Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeIntroduction

CMMS for Aviation and Aerospace industry refers to a Computerized Maintenance Management System specifically designed and utilized within the context of aerospace and aviation operations. CMMS is a software-based solution that assists organizations in managing, tracking, and optimizing maintenance activities for aircraft, equipment, and facilities. In the aerospace and aviation sector, where safety, compliance, and efficiency are paramount, CMMS plays a crucial role in maintaining the airworthiness of assets and ensuring regulatory adherence.

What is the Aviation Industry?

The aviation industry encompasses all activities related to the design, manufacturing, operation, and maintenance of aircraft. It plays a critical role in facilitating air travel, both for passengers and cargo. The aviation industry is diverse and includes various segments:

Commercial Aviation: This segment involves the operation of airlines that provide passenger and cargo transportation services. Commercial aviation includes scheduled flights, charter services, and airfreight.

General Aviation: General aviation covers non-commercial activities and includes private and recreational flying, business aviation, flight training, and activities not associated with airlines or military aviation.

Military Aviation: Military aviation involves the design, manufacturing, and operation of aircraft for defense purposes. This includes fighter jets, transport planes, reconnaissance aircraft, and other military aviation assets.

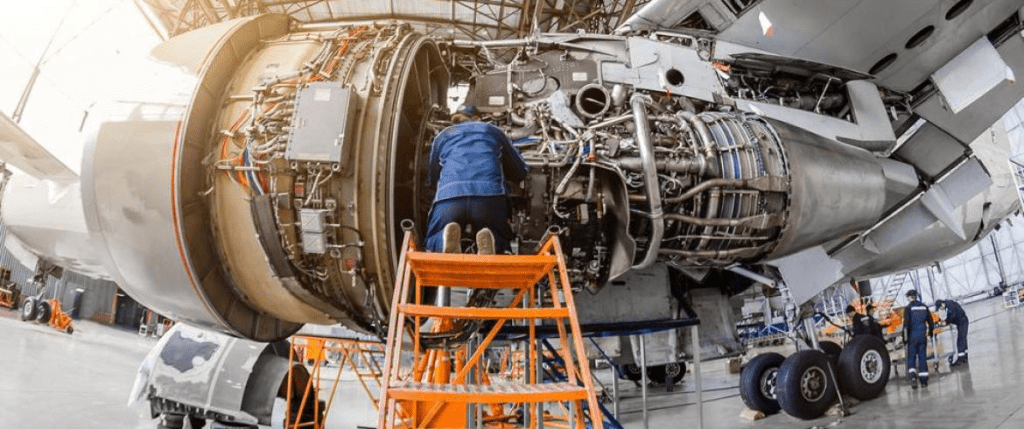

Aircraft Maintenance, Repair, and Overhaul (MRO): MRO services focus on the maintenance, repair, and overhaul of aircraft to ensure their continued airworthiness. This includes routine maintenance, inspections, and repairs to extend the lifespan and safety of aircraft.

Aerospace Engineering: Aerospace engineers are involved in designing and developing aircraft and spacecraft. They work on various aspects, including aerodynamics, materials, propulsion systems, avionics, and structural design.

Research and Development: Ongoing research and development efforts focus on advancing technologies in aviation, including more fuel-efficient engines, advanced avionics, lightweight materials, and innovations to enhance safety and efficiency.

The aviation industry is a global network that connects people, facilitates trade and tourism, and contributes significantly to economic development. It involves collaboration between governments, industry stakeholders, and regulatory bodies to ensure safe and efficient air transportation worldwide.

Next, read which industries benefit the most from CMMS.

What is the Aerospace Industry?

The aerospace industry is a broad and multifaceted sector encompassing the design, development, manufacturing, operation, and maintenance of aircraft and spacecraft. This industry is crucial in advancing technology, supporting global transportation, and exploring space. Here are key aspects of the aerospace industry:

Aircraft Manufacturing: The aerospace industry involves the design and production of various types of aircraft, including commercial airplanes, military aircraft, helicopters, and unmanned aerial vehicles (UAVs or drones). Major aerospace companies like Boeing, Airbus, and Lockheed Martin are known for their contributions to aircraft manufacturing.

Spacecraft Manufacturing: Aerospace companies are involved in designing and building spacecraft for a range of purposes. This includes satellites for communication, Earth observation, navigation, and spacecraft for space exploration missions. Companies like SpaceX, Northrop Grumman, and Thales Alenia Space operate in this space.

Space Launch Services: The aerospace industry includes companies that provide space launch services. These companies design, manufacture, and operate launch vehicles to carry satellites, payloads, and crewed spacecraft into space. Examples include SpaceX, United Launch Alliance (ULA), and Arianespace.

Aerospace Engineering: Aerospace engineers are involved in the design, development, and testing of aircraft and spacecraft. They work on various aspects such as aerodynamics, materials science, propulsion systems, avionics, and structural design.

Aerospace Research and Development: Continuous research and development efforts drive innovation in the aerospace industry. This includes advancements in materials, propulsion technologies, navigation systems, and safety features.

Aerospace Maintenance, Repair, and Overhaul (MRO): MRO services in the aerospace industry focus on maintaining, repairing, and overhauling aircraft and spacecraft. This ensures the continued airworthiness and reliability of the vehicles throughout their operational lifespan.

Space Tourism and Commercial Space Activities: With the emergence of commercial space companies, the aerospace industry is witnessing the development of space tourism and other commercial space activities. Companies like Blue Origin and Virgin Galactic are pioneering efforts to make space travel accessible to private individuals.

The aerospace industry is dynamic and continuously evolving, driven by technological advancements, exploration goals, and market demands. It plays a vital role in shaping the future of transportation, communication, and scientific discovery.

Read also how can CMMS help in manufacturing.

Challenges Facing the Aerospace Industry

The aerospace industry faces several challenges that impact its operations, growth, and overall sustainability. These challenges are diverse and can arise from technological, economic, regulatory, and geopolitical factors. Here are some key challenges facing the aerospace industry:

Supply Chain Disruptions: The aerospace industry relies on complex and globalized supply chains for components and materials. Disruptions, whether caused by natural disasters, geopolitical tensions, or other factors, can lead to delays, increased costs, and challenges in meeting production demands.

Technological Advancements: Rapid technological advancements, while offering opportunities for innovation, also present challenges. Integrating new technologies, such as electric propulsion, autonomous systems, and advanced materials, requires significant investments, adaptation to changing industry standards, and addressing potential safety concerns.

Workforce Shortages: The industry faces challenges related to a shortage of skilled professionals, including engineers, pilots, and maintenance technicians. An aging workforce and increased demand for aviation services contribute to workforce gaps.

Market Competition: Intense competition among aircraft manufacturers and airlines can lead to pricing pressures and reduced profit margins. Maintaining a competitive edge requires continuous innovation, cost management, and strategic market positioning.

Rising Fuel Costs: Fluctuations in fuel prices impact the operational costs of airlines. High fuel costs can strain profit margins and affect the economic viability of airlines, especially during periods of economic uncertainty.

Addressing these challenges requires collaboration between industry stakeholders, governments, and regulatory bodies. The industry’s ability to innovate, adapt to emerging technologies, and navigate economic and geopolitical uncertainties will be crucial to its long-term sustainability and success.

Consider reading about the benefits of using CMMS software.

How can CMMS for Aviation and Aerospace Help the Industry?

CMMS for Aviation and Aerospace can offer numerous advantages to the industry by streamlining maintenance processes, ensuring regulatory compliance, improving asset management, and enhancing overall operational efficiency. Here are several ways in which CMMS can help the aerospace industry:

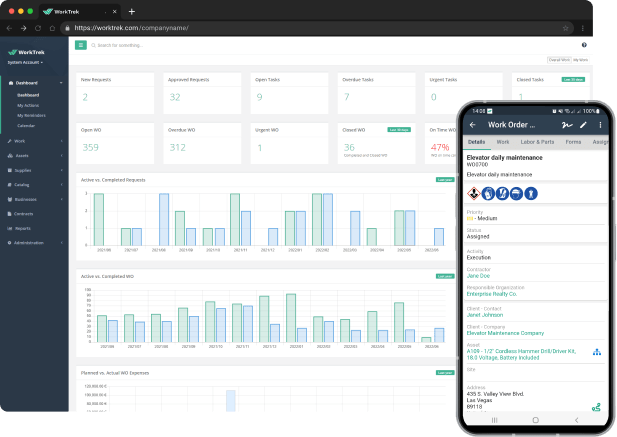

Maintenance Planning and Scheduling: CMMS facilitates efficient planning and scheduling of maintenance activities. It helps in organizing routine inspections, preventive maintenance tasks, and repairs, ensuring that critical maintenance is performed on time and in compliance with regulatory requirements.

Asset Management: CMMS helps in managing and tracking the entire lifecycle of aircraft, engines, and other critical assets. It provides a centralized repository for asset details, maintenance history, and performance data. This contributes to optimizing asset performance, minimizing downtime, and extending the lifespan of assets.

Inventory Management: Effective inventory management is crucial for aerospace organizations to ensure the availability of spare parts and minimize downtime. CMMS helps in tracking inventory levels, managing stock levels, and automating reorder processes, thereby improving overall maintenance efficiency.

Work Order Management: CMMS streamlines work order management by facilitating the creation, tracking, and completion of work orders for maintenance activities. It provides a systematic approach to managing work orders, allowing organizations to prioritize tasks, assign resources, and monitor progress in real time.

Mobile Accessibility: Best CMMS solutions offer mobile accessibility, enabling maintenance teams to access work orders, checklists, and asset information on mobile devices. This is particularly beneficial for technicians working in hangars, on the tarmac, or in remote locations.

Challenges Facing the Aviation Industry

The aviation industry faces a range of challenges that impact its operations, growth, and overall sustainability. These challenges stem from various factors, including economic, technological, regulatory, and environmental considerations. Here are some key challenges facing the aviation industry:

Fuel Price Volatility: Fluctuations in oil prices directly impact the operational costs of airlines. Sudden increases in fuel prices can strain airline profitability, leading to challenges in managing costs and setting competitive ticket prices.

Environmental Regulations and Sustainability: Increasing concerns about climate change and environmental sustainability have led to stricter regulations on aviation emissions. Airlines are under pressure to reduce their carbon footprint, adopt fuel-efficient technologies, and explore alternative sustainable aviation fuels.

Infrastructure Limitations: Congestion at major airports, outdated air traffic management systems, and limited runway capacity pose challenges to the efficient movement of aircraft. Modernizing and expanding aviation infrastructure is a complex and costly undertaking.

Pilot and Technician Shortages: A growing shortage of skilled aviation professionals, including pilots and maintenance technicians. An aging workforce, increased demand for air travel, and stringent training requirements contribute to workforce challenges.

Addressing these challenges requires collaboration among industry stakeholders, governments, regulatory bodies, and technology providers. The ability to innovate, invest in sustainable practices, and navigate complex global dynamics will be critical for the aviation industry’s resilience and long-term success.

Read also, how to train your employees for CMMS.

How can CMMS Help the Aviation Industry?

CMMS for Aviation and Aerospace can provide significant benefits to the industry by enhancing maintenance practices, ensuring compliance with regulations, improving asset management, and optimizing overall operational efficiency. Here are ways in which CMMS can help the aviation industry:

Maintenance Planning and Scheduling: CMMS enables aviation organizations to plan and schedule maintenance activities efficiently. It helps in organizing routine inspections, preventive maintenance, and repairs, ensuring that critical tasks are performed on time and by regulatory requirements.

Asset Management: CMMS assists in managing and tracking the entire lifecycle of aircraft, engines, and other critical assets. It provides a centralized repository for asset details, maintenance history, and performance data. This helps in optimizing asset performance, minimizing downtime, and extending the lifespan of assets.

Inventory Management: Effective inventory management is crucial for aviation organizations to ensure the availability of spare parts and minimize downtime. CMMS helps in tracking inventory levels, managing stock levels, and automating reorder processes, improving overall maintenance efficiency.

Work Order Management: CMMS facilitates the creation, tracking, and completion of work orders for maintenance activities. It provides a systematic approach to managing work orders, allowing organizations to prioritize tasks, assign resources, and monitor progress in real time.

Document Management: Aviation organizations deal with extensive documentation, including maintenance manuals, procedures, and compliance records. CMMS centralizes document management, making it easier for technicians to access up-to-date information, reducing errors, and ensuring standardized procedures are followed.

Mobile Accessibility: Many modern CMMS solutions offer mobile accessibility, allowing maintenance teams to access work orders, checklists, and asset information on mobile devices. This is particularly beneficial for technicians working on the tarmac or in remote locations.

Data Analysis and Reporting: CMMS generates reports and analytics based on maintenance data, providing insights into asset performance, maintenance trends, and resource utilization. Data-driven analysis helps organizations make informed decisions, identify areas for improvement, and optimize maintenance strategies.

Consider reading also how to optimize your CMMS for asset management.

Conclusion

Implementing a robust CMMS system tailored to the specific needs of the aerospace and aviation industry can lead to improved safety, increased operational efficiency, and enhanced regulatory compliance. It provides a comprehensive solution for managing maintenance processes and assets critical to the industry’s success.

Next, read how to implement CMMS software.