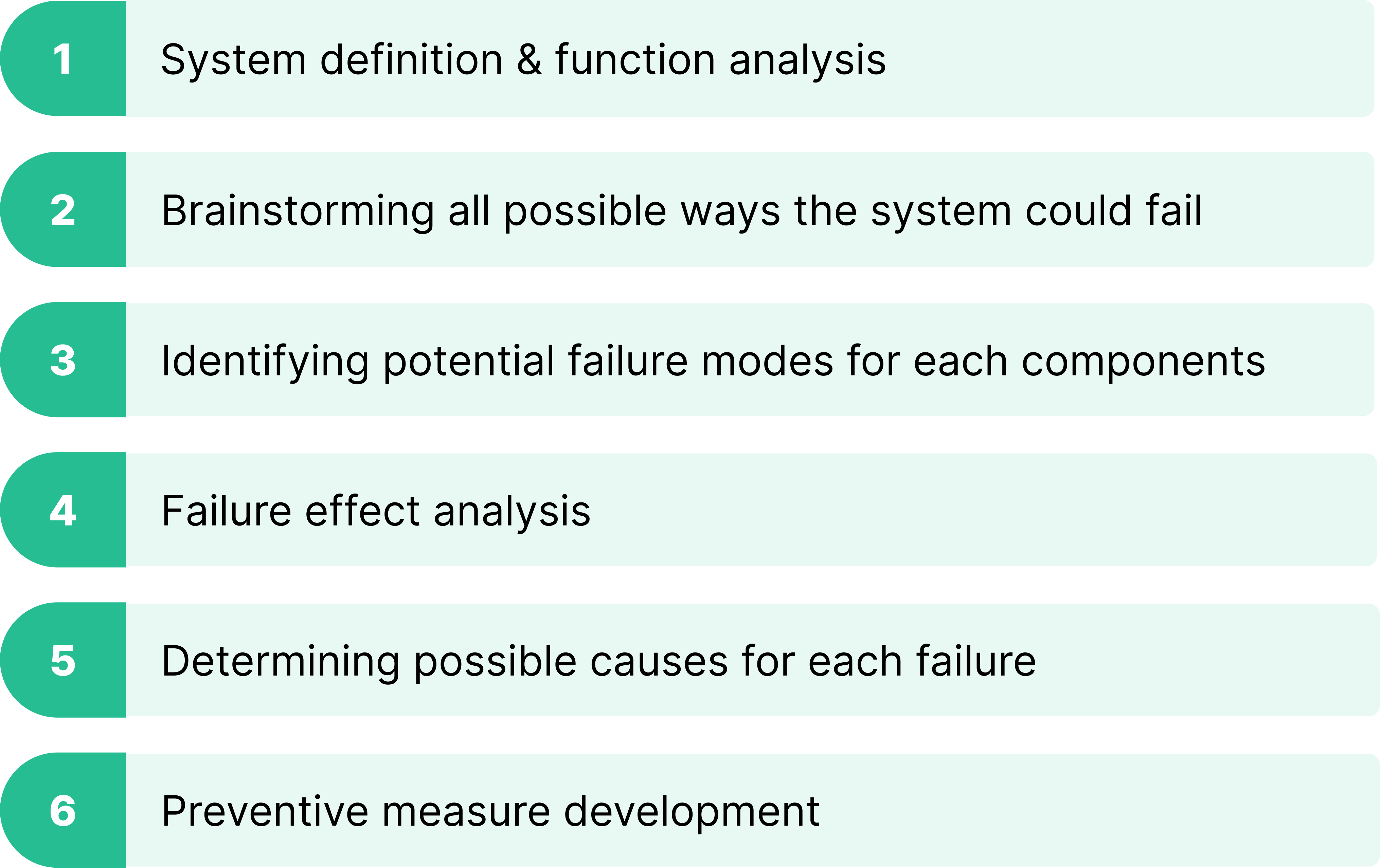

Stages of SFMEA

Source: WorkTrek

The SFMEA process unfolds in several key stages. It starts with system definition and function analysis, where the team outlines the system’s components and their intended purposes.

Next, they identify potential failure modes for each component. This step involves brainstorming all possible ways the system could fail.

The team then analyzes these failures’ effects, considering immediate and long-term impacts on system performance and safety.

After that, they determine possible causes for each failure mode. This helps in developing preventive measures.

Risk Assessment

Risk assessment is a crucial part of SFMEA. The team evaluates each failure mode based on three factors:

- Severity: How serious are the consequences?

- Occurrence: How likely is the failure to happen?

- Detection: How easily can the failure be detected?

These factors are rated on a scale, typically from 1 to 10.

