Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Nearly half of industrial workers experience a safety incident at their facility within a year.

- Business leaders observe higher productivity as a result of effective communication.

- Workers without the skills to perform effectively often consider quitting their jobs.

Successful maintenance supervisors and managers do far more than simply ensure that equipment is repaired on time and in the most cost-effective way possible.

When they fully embrace their role, they become strategic partners for the entire organization, and not just leaders of a function often seen as an unavoidable expense.

These professionals help companies save money, reduce risk, and elevate operational efficiency to new heights.

So, if you aspire to join their ranks, keep reading to discover what sets the best maintenance supervisors apart from the rest.

Make Safety Non-Negotiable

First and foremost, successful maintenance leaders set and enforce safety standards, always leading by example and never cutting corners.

Muhammad Rehan, Reliability Engineer at BHP, an Australian multinational mining and metals corporation, agrees:

By doing so, supervisors play a vital role in creating a safer workplace and reducing the risk of accidents, injuries, or worse.

After all, maintenance work is inherently hazardous, with technicians regularly handling electricity, rotating equipment, pressurized systems, heights, confined spaces, and chemicals.

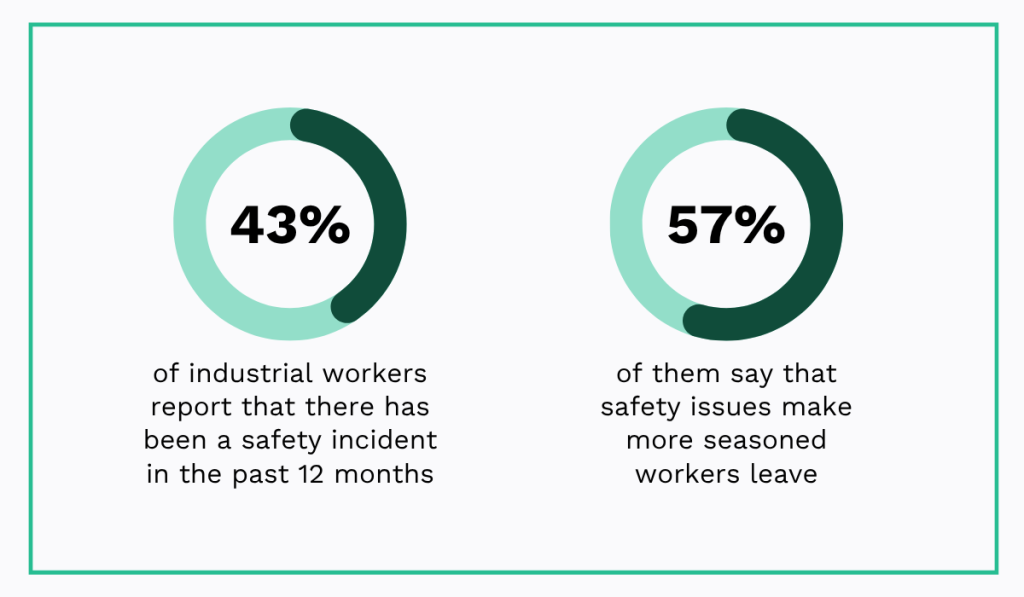

The 2024 Vector Solutions research highlights just how serious the situation is in industrial environments.

As it turns out, nearly half of industrial workers report experiencing a safety incident at their facility within a year.

Even more worryingly, more than half say these issues influence their decision to leave their workplace.

That’s where you, as a supervisor, come in.

Your role is to create a culture of safety and compliance: not only to protect the company from fines and legal trouble but, more importantly, to ensure your team feels protected and valued.

One of the most effective ways to achieve this is by making safety procedures clear, accessible, and ever-present.

Include PPE requirements, potential hazards, and safety reminders in every work order, display them prominently on bulletin boards, and reinforce them in every meeting.

Kristen Panella, Founder of 2SAFE Consulting, a firm that specializes in safety training, industrial hygiene testing, and more, notes that the number one cause of safety incidents is a lack of knowledge.

He recalls one of his past investigations:

“I was at a facility, and a gentleman was in a forklift. It lifted him up, […] He was not wearing fall protection. I said, “You’re 20 feet in the air. Why aren’t you wearing fall protection?” He said, ‘You’re the first person to say anything about that.'”

This should never happen on your watch.

Keep reinforcing safety practices and reward good behavior until a safety-first mindset becomes second nature.

Foster Effective Communication

Good supervisors understand the importance of clear, efficient, two-way communication with everyone involved in maintenance operations, from technicians and operators to management.

They ensure everyone is aware of priorities, expectations, and status updates on work orders or shutdowns, along with the reasons behind them.

Ultimately, communication can make or break operational success, regardless of industry, sector, or department.

Maintenance is no exception.

Poor communication leads to delays, rework, and safety incidents.

However, when done right, it significantly improves coordination, morale, and response times.

The 2024 Grammarly survey supports this, revealing that most business leaders observed higher employee productivity and confidence as a result of effective communication.

One of the simplest yet most effective steps you can take here is to hold daily or weekly team meetings (or toolbox talks) to discuss the day’s tasks, hazards, and priorities.

That’s the approach taken by Luncedo Gadu, Maintenance Manager at the Boardwalk hotel.

He explains:

Having worked as a maintenance manager in the construction and petrochemical industries, and now in hospitality, Gadu has learned that without clear communication, nothing gets done.

Or it gets done poorly.

So, take a page from his book: start each shift with a brief toolbox talk or morning huddle to discuss the day’s key topics.

Keep these meetings short but consistent to set the rhythm and structure for the team without wasting time.

Most importantly, encourage your team to share updates, concerns, or challenges.

After all, good communication also means listening.

So, to help open up discussions, consider asking these questions in each meeting:

- What tasks are you currently working on?

- Do we expect any issues or delays?

- Is there anything we should coordinate with production about?

- Are there any issues or obstacles hindering progress?

- Do you need any additional resources or support?

These questions add structure to your meetings and show your team that they’re heard, valued, and supported.

Continuously Train Your Team

Good maintenance supervisors know they’re only as strong as their team.

That’s why they continuously sharpen their technical, safety, and communication skills through ongoing training, mentoring, and cross-training.

Denise Buklis, Senior Aircraft Maintenance Manager at ACASS, a worldwide provider of business aviation support services, is all for this approach:

This is because well-trained technicians make fewer mistakes, troubleshoot faster, and feel more confident and valued.

Put simply, training makes them better workers overall.

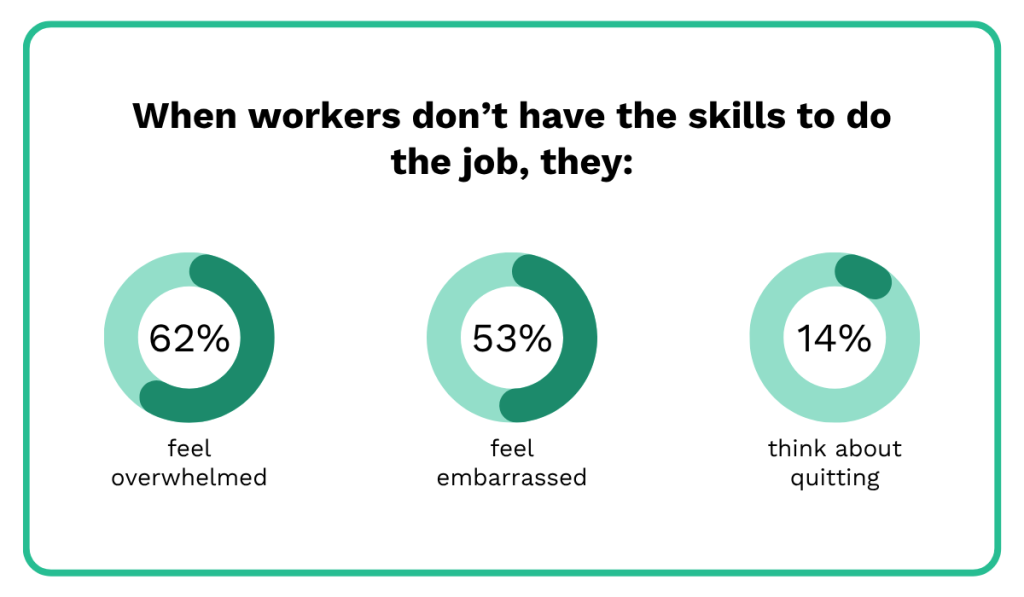

On the other hand, a lack of proper training has the complete opposite effect, leading to stress and burnout.

In fact, according to the 2025 Axonify survey, employees who lack the skills or resources to perform effectively claim they often feel overwhelmed, embarrassed, or even consider quitting.

The only way to prevent this is through continuous training.

However, not just any training will do.

Different skills and learning styles call for different approaches, so it’s important to choose the right method for your team.

AJ Ruperto, Manager of Video Acquisition at KPA, a provider of safety management and workforce compliance solutions, elaborates:

While Ruperto is referring to safety training here, the same applies to any type of training.

The bottom line is that most successful programs blend theoretical instruction with hands-on experience, helping workers understand both the what and the why.

If you’d like to explore this topic further, check out our dedicated article on developing an effective maintenance training program.

You’ll find practical tips to help you fully meet your team’s learning needs, just like a truly great supervisor does.

Prioritize Proactive Maintenance

Effective supervisors focus on minimizing the need for “putting out fires.”

Instead, they prioritize scheduled inspections, lubrication, and part replacements before breakdowns occur.

Zach Williams, Engineering Manager at Kito Crosby Australia, an industrial equipment supplier specializing in custom hoists and lifting solutions, explains why this matters:

Ultimately, this extends asset life, reduces maintenance costs, and helps the team manage workloads more effectively.

More importantly, it minimizes that dreaded and costly unplanned downtime.

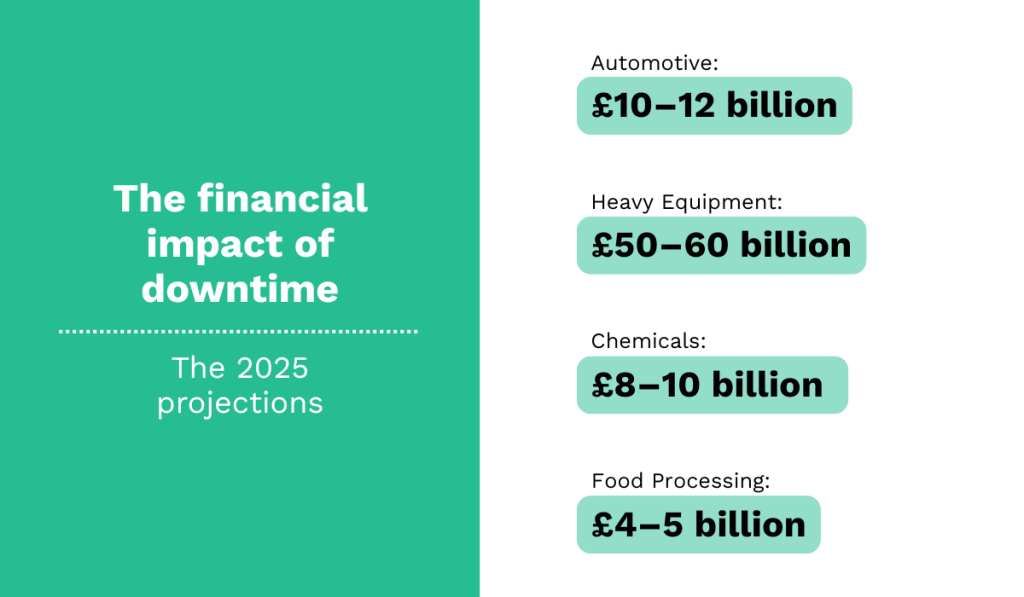

To understand just how costly this issue can be, take a look at findings from IDS-INDATA, which show that in 2025, downtime losses could total tens of billions across various industries.

As a maintenance supervisor, it’s important to recognize this risk and always prioritize operational continuity.

The best way to achieve that is through a robust preventive maintenance program: one that ensures each asset receives the necessary attention before a major failure occurs.

For this, you’ll need to closely monitor asset performance and condition, and develop maintenance schedules that consider several key factors:

- Manufacturer recommendations

- Asset criticality

- Historical performance data

- Maintenance cost vs. downtime cost

- Regulatory requirements

It’s important to weigh all these factors carefully because you simply can’t give every asset the same level of attention.

The most effective preventive maintenance programs prioritize the assets most critical to operations and those that pose the greatest risk if neglected.

Less critical assets can be placed on simpler time-based schedules or, in some cases, managed reactively.

Rely on Data for Decision-Making

Experienced maintenance supervisors develop a strong intuition over the years on the job, but they know better than to rely on it alone.

Instead, they leverage data to guide their planning, justify budgets, identify weak spots, and boost overall operational efficiency.

They avoid guesswork, assumptions, or “we’ve always done it this way” thinking, and instead rely on reports and dashboards to keep their decisions agile and evidence-based.

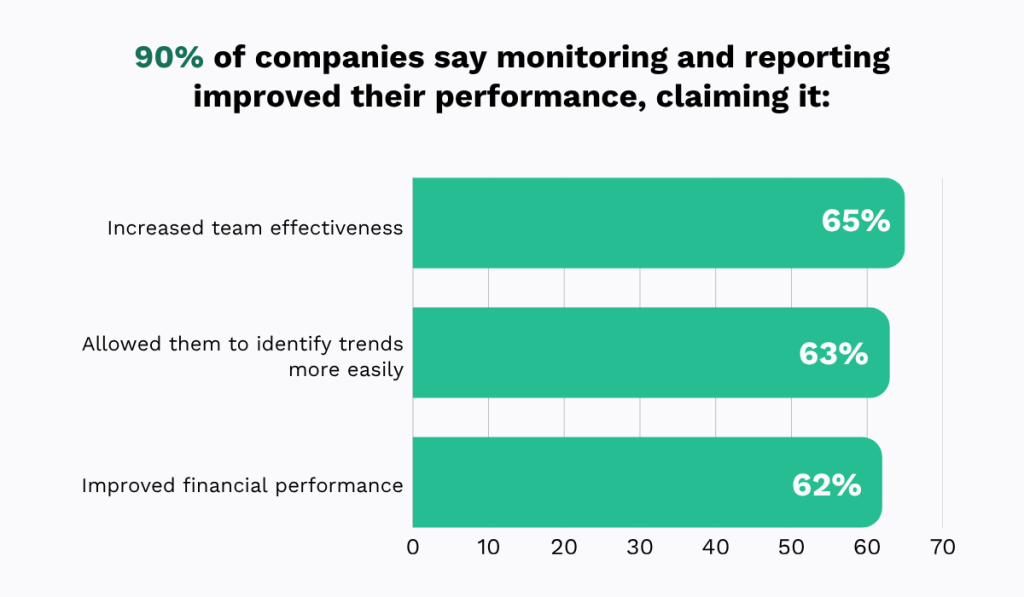

The 2023 Databox survey supports this approach, showing that most companies see improved performance through monitoring and reporting.

Specific benefits include increased effectiveness, easier trend identification, and even better financial outcomes.

You can achieve the same results by gathering relevant performance data and turning it into actionable reports.

This should be done regularly (weekly, monthly, or quarterly), depending on the metric and your goals.

Now, when it comes to KPIs, it’s tempting to track everything at once, but that can quickly lead to data overload.

So instead, start with the essentials, such as:

| MTBF (Mean Time Between Failures) | How often equipment fails |

| MTTR (Mean Time to Repair) | How long it takes to fix |

| Downtime | Total unplanned downtime per asset |

| PM Compliance | Percentage of preventive tasks completed on schedule |

Over time, you can expand this list, but always ensure KPIs align with your goals.

For example, if reducing costs is the priority, focus on metrics like preventive maintenance compliance, planned vs. unplanned expenses, and the cost of downtime.

A highly skilled maintenance supervisor knows they can’t track everything at once, so they focus on the data that matters most, right now, to make informed, impactful decisions.

Use the Right Tools

With the right digital tools, everything mentioned above becomes far easier to implement.

Manual data entry, constant updates, and the risks of human error or miscommunication become things of the past.

Here, it’s especially worth mentioning CMMS solutions.

They automate all important processes, centralizing work orders, asset data, schedules, and performance metrics, and making maintenance operations more efficient and accurate.

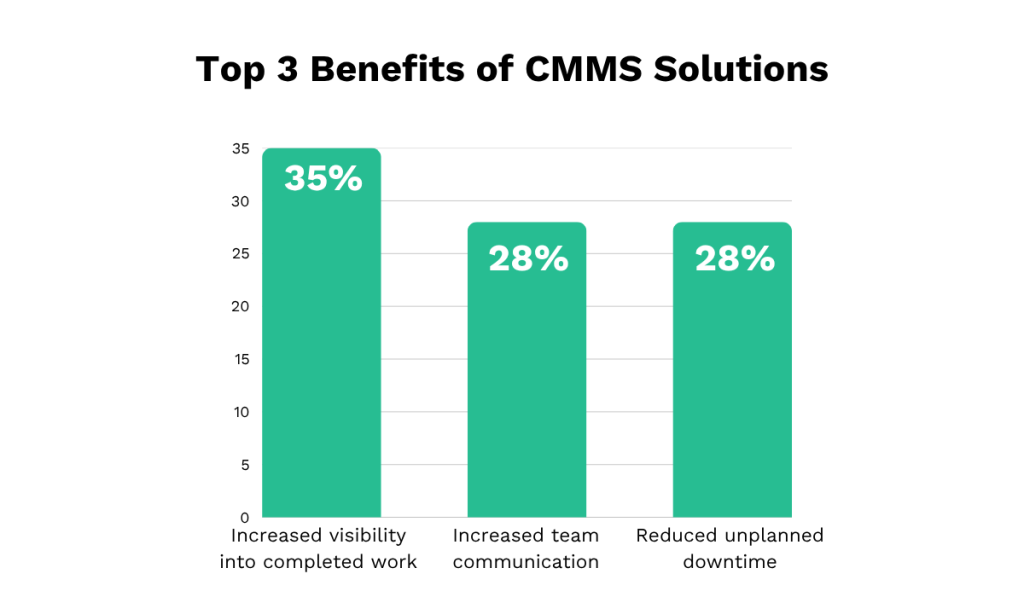

In fact, research has already shown that CMMS solutions improve transparency, enhance communication, and reduce unplanned downtime.

Essentially, they act like a central control room for all maintenance operations, providing unprecedented visibility and control.

For example, our CMMS solution, WorkTrek, enables you to:

- Upload safety rules, hazard reminders, and LOTO procedures, and attach them to work orders to boost safety and compliance.

- Leave notes, feedback, and updates within work orders and communicate through our mobile app to improve communication.

- Access 50+ pre-built reports and KPIs for truly data-driven decision-making.

- Create, assess, prioritize, track, and record all work orders in one place, increasing accountability and accuracy.

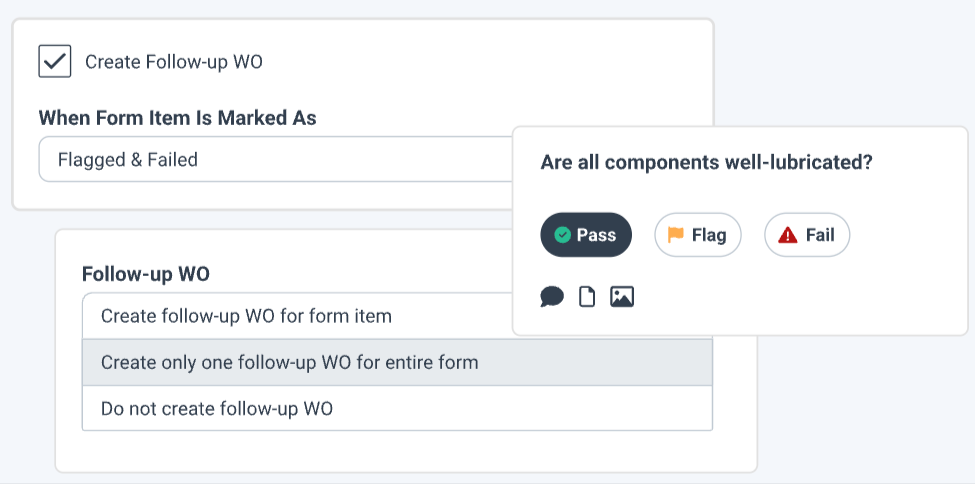

Most importantly, WorkTrek includes a preventive maintenance scheduling feature that lets you plan proactive maintenance based on the triggers you choose.

This includes time-based (daily, weekly, monthly) or meter-based (usage time, mileage, temperature, pressure, and more) triggers.

Additionally, if an inspection fails, WorkTrek automatically generates a follow-up work order to ensure timely action.

The bottom line: the era of paper logs, manual updates, and human error is over.

Successful supervisors embrace advanced tools like WorkTrek, making maintenance operations smarter, more efficient, and smoother than ever.

Conclusion

After reading through all these tips, you’ve likely noticed an important theme: the best maintenance supervisors don’t necessarily work harder than everyone else.

They work smarter.

They rely on relevant data, encourage continuous learning and improvement, and never shy away from new tools, machinery, and methods.

At the same time, they always put their team first, prioritizing safety, listening to concerns, and valuing every opinion.

Becoming that kind of supervisor certainly doesn’t happen overnight.

But with patience, curiosity, and a commitment to growth, you can absolutely get there.

And when you do, you won’t just lead a great team. You’ll help build a company everyone’s proud to be part of.