Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways

- Preventive maintenance audits deliver an average ROI of 545%, with every dollar spent saving five dollars in reduced failures and downtime

- Organizations conducting regular preventive maintenance audits reduce equipment breakdowns by up to 90% and extend asset lifespan by 20-40%

- A comprehensive audit process involves 7 critical steps, from planning through continuous improvement, typically requiring 2-4 weeks for completion

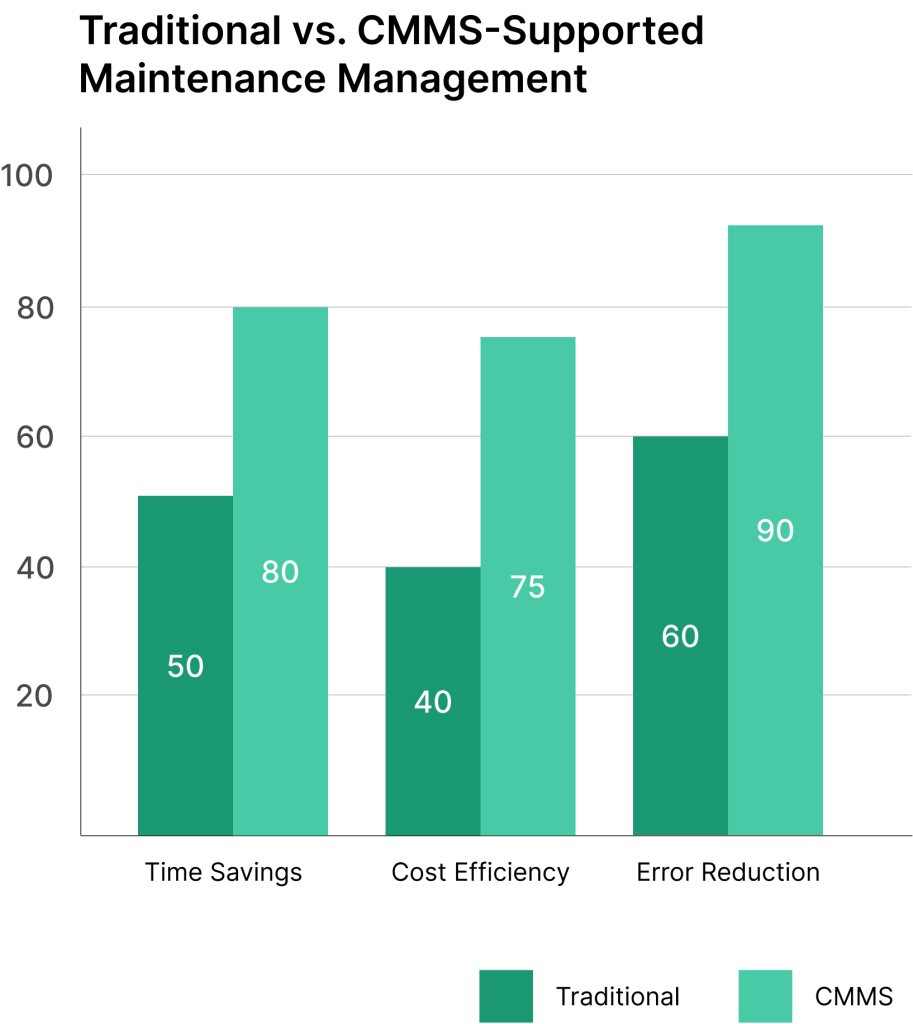

- Modern CMMS platforms can reduce audit time by 50% while improving the accuracy and actionability of findings

Here’s the reality: according to recent industry data, unplanned downtime costs Fortune Global 500 companies $1.4 trillion annually—that’s 11% of their total revenue disappearing due to equipment failures.

Yet research from McKinsey shows that 70-85% of equipment failures are entirely preventable with proper maintenance practices.

What is the bridge between reactive chaos and proactive control? A well-executed preventive maintenance audit.

This comprehensive guide walks you through exactly how to conduct a preventive maintenance audit that transforms your maintenance operations from costly reactive scrambling to profitable proactive management. You’ll discover the proven 7-step process, real-world examples from successful implementations, and downloadable tools to get started immediately.

Let’s take a detailed look.

What Is a Preventive Maintenance Audit?

A preventive maintenance audit is a comprehensive evaluation of your organization’s preventive maintenance program. The goal is to examine everything from maintenance schedules and procedures to equipment performance and team capabilities.

Think of it as a comprehensive health check for your maintenance operations. This is where you can identify gaps, validate successes, and provide a roadmap for continuous improvement.

Unlike routine inspections that focus on individual assets, a preventive maintenance audit examines your entire maintenance ecosystem.

The audit process scrutinizes your maintenance documentation, assesses compliance with safety regulations, and measures the effectiveness of your current maintenance strategies.

But here’s what a preventive maintenance audit isn’t: it’s not a blame game or a witch hunt.

The most successful audits create an environment of continuous improvement rather than finger-pointing.

They focus on systemic issues rather than individual failures, seeking to understand why maintenance procedures might be skipped or delayed rather than simply documenting non-compliance.

A properly conducted audit answers critical questions about your maintenance program:

- Are we performing the right preventive maintenance tasks at the right frequency?

- Do our maintenance schedules optimize resource allocation while minimizing downtime?

- How effectively are we tracking maintenance history and using that data for improvement?

- What equipment failures could we prevent with better maintenance practices?

- Where are the gaps between our documented procedures and actual practices?

The ultimate goal? Creating a data-driven foundation for maintenance decisions that reduce costs, improve reliability, and extend equipment life.

When to Conduct a Preventive Maintenance Audit?

Timing is everything in maintenance, and knowing when to conduct your preventive maintenance audit can mean the difference between proactive improvement and reactive scrambling.

Recommended Audit Frequency

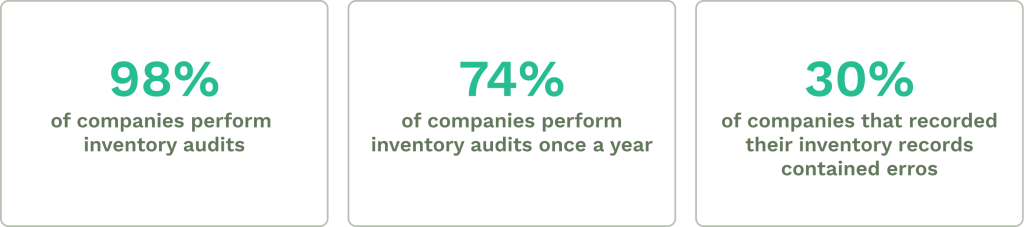

There are some basic industry guidelines: conduct comprehensive preventive maintenance audits annually or semi-annually.

Fiix Software’s analysis of high-performing maintenance organizations shows that annual audits strike the optimal balance between thoroughness and resource investment for most facilities.

However, your specific frequency should reflect your operations.

Critical assets operating in harsh environments might warrant quarterly reviews of their preventive maintenance effectiveness.

Facilities with strong CMMS implementation and consistent high performance might extend to 18-month cycles.

Triggering Events That Demand Immediate Audits

Sometimes you can’t wait for the scheduled audit. These situations call for immediate evaluation:

After Major Equipment Failures

When critical assets fail despite preventive maintenance, it signals potential systemic issues. A focused audit can identify whether the failure resulted from inadequate maintenance schedules, improper procedures, or execution gaps.

Following Safety Incidents

Any maintenance-related injury or near-miss should trigger an audit of relevant procedures and practices. This isn’t about blame—it’s about preventing recurrence.

During Performance Degradation

When key performance indicators trend downward—rising maintenance costs, increasing equipment downtime, declining schedule compliance—an audit can diagnose root causes before they become critical.

Before Major Capital Investments

Planning significant equipment purchases or upgrades? An audit ensures your maintenance program can properly support new assets from day one.

After Organizational Changes

New leadership, reorganizations, or significant staff turnover can disrupt established maintenance practices. Audits help identify and address gaps before they impact operations.

The 7-Step Process for Conducting a Preventive Maintenance Audit

Now, let’s get into how actually to conduct your audit.

Step 1: Define Scope and Objectives

Stars with crystal-clear objectives and boundaries.

Begin by answering fundamental questions:

- What specific aspects of your preventive maintenance program need evaluation?

- Are you focusing on a particular department, equipment category, or facility?

- What outcomes do you need—cost reduction, reliability improvement, compliance verification, or all of the above?

Your scope definition should specify:

- Physical boundaries: Which facilities, departments, or production lines are included

- Asset categories: All equipment, critical assets only, or specific types

- Program elements: Maintenance schedules, procedures, documentation, training, or comprehensive evaluation

- Time frame: Historical data period to review (typically 6-12 months)

- Success criteria: Specific, measurable outcomes you’ll use to evaluate success

Don’t try to boil the ocean. A focused audit of critical assets often delivers more value than a surface-level review of everything.

As one maintenance manager at a chemical processing plant told us, “Our first audit tried to cover everything and accomplished nothing. The second audit focused on our top 20% of critical equipment and transformed our entire operation.”

Create an audit charter document that all stakeholders sign off on. This prevents scope creep and ensures everyone understands what’s being evaluated and why. Include estimated timelines, resource requirements, and communication protocols.

Pro tip: Involve your maintenance personnel from day one. They know where the bodies are buried, and their buy-in is essential for implementing improvements.

Frame the audit as an opportunity to finally fix those persistent problems they’ve been complaining about for years.

Step 2: Assemble Your Audit Team

The makeup of your audit team can make or break your preventive maintenance audit.

You need a balanced mix of perspectives: maintenance expertise, operational knowledge, and fresh eyes. The ideal team includes:

Internal Team Members:

- Lead auditor with maintenance management experience

- Senior maintenance technician who knows equipment intimately

- Operations representative who understands production requirements

- Safety specialist familiar with regulatory requirements

- CMMS administrator or data analyst for information gathering

External Perspective:

Consider including an external auditor or consultant, especially for your first comprehensive audit. They bring industry best practices, objective assessment, and comparative benchmarking that internal teams might miss.

Define clear roles and responsibilities.

- Who conducts equipment inspections?

- Who reviews maintenance documentation?

- Who interviews maintenance personnel?

- Clear accountability prevents important areas from falling through cracks.

Schedule a kickoff meeting for the audit team to review objectives, methodology, and timeline. Define and establish communication protocols.

Those include how often the team will meet, how findings will be documented, and who needs to be informed of critical discoveries.

Remember: your audit team members still have day jobs. Plan for realistic time commitments and consider backfill support for critical roles.

Nothing derails an audit faster than team members getting pulled away for emergency repairs.

Step 3: Conduct Pre-Audit Data Collection

Start a full data collection before anyone sets foot on the shop floor. This lays the groundwork for the audit.

Start with your maintenance documentation.

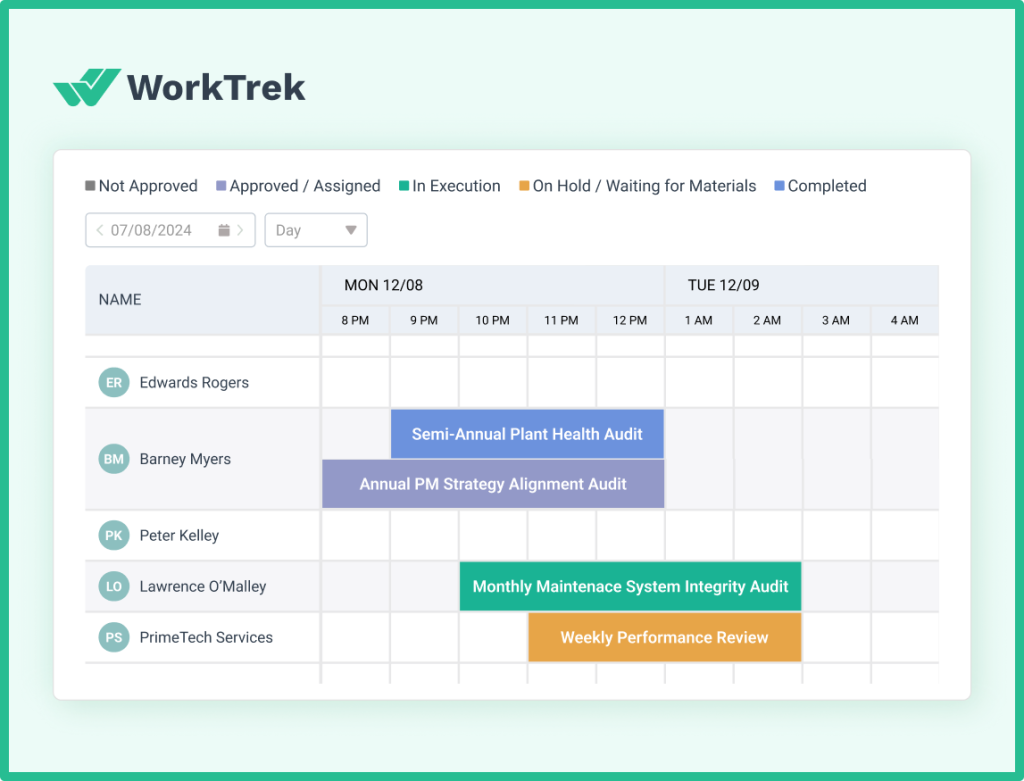

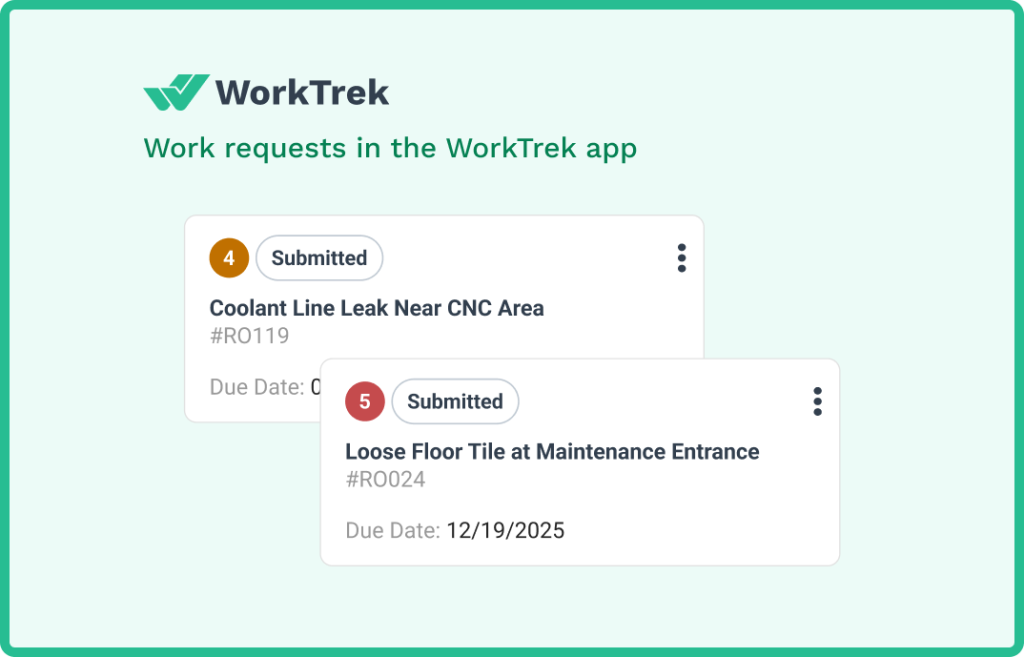

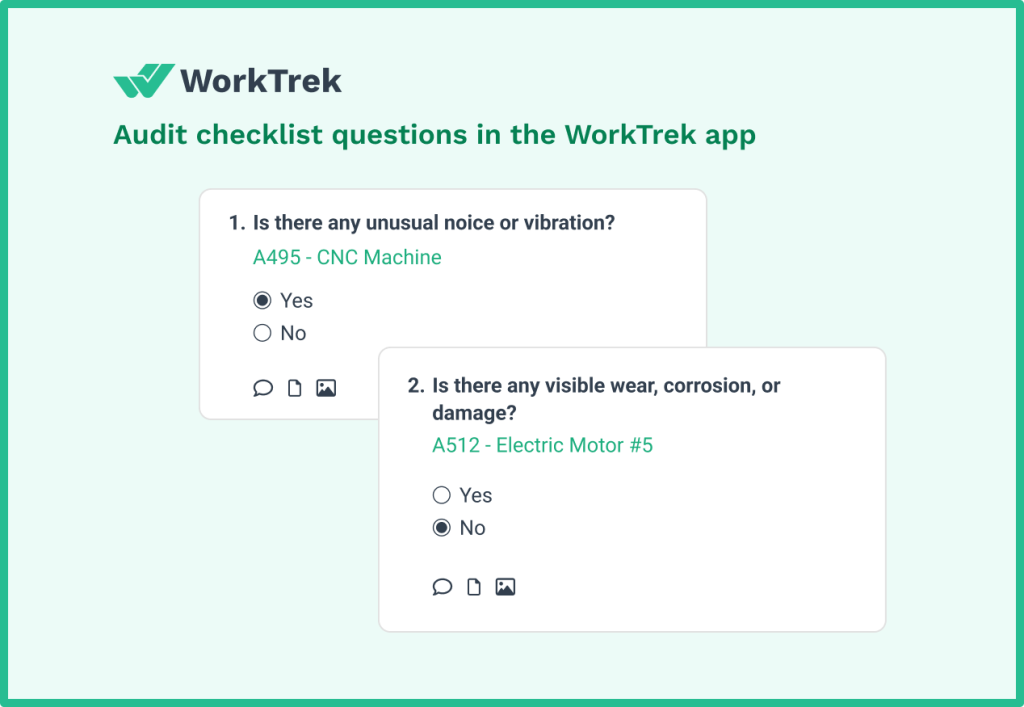

A computerized maintenance management system like WorkTrek makes this exponentially easier. CMMS users complete maintenance audits 50% faster than those relying on paper records. Pull together:

Maintenance History and Records:

- Work order completion rates for the past 6-12 months

- Preventive maintenance schedule compliance data

- Equipment failure reports and root cause analyses

- Maintenance costs are broken down by labor, parts, and contractors

- Downtime logs with duration and impact

Current Maintenance Procedures:

- Preventive maintenance task lists for all included equipment

- Standard operating procedures for maintenance activities

- Safety protocols and lockout/tagout procedures

- Training records and certification documentation

- Vendor recommendations and equipment manuals

Performance Metrics:

- Key performance indicators trends (MTBF, MTTR, OEE)

- Budget vs. actual maintenance expenses

- Planned vs. unplanned maintenance ratios

- Inventory turnover and stockout incidents

- Schedule compliance percentages

Don’t just collect data but focus on analyzing it for patterns. Here a few questions to ask:

- Are certain equipment types failing more frequently?

- Do maintenance schedules show consistent delays during specific periods?

- Are there gaps between documented procedures and work order descriptions?

Create data visualization dashboards that highlight trends and anomalies. Heat maps showing equipment reliability, Pareto charts of failure modes, and trend lines of maintenance costs help identify focus areas for the physical audit phase.

One pharmaceutical manufacturer discovered through pre-audit analysis that 60% of their “preventive” maintenance was actually corrective work that had been miscategorized.

This insight completely changed their audit approach and led to a fundamental restructuring of their maintenance workflows.

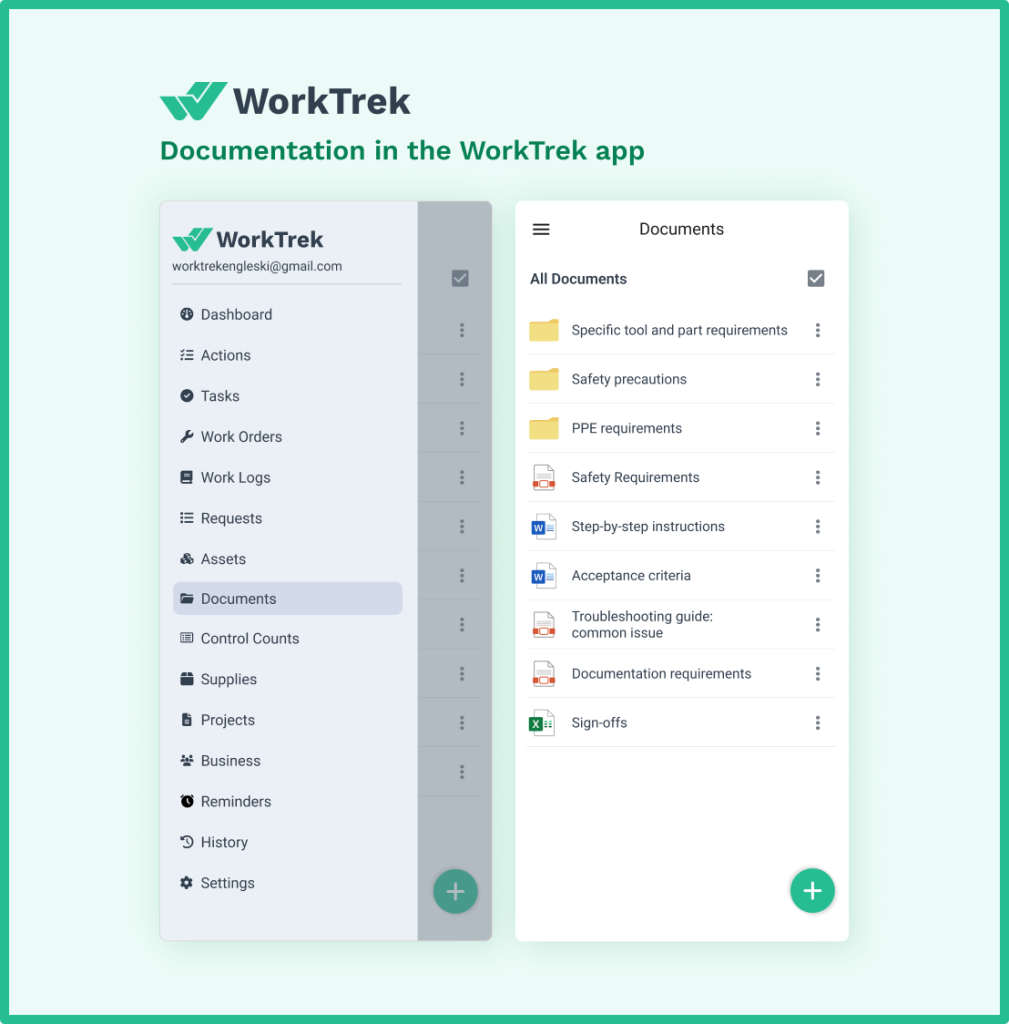

Step 4: Review Maintenance Documentation

Documentation review is the backbone of your preventive maintenance audit. This helps reveal gaps between intended and actual practices.

