Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Operation and maintenance costs for wind turbines can account for 20-35% of the total levelized cost per kWh over the turbine’s lifetime.

- 75% of asset owners rate new wind turbines as only “fair” or “poor” for reliability, with widespread early-life failures in blades, gearboxes, and main bearings.

- Predictive maintenance powered by IoT and AI can reduce unplanned downtime by 25-30% and significantly lower repair costs across wind farms.

Wind energy is one of the fastest-growing renewable energy sources globally, and for good reason. Predictive maintenance is playing an increasingly vital role in maximizing its efficiency and reliability.

It’s clean, increasingly cost-effective, and has massive potential to meet the world’s energy demands. In 2022, wind turbines operating across all 50 U.S. states generated more than 10% of the country’s total energy, adding $20 billion to the economy.

However, maintaining wind turbines presents unique challenges that can significantly impact energy production, operational costs, and overall efficiency.

From remote locations and extreme weather conditions to complex mechanical systems and aging infrastructure, wind farm operators face a constant battle to keep turbines spinning reliably.

In this article, we’ll explore the six biggest challenges of wind turbine maintenance and examine how modern solutions, including advanced CMMS platforms, are helping the wind energy industry overcome these obstacles.

1. Working at Height in Remote Locations

One of the most fundamental challenges in wind turbine maintenance is simply getting to the equipment that needs servicing.

Wind turbines are typically installed in remote locations where wind resources are strongest—on offshore platforms, mountain ridges, or in isolated rural areas. This geographic isolation creates significant logistical hurdles for maintenance teams.

Wind turbine service technicians, often called “windtechs” or “skyworkers,” must regularly climb towers that can exceed 300 feet in height to perform inspections, repairs, and routine maintenance. This work requires specialized skills, physical fitness, and strict adherence to safety protocols.

The Bureau of Labor Statistics recognizes wind turbine service technicians as the fastest-growing U.S. job of the decade, with nearly 150,000 (2023) people currently working in the wind industry across all 50 states. This growth reflects the expanding wind energy sector, but it also highlights the increasing demand for skilled workers willing to take on this challenging role.

The combination of height and remote locations means that even routine maintenance tasks become complex operations. Technicians must transport tools, spare parts, and equipment to sites that may lack proper road access. Weather windows for safe climbing are limited, and emergency repairs can be delayed for days or weeks, depending on conditions and accessibility.

Many wind farms are located in areas where routine checkups require workers to travel long distances, so inspections don’t happen as frequently as they should. This infrequency can lead to small problems escalating into major failures, increasing both downtime and repair costs.

The challenge is particularly acute for offshore wind turbines, where maintenance visits can cost upwards of $20,000 each, and weather conditions often restrict access to just a few days per month.

Proper planning and scheduling become essential to maximize the efficiency of each site visit and reduce the number of trips required.

2. Harsh Environmental Conditions and Weather Extremes

Wind turbines are designed to operate in the very conditions that make them productive. This is high winds, exposed locations, and variable weather. However, these same environmental factors accelerate wear and tear on turbine components, creating ongoing maintenance challenges.

Temperature Swings

Temperature fluctuations are a significant concern. Turbines in colder climates face issues with ice accumulation on blades, which reduces aerodynamic efficiency and can create dangerous imbalances. The weight of ice buildup can also damage turbine blades and other components, requiring specialized de-icing systems and more frequent inspections during winter months.

Salt

In coastal and offshore environments, salt spray and moisture create corrosive conditions that attack metal components, electrical systems, and protective coatings.

Sand and Debris

Blade erosion from wind-blown sand, rain, and debris is a constant battle, with even small imperfections in blade surfaces reducing energy output and potentially leading to larger structural problems.

Lightning

Lightning strikes pose another serious threat to wind turbines, particularly taller structures that naturally attract electrical discharges.

A single lightning event can damage control systems, sensors, and other electronics, leading to costly repairs and extended downtime. Wind turbine maintenance costs can skyrocket when turbines are constantly damaged by lightning strikes, making proper lightning protection systems essential.

General Component Fatigue

According to research, aging turbines naturally experience component fatigue, with the likelihood of failures increasing significantly after around six to seven years of operation.

Harsh offshore environments can include exposure to saltwater, high winds, storms, and lightning strikes, which accelerate wear and increase failure rates compared to onshore installations.

The challenge of environmental stress is compounded by the fact that wind turbines are expected to be in motion for approximately 66% of their lifespan.

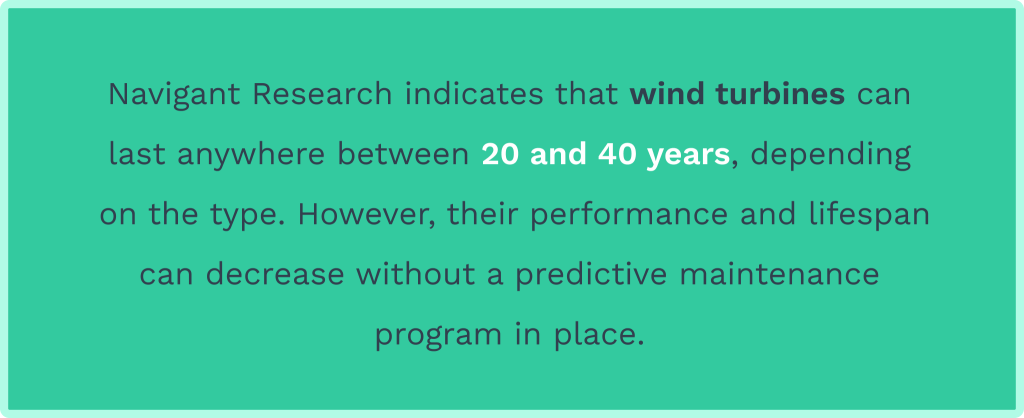

Considering that the average lifespan of a wind turbine today is about 20 to 25 years this means turbines are expected to be in motion for 13.2 years or almost 80,000 hours. This is clearly an enormous amount of operational stress on moving parts and components.

Faulty sensors are another common issue, particularly in extreme environments. Temperature sensors, vibration monitors, and other diagnostic equipment can fail or provide inaccurate readings, making it difficult for maintenance teams to assess actual turbine conditions and plan appropriate interventions.

3. Complex Mechanical Systems and Component Failures

Wind turbines contain hundreds of moving parts working in concert to convert wind energy into electricity. This mechanical complexity creates numerous potential failure points, with some components proving more problematic than others.

Gearbox Failures

Gearboxes are among the most critical and failure-prone components in wind turbines. They’re responsible for increasing the rotor’s relatively slow rotation (typically 10-20 RPM) to the high speeds needed for efficient power generation (around 1,500-1,800 RPM for many generators).

Research shows that gearboxes are replaced at a rate of about 5% during the first 10 years of operation, making them “the most common and most critical failure” in wind turbines. Gearbox failures, along with generator failures, cause the most downtime and greatest economic losses of all failure types.

Most gearboxes don’t make it past ten years of operation, falling short of their 20-year design lifespan.

The bearings and gears account for 96% of the failing components in the gearbox. Contributing factors include dirty or water-contaminated lubrication, improper bearing settings, significant temperature fluctuations, infrequent or improper maintenance, and transient loads that cause sudden accelerations.

When a gearbox fails, it’s an expensive incident.

Typically, the gearbox accounts for 13% of the turbine’s overall cost and requires specialized equipment. This often requires a heavy-lift vessel (HLV) for offshore installations to replace it.

During replacement, the turbine may be offline for anywhere from a few days to several months, depending on parts availability and weather conditions. Every day the turbine isn’t spinning means lost revenue for wind farm operators.

Blade Damage and Maintenance

Turbine blades are the face of wind energy, but they’re also vulnerable to a wide range of problems. As the wind industry pushes for greater energy output, rotor blades are growing larger, some of which are now reaching arcs of up to 262 feet (80 meters).

While larger blades produce more power, they also present greater maintenance challenges.

Blade defects from manufacturing, transport damage, and excessive loading during operation are driving higher downtime and spiraling maintenance costs, often far beyond what project models originally anticipated.

Even small imperfections in blade surfaces can grow over time, compromising structural integrity and aerodynamic performance.

Blade erosion is particularly problematic on the leading edges, where wind-blown particles constantly strike the surface at high speeds. This erosion creates rough spots that disrupt airflow, reducing efficiency and potentially creating stress concentrations that can lead to cracks or other structural damage.

Regular blade inspections are difficult due to the size and height of modern turbines.

Traditional visual inspections require technicians to rappel down blade surfaces, a time-consuming and dangerous process.

Thankfully, new technologies like drone inspections are becoming more common, but they still require skilled operators and favorable weather conditions.

Blade repairs and replacements are among the most expensive maintenance activities in wind energy.

For example, an average blade repair can cost upwards of $30,000, while replacing a single blade might cost around $200,000.

Crane mobilization for major blade repairs can add up to $350,000 per week, making it crucial to detect and address blade issues early before they escalate.

Generator and Electrical System Issues

The generator is the heart of any wind turbine. It converts mechanical energy from the rotating shaft into electrical energy, making it essential for power production. When the generator fails, no power is produced, costing wind farm operators valuable revenue.

Several factors can cause generator failures, including wind loading, weather extremes, and thermal cycling.

Mechanical or electrical failure of the bearings, excessive vibration, voltage irregularities, and cooling system failures can lead to excessive heat and even fire. Additional risk factors include manufacturing or design faults, improper installation, lubricant contamination, and inadequate electrical insulation.

Research covering 44.2 GW of wind turbine data shows that generator failures involve multiple failure modes and contributing causes.

Common issues include:

- Rotor winding interconnection problems (particularly in doubly-fed induction generators)

- Slip ring scoring

- Magnetic slot wedge failures

Electrical equipment is the most common cause of stoppages, with approximately 5.5 incidents per 10 machine-years, according to German Wind Energy Measurement Programme data. While electrical failures may be more frequent, they typically result in shorter downtime compared to major mechanical failures.

