Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeWhat situations are ideal for breakdown maintenance? Breakdown maintenance involves fixing equipment only after it fails. This approach can work well for non-critical systems where downtime isn’t a major issue.

A breakdown maintenance strategy is best used for low-priority assets that don’t significantly impact business operations if they stop working.

Companies often use this method for simple items like light bulbs or backup systems. It can save money on regular check-ups and repairs. But it’s not ideal for critical assets that keep a business running.

This article covers scenarios for when to use breakdown maintenance. Those scenarios depend on the importance of the equipment and the risk of failure. Waiting until they break is acceptable for some assets.

For others, it can lead to costly delays and safety issues.

Understanding Breakdown Maintenance

Breakdown maintenance is a repair approach used when equipment fails unexpectedly. It involves fixing or replacing components after they stop working. This strategy has both pros and cons for businesses. Companies often need to perform breakdown maintenance due to budget constraints, which can impact other maintenance strategies like preventive maintenance.

Definition and Key Concepts

Breakdown maintenance occurs when equipment breaks and needs urgent repairs. Unlike planned upkeep, it’s reactive. Teams fix issues as they arise, not before.

Key features of breakdown maintenance:

- Repairs occur after failure

- No planned schedules

- It can be costly and disruptive

- Sometimes called “run-to-failure” maintenance

- Reduces unnecessary preventive maintenance

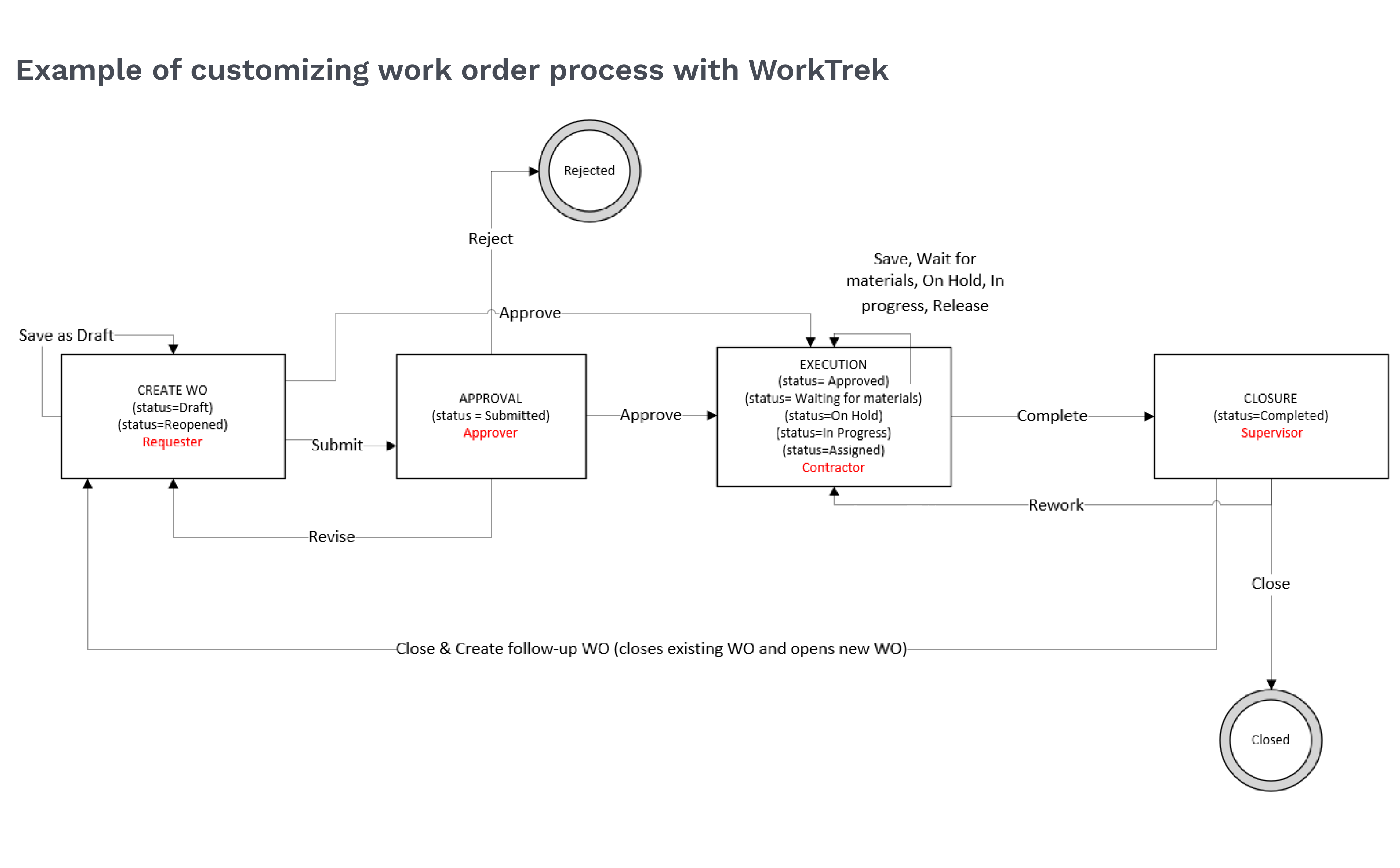

A breakdown maintenance workflow is a structured, step-by-step action plan for effectively managing equipment failures. This approach works for some less critical items, such as letting office light bulbs burn out before changing them.

Source: WorkTrek

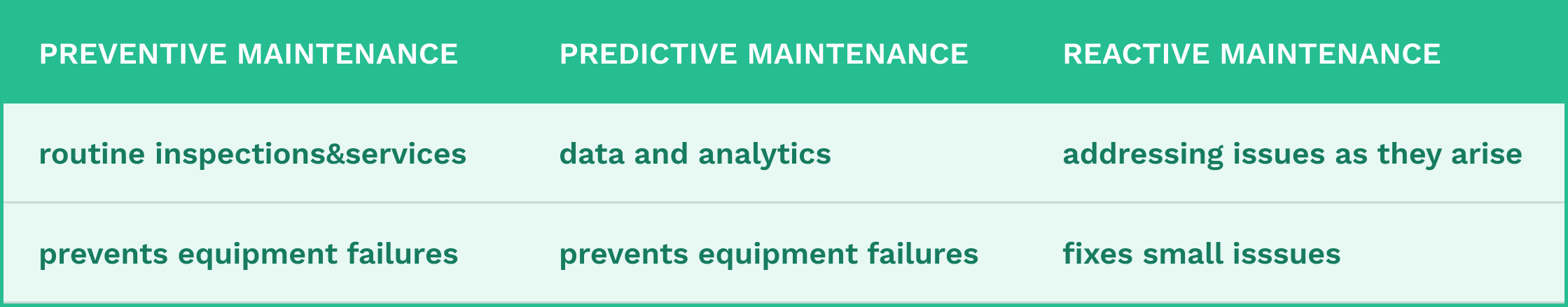

Comparison with Other Maintenance Types

Breakdown maintenance differs from other upkeep methods in several ways.

Preventive maintenance involves regular, scheduled checks and repairs. It aims to stop breakdowns before they happen. This can save money in the long term but needs more upfront planning.

Predictive maintenance uses data to guess when parts might fail. It can be very effective but needs special tools and skills.

Corrective maintenance fixes minor issues before they become big problems. It’s less urgent than breakdown repairs but still reactive.

A strategic combination of preventive and breakdown maintenance is essential for efficiently managing high-value assets while saving costs on less critical components. This approach can also reduce downtime costs.

When to Apply Breakdown Maintenance

Breakdown maintenance is best used in specific situations that can be cost-effective and safe. It works well for non-critical equipment and items with short lifespans.

The key is knowing when this approach makes sense. A breakdown maintenance plan is essential to effectively manage equipment failures and differentiate between breakdown and preventive maintenance strategies to optimize maintenance costs.

Run-to-Failure Maintenance Scenarios

Run-to-failure maintenance is suitable for equipment that can fail without major consequences. This approach works for items that are cheap and easy to replace. Examples include:

• Light bulbs

• Fuses

• Batteries

These items often have predictable lifespans. Replacing them only when they fail can save time and resources. It’s more efficient than checking and replacing them regularly.

Spare Parts

Organizations can plan for eventual failures and keep spare parts on hand, minimizing downtime when replacements are needed.

Examples of breakdown maintenance show that while this strategy is cost-effective for noncritical parts, it is unsuitable for industries where safety is paramount, such as aviation and automotive.

Dealing with Non-Critical Equipment

Non-critical equipment is ideal for breakdown maintenance. These items don’t affect safety or core operations if they fail. Examples might include:

• Office printers

• Vending machines

• Backup systems

For these items, the cost of constant monitoring may outweigh the benefits. It’s often cheaper to fix them only when they break.

Companies should assess each piece of equipment. They need to determine its importance to operations.

This helps decide if breakdown maintenance is appropriate. Unplanned breakdown maintenance can occur with non-critical equipment, making it essential to have resources ready to address unexpected failures.

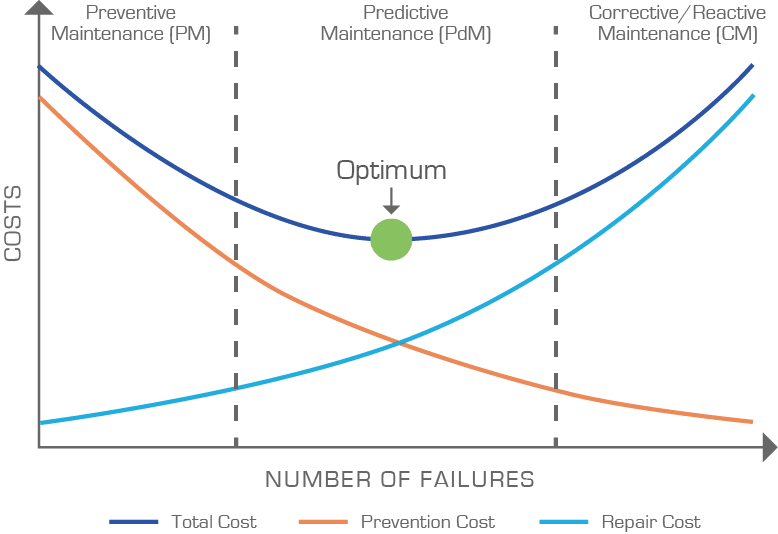

Considering Cost-Effectiveness and Safety

Cost and safety are critical factors in choosing a maintenance strategy. Breakdown maintenance can be cost-effective for certain items. It eliminates the expense of regular inspections and preventive work.

But safety must come first. Breakdown maintenance is not suitable for:

• Critical safety equipment

• Machinery that could cause injury if it fails

• Systems that would lead to costly downtime

Companies must weigh the risks and benefits. They should consider the potential costs of equipment failure. This includes repair expenses, lost productivity, and safety impacts.

In some cases, a mix of strategies works best. Critical systems receive preventive care, while less important items use the breakdown approach.

Source: IVC

Planning for Breakdown Maintenance

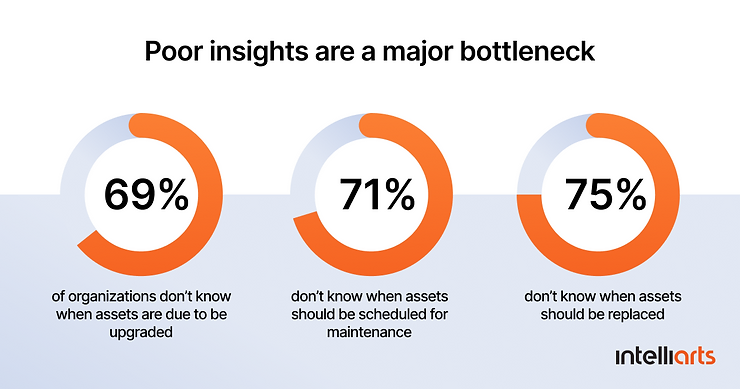

Planning for breakdown maintenance involves using systems, managing inventory, and optimizing workflows. These steps help companies respond quickly when equipment fails unexpectedly.

Effective asset management is crucial to minimize the occurrence of breakdowns and ensure efficient maintenance planning.

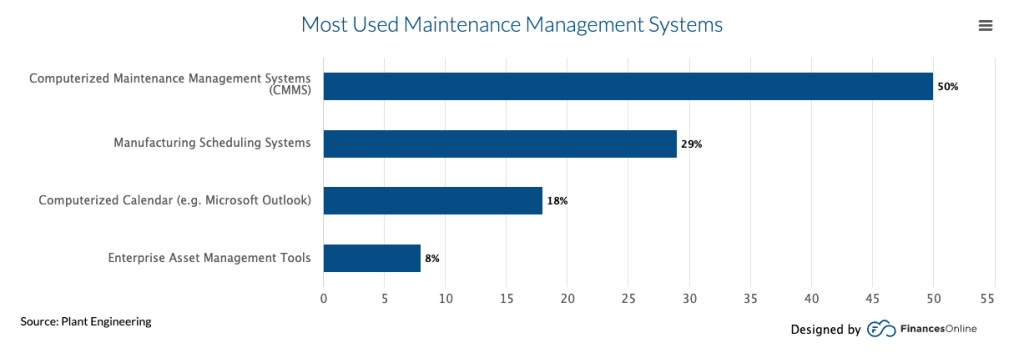

CMMS Software

Maintenance management systems, like CMMS software, are key for planning breakdown maintenance. These tools track equipment history, schedule repairs, and store important data about each machine.

CMMS software sends alerts when parts need replacing, helping prevent some breakdowns before they happen. The system can also track repair costs and downtime for each piece of equipment.

Good CMMS software is easy to use. It should work on mobile devices so technicians can access info anywhere. Look for systems that generate clear reports to help with planning.

Source: FinancesOnline

Inventory Management for Spare Parts

Keeping the right spare parts on hand is crucial for quick repairs. A good inventory system, generally part of most mature CMMS systems, tracks what parts are in stock.

It also shows where each part is stored. Implementing efficient inventory management procedures is essential for a successful breakdown maintenance program.

Set up automatic reordering for critical parts. This ensures you never run out when you need them most. Consider keeping extra stock of parts that are hard to get or have extended lead times.

Group similar parts together in storage. Label everything clearly. Use barcodes or RFID tags to track parts easily. Regular inventory checks help catch errors and prevent shortages.

Source: intelliarts

Workflow Optimization

Creating clear workflows helps teams respond faster to breakdowns. Start by listing all steps in the repair process. Then look for ways to streamline each step.

Make sure everyone knows their role when a breakdown occurs. Create checklists for common repairs. This helps even new team members work efficiently.

Use mobile apps to report issues quickly. Set up a system to prioritize urgent repairs. Train staff regularly on breakdown procedures. Practice scenarios to find weak spots in your process.

Track how long each repair takes. Use this data to find bottlenecks and improve your workflow over time.p

Identifying Critical Equipment

Knowing which machines are vital helps decide when to use breakdown maintenance.

Critical equipment:

- Directly impacts production or safety

- Has no backup or spare

- It causes major issues if it fails

Non-critical equipment:

- It doesn’t stop primary operations if it breaks

- Has backups available

- It causes only minor problems when down

Other maintenance types often work better for critical machines, helping avoid costly shutdowns. However, breakdown maintenance might be okay for non-critical items if it’s cheaper overall.

Executing Breakdown Maintenance

Breakdown maintenance requires quick action and a clear plan. The process involves immediate repairs, proper documentation, and thorough testing to get equipment back up and running.

Steps in Immediate Repair Procedures

When a breakdown occurs, the first step is to assess the situation. Safety comes first. Make sure the area is secure and workers are not at risk.

Next, identify the problem. This may involve visual checks or using diagnostic tools. Once the issue is clear, gather the needed tools and parts.

The next decision is whether to repair or replace. For simple fixes, on-site repair may work. Complex issues might need a full replacement.

Work quickly but carefully. Rushing can lead to mistakes. Follow proper repair procedures to avoid further damage.

Work Orders and Emergency Maintenance

Emergency maintenance needs a system. Start by creating a detailed work order. This document should explain the problem, list the required parts, and outline the repair plan.

Assign the job to the right team. Choose technicians with the skills for the specific breakdown. Make sure they have all the necessary information.

Prioritize the work order based on how critical the equipment is. Some breakdowns can wait, while others need immediate attention. Use a clear system to rank urgency.

Track the repair process. Update the work order as steps are completed. This helps manage the job and provides a record for future reference.

Many of these steps can be automated using a CMMS system like WorkTrek.

Source: WorkTrek

Performance and Functional Tests

Testing is crucial after repairs. Basic operational checks ensure the equipment runs without unusual noises or vibrations.

Next, more detailed functional tests should be performed to ensure all parts of the machine work properly. Check speeds, temperatures, and other key metrics.

Compare current performance to usual standards. Look for any signs that the repair might not be complete or effective.

Document all test results. This information helps verify the repair’s success and can guide future maintenance decisions. It also provides a baseline for monitoring the equipment’s ongoing performance.

Monitoring and Improving Maintenance Operations

Tracking maintenance data helps companies make smart choices about equipment upkeep. It can lead to big cost savings and better ways to prevent breakdowns.

Using Maintenance Data for Better Decisions

Maintenance reports are key tools for making good choices. They show when machines break down and how often, which helps plan future events. Companies can use failure data to spot trends. For example, they might see that certain parts wear out faster than others.

By looking at these reports, managers can:

- Find weak spots in their equipment

- Schedule repairs at the best times

- Order parts before they’re needed

This data also shows if planned breakdown maintenance is working well. If not, the team can switch to other methods.

Source: WorkTrek

Cost Savings through Maintenance Analysis

Looking at maintenance costs can save money. Teams can cut equipment downtime by fixing problems early and avoid buying new machines too soon.

Here’s how analysis helps:

- It shows which repairs cost the most

- It finds ways to make fixes cheaper

- It proves when it’s time to replace old equipment

Smart companies use this information to create better budgets. They spend less on rush repairs and more on planned work, which leads to fewer surprises and lower overall costs.

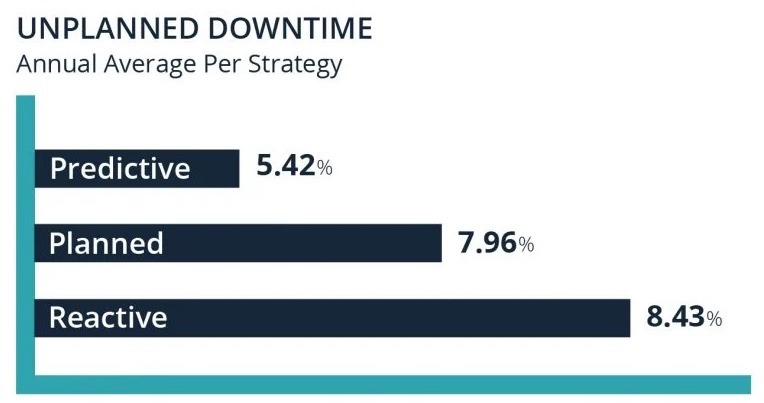

Integrating Preventive and Predictive Approaches

Mixing preventive and predictive maintenance can prevent many breakdowns. Preventive maintenance means fixing things on a schedule, while predictive maintenance uses data to guess when something might break.

For certain assets, preventive maintenance costs can be higher than the costs of addressing failures as they occur, particularly for inexpensive or less critical machinery.

These methods work well together:

- Preventive tasks keep machines running smoothly

- Predictive tools catch problems early

Teams can use both to make a strong plan. They might do monthly basic checks but also watch for signs of wear. This combo helps catch issues before they become big problems.

By using both, companies can reduce equipment downtime and save money. They fix only what needs fixing when it needs it. This smart approach keeps machines running longer and better.

Source: Oden Technologies

Maintenance Technologies and Trends

New tech is changing how companies handle equipment upkeep. Smart tools and software make maintenance faster and more precise. They help catch problems early and keep machines running smoothly.

AI in Maintenance Management

AI is transforming maintenance practices. It can predict when equipment might fail before it happens, helping prevent costly breakdowns and unplanned downtime.

AI analyzes data from sensors on machines. It spots patterns that humans might miss. It alerts maintenance teams when it sees signs of trouble, allowing for quick fixes before big problems occur.

Some AI systems can even suggest the best repair methods. They learn from past maintenance records and improve over time, making repairs faster and more effective.

Benefits of Maintenance Management Software

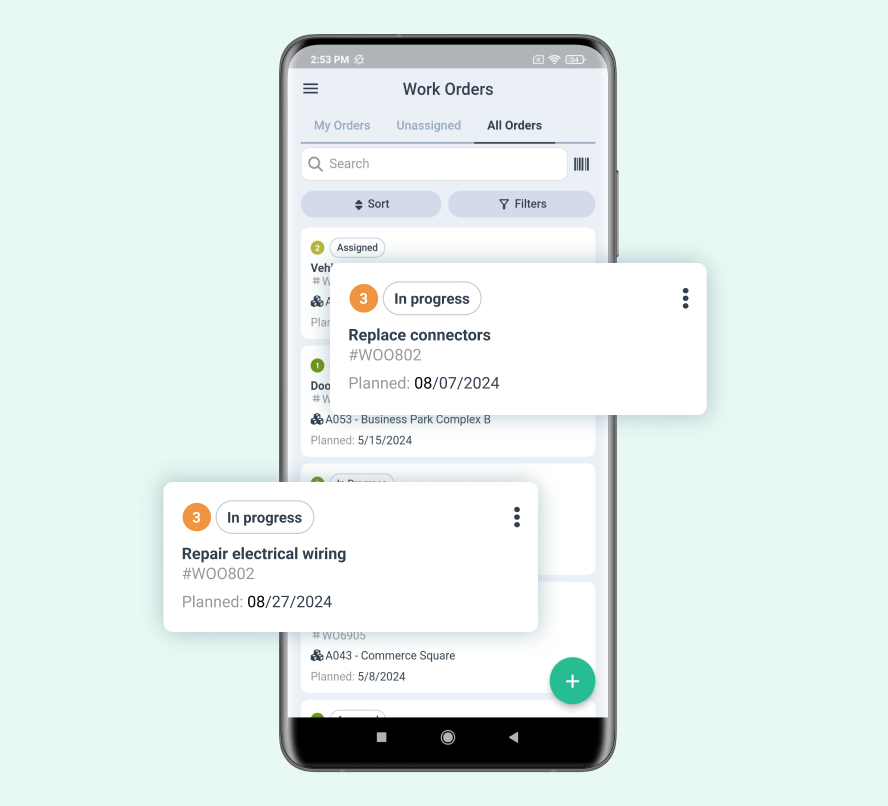

Maintenance management software boosts productivity. It helps teams track all their equipment and schedule upkeep tasks.

The software stores detailed maintenance records, making it easy to see each machine’s history. Teams can quickly find information on past repairs and part replacements.

Good maintenance software also helps plan work orders. It can set up regular check-ups for equipment. This keeps machines in top shape and reduces surprise breakdowns.

Many programs offer mobile access. Workers can update records and check tasks from anywhere, speeding up work and improving communication.

Source: WorkTrek

Customization and Maintenance Apps

Custom maintenance apps can be created to meet a company’s exact needs and work with specific equipment or processes.

These apps often have user-friendly interfaces. Workers can easily log issues or request repairs. This helps catch small problems before they grow.

Some apps use QR codes or barcodes. Workers can scan equipment to see its maintenance history, which puts important information at their fingertips.

Mobile maintenance apps also work offline, which is helpful in areas with poor internet. Workers can still access and update information, which syncs later.