Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

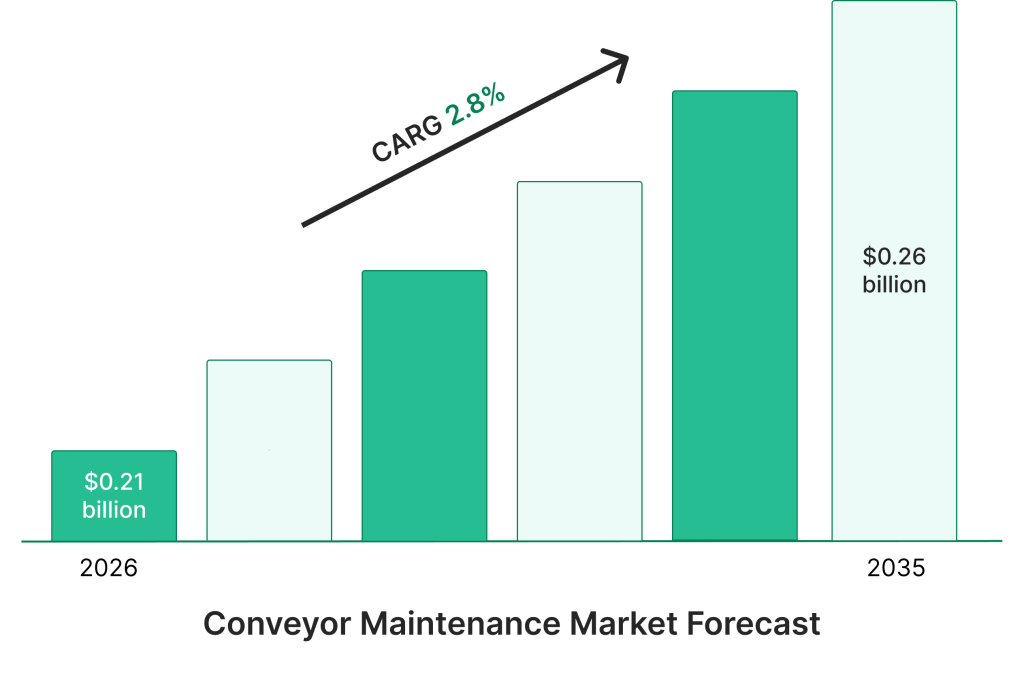

- Reactive maintenance costs 3-4 times as much as preventive maintenance over the equipment’s lifespan, and unplanned downtime costs industrial manufacturers an estimated $50 billion annually, according to the U.S. Department of Energy.

- Most conveyor failures are preventable through consistent visual inspections that take just 10-15 minutes per shift

- Proper belt tension can extend belt life by up to 50% while reducing energy consumption, and even small misalignments cause significant wear, leading to premature failure and unexpected downtime.

Conveyor systems are the backbone of modern manufacturing and distribution operations. When your conveyor belt stops running, so does your production line. Yet many facilities treat conveyor maintenance as an afterthought, waiting for breakdowns to happen before taking action.

That reactive approach is costing manufacturers billions in lost productivity. According to research from the U.S. Department of Energy, unplanned downtime costs industrial manufacturers an estimated $50 billion annually, with conveyor failures ranking among the most common culprits.

The good news? Most conveyor problems are entirely preventable. With the right maintenance approach, you can keep your belt and conveyor system running smoothly while extending equipment lifespan and reducing unexpected downtime.

This guide walks you through everything you need to know about conveyor maintenance, from daily inspections to advanced preventative maintenance strategies that actually work.

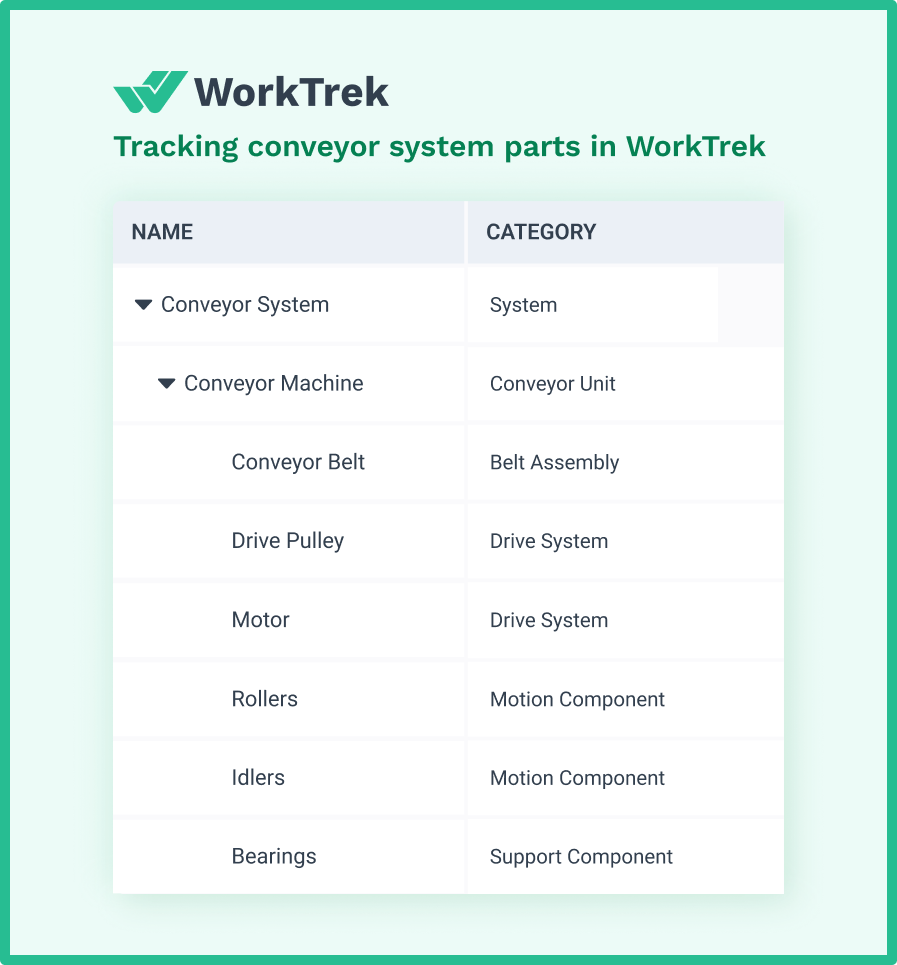

Understanding Your Conveyor System Components

Before diving into maintenance procedures, you need to understand what makes your conveyor system tick.

A typical belt-and-conveyor system consists of several critical components that work together to move materials efficiently.

The conveyor belt itself is the most visible part, but it’s just one piece of the puzzle. Drive motors provide the power, while pulleys and rollers support the belt and control its movement. Bearings reduce friction at connection points, and idlers support the belt along its length.

Electrical components control the entire operation, from motor speed to emergency stops. The gearbox transfers power from the motor to the drive pulley, and proper tension mechanisms keep everything aligned and prevent belt slippage.

Each component plays a specific role in normal conveyor operation. When one element fails or operates inefficiently, it creates a cascade effect that impacts the entire system. That’s why comprehensive conveyor maintenance requires attention to every part, not just the obvious ones.

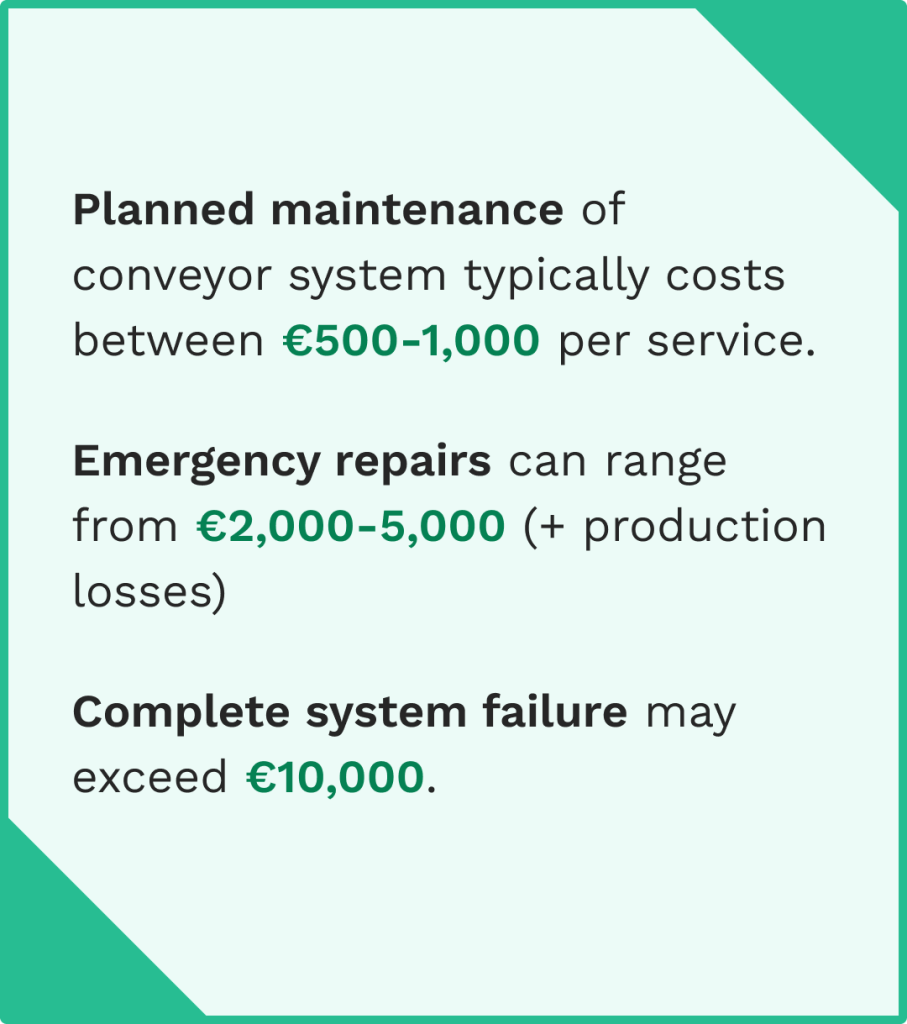

The Real Cost of Poor Conveyor Maintenance

The numbers tell a sobering story.

For a mid-sized manufacturing facility operating 24/7, a single conveyor breakdown lasting just four hours can cost $25,000 or more in lost production. That doesn’t even account for emergency repair costs, overtime labor, or the ripple effects throughout your supply chain.

Material buildup alone causes significant problems. When debris accumulates on rollers, pulleys, or the belt surface, it creates uneven load distribution and increased wear. This seemingly minor issue leads to belt misalignment, unusual noise, and eventually, complete system failure.

Reactive maintenance costs three to four times as much as preventive maintenance over the equipment’s lifespan. Yet many facilities still operate in reactive mode, essentially throwing money away on problems they could have prevented.

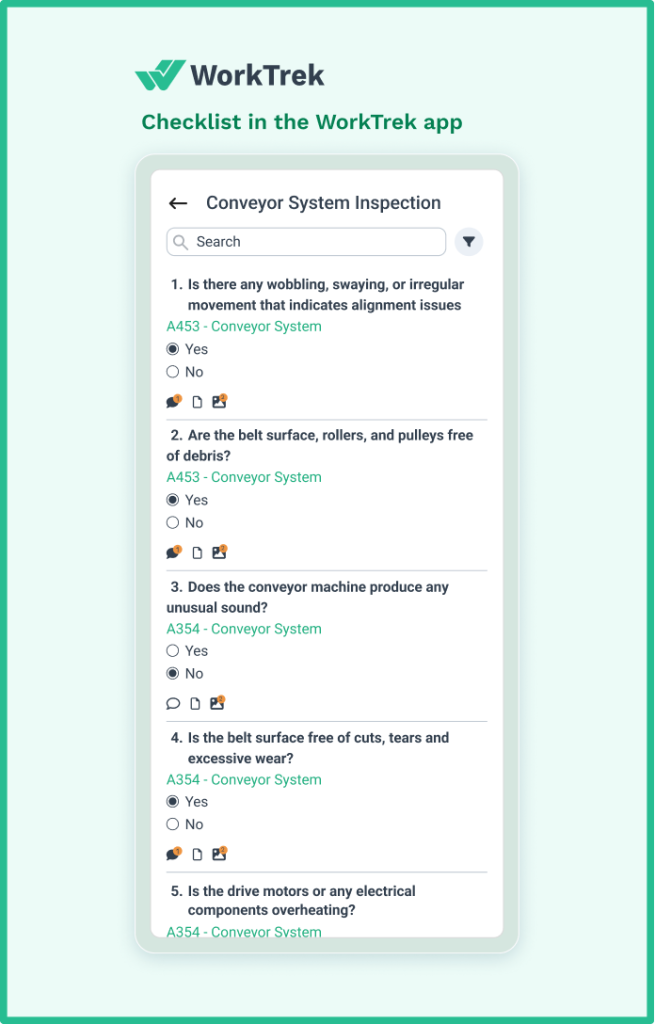

Daily Visual Inspection Checklist

It all starts with consistent daily visual inspections. Your maintenance team should complete these checks at the start of each shift, taking just 10-15 minutes to spot potential problems before they escalate.

Start by watching the conveyor belt during operation. Look for any wobbling, swaying, or irregular movement that indicates alignment issues.

The belt should track straight and centered on the pulleys without drifting to either side.

Check for material buildup on the belt surface, rollers, and pulleys. Even small accumulations of debris can throw off belt alignment and create uneven wear patterns. Note any areas where product spillage occurs regularly, as these spots need more frequent cleaning.

Listen carefully during the operation. Unusual noise often signals problems with bearings, misalignment, or loose connections. A healthy conveyor system produces a consistent, steady sound. Any squealing, grinding, or rattling deserves immediate attention.

Inspect the belt surface for cuts, tears, or excessive wear. Check belt tension by pressing down on the slack side of the belt between pulleys. It should give slightly but feel firm and resilient. If it feels loose or sags excessively, you’ll need to adjust belt tension soon.

Look at drive motors and electrical components for signs of overheating, unusual vibration, or loose connections.

Check that all safety guards remain in place and functioning correctly. These simple daily checks catch most problems while they’re still minor and inexpensive to fix.