Hydraulic and Yaw System Problems

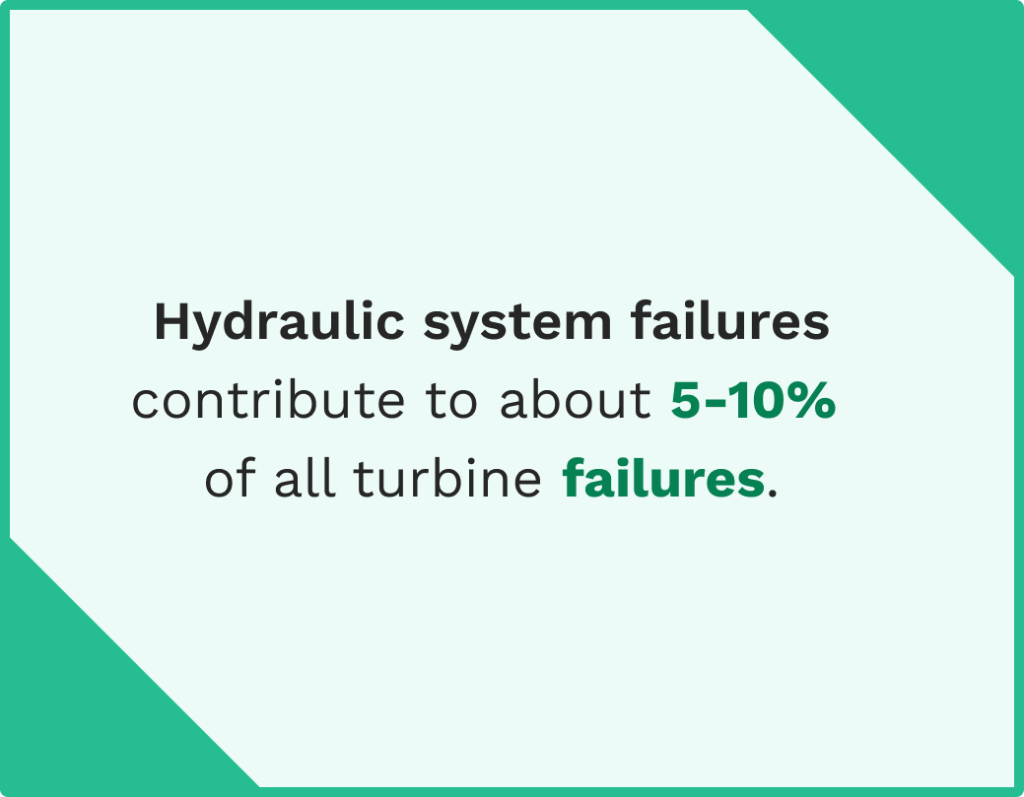

Hydraulic systems control various functions in wind turbines, including blade pitch adjustment and braking. These systems must operate reliably under varying conditions and loads.

Hydraulic fluid leaks, contamination, and component wear can all lead to system failures that affect turbine operation.

Yaw systems are particularly challenging to maintain. The yaw component of a wind turbine facilitates the orientation of the rotor towards the wind, ensuring optimal energy capture. Yaw brakes secure the position of the nacelle after re-orientation.

The difference in yaw brake caliper weight can range from 60 to 200kg, and some turbines feature up to 20 yaw brakes to control their position.

This places substantial strain on maintenance personnel, especially given the scale of modern wind farms and the fact that many turbines lack built-in elevators.

Yaw brake dust is another concern. Braking systems produce harmful dust that contaminates the local environment and poses health risks to maintenance personnel who come into close contact with it during servicing.

Large installations with multiple turbines require careful selection of environmentally-friendly brake pad materials and proper disposal procedures.

A phenomenon known as “glazing” can result in noisy yaw brakes. When there is no wind and low usage, yaw brake discs collect dirt, rust, and moisture as temperatures fluctuate.

When the wind returns and braking resumes, this detritus is collected by the brake pad and pressed into the pad and disc surfaces under high braking force, creating glazing. This reduces braking performance, compromises safety, and creates excessive noise that can disturb both local residents and wildlife.

4. High Maintenance Costs and Budget Constraints

The financial impact of wind turbine maintenance is substantial and often underestimated in initial project planning.

Understanding the true cost structure is essential for wind farm operators who want to maximize their return on investment while ensuring reliable power generation.

For a new turbine, operation and maintenance costs may account for 20-25% of the total levelized cost per kWh over the turbine’s lifetime.

If the turbine is fairly new, this share may only be 10-15%, but it can increase to 20-35% by the end of the turbine’s lifetime as components age and failures become more frequent.

Wind Turbine O&M Market

The wind turbine operations and maintenance market was valued at $23.8 billion in 2024 and is expected to grow at a CAGR of 8.2% from 2025 to 2035. This growth reflects both the expansion of installed capacity and the increasing sophistication of maintenance practices.

Corrective Maintenance

Corrective maintenance accounted for approximately 35% of the market share in 2024, driven by mechanical wear, environmental stress, and unplanned failures.

These reactive interventions are significantly more expensive than planned preventive maintenance, with emergency repair costs including premium labor rates, expedited parts shipping, and extended downtime.

Offshore Turbine Costs

Offshore wind turbines cost about three times as much to operate and maintain as their onshore counterparts. The cost of operating and maintaining an offshore wind farm accounts for around 40% of the project’s total life-cycle cost.

The difficulty and expense of offshore maintenance have increased with the advent of large-capacity turbines that require specialized vessels and equipment.

Cost of Poor Maintenance

Poor maintenance strategies can cost $800- $1,600 per day in unnecessary downtime for offshore wind operations. For offshore wind farms where a maintenance visit runs $20,000 or more, every inspection needs to count. Gearboxes and blades now account for over two-thirds of scheduled O&M costs, underscoring why these components are so often flagged in reliability assessments.

Raising Cost of Material

Rising material and labor costs compound the challenge. Components are becoming more expensive to procure, and the specialized skills required for wind turbine maintenance command premium wages. Turbine technicians must be trained in electrical systems, mechanical repair, hydraulics, and advanced safety procedures—all while working at extreme heights in challenging conditions.

Cost Increase of Wind Turbines

Original equipment manufacturers (wroktrek-wind-turbine-maintenance-aging-equipment) have been raising turbine prices due to cost increases and rising interest rates. In 2022, Nordex raised its prices by approximately 12%, and other manufacturers followed suit. These price increases affect both new installations and replacement parts, putting additional pressure on maintenance budgets.

Some costs are less obvious but equally important. Insurance premiums, land rental fees, administrative overhead, and the cost of holding spare parts inventory all contribute to the total cost picture. When these hidden costs are factored in, the true financial burden of wind turbine maintenance becomes clear.

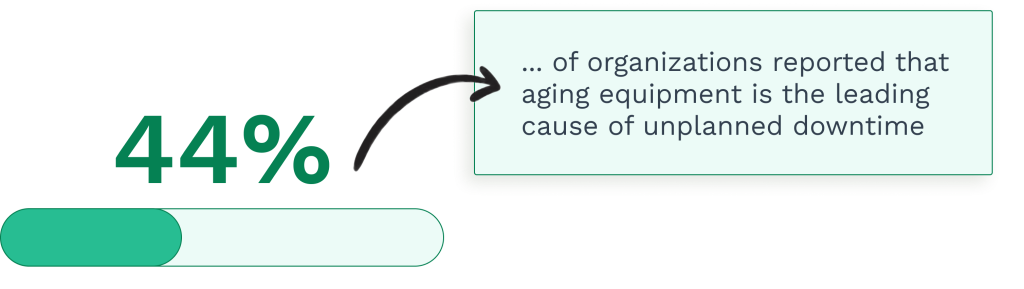

5. Aging Infrastructure and Limited OEM Support

As the wind energy industry matures, a significant challenge is emerging: aging infrastructure and declining support from original equipment manufacturers for older turbine models.

Recent findings from industry reports show that 75% of asset owners rate their new turbines as only “fair” or “poor” for reliability.

Early Failures

Performance data confirm widespread early-life failures, particularly in critical components such as blades, gearboxes, and main bearings. Many of these failures stem from the fast pace of turbine innovation, as OEMs push for bigger, lighter, more efficient designs that often cut safety margins thin.

Support for Aging Equipment

At the same time, OEM support for older platforms is declining. Mature turbines—those between five and fifteen years old—are being deprioritized, even though they remain stable, well-understood machines.

With the right approach, these assets could deliver significant value. However, without access to spare parts or engineering support, many are becoming harder and more expensive to maintain.

Parts Availability

This creates a challenging situation for wind farm operators managing mixed fleets of different turbine models and ages. Parts availability becomes unpredictable, and when components do fail, finding suitable replacements can require extensive lead times or expensive custom fabrication.

The problem is particularly acute in regions where the offshore wind industry is still developing and supply chains are immature. Wind farm operators in these areas may struggle to source even common replacement parts, leading to extended downtime and lost revenue.

Comprehensive Maintenance Schedule

Maintenance schedules become more critical as turbines age. Without proactive intervention, aging turbines experience accelerated degradation. Component fatigue becomes more likely after about six to seven years of operation, making regular inspections and condition monitoring essential.

The challenge extends beyond physical parts. Many older turbines use control systems, software, and monitoring equipment that is no longer supported by manufacturers.

Cybersecurity Concerns

Cybersecurity vulnerabilities in outdated systems can’t be patched, and integration with modern predictive maintenance tools may be difficult or impossible.

For wind farm operators looking to maximize the value of aging assets, the path forward often involves working with independent service providers who specialize in legacy equipment maintenance. These companies can often source or fabricate replacement parts, retrofit modern monitoring systems onto older turbines, and provide engineering support that OEMs no longer offer.

However, this approach requires careful planning and often higher maintenance budgets. The trade-off is that keeping older turbines operational can still be more cost-effective than premature decommissioning and replacement, particularly for wind farms in good locations with otherwise sound infrastructure.

6. Safety Risks and Technician Shortages

Safety, like in any maintenance operation, is paramount in wind turbine maintenance.

However, the nature of the work creates inherent risks that must be carefully managed. Working at heights of 300 feet or more, often in adverse weather, with heavy equipment and electrical systems demands constant vigilance and rigorous safety protocols.

