Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- The global predictive maintenance market is projected to grow from $10.6 billion in 2024 to $47.8 billion by 2029, with a CAGR of 35.1%

- Fortune Global 500 companies lose approximately $1.4 trillion annually due to unplanned downtime

- Predictive maintenance analytics can reduce maintenance costs by 5-10% and increase equipment uptime by 10-20%

When equipment fails it can be expensive. But what if you could predict failures before they happen?

That’s exactly what predictive maintenance analytics delivers: The ability to anticipate equipment failures, optimize maintenance schedules, and significantly reduce unplanned downtime through data-driven insights.

This is the opposite of reactive maintenance, where you fix things after they break. Preventive maintenance, on the other hand, while superior to reactive maintenance, follows rigid schedules.

Predictive maintenance, on the other hand, utilizes real-time data, machine learning algorithms, and advanced analytics to inform you precisely when equipment requires attention.

This guide will walk you through everything you need to know about predictive maintenance analytics, from basic concepts to advanced implementation strategies.

What is Predictive Maintenance Analytics?

Predictive maintenance analytics is a data-driven approach that uses historical data, real-time monitoring, and advanced algorithms to predict when equipment failures are likely to occur.

Unlike traditional maintenance strategies, predictive maintenance relies heavily on continuous monitoring and data analysis to identify patterns that indicate potential equipment problems.

At its core, predictive maintenance analytics combines several key elements:

- Sensor data collection from critical assets and rotating equipment

- Historical data analysis to identify failure patterns

- Machine learning models that learn from past equipment performance

- Real-time monitoring to detect anomalies as they develop

- Predictive insights that enable a proactive maintenance strategy

The fundamental difference between predictive maintenance and other maintenance strategies lies in its approach to data.

While preventive maintenance follows predetermined schedules and reactive maintenance responds to failures, predictive maintenance utilizes data analytics to optimize maintenance timing based on the actual condition of the equipment.

This proactive maintenance approach enables maintenance teams to perform maintenance only when necessary, reducing both maintenance costs and the risk of unexpected equipment failures.

How Predictive Maintenance Analytics Works

Predictive maintenance analytics operates through a sophisticated process that transforms raw data into actionable maintenance insights. Here’s how the process works:

Data Collection and Continuous Monitoring

The predictive maintenance journey begins with comprehensive data collection from multiple sources:

- IoT sensors monitor vibration, temperature, pressure, and other critical parameters

- SCADA systems provide operational data from industrial processes

- CMMS systems contribute historical repair and failure data

- Equipment performance metrics track overall equipment effectiveness

With continuous monitoring, predictive maintenance creates a comprehensive asset health assessment.

Advanced Analytics and Machine Learning

Once data is collected, predictive maintenance systems employ various analytical techniques:

Machine Learning Algorithms

These systems learn from historical data to identify patterns that precede equipment failures. The algorithms continuously improve their predictions as more data becomes available.

Artificial Intelligence

AI processes vast amounts of sensor data in real-time, identifying subtle changes that might indicate developing problems.

Predictive Models

These mathematical models utilize statistical analysis to predict when equipment is likely to fail, allowing maintenance teams to plan effective interventions.

Pattern Recognition and Anomaly Detection

One of the advanced technologies that enables predictive maintenance is pattern recognition and anomaly detection.

The system can continuously compare current performance against established baselines, flagging anomalies that could indicate potential problems.

For example, a gradual increase in bearing temperature or changes in vibration patterns might signal impending mechanical failure.

With pattern and anomaly detection, maintenance teams can get notified early of a potential catastrophic failure. This can reduce downtime.

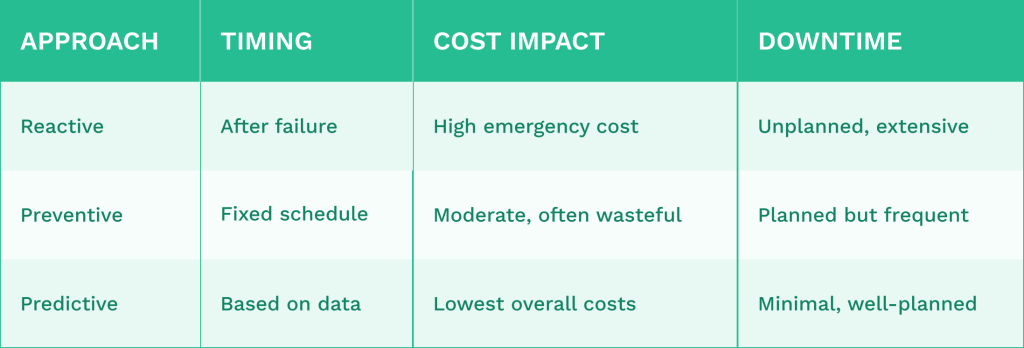

Predictive Maintenance vs. Preventive and Reactive Approaches

Let’s cover the differences in the various maintenance strategies.

The three most popular strategies are Predictive, Preventive, and Reactive maintenance.

Reactive maintenance waits for equipment to break down completely before making repairs. This approach leads to unexpected downtime and emergency repair costs.

Preventive maintenance, on the other hand, follows fixed schedules regardless of actual equipment condition. This approach potentially wastes money on unnecessary maintenance and replacement parts.

Predictive maintenance is different from both approaches. It bases decisions on real equipment conditions and performance data rather than schedules or breakdowns.

The Benefits of Predictive Maintenance Analytics

Several organizations implementing predictive maintenance analytics report significant operational and financial improvements.

Reduced Unplanned Downtime

According to Siemens’ 2024 True Cost of Downtime report, the 500 biggest companies globally lose approximately $1.4 trillion annually due to unplanned downtime. This is equivalent to 11% of their total revenues.

In the automotive sector alone, an idle production line in a major plant can cost up to $2.3 million per hour.

Companies that implement predictive maintenance analytics can anticipate equipment failures and schedule maintenance during planned downtime windows.

With predictive maintenance, organizations can significantly reduce the frequency and duration of unplanned outages.

Research shows that companies implementing predictive maintenance strategies experience substantial improvements.

On average, plants now suffer 25 monthly downtime incidents, down from 42 in 2019, with average large plants losing 27 hours per month to unplanned downtime.

This is a significant decrease from 39 hours in 2019.

Optimized Maintenance Costs

With predictive maintenance, organizations can optimize their maintenance expenses in several ways:

Reduced Emergency Repairs

By identifying potential failures early, maintenance teams can avoid costly emergency interventions that often require overtime labor and expedited parts delivery.

Extended Equipment Life

Proper timing of maintenance activities helps maximize asset lifespan, delaying expensive equipment replacements.

Improved Resource Allocation

Maintenance teams can allocate personnel and materials more efficiently when they know exactly when and where maintenance will be needed.

According to research, predictive maintenance can reduce maintenance costs by 5-10% and increase equipment uptime by 10-20%.

Improved Operational Efficiency

Implementing predictive maintenance analytics transforms how maintenance teams operate:

- Better maintenance schedules based on actual equipment condition rather than arbitrary time intervals

- Improved equipment performance through optimal maintenance timing

- Increased overall operational efficiency by eliminating unnecessary maintenance tasks

- Enhanced equipment reliability through proactive intervention

Safety Improvements

Every maintenance organization wants to improve safety. The good news is that predictive maintenance can contribute significantly to workplace safety by:

- Identifying potential safety hazards before they become dangerous

- Reducing the likelihood of catastrophic equipment failures

- Enabling maintenance in controlled conditions rather than emergencies

- Providing early warning of critical equipment degradation

Technologies and Components of Predictive Maintenance

Successful predictive maintenance implementation relies on several integrated technologies. These technologies work together to collect, process, and analyze equipment data.

IoT Sensors and Data Collection

The foundation of any predictive maintenance program lies in comprehensive data collection:

Sensors monitor rotating equipment for changes in vibration patterns that could indicate bearing wear, misalignment, or other mechanical issues.

Temperature Monitoring

Thermal sensors detect overheating conditions that often precede equipment failure.

Chemical analysis of lubricants reveals equipment wear patterns and contamination issues.

Pressure Sensors

Monitor hydraulic and pneumatic systems for performance degradation.

Current Sensors:

Detect electrical anomalies in motors and other electrical equipment.

These sensors continuously collect data, creating a comprehensive picture of the health of all critical equipment assets.

Computerized Maintenance Management Systems (CMMS)

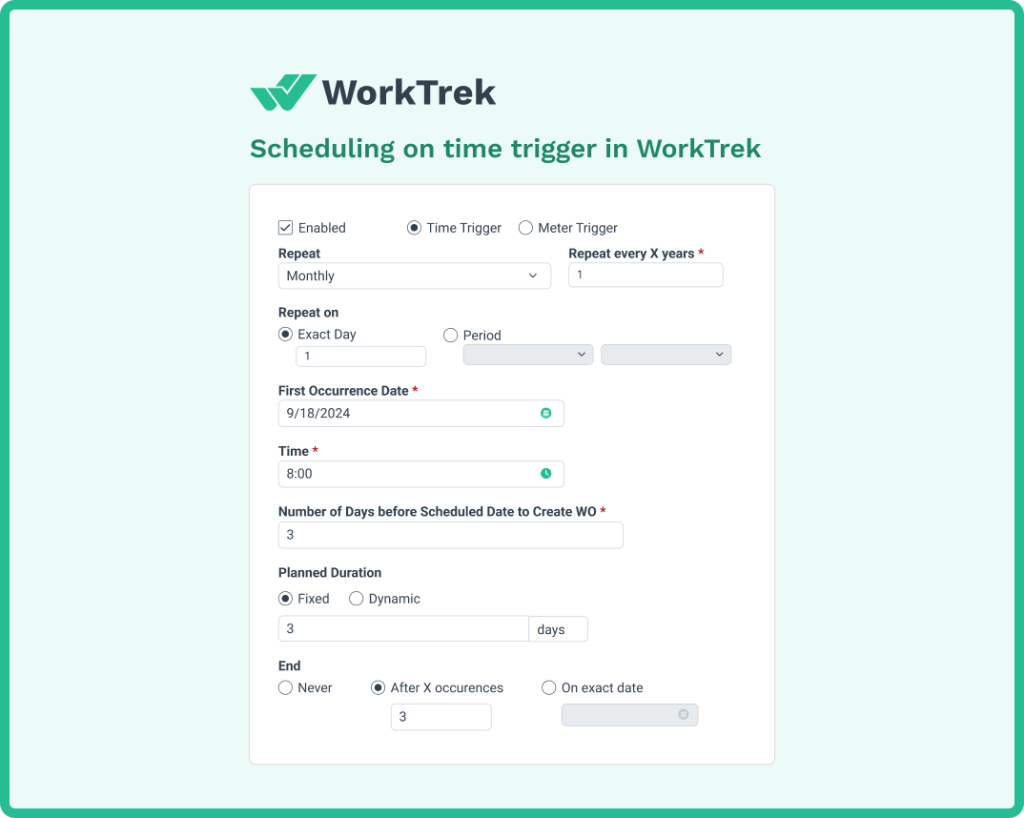

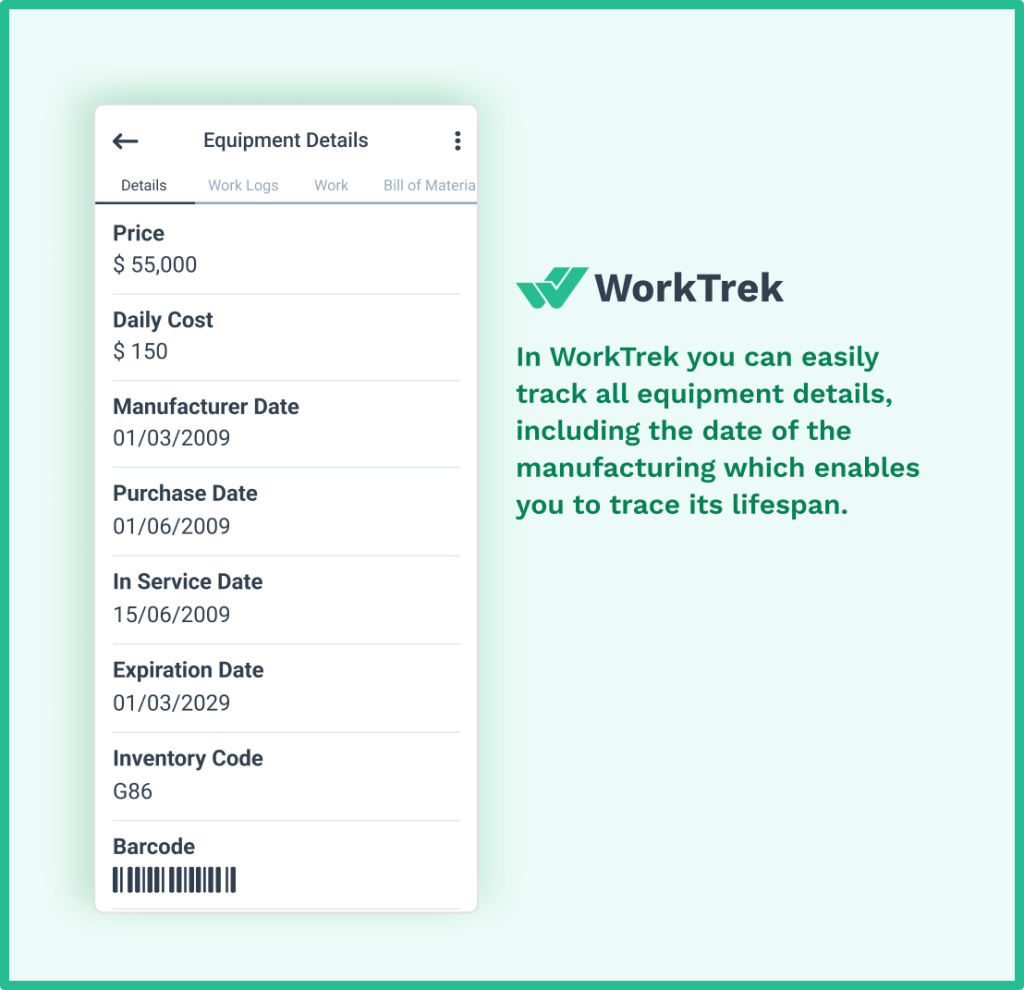

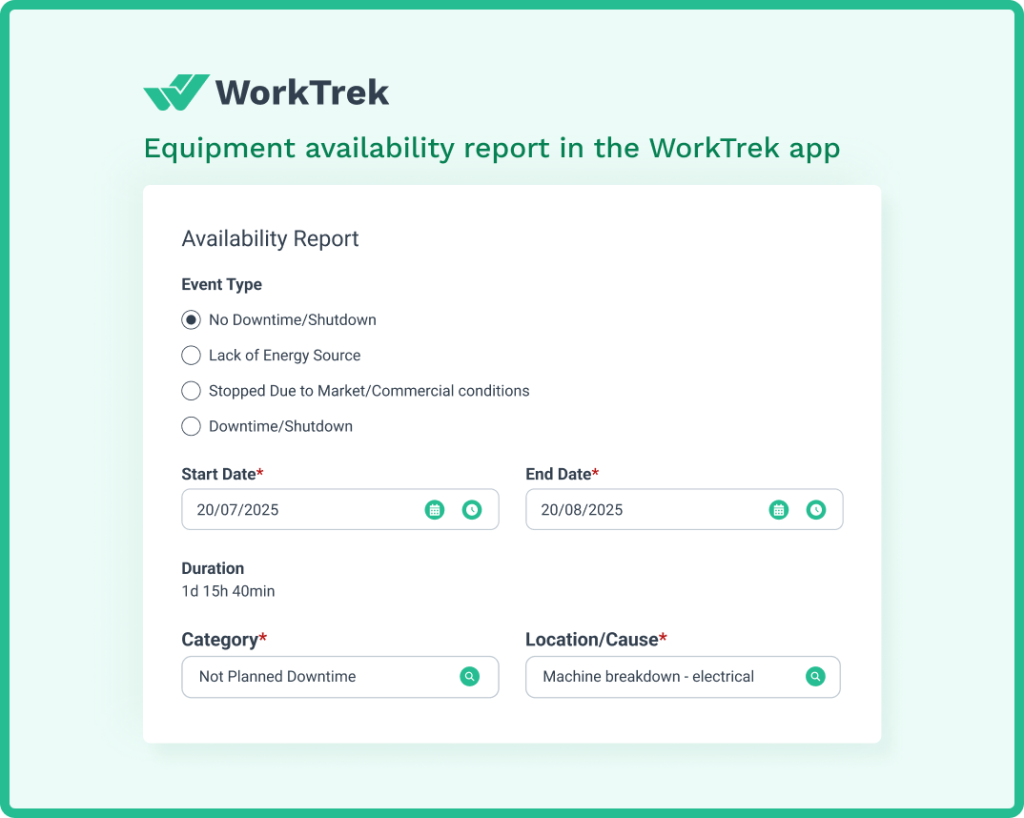

Modern computerized maintenance management systems like WorkTrek serve as the nerve center for predictive maintenance analytics.

An ideal CMMS platform will include the following features:

- Integrate data from multiple sensor sources

- Stores historical maintenance data and equipment performance metrics

- Provides analytics capabilities for identifying trends and patterns

- Automates work order creation when maintenance is predicted

- Tracks key performance indicators related to maintenance effectiveness

Role of Artificial Intelligence and Machine Learning

AI can transform raw sensor data into actionable maintenance insights. Machine learning is the underlying technology that powers AI, which can learn normal equipment behavior patterns and identify when conditions deviate from expected ranges.

Anomaly Detection Algorithms

Compare current sensor readings against historical baselines. When values fall outside normal parameters, the system flags potential issues for investigation.

Predictive maintenance algorithms use multiple data sources to forecast failure timelines. These algorithms consider factors like operating hours, environmental conditions, and maintenance history.

Deep learning models can identify complex patterns that traditional analysis might miss. They excel at processing image data from thermal cameras or analyzing complex vibration signatures.

Machine learning systems improve accuracy over time as they process more data. Initial deployment might achieve 70% accuracy, but systems often reach 90% or higher after several months of operation.

Neural networks can simultaneously analyze data from dozens of sensors to create comprehensive equipment health assessments. This multi-sensor approach provides more reliable predictions than single-point monitoring.

Supervised Learning

Algorithms are trained on historical failure data and learn to recognize patterns that precede equipment problems.

Unsupervised Learning

Systems can automatically identify anomalies without prior knowledge of what constitutes normal or abnormal behavior.

Cloud Computing and Edge Analytics

Modern predictive maintenance systems need an underlying technology to analyze all of this data. That is where cloud and edge computing come in:

Cloud Platforms

Provide scalable computing power for complex analytics and long-term data storage. They remove the need for organizations to worry about hardware or managing server equipment.

Edge Computing

Edge computing occurs when analytics are performed close to the equipment. Instead of pushing your raw data to the cloud, with Edge computing, you can perform analysis close to the equipment. This reduces the need for bandwidth or latency of pushing data back and forth to cloud servers.

Hybrid Architectures

This is when you combine edge and cloud computing to optimize both response time and analytical depth.

Data Analytics and Predictive Models

Data analytics platforms process massive amounts of sensor information to create predictive models. These systems identify failure patterns and estimate remaining equipment life.

Statistical models

Analyzes historical failure data to identify common failure modes and their warning signs. These models help establish maintenance intervals based on actual equipment performance rather than manufacturer recommendations.

Regression Analysis

Can predict future equipment performance based on current trends. If bearing temperatures are gradually increasing, regression models can estimate when replacement will be necessary.

Time Series Analysis

Examines how equipment conditions change over time. This analysis helps distinguish between normal wear patterns and accelerated degradation.

Machine Learning Models

Can process data from multiple equipment types simultaneously to identify fleet-wide maintenance trends. This approach helps optimize spare parts inventory and maintenance scheduling.

Advanced analytics platforms can integrate weather data, production schedules, and operator behavior to create more accurate predictions. This comprehensive approach considers all factors that affect equipment performance.

Building a Predictive Maintenance Strategy

A successful predictive maintenance strategy starts with understanding current practices and equipment needs.

Organizations should start by evaluating their existing maintenance approach and select the right assets to monitor for maximum impact.

Assess Current Maintenance Practices

Many facilities employ a combination of reactive and preventive maintenance approaches.

Start by documenting the current maintenance challenges before implementing predictive systems.

Common issues to evaluate are unexpected downtime, high repair costs, and inefficient maintenance scheduling.

Key areas to evaluate:

- Current maintenance costs per asset

- Average equipment downtime per month

- Maintenance team workload and capacity

- Existing technology, like CMMS or ERP systems

It is nearly impossible to build a predictive maintenance program without a CMMS system like WorkTrek.

With a CMMS you can track work orders and maintenance history in a single system.

On the other hand, enterprise resource planning systems manage a broader range of operational data. These existing systems can integrate with predictive maintenance platforms.

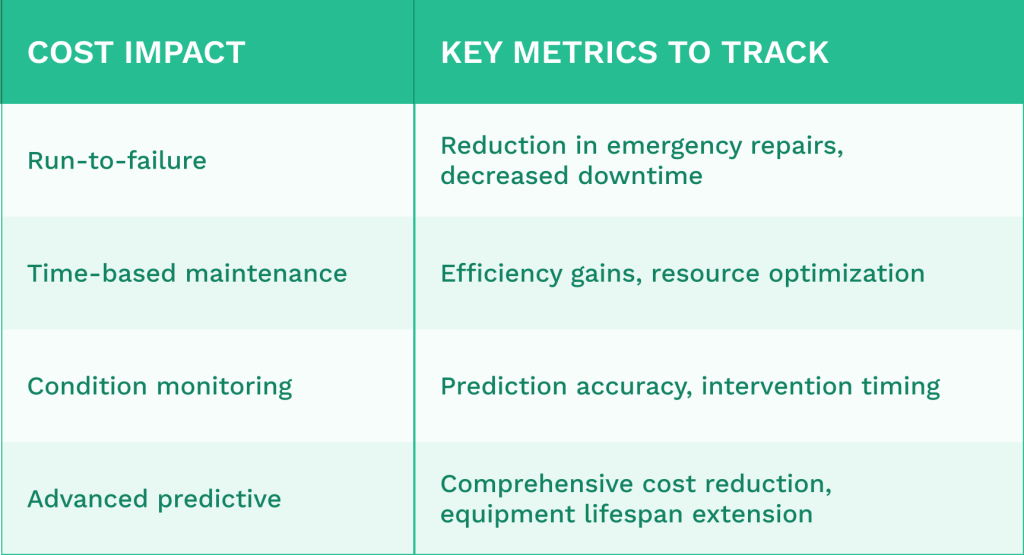

Cultural and Maintenance Maturity

Implementing predictive maintenance requires understanding current maintenance maturity levels.

Organizations using run-to-failure approaches need to change their approach and start tracking different metrics.

Data-driven maintenance decisions only become possible when organizations understand their baseline performance and the overall culture and approach of their maintenance teams.

Selecting Equipment and Assets

The common industry practice is to start by identifying the equipment that is most critical to your organization.

However, critical assets may not be the best starting point for new programs despite seeming like obvious choices.

Better candidates for predictive monitoring:

- Equipment that fails frequently

- Assets with multiple identical units

- Machines with predictable failure patterns

- Equipment with moderate repair costs

Frequently failing equipment provides more learning opportunities than critical assets that rarely break down.

A machine that fails once every five years won’t provide enough sensor data for a 12-month pilot program.

One approach is to identify multiple identical assets. This allows maintenance teams to compare performance and refine their procedures.

A facility with 100 conveyor motors can monitor 20 units and see patterns and cost savings quickly.

Equipment characteristics to consider:

- Failure frequency: Monthly vs. yearly breakdowns

- Repair complexity: Simple motor replacement vs. major overhauls

- Business impact: Production line shutdown vs. minor delays

- Replacement cost: $500 parts vs. $50,000 components

The goal is building confidence through multiple successful predictions rather than waiting for one critical failure. This will also provide the machine learning models with the necessary data to create predictions.

Small wins create stakeholder buy-in and prove the system works before expanding to more complex assets.

Setting Maintenance Goals and KPIs

Any new project should include goals and KPIs that you can track. These goals should align with current organizational capabilities and expected outcomes.

KPIs by maintenance maturity level:

Operational efficiency improvements go beyond just maintenance savings. Equipment performance metrics should track both technical and business outcomes.

Technical metrics include vibration levels, temperature readings, and failure prediction accuracy.

Business impact measurements:

- Maintenance schedule optimization

- Reduced overtime costs

- Improved equipment lifespan

- Better production planning

Soft metrics can demonstrate value to different stakeholders.

Maintenance can greatly benefit from actionable insights that improve daily operations. Management needs clear cost savings and productivity gains.

Challenges in Implementing Predictive Maintenance Analytics

While predictive maintenance analytics offers significant benefits, organizations face several challenges during implementation.

Data Integration and System Compatibility

Many organizations struggle with integrating predictive maintenance analytics into existing systems:

Legacy Equipment

Older machinery often lacks built-in sensors or connectivity options, requiring expensive retrofitting.

Data Silos

Information stored in separate systems makes it difficult to create comprehensive analytics.

System Integration

Connecting CMMS platforms, sensor networks, and analytics tools requires careful planning and technical expertise.

According to industry research, 31% of companies still manage their asset registers in spreadsheets. This clearly presents a major challenge of moving from reactive to predictive maintenance strategies.

Skills and Expertise Requirements

Successful predictive maintenance analytics implementation requires specialized knowledge and staff training:

Data Science Skills

Organizations need personnel capable of developing and maintaining machine learning models.

Domain Expertise

Understanding equipment behavior and failure modes is essential for effective analytics.

Change Management

Training maintenance teams to use new technologies and interpret predictive insights.

According to maintenance professionals, the major challenges include hiring, onboarding, and retaining staff (48%), streamlining processes (27%), and adopting technology (25%).

Cost and ROI Considerations

While predictive maintenance analytics delivers significant long-term value, initial implementation costs can be substantial:

Technology Investment

Sensors, software platforms, and computing infrastructure require upfront capital.

Training Costs

Personnel need training on new systems and analytical techniques.

Integration Expenses

Connecting existing systems and retrofitting legacy equipment adds complexity and cost.

Organizations must carefully evaluate the return on investment, considering both implementation costs and expected benefits.

Data Security and Privacy

As predictive maintenance systems collect and process vast amounts of operational data, security becomes a critical concern:

Cybersecurity Risks

Connected sensors and IoT devices create potential entry points for cyber attacks.

Data Protection

Sensitive operational data requires robust security measures to prevent unauthorized access.

Compliance Requirements

Organizations must ensure predictive maintenance systems comply with relevant data protection regulations.

How CMMS Can Help with Predictive Maintenance Analytics

A modern computerized maintenance management system serves as the backbone of successful predictive maintenance analytics programs.

By centralizing data collection, analysis, and maintenance execution, CMMS platforms enable organizations to leverage the power of predictive insights fully.

Centralized Data Management

CMMS platforms excel at integrating data from multiple sources:

- Sensor Integration: Modern CMMS solutions like WorkTrek can connect directly with IoT sensors and monitoring equipment to automatically collect performance data

- Historical Data Storage: All maintenance records, equipment specifications, and performance metrics are stored in a centralized database

- Real-Time Monitoring: Continuous data collection enables immediate detection of performance anomalies

- Data Standardization: CMMS platforms ensure consistent data formats and quality across all equipment and locations

Automated Analytics and Alerting

Advanced CMMS platforms include built-in analytics capabilities that transform raw data into actionable insights:

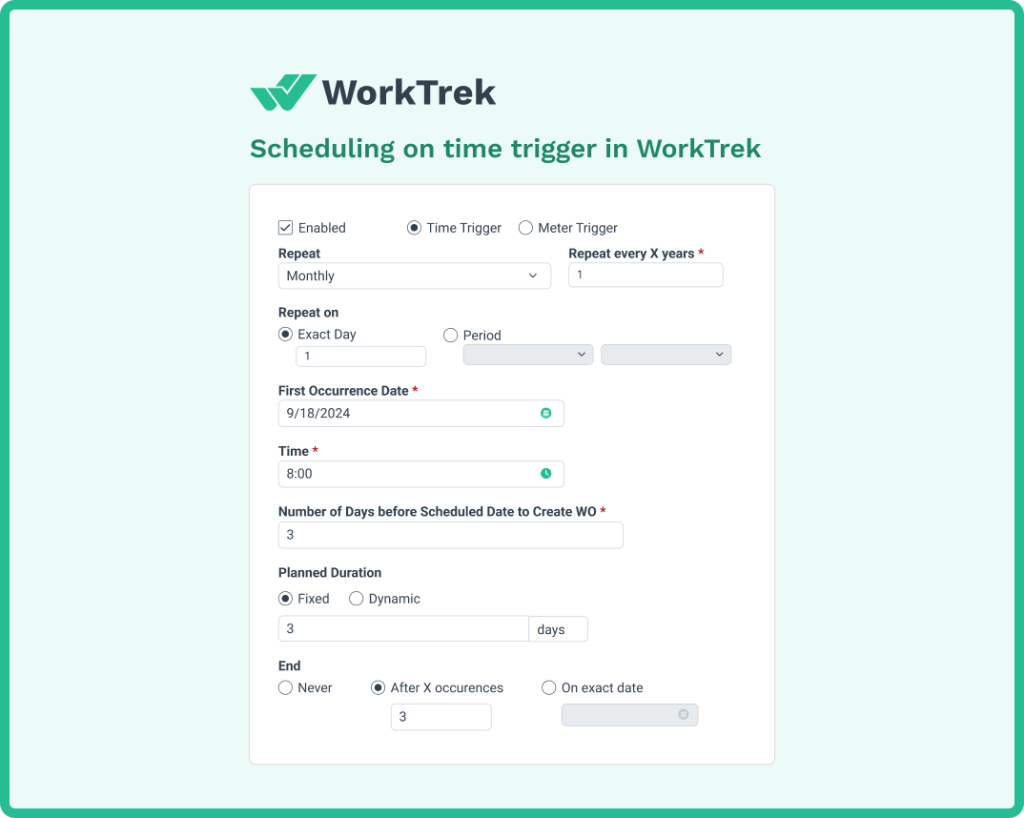

Condition-Based Triggers

The system automatically generates work orders when sensor readings indicate potential problems

Trend Analysis

Historical data analysis identifies a gradual performance degradation that might otherwise go unnoticed

Predictive Alerts

Machine learning algorithms analyze patterns to predict failures before they occur

Customizable Dashboards

Maintenance managers can view key performance indicators and equipment health status at a glance

Integration with Existing Systems

WorkTrek’s flexible architecture enables seamless integration with existing systems:

- ERP Integration: Connect with enterprise resource planning systems for comprehensive asset management

- SCADA Connectivity: Pull operational data directly from industrial control systems

- Third-Party Sensors: Support for multiple sensor types and communication protocols

- Cloud and On-Premise Options: Deploy in the configuration that best meets your organization’s needs

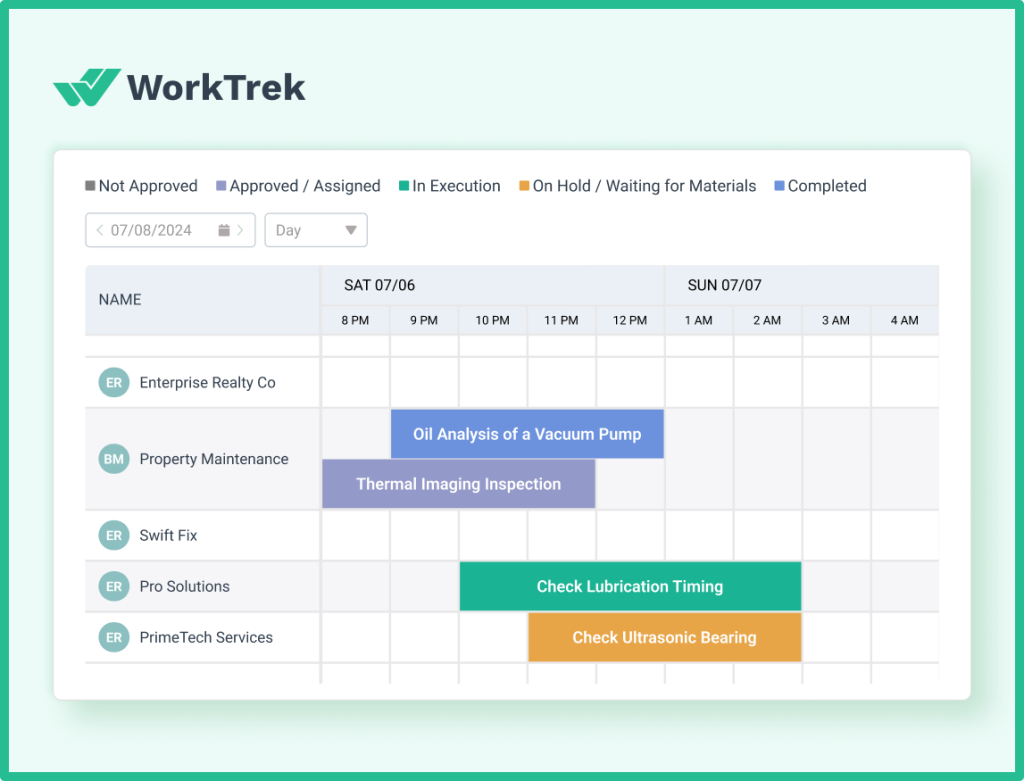

Predictive Maintenance Workflow in WorkTrek

Here’s how WorkTrek streamlines the predictive maintenance process:

- Data Collection: Sensors and integrated systems continuously feed data into WorkTrek’s analytics engine

- Pattern Recognition: Machine learning algorithms identify anomalies and predict potential failures

- Automatic Scheduling: The system generates maintenance recommendations and schedules work orders

- Resource Planning: WorkTrek ensures the right technicians, parts, and tools are available when needed

- Execution Tracking: Mobile applications guide technicians through maintenance procedures and capture completion data

- Continuous Improvement: Analytics identify opportunities to optimize maintenance schedules and procedures

With this integrated approach, maintenance managers can ensure that predictive insights translate directly into effective maintenance actions.

A Step-by-Step Guide for Implementing Predictive Maintenance

As we described in this article, any successful predictive maintenance analytics requires careful planning and systematic execution.

Below is a step-by-step guide on how to start and implement predictive maintenance:

Step 1: Assess Current Maintenance Practices

Start by evaluating your existing maintenance strategies:

Inventory Current Assets

One of the first steps in the process should be a full inventory of all critical assets and their condition

Analyze Maintenance Data

Once you have the full equipment inventory, review all your maintenance records to ensure they are accurate and up to date. It is important to look at all success & failure patterns, along with costs.

Identify Critical Assets

Focus on prioritizing critical equipment that is important to your operation. This includes equipment that, if it fails, can be critical to operations or have a safety and financial impact on the operation.

Evaluate Current Technologies

Assess existing sensors, monitoring equipment, and maintenance management systems.

Step 2: Develop a Predictive Maintenance Strategy

Once you’ve identified all your critical assets and evaluated your current technologies, it is now time to start developing your predictive maintenance plan.

Define Objectives

It should all start by establishing clear goals for reducing downtime, optimizing costs, and improving reliability. Define the KPIs that you want to track as part of your plan.

Select Initial Assets:

There is no reason to go all in at the start. Start by choosing a manageable subset of critical equipment for your pilot program. Also, get buy-in from all the equipment users.

Determine Success Metrics

Define analytical ways to track success. Define the most important key performance indicators to measure program effectiveness and continuously monitor this progress.

Establish Budget

Plan for technology investments, training costs, and ongoing operational expenses. This could include costs for the CMMS platform and sensors.

Step 3: Choose the Right Technology Platform

Selecting the appropriate CMMS and analytics platform is key to your program’s success:

Evaluate CMMS Options:

Look for platforms that offer predictive maintenance capabilities, sensor integration, and advanced analytics

Consider WorkTrek

As the leading solution for predictive maintenance analytics, WorkTrek offers the comprehensive capabilities necessary for a successful implementation.

Plan Integration

Any system you choose should easily integrate with existing systems and sensor networks.

Scalability Planning

Select solutions that can grow with your predictive maintenance program. Evaluate how the application is hosted and ask for performance reports.

Step 4: Install Monitoring Equipment and Sensors

The next step in the process is to start deploying sensors on all the equipment you’ve selected for your pilot program.

Vibration Sensors

These can be installed on rotating equipment to monitor mechanical condition.

Temperature Sensors

These sensors can report when equipment falls outside of safe operating temperatures. Deploy throughout facilities to detect overheating conditions.

Pressure Monitors

These are ideal for placement on hydraulic and pneumatic systems.

Current Sensors

These sensors are designed to be placed on electric circuits to monitor electrical equipment for performance anomalies

Environmental Sensors

Track ambient conditions that affect equipment performance.

Step 5: Configure Analytics and Machine Learning Models

The CMMS system that you choose should have extensive analytical capabilities that will help drive your predictive insights:

Historical Data Loading

Your system should be configured to import and record all maintenance records and equipment performance data. More importantly, this data needs to be easily accessible.

Model Training

The historical data collected by your CMMS system can then be used to train the predictive maintenance models.

Threshold Setting

Each piece of equipment should have specific failure thresholds. While the predictive maintenance systems can use machine learning to define these numbers, this process can take a few months before the systems learn. It will be helpful to start by establishing alert levels for various equipment parameters.

Validation Testing

Test, test & test. All of these automated systems can take some time to train. Do manual spot checks on specific failures to make sure that the systems are accurately predicting failures.

Step 6: Train Your Maintenance Team

It would be impossible to launch a successful predictive maintenance program without a well-trained maintenance team:

System Training

Start by selecting a user-friendly CMMS system, such as WorkTrek. However, that alone is not sufficient. Set up a training program to teach your staff how to use the systems in place effectively and translate the predictive insights.

Data Interpretation

Along with alerts and reports, predictive maintenance helps technicians understand what various sensor readings and alerts mean

Workflow Changes

Modify maintenance procedures to incorporate predictive insights

Continuous Learning

Establish ongoing training programs to keep skills current

Step 7: Launch Pilot Program

Begin with a controlled, smaller implementation to validate your approach:

Start Small

Focus on a limited number of critical assets for initial implementation. This will make it easier to measure progress and is less disruptive to the overall operation.

Monitor Results

Track key performance indicators to measure program effectiveness.

Gather Feedback

Collect input from maintenance technicians and management. This should include both negative and positive feedback. Also, do this consistently.

Refine Processes

Keep iterating and adjust procedures based on early experience and results. It is not easy to get it right the first time.

Step 8: Scale and Optimize

Once you’ve gained experience and collected sufficient data, start looking at scaling your predictive maintenance plan.

Add Equipment

Gradually start to include more assets in the predictive maintenance program.

Enhance Analytics

Continue to monitor and improve models based on the data and analytics from your CMMS.

Process Improvement

Continuously optimize maintenance workflows and procedures. Keep iterating and evaluating your process.

ROI Measurement:

Use the results to regularly assess the financial benefits of predictive maintenance analytics.

Key Performance Indicators to Track

There are a number of key performance indicators that you can track for predictive maintenance.

They are broken up into reliability, cost, Performance, and operational KPIs. Below is a list of the ones you should be tracking:

Equipment Reliability Metrics

Mean Time Between Failures (MTBF)

Measures average operating time between equipment failures, with increasing MTBF indicating improved reliability.

MTTR tracks the average time required to restore equipment to operation, with decreasing MTTR showing maintenance efficiency improvements

Overall Equipment Effectiveness (OEE)

OEE combines availability, performance, and quality metrics to provide a comprehensive measurement of equipment productivity.

Equipment Availability:

This measures the percentage of time equipment is available for production, which is directly impacted by effective predictive maintenance.

Maintenance Cost Optimization

Maintenance Cost per Unit of Production

Relates maintenance spending to output that enables cost optimization analysis.

Planned vs. Unplanned Maintenance Ratio

Generally, higher ratios of planned work indicate better predictive maintenance effectiveness.

Maintenance Cost as a Percentage of Replacement Asset Value

This is a great KPI to help you identify over- or under-investment in maintenance activities

Emergency Repair Frequency

With a successful predictive maintenance plan in place, you should be able to reduce your emergency repair frequency. If this ratio is increasing, evaluate your predictive maintenance plan.

Predictive Analytics Performance

Prediction Accuracy:

Measures how often predictive models correctly identify impending failures.

False Positive Rate

Tracks unnecessary maintenance actions triggered by incorrect predictions.

Lead Time Accuracy

Predictive maintenance should provide you with accurate predictions of failure. Evaluates how precisely the system predicts when failures will occur. If accuracy decreases, adjust the program accordingly.

Condition Monitoring Coverage

Measure the percentage of critical assets under continuous monitoring.

Operational Impact Metrics

Unplanned Downtime Reduction

Measures the decrease in unexpected equipment outages. A successful predictive maintenance plan should reduce downtime. If that is not the case,e then adjust your plan.

Inventory Optimization

Not having the right parts in stock slows down repairs, and having too many increases expenses. With better failure prediction, you should see an improvement in spare parts management.

Energy Efficiency Improvements

Monitors equipment energy consumption optimization through predictive maintenance.

Safety Incident Reduction

Safety is critical to all organizations. Measures a decrease in maintenance-related safety incidents.

The Future of Predictive Maintenance Analytics

The technology underlying predictive maintenance is quickly evolving. As AI and machine learning models evolve, and there is an improvement in IoT sensors the prediction models will improve.

Below are a few technologies to look for in the coming years:

Artificial Intelligence Advancement

AI and machine learning algorithms are continuing to evolve and improve.

Improved Accuracy

With better AI models, predictions will improve and false positives will reduce.

Automated Model Training

As AI technology involves models that will become smarter and will continuously enhance their predictive capabilities.

Multi-Modal Analysis:

Instead of building models per IoT type, new models can manage data from various data sources, reducing overall complexity.

Natural Language Processing

As these models involve, new AI systems can interpret maintenance notes and technical documentation. It will also enable maintenance teams to ask questions through a chatbot and get results.

IoT Expansion

IoT devices are constantly improving and covering more equipment types.

Cloud Computing Integration

Cloud platforms are enabling smaller organizations to access sophisticated analytics. This reduces the need to set up a complex computing infrastructure locally to support predictive maintenance.

Scalable Computing Power

Access to advanced analytics without large infrastructure investments.

Software as a Service:

Predictive maintenance capabilities are available through subscription models. This enables organizations to start with lower capital investment.

Data Storage Solutions

Cloud providers can provide secure, scalable storage for large volumes of sensor and maintenance data at reasonable cost.

Digital Twin Technology

Digital twins create virtual replicas of physical assets for advanced simulation and prediction. This reduce the need to test on production equipment reducing downtime.

Real-Time Modeling

Virtual equipment models that mirror actual operating conditions

Scenario Testing

Ability to test maintenance strategies without affecting actual equipment

Optimization Algorithms

Using digital twins you can optimize maintenance timing and resource allocation.

Predictive Simulation

Testing various operating scenarios to predict equipment behavior

Conclusion

Predictive maintenance analytics is a fundamental shift from reactive and preventive approaches.

As this article has outlined, it leverages real-time data, advanced analytics, and machine learning algorithms to optimize maintenance.

The evidence is compelling: with the global predictive maintenance market projected to grow from $10.6 billion in 2024 to $47.8 billion by 2029. With Fortune Global 500 companies losing $1.4 trillion annually due to unplanned downtime the business case for predictive maintenance analytics has never been stronger.

Predictive maintenance isn’t just about technology; it requires an organizational transformation.

Implementing the right tools, training, and commitment, predictive maintenance can transform your maintenance operations and deliver significant competitive advantages.