The product of these ratings gives the Risk Priority Number (RPN).

High RPN values indicate critical areas needing immediate attention. The team then develops action plans to reduce potential failures. This might involve design changes, additional controls, or improved detection methods.

Regular reviews ensure the effectiveness of these measures. The team updates the SFMEA as the system evolves or new information becomes available.

Analysis Outcomes

SFMEA produces key insights to improve system reliability and safety. It examines failure effects, identifies root causes, and develops targeted mitigation strategies.

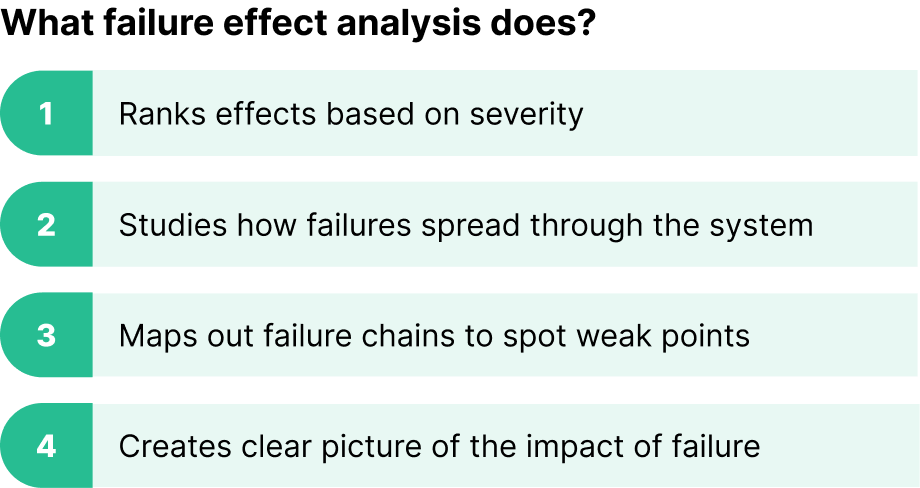

Failure Effect Analysis

Source: WorkTrek

Failure effect analysis examines how system failures impact performance and safety. It ranks effects based on severity. Critical failures that could harm users or damage equipment are prioritized.

Teams study how failures spread through the system. They map out failure chains to spot weak points. This helps catch problems early before they grow.

Potential failure effects are rated on a scale. Minor issues may only cause slight inconvenience, while major failures could lead to system shutdown or safety hazards.

The analysis creates a clear picture of the impact of failure. This guides where to focus improvement efforts.

Root Cause Analysis

Root cause analysis digs deep to find the source of failures. It asks why problems happen and digs until it considers the core issue.

Teams use tools like fishbone diagrams to map out possible causes. They look at design flaws, part defects, and human error.

Testing and data help confirm true root causes. This prevents time from being wasted on surface-level fixes that don’t solve the real problem.

Identifying failure modes is a key step. These are the specific ways a system can fail. Examples include parts wearing out, software bugs, or electrical shorts.

Understanding the root causes points to the most effective solutions.

Risk Mitigation Strategies

Risk mitigation strategies aim to prevent failures or reduce their impact. Teams develop plans to address the highest-risk issues first.

Common approaches include:

- Redesigning weak components

- Adding backup systems

- Improving quality control

- Enhancing user training

Corrective actions are specific steps to fix problems. These might involve changing materials, updating software, or revising procedures.

Proactive measures help catch issues early. Examples include adding sensors to detect wear or scheduling more frequent inspections.

Teams track the effectiveness of strategies and adjust plans based on real-world results to improve system reliability over time.

Implementing SFMEA Findings

Putting SFMEA results into action helps boost product quality and system reliability. Companies use specific steps to turn insights into tangible improvements.

Corrective Actions Execution

Source: WorkTrek

Organizations swiftly fix issues in SFMEA. They make a list of the top problems and create fixes for each one. Teams set clear goals and deadlines for these fixes.

Managers assign tasks to skilled workers. They track progress closely using charts or software, and regular check-ins help keep work on track.

Some fixes may require new tools or methods. Companies invest in training to help staff use these new approaches, and they also update work instructions to reflect changes.

As fixes roll out, teams test to ensure their effectiveness. They look at data to see if failures decrease. If a fix doesn’t help, they try a new solution.

Improving Product Quality

SFMEA findings lead to better products. Teams use the data to spot weak points in design or production and make targeted upgrades.

Engineers may redesign parts to be stronger or easier to make, which can reduce defects. Based on SFMEA results, production lines might receive new quality checks.

Companies often create new test plans. These focus on areas where SFMEA showed high risk. More thorough testing catches issues before products ship.

Staff training also gets an update. Workers learn about common failure modes and how to spot them, which helps prevent problems early in the process.

Tracking quality metrics helps show if changes work. Teams look at things like defect rates and customer feedback. Good results can mean fewer warranty claims and recalls.

Enhancing System Reliability and reducing failure mode

SFMEA helps make systems more dependable. Teams use the analysis to find weak links in system design. They then work to strengthen these areas.

Engineers might add backup systems for critical parts, which prevent total failure if one part breaks. They also examine how different parts work together. Sometimes, small changes can make big improvements in reliability.

Maintenance plans get updated based on SFMEA. Teams focus more on parts likely to fail, setting up checks and replacing parts before they break.

Companies often invest in better monitoring tools. These tools help catch problems early, allowing staff to fix issues before they cause system shutdowns.

Reliability engineering teams use SFMEA data to set new goals. They track system uptime and failure rates. As reliability improves, happier customers and lower costs follow.

SFMEA in Various Industries

System FMEA (SFMEA) is a powerful risk management technique used in various sectors. It helps identify potential system failures and their impacts. Cross-functional teams in various industries use SFMEA to improve product quality and safety.

Automotive Industry

The automotive sector widely uses SFMEA to enhance vehicle safety and reliability. Car makers apply this method to complex systems like braking, steering, and electrical components.

SFMEA helps spot potential issues in new car designs before production starts. By catching problems early, this saves time and money, and it also helps meet strict safety regulations.

For example, an SFMEA might look at a car’s anti-lock braking system. The team would list possible failures, their effects, and ways to prevent them. This could lead to design changes that make the brakes safer and more dependable.

Medical and Healthcare

In healthcare, SFMEA is important for patient safety. It analyzes medical devices, hospital processes, and treatment plans.

Illustration: WorkTrek / Quote: National Library of Medicine

Medical device makers use SFMEA to find risks in new products. This helps create safer devices for patients and doctors, and hospitals use it to improve patient care processes.

An SFMEA for an infusion pump might examine risks like incorrect dosing or power failures. The team would then devise ways to prevent these issues or reduce their impact.

Manufacturing Sector

The manufacturing industry uses SFMEA to improve product quality and reduce waste. It’s applied to production lines, equipment, and entire factories.

Illustration: WorkTrek / Quote: Coast

SFMEA helps manufacturers spot potential problems in their processes. This leads to fewer defects, less downtime, and better products.

For instance, a food processing plant might use SFMEA to analyze its canning line. The team would look at risks like contamination or improper sealing and create steps to prevent these issues, ensuring food safety and quality.

Integration with Quality Frameworks

System FMEA integrates seamlessly with established quality management approaches. It enhances product design and lifecycle processes through systematic risk analysis and prevention.

Six Sigma and Lean

System FMEA aligns well with Six Sigma and Lean methodologies. In Six Sigma, SFMEA supports the Define and Measure phases by identifying potential failure modes early. It helps teams focus on critical quality characteristics.

Lean principles benefit from SFMEA’s waste reduction potential. Catching issues before production minimizes rework and scrap, supporting the Lean goal of streamlining processes.

Teams often use SFMEA alongside other Six Sigma tools, such as control charts and process capability studies. This combination provides a comprehensive approach to quality improvement.

Continuous Improvement

SFMEA plays a key role in continuous improvement efforts. It provides a structured method for evaluating and enhancing systems over time.

Organizations use SFMEA results to track improvements in system reliability. They can measure the reduction in high-risk failure modes as changes are implemented.

Regular SFMEA reviews keep quality efforts focused on the most critical areas. This aligns with the Plan-Do-Check-Act cycle standard in many quality frameworks.

Illustration: WorkTrek / Quote: British AssessementBureau

SFMEA also supports knowledge sharing across teams and projects. Lessons learned from one analysis can inform future designs and processes.

Summary

System FMEA (SFMEA) is a key tool for improving product and system reliability. It helps teams find and fix problems early in the design process.

SFMEA looks at how different parts of a system work together. It checks for ways the system could fail and what might happen if it does.

The main steps of SFMEA are:

- List system functions

- Find possible failure modes

- Note the effects of each failure

- Rate how severe each failure would be

- Figure out what could cause each failure

- Rate how likely each failure is

- List current controls

- Rate how easy it is to detect each failure

- Calculate risk priority numbers

- Make plans to reduce high risks

SFMEA helps teams focus on the most critical risks. It creates a clear record of potential issues and solutions.

Using SFMEA can lead to safer, more reliable products and reduce costly fixes later in development. SFMEA is widely used in many fields, such as auto, aerospace, and medical devices.

By using SFMEA, companies can boost quality and customer satisfaction. It’s a vital part of good system design and risk management.