Potential Falls

Falls from height are the most obvious danger, but they’re far from the only concern.

Technicians face risks from electrical shock, arc flash, confined spaces, rotating machinery, heavy lifting, extreme weather, and the physical demands of climbing ladders that can extend for hundreds of feet.

The European Agency for Safety and Health at Work has published comprehensive guidance on occupational safety and health in the wind energy sector, covering hazards throughout a turbine’s life cycle from manufacturing and installation through operation, maintenance, and decommissioning.

This reflects the industry’s recognition that safety must be built into every aspect of wind energy operations.

Labor Shortage

Despite growing awareness and improving safety practices, the wind industry faces a critical challenge: a shortage of qualified technicians. The U.S. Bureau of Labor Statistics projects that wind turbine service technicians will be the fastest-growing job in the decade, but the current workforce can’t keep pace with industry expansion.

Training Technicians

Training new technicians is time-consuming and expensive. They need technical skills in mechanics, hydraulics, and electrical systems, plus specialized training in working at height, confined space entry, and emergency rescue procedures.

Many training programs take 12-18 months to complete, and even then, newly certified technicians need several years of field experience before they can work independently on complex repairs.

High Physical Demands

The physical demands of the job also limit the pool of potential workers. Climbing hundreds of feet multiple times per day, working in cramped nacelles, and handling heavy tools and parts requires excellent physical fitness. Many experienced technicians eventually move into supervisory or planning roles as the physical toll becomes unsustainable.

Staff Retention

Retaining skilled workers is challenging when they can earn similar or better wages in other industries without the risks and physical demands of wind turbine work.

Some companies are addressing this by improving compensation packages, offering career development opportunities, and optimizing scheduling to improve work-life balance.

Technologies to Improve Safety

The wind energy industry is also investing in technologies that can reduce safety risks and labor requirements. Remote monitoring systems enable some diagnostics and troubleshooting without site visits.

Automated inspection technologies, such as drones, can perform visual blade inspections without requiring technicians to work at height. Robotic systems are being developed for some maintenance tasks in hazardous or difficult-to-reach areas.

However, these technologies complement rather than replace skilled technicians. The human expertise to interpret diagnostic data, make repair decisions, and perform complex maintenance tasks remains essential.

The challenge is to ensure there are enough trained, qualified, and motivated workers available to meet the growing demands of the wind energy sector.

Conclusion

The biggest challenges of wind turbine maintenance are: remote locations, harsh environments, complex mechanical systems, high costs, aging infrastructure, and safety concerns. These issues are not going away.

As wind energy continues its rapid growth, these challenges will only become more critical to address.

What’s changing is how the wind industry approaches these challenges. Modern maintenance practices emphasize early detection, predictive analytics, and proactive intervention rather than running equipment to failure.

Advanced technologies like condition monitoring, drone inspections, and AI-powered diagnostics are providing unprecedented insight into turbine health.