Essential Weekly Maintenance Tasks

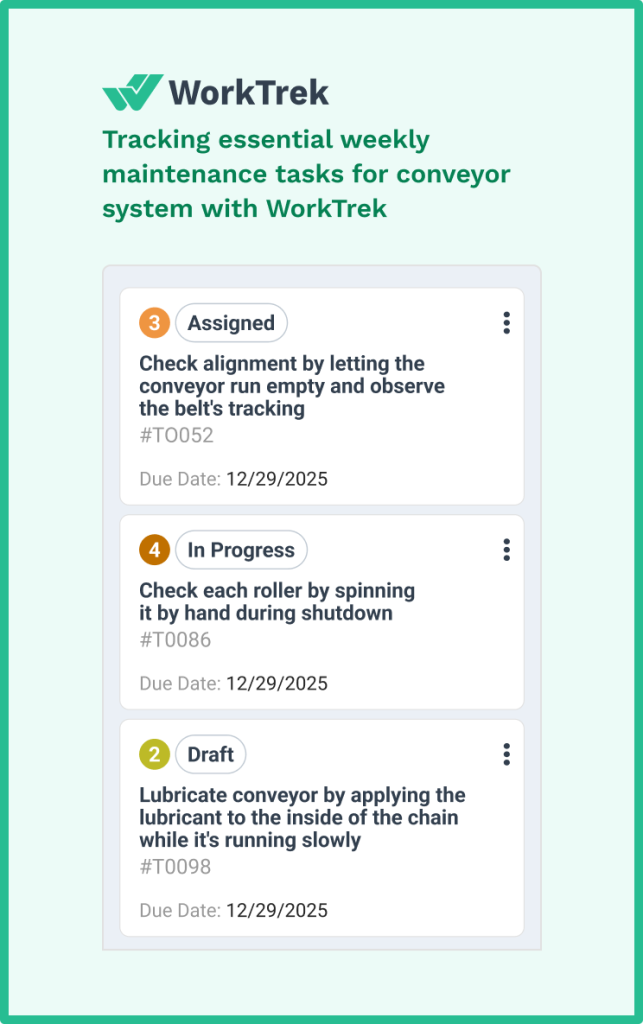

Weekly maintenance goes beyond daily visual inspection, targeting components that require regular attention but don’t require daily service. Schedule these tasks for slower production periods or during planned downtime.

Belt Alignment and Tracking

Belt alignment is important for smooth operation and preventing increased wear. Misaligned belts create uneven load distribution, cause edge damage, and significantly shorten belt life.

To check alignment, let the conveyor run empty and observe the belt’s tracking. It should remain centered on all pulleys and idlers without contacting the frame or guards. If the belt drifts to one side, you’ll need to adjust pulley alignment.

Most conveyor systems use adjustable take-up pulleys to correct tracking. Small adjustments go a long way.

Turn the adjustment bolt on the side where the belt is moving away from in quarter-turn increments, allowing the belt to complete several revolutions between adjustments.

Roller and Idler Inspection

Rollers and idlers support your conveyor belt and ensure smooth operation. When they fail, they create flat spots on the belt and cause irregular motion.

Check each roller by spinning it by hand during shutdown. It should rotate freely without grinding, squealing, or resistance. Sticky or seized rollers need immediate replacement before they damage the belt.

Look for material buildup around roller bearings and idlers. This debris restricts rotation and creates hot spots that accelerate wear. Clean thoroughly with appropriate tools and solvents based on your material type.

Lubrication Schedule

Proper lubrication reduces friction and extends bearing life throughout your conveyor system. Different components require different lubricants and frequencies.

Bearings typically need greasing every 500-1000 operating hours, though this varies by manufacturer and operating conditions.

Use the lubricant type specified in your equipment manual and recommended by the manufacturer.

Over-lubrication causes as many problems as under-lubrication, so follow recommended quantities precisely.

Chain-driven conveyors need regular chain lubrication to prevent slippage and wear. Apply lubricant to the inside of the chain while it’s running slowly, allowing it to penetrate all contact points.

Gearbox oil levels need weekly checks. Low oil causes overheating and premature gear failure. Check for leaks around seals and gaskets, as these indicate maintenance needs before they become major repairs.

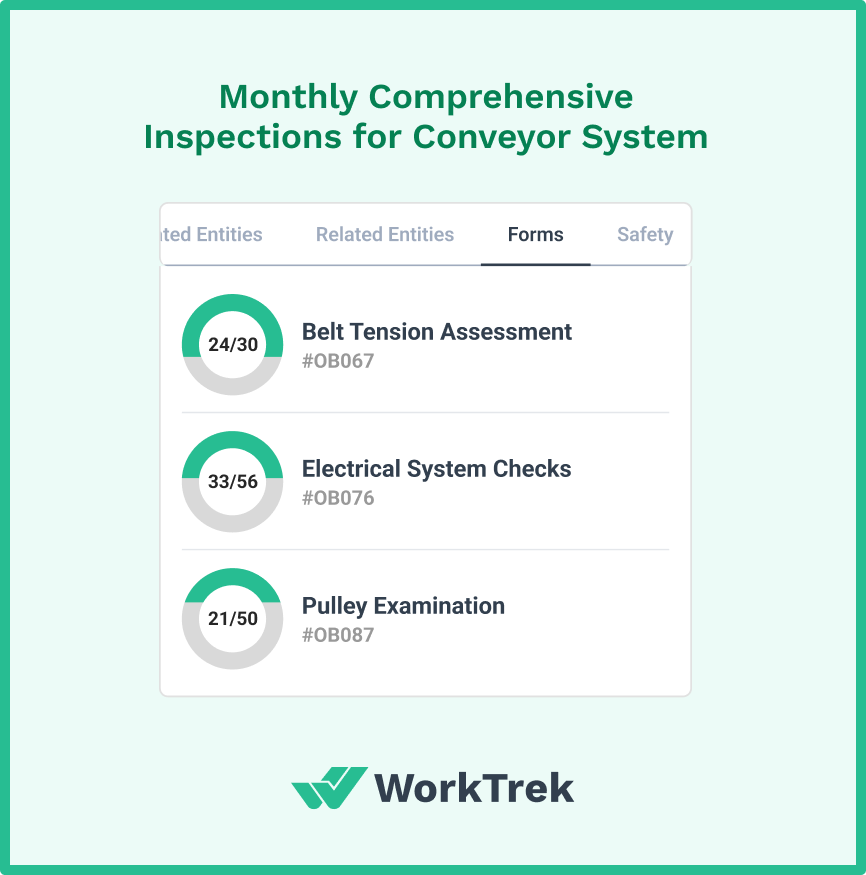

Monthly Comprehensive Inspections

Monthly inspections provide opportunities to examine components that wear gradually and need systematic tracking. These deeper dives catch developing problems before they cause unexpected downtime.

Belt Tension Assessment

Belt tension directly affects conveyor performance and component life. Too loose, and you get belt slippage. Too tight, and you create excessive load on bearings and motors, shortening their lifespan.

According to research from the Conveyor Equipment Manufacturers Association, proper belt tension can extend belt life by up to 50% while reducing energy consumption.

Most belt and conveyor systems use one of three tensioning methods: gravity take-up, screw take-up, or automatic tensioning systems. Check your manufacturer’s specifications for the correct tension measurement for your specific belt type and width.

For manual systems, adjust belt tension when slack exceeds 2-3% of the center span between pulleys. Make small adjustments and allow the belt to run for several hours before rechecking, as tension changes with temperature and belt stretch.

Electrical System Checks

Electrical components control your entire conveyor operation but are often overlooked during maintenance rounds. Monthly inspections should include thorough reviews of the electrical system.

Check all electrical connections for tightness, corrosion, or damage. Loose connections create resistance, generate heat, and eventually fail. Tighten any loose terminals and clean corroded connections.

Inspect motor wiring for fraying, cracking, or exposure. Damaged insulation creates short circuit risks and safety hazards for your team. Replace damaged wiring immediately rather than waiting for failure.

Test emergency stop functionality monthly. Every e-stop button and pull cord should bring the conveyor to an immediate halt. Non-functioning safety systems create liability risks and violate OSHA requirements in most jurisdictions.

Pulley Examination

Pulleys guide your conveyor belt and transfer drive force from the motor. When pulleys wear unevenly or develop coating buildup, they cause belt slippage and tracking problems.

Inspect the drive pulley for worn lagging or coating. The pulley surface should feel slightly tacky with even texture. Smooth, glazed areas indicate wear that reduces traction and leads to prevent slippage problems.

Check tail and snub pulley alignment using a laser alignment tool or straightedge. Pulleys out of parallel by even 1/4 inch create significant belt wear and tracking issues. Adjust mounting bolts to bring pulleys into proper alignment.

Look for material build up on pulley faces. Debris creates uneven surfaces that throw off belt tracking. Clean pulleys thoroughly during shutdown, taking care not to damage lagging or coatings.

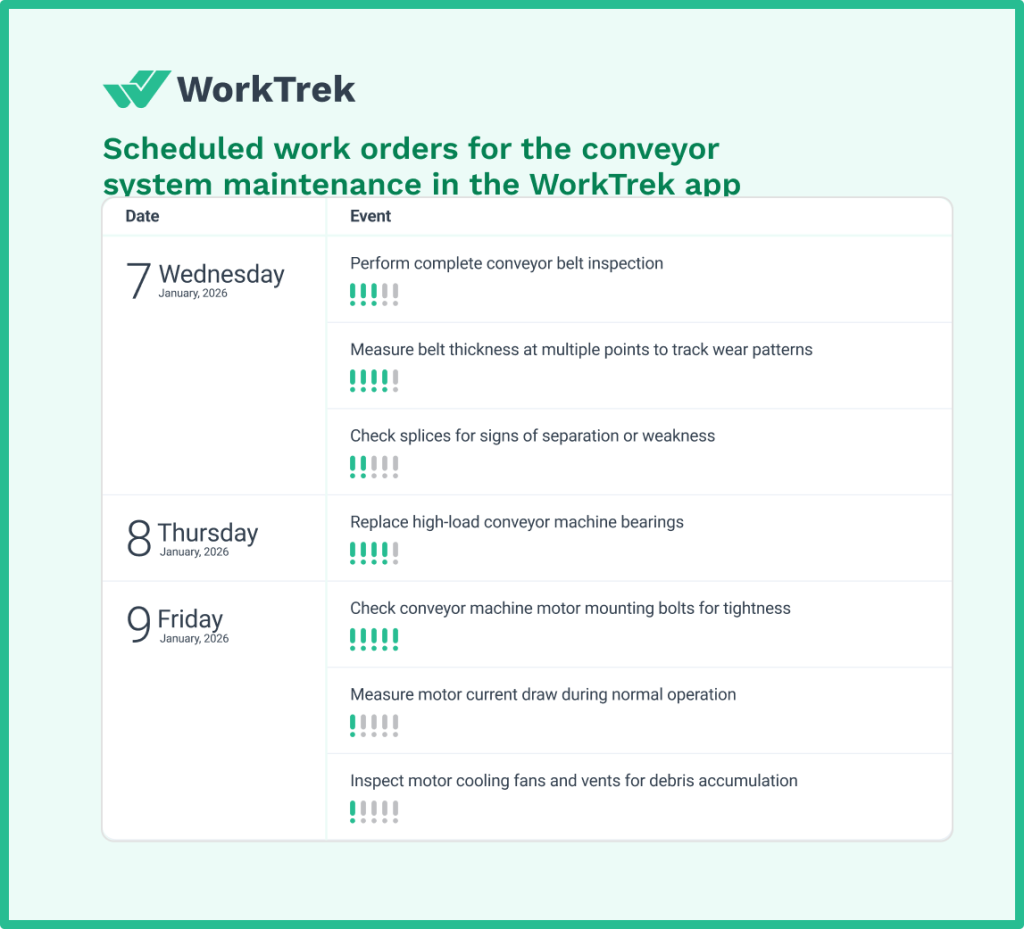

Seasonal and Quarterly Deep Maintenance

Some conveyor maintenance tasks need less frequent attention but require more extensive work. Schedule these during planned shutdowns or slower production periods.

Complete Belt Inspection

Every three to six months, conduct a comprehensive belt inspection. This means running the empty conveyor slowly while examining every inch of belt surface for damage.

Look for longitudinal cracks, gouges, tears, or areas where plies have separated. These defects weaken the belt and lead to catastrophic failure if left unchecked. Mark damaged areas with chalk and photograph them for documentation.

Measure belt thickness at multiple points to track wear patterns. Uneven wear indicates alignment or loading issues that need correction. Most belts should be replaced when they’ve lost 20-30% of their original thickness, though this varies by application.

Check splices carefully for signs of separation or weakness. Most belt failures occur at splices, so this inspection is critical. Watch for gaps between plies, adhesive failure, or mechanical fastener looseness.

Bearing Replacement Schedule

Bearings are wear items that need periodic replacement regardless of apparent condition. Studies show that scheduled bearing replacement reduces unexpected failures by up to 70% compared to run-to-failure approaches.

Track bearing operating hours for each critical location in your system. Replace high-load bearings (drive pulley, high-tension idlers) every 15,000-20,000 hours of operation. Less critical bearings can often run 25,000-30,000 hours before replacement.

When replacing bearings, always replace seals simultaneously. Old seals allow contaminant entry and lubricant escape, negating the benefits of new bearings.

Consider upgrading to sealed bearings in harsh environments. Though initially more expensive, sealed bearings last longer and reduce maintenance frequency in dusty or wet conditions.

Drive Motor Maintenance

Drive motors power your entire conveyor system, yet they’re often neglected until they fail. Quarterly maintenance keeps motors running efficiently and prevents unexpected downtime.

Check motor mounting bolts for tightness. Vibration loosens mounting hardware over time, allowing motors to shift position and throw off belt alignment.

Measure motor current draw during normal operation. Compare readings to nameplate specifications. Current draw significantly above rating indicates motor problems or excessive system load.

Inspect motor cooling fans and vents for debris accumulation. Blocked cooling passages cause overheating and premature motor failure. Clean thoroughly with compressed air, being careful not to damage fan blades.

Test motor insulation resistance annually using a megohmmeter. Readings below one megohm per 1,000 volts of motor rating indicate insulation breakdown and impending failure. Address low readings immediately to prevent unplanned motor replacement.

Common Conveyor Problems and Solutions

Even with excellent preventative maintenance, problems occasionally arise. Recognizing symptoms quickly and knowing how to respond minimizes downtime and repair costs.

Belt Slippage Issues

Belt slippage occurs when the drive pulley can’t grip the belt sufficiently to move the load. You’ll notice the motor running, but the belt moving slowly or intermittently.

The most common cause is inadequate belt tension. Adjust the belt tension according to the manufacturer’s specifications. Remember that new belts stretch during initial operation and need retensioning after the first few weeks.

Worn or contaminated pulley lagging also causes slippage. Oil, grease, or product buildup on the drive pulley creates a slippery surface. Clean the pulley thoroughly and consider relagging if wear is excessive.

Overloading causes slippage even with proper tension. Review your system’s rated capacity and ensure loads don’t exceed design specifications. If increased capacity is needed, you may need a larger drive motor or gearbox upgrade.

Mistracking and Alignment Problems

Mistracking happens when the belt drifts to one side instead of running centered on the pulleys. This creates edge wear, increases friction, and can cause the belt to rub against the frame.

Start by checking pulley alignment. Use a laser alignment tool or straightedge to verify all pulleys are parallel. Adjust mounting bolts to correct misalignment, making small changes and checking results.

Uneven loading causes mistracking even with perfect pulley alignment. Ensure material feeds onto the belt center, not off to one side. Adjust chutes, hoppers, or loading points to center material properly.

Check for buildup on rollers or idlers. Material accumulation makes one side higher than the other, pushing the belt off-center. Clean all rollers thoroughly and inspect for damaged or seized units.

Excessive Noise and Vibration

Unusual noise signals a problem that needs immediate attention. Different sounds indicate different issues, so learning to distinguish them helps diagnose problems quickly.

Squealing typically indicates bearing failure or belt slippage. Check all bearings for roughness when spinning by hand. Test belt tension and adjust if needed. Inspect for debris that could cause the belt to rub against guards or frames.

Grinding sounds usually mean bearing failure or foreign objects caught in moving parts. Shut down immediately to prevent additional damage. Locate the noise source precisely and inspect for failed bearings or trapped debris.

Rhythmic thumping or knocking often indicates damaged splices, flat spots on rollers, or loose mechanical connections. Inspect the belt for splice separation. Check all rollers for flat spots or rough rotation. Tighten loose bolts and mounting hardware.

Excessive vibration points to imbalance, misalignment, or looseness somewhere in the system. Check motor and pulley mountings for tightness. Verify pulley alignment and balance. Inspect for eccentric rotation in pulleys or rollers.

How CMMS Transforms Conveyor Maintenance

Traditional paper-based or spreadsheet maintenance tracking falls apart quickly in real-world operations. Technicians miss scheduled tasks during busy periods, inspection data gets lost, and you have no visibility into emerging patterns that signal developing problems. Learn how predictive maintenance tools can help prevent these issues.

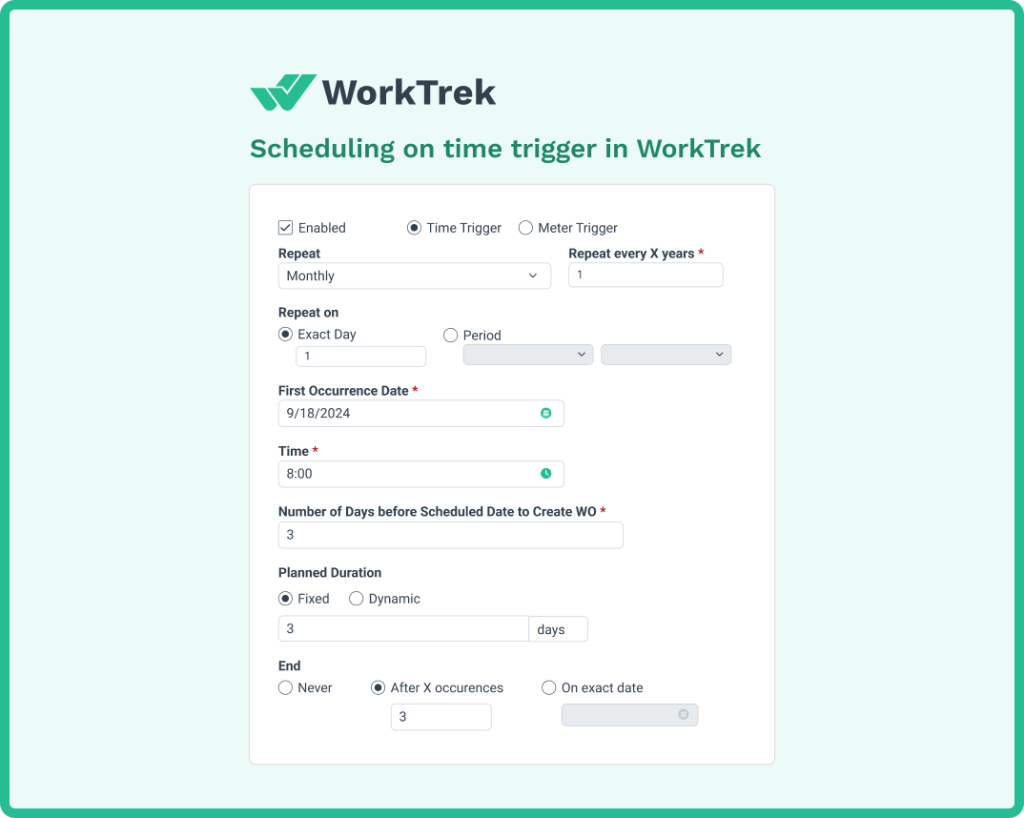

Automated Maintenance Scheduling

CMMS software automatically generates work orders based on time intervals, operating hours, or meter readings. Your daily visual inspections, weekly lubrication tasks, and quarterly deep maintenance all appear on technician schedules without manual tracking.

The system can be configured to send reminders before tasks come due, preventing the “oops, we forgot” scenarios that lead to equipment failure.

Complete Maintenance History Tracking

Every inspection, repair, and part replacement gets documented in your CMMS. This historical data becomes invaluable for troubleshooting recurring problems and optimizing maintenance frequencies.

When a conveyor belt fails prematurely, you can review maintenance records to identify root causes. Was lubrication performed on schedule? Did inspection note developing cracks? Has this belt location failed multiple times?

These insights help you move from reactive repairs to proactive improvements.

Inventory Management Integration

CMMS tracks spare parts inventory and alerts you when stock levels run low. For conveyor maintenance, this means having belts, bearings, pulleys, and other critical components on hand when needed.

According to a study by Reliable Plant, unplanned parts procurement adds an average of 4-6 hours to repair times, extending downtime and increasing costs. CMMS prevents these delays by ensuring parts availability.

The system also tracks part usage patterns, helping optimize inventory levels. You’ll know which components fail most frequently and ensure adequate stock without tying up excess capital in slow-moving parts.

Mobile Accessibility for Technicians

Modern CMMS platforms offer mobile apps that put maintenance information in technicians’ hands wherever they work. Your team can access work orders, equipment manuals, and inspection checklists right at the conveyor location.

Performance Analytics and Reporting

CMMS aggregates maintenance data into dashboards and reports that reveal system performance trends. You can track key metrics like mean time between failures, maintenance costs per conveyor, and planned versus unplanned maintenance ratios.

Why WorkTrek is the Ideal CMMS for Conveyor Maintenance

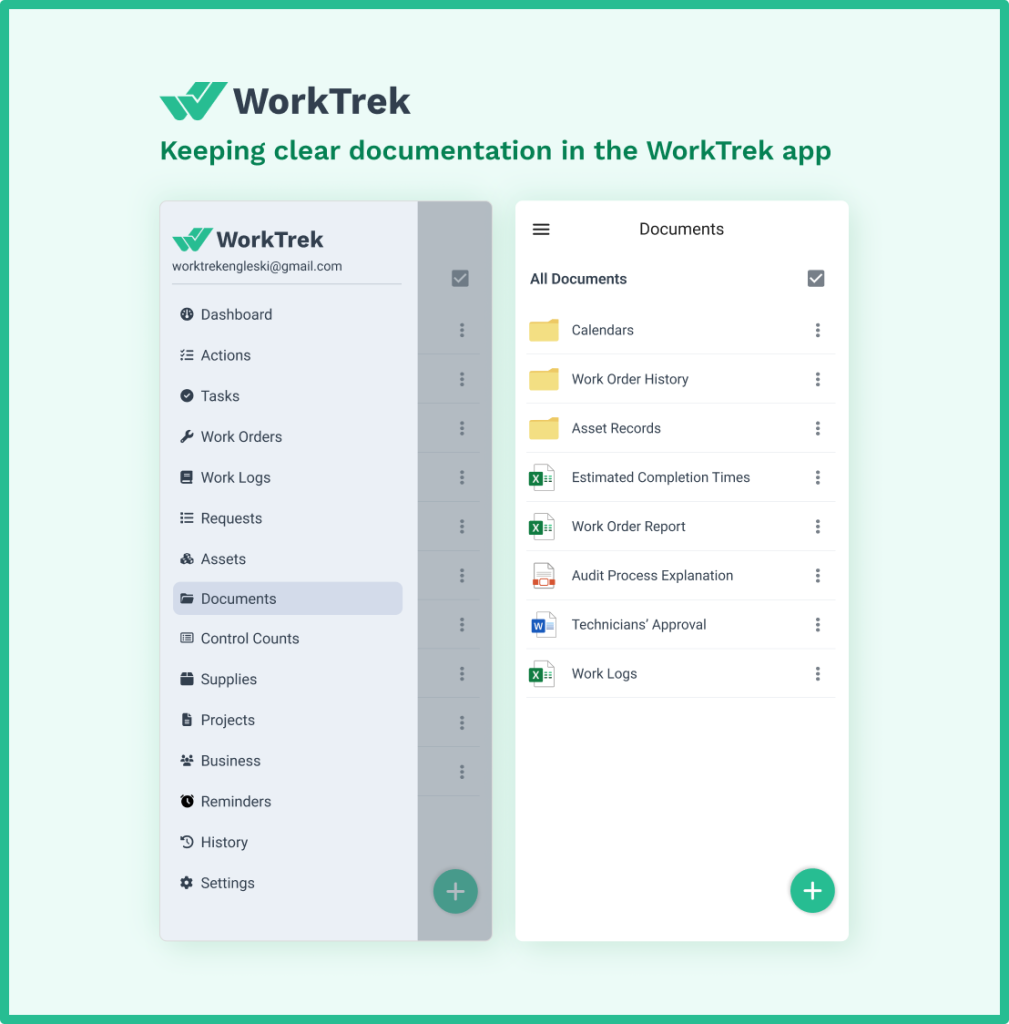

WorkTrek delivers CMMS capabilities specifically designed for manufacturing operations. The intuitive platform enables maintenance teams to achieve productivity within days, with a straightforward mobile app requiring minimal training.

Customizable checklists adapt to conveyor maintenance needs—from daily inspections to monthly reviews. The asset hierarchy organizes maintenance by conveyor line while tracking individual components. Real-time dashboards display compliance rates and emerging issues across all systems.

Integration capabilities connect with existing inventory and SCADA controls. WorkTrek scales effortlessly from five conveyor lines to fifty, supporting increasingly sophisticated strategies as programs mature.

Manufacturing facilities report significant improvements in conveyor reliability and maintenance efficiency.

Conclusion: From Reactive to Proactive

Conveyor maintenance doesn’t have to be complicated, but it must be systematic. The difference between smooth operation and costly, unexpected downtime comes down to consistently executing fundamental practices.

Your conveyor system will tell you what it needs if you listen—unusual noise, irregular movement, and gradually declining performance all signal developing problems. Catching them early through regular inspections and preventative maintenance is always cheaper than dealing with catastrophic failures.

The facilities that excel at conveyor maintenance share common characteristics:

- They schedule maintenance based on data rather than waiting for problems to arise.

- They empower technicians with proper tools, training, and information.

- They use technology such as WorkTrek CMMS to automate scheduling and track results.

- Additionally, they treat maintenance as an investment rather than an expense.

Take control of your conveyor maintenance today. Your production schedule, your maintenance budget, and your sanity will all benefit.