Start with preventive maintenance schedules. Compare them against manufacturer recommendations, industry standards, and equipment criticality. A few questions to ask include:

Are you over-maintaining non-critical assets while under-maintaining critical equipment? McKinsey’s analysis shows that up to 30% of preventive maintenance tasks add no value.

Examine maintenance procedures for completeness and clarity. Can a competent technician follow them without confusion? Do they include:

- Specific tool and part requirements

- Safety precautions and PPE requirements

- Step-by-step instructions with acceptance criteria

- Troubleshooting guidance for common issues

- Documentation requirements and sign-offs

Check maintenance records for accuracy and completeness.

- Consistent data entry formats

- Complete failure descriptions with root causes

- Accurate labor and parts tracking

- Proper coding of work types (preventive, predictive, corrective)

- Timely entry of information

Evaluate your maintenance data management.

- How easily can you retrieve specific maintenance history?

- Can you quickly identify recurring problems?

- Are maintenance logs providing valuable insights or just consuming file space?

Review training documentation to ensure maintenance personnel have the skills needed for assigned tasks. Industry data shows that inadequately trained maintenance staff increase equipment failure rates by up to 50%.

Don’t forget to assess compliance documentation. With safety regulations and industry standards constantly evolving, your audit should verify that maintenance practices align with current requirements. This is particularly critical for industries with strict regulatory oversight like pharmaceuticals, food processing, and aerospace.

Step 5: Execute Physical Equipment Inspections

Now comes the moment of truth: Compare documentation with reality through hands-on equipment inspections.

Physical inspections reveal what paperwork can’t: the actual condition of equipment, the reality of maintenance practices, and the effectiveness of preventive maintenance tasks.

This isn’t a white-glove inspection looking for dust; it’s a systematic evaluation of whether your preventive maintenance program actually prevents failures.

Start with critical assets and use a structured inspection checklist that examines:

Equipment Condition Indicators:

- Unusual noises, vibrations, or temperatures

- Visible wear, corrosion, or damage

- Fluid leaks or contamination

- Alignment and balance issues

- Proper lubrication levels and conditions

Maintenance Execution Evidence:

- Completion tags and inspection stickers

- Lubrication charts and routes

- Predictive maintenance data collection points

- Spare parts availability and organization

- Tool availability and condition

Evaluate and watch maintenance personnel perform routine preventive maintenance tasks. Some things to look for include:

- Are they following documented procedures?

- Do they have the right tools?

- Are they taking shortcuts that might compromise effectiveness?

For a structured way to assess and optimize your process, use this maintenance audit checklist.

Document everything with photos and detailed notes. Modern maintenance audit apps allow real-time documentation with automatic timestamp and location data. This creates an indisputable record and helps communicate findings to stakeholders who weren’t present during inspections.

Pay special attention to equipment with high failure rates or excessive maintenance costs identified during data analysis.

Often, physical inspection reveals root causes that maintenance records miss—inadequate ventilation causing overheating, contamination from nearby processes, or operator abuse between maintenance intervals.

Step 6: Analyze Findings and Identify Gaps

With data collected and inspections complete, it’s time to transform raw information into actionable insights.

Practical analysis identifies not just what’s wrong, but why it isn’t good and what impact it has on maintenance operations.

Focus on categorizing and prioritizing findings:

Gap Classification Framework: Learn more about Computerized Maintenance Management Systems (CMMS) like WorkTrek and how they support effective maintenance strategies.

- Critical: Safety hazards, regulatory non-compliance, or issues affecting critical asset reliability

- Major: Significant impact on maintenance costs, equipment performance, or schedule compliance

- Minor: Opportunities for improvement with limited operational impact

- Observational: Best practice suggestions or emerging trends to monitor

Create a findings matrix that maps each gap to:

- Root cause (systemic issue vs. isolated incident)

- Affected assets or processes

- Current impact (downtime, costs, safety risk)

- Potential consequences if unaddressed

- Estimated effort to resolve

Look for patterns across findings. Multiple equipment inspections revealing inadequate lubrication might indicate training gaps, unclear procedures, or resource constraints. Document version control issues across several procedures could signal a broken management of change process.

Benchmark against industry standards.

- How does your 70% preventive maintenance schedule compliance compare to the 90% achieved by world-class performers?

- Are your maintenance costs at 5% of the replacement asset value in line with the 2-3% best-practice target?

These comparisons help prioritize improvement efforts.

Don’t just focus on problems. Document what’s working well since these successes can be replicated across other areas.

Step 7: Develop Action Plans and Recommendations

The rubber meets the road when you transform audit findings into concrete action plans that drive measurable improvements.

Your recommendations should be specific, actionable, and achievable. Vague suggestions like “improve maintenance practices” waste everyone’s time. Instead, provide detailed roadmaps:

Structure each recommendation with:

- Clear problem statement with supporting data

- Specific actions required

- Responsible parties and timelines

- Resource requirements (budget, personnel, tools)

- Success metrics and measurement methods

- Risk assessment if not implemented

Prioritize recommendations using a value-effort matrix.

Quick wins

High-value improvements requiring minimal effort should be implemented immediately to build momentum. These might include updating critical equipment maintenance schedules, implementing missing safety procedures, or establishing basic performance metrics.

Medium-term

This typically requires more planning or resources. Examples include maintenance training programs, CMMS implementation or optimization, or preventive maintenance schedule overhauls. These initiatives might take 3-6 months but deliver substantial returns.

Long-term

Using strategic recommendations to address systemic issues. Transition to reliability-centered maintenance, implementing predictive technologies, or restructuring maintenance organizations requires significant investment but can transform maintenance performance.

Create detailed implementation plans for each recommendation:

Example: Improving Preventive Maintenance Schedule Compliance

- Week 1-2: Analyze root causes of missed PM tasks (resource constraints, unclear priorities, access issues)

- Week 3-4: Redesign PM scheduling to balance workload and production requirements

- Week 5-6: Train maintenance personnel and planners on new scheduling process

- Week 7-8: Pilot new schedule with critical equipment

- Week 9-12: Roll out across all equipment with daily compliance monitoring

- Success metric: Achieve 85% PM compliance within 90 days

Include cost-benefit analysis for significant investments. If implementing a CMMS will cost $50,000 but reduce maintenance costs by $15,000 monthly through better planning and inventory management, that 3-month payback period makes approval easier.

Post-Audit: Implementation and Continuous Improvement

The audit report is the starting gun for transformation.

Creating an Implementation Roadmap

Transform your recommendations into a phased implementation plan that maintains momentum while avoiding change fatigue.

Start with a 30-60-90-day quick-win plan.

Focus on immediately actionable improvements that demonstrate the audit’s value. These might include:

- Updating critical maintenance schedules based on failure history

- Implementing missing safety procedures

- Establishing daily maintenance KPI tracking

- Organizing maintenance supplies and tools

Establish governance structures for longer-term initiatives. Create a maintenance improvement committee that meets weekly initially, then monthly as initiatives mature. Include representatives from maintenance, operations, safety, and finance to ensure balanced decision-making.

Tracking Progress and Measuring Success

You can’t manage what you don’t measure. Establish baseline metrics before implementing changes, then track progress religiously.

Essential metrics to monitor include:

- Schedule compliance: Target 90% for critical equipment

- Planned maintenance percentage: Aim for 80% planned, 20% unplanned

- Mean Time Between Failures (MTBF): Should increase by 20-30% within 6 months

- Maintenance cost per unit produced: Should decrease by 10-15% annually

- Safety incidents: Zero tolerance for preventive maintenance-related injuries

Addressing Resistance to Change

Let’s be honest: change is hard, and maintenance teams can be particularly resistant after years of “we’ve always done it this way.”

Address resistance head-on through:

Communication: Explain why changes are necessary using audit data. When technicians understand that improved PM schedules will reduce middle-of-the-night emergency calls, buy-in increases.

Involvement: Include front-line maintenance personnel in improvement planning. They often have the best solutions but rarely get asked.

Training: Invest in skills development. According to Plant Engineering surveys, 29% of maintenance technicians feel unprepared for modern maintenance requirements. Comprehensive training programs address both competence and confidence.

Recognition: Celebrate successes publicly. When PM compliance improves or equipment reliability increases, acknowledge the team’s efforts.

Patience: Cultural change takes time. Industry research suggests that new maintenance practices take 18-24 months to become fully embedded.

How CMMS Software Transforms Preventive Maintenance Audits

The difference between auditing with and without a computerized maintenance management system is like comparing GPS navigation to wandering with a paper map.

Modern CMMS platforms don’t just make audits easier; they make them exponentially more valuable.

Data Accessibility and Accuracy

The foundation of any effective preventive maintenance audit is data, and CMMS software serves as your single source of truth.

Instead of hunting through file cabinets and spreadsheets, auditors can instantly access:

- Complete maintenance history for every asset

- Real-time schedule compliance metrics

- Detailed cost breakdowns by equipment, department, or work type

- Failure patterns and root cause analysis

- Inventory levels and parts consumption trends

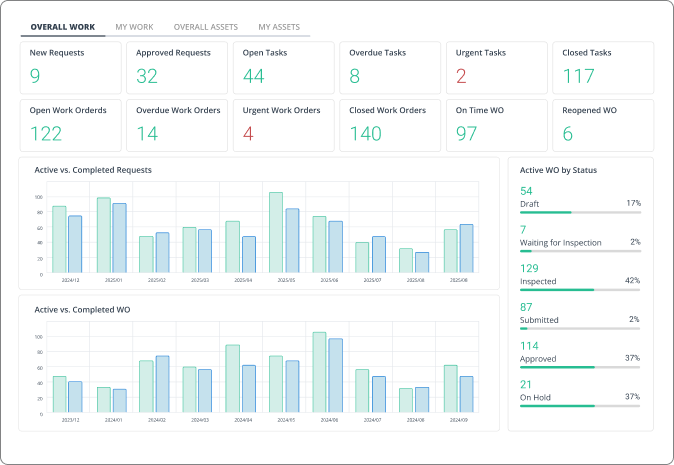

WorkTrek’s analytics dashboard, for example, provides instant visibility into maintenance performance metrics that would take weeks to compile manually.

You can identify equipment with declining reliability, maintenance tasks consistently running over schedule, or technicians requiring additional training. This can all happen within minutes rather than days.

The accuracy improvement is equally dramatic. Manual data entry errors, which studies show affect up to 26% of paper-based maintenance records, virtually disappear with CMMS automation.

Barcode scanning, mobile data entry, and automated workflows ensure information is captured correctly the first time.

Streamlined Audit Execution

A CMMS transforms the audit process from a disruptive special project into an integrated operational review.

Audit checklists can be built directly into the system, with automatic scoring and compilation of findings.

As auditors complete inspections, results flow immediately into corrective action workflows. No more transcribing notes or losing critical observations in paperwork shuffles.

Predictive analytics within modern CMMS platforms can even pre-identify audit focus areas. By analyzing failure patterns, maintenance costs, and compliance trends, the system highlights potential gaps before auditors begin their review. This targeted approach ensures that limited audit resources focus on the highest-impact opportunities.

Continuous Improvement Through Automated Monitoring

Here’s where CMMS software truly shines: transforming periodic audits into continuous improvement engines.

Instead of waiting 12 months to discover issues with the preventive maintenance schedule, CMMS platforms provide real-time alerts when compliance drops below targets. Maintenance managers can address problems immediately rather than letting them compound into audit findings.

Automated reporting eliminates the “audit scramble” where teams frantically compile documentation before reviews.

Consider how WorkTrek’s preventive maintenance module handles this:

- Automatic schedule generation based on manufacturer recommendations and operational constraints

- Real-time compliance tracking with drill-down capability to understand missed tasks

- Predictive alerts when maintenance tasks are likely to be delayed, and integrated corrective action management to address gaps.

These features ensure your maintenance program continuously improves between formal audits.

ROI Justification Through Clear Metrics

Perhaps most importantly, CMMS software quantifies the value of your preventive maintenance program and audit improvements.

According to the 2024 MaintainX State of Industrial Maintenance Report:

- Organizations using CMMS reduce unplanned downtime by 32%

- Work order completion rates increase by 53%

- Maintenance teams save 250 hours annually through improved efficiency

- 59% reduce costs through better parts inventory management

The ability to model “what-if” scenarios adds another dimension. What would happen if we increased PM frequency on critical assets? How much could we save by optimizing maintenance routes? CMMS simulation capabilities let you test improvements virtually before committing resources.

Conclusion: Your Path to Maintenance Excellence

The evidence is overwhelming: preventive maintenance audits transform maintenance operations from costly necessities into competitive advantages.

We’ve covered the complete journey: from understanding what preventive maintenance audits are and why they matter, through the detailed 7-step process for conducting them, to real-world examples of their transformative power.

Remember, perfection isn’t the goal; focus on progress.

Start today. Your future self—and your equipment—will thank you.

Source: WorkTrek

Source: WorkTrek