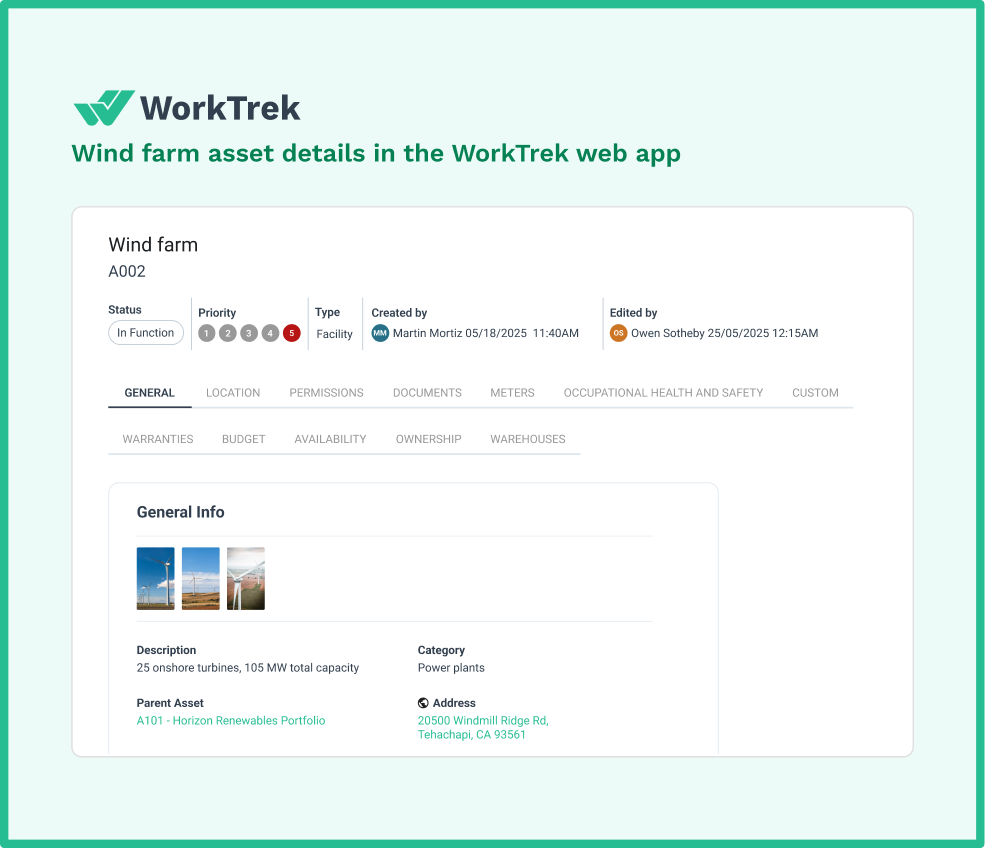

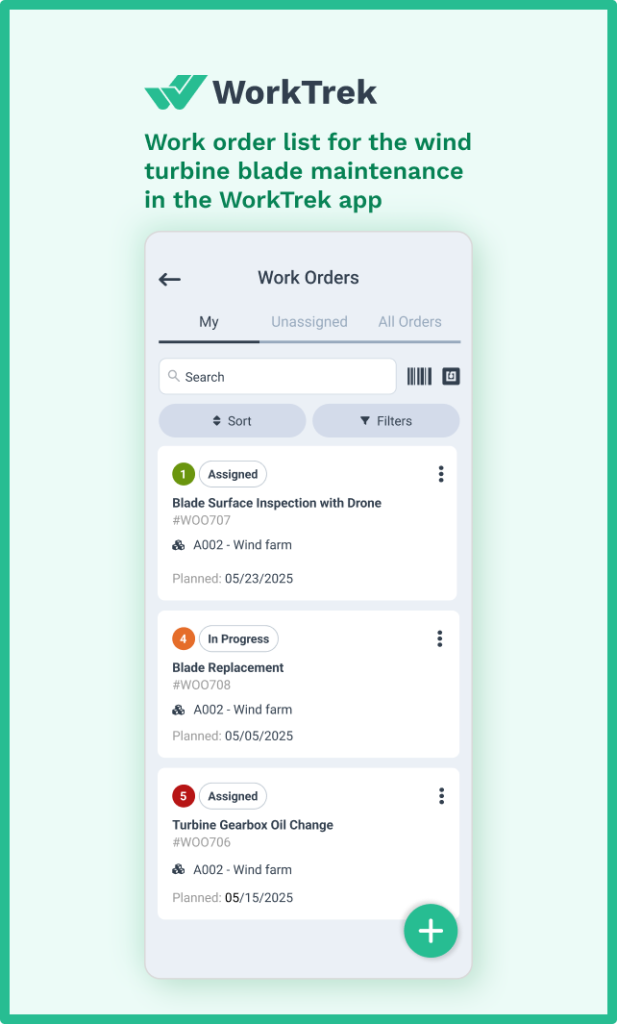

Digital tools, particularly CMMS platforms like WorkTrek, are transforming how maintenance teams plan, execute, and optimize their work.

By centralizing information, automating routine tasks, and providing data-driven insights, these systems help wind farm operators get the most value from every maintenance dollar while maximizing energy production and turbine availability.

With proper planning, modern tools, and a commitment to continuous improvement, wind farm operators can keep their turbines spinning reliably for decades, delivering clean energy and strong returns on investment.