Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeAsset and inventory management processes add unique value to operations by providing a reliable framework to track individual consumables, industrial equipment, and other critical assets. Assets are defined as equipment used to run a business, while inventory consists of finished goods or parts used in manufacturing.

Asset tracking doesn’t have to be a nightmare. It can be a streamlined process that gives businesses a clear understanding of the location and status of their assets. All you need are the right tools.

What Is An Asset?

An asset is an item of value owned by an organization or individual. Assets are divided into tangible assets (physical assets such as land and machinery) and intangible assets (information technology assets such as copyrights, trademark rights, and computer software).

Within tangible assets, there are two subcategories: current assets (cash, inventory) and fixed assets (equipment, buildings, machinery, and other physical resources used in the operations of a business that are unlikely to be sold). When we talk about asset lifecycle management, we’re talking about managing the lifecycle of fixed assets.

Why Is Asset Tracking Important?

People usually do business to make money. Assets enable companies to do this. Businesses buy (or lease) assets at cost and use them to produce goods or services that generate revenue.

Assets are also a measure of a company’s value. Money-making organizations continue to grow by adding new assets or optimizing the use of existing ones. A thriving business is an attractive opportunity for investors, who may inject additional capital into the business to help it grow.

How does maintenance management affect assets? The maintenance team is tasked with maintaining the company’s assets. To do this, the maintenance team must have sufficient information about available assets, such as their location and condition. Armed with this knowledge, maintenance teams can develop maintenance plans to keep assets in optimal operating condition.

What Is A CMMS?

The acronym CMMS stands for Computerized Maintenance Management System. This software package was designed to manage maintenance globally, on a strategic, financial, and operational level. It is today the essential software of the industrial sector. Much more than simple computer programming, it is an assistant for maintenance teams, the cornerstone of industrial efficiency.

Because you can use it to achieve different goals, there are different ways to describe computerized maintenance management software. On the one hand, it is sophisticated software that captures and uses thousands of data points to provide an overview of how a facility is an operating or detailed information about individual pieces of equipment. In terms of functionality, CMMS software offers businesses the ability to monitor inventory levels, manage work orders, set up and schedule preventive maintenance programs, and quickly generate accurate reports. But on another level, it’s just the solution maintenance managers need. Automating processes and streamlining workflows makes your life less stressful by making your workday more predictable.

CMMS Software: Managing Asset Data

A supporting component of a proactive maintenance foundation is the integration of CMMS (Computerized Maintenance Management System) software, which creates a database for all the information gathered from maintenance monitoring sensors throughout the enterprise facility. CMMS software creates a framework that guides owners and users on how to organize this related data and establishes an interoperability hierarchy to determine how this data impacts different plant operations. CMMS software enables maintenance professionals to figure out how best to respond to asset degradation or impending failure before productivity is fully impacted.

How to Use CMMS Software for Asset Management

Asset tracking is an essential feature for any business to maximize return on investment. Asset maintenance management provides clear data to strategically optimize a company’s assets and equipment.

Why do you need asset management?

Plant maintenance is very important for industries with a large number of machines and equipment. Since these assets are often expensive and represent a significant portion of the capital investment, proper maintenance is critical to getting the most out of them.

What is a CMMS good for?

A Computerized Maintenance Management System (CMMS) is a business tool that centralizes maintenance information and simplifies maintenance operations. It acts as an asset management software that manages equipment maintenance, and work orders, tracks inventory, and stores various equipment asset information.

Asset management software capabilities in CMMS software help to proactively track and manage assets across a company’s multiple locations, giving maintenance managers quick access to relevant information from any device whenever they need it.

Features of Asset Tracking & Management Software in CMMS

A CMMS has many functions that support asset maintenance management:

Asset Tracking

All assets of the organization are always tracked. However, it may not be economically feasible to keep track of every single asset all the time, so better to keep track of the more important assets. Organizations classify their assets into more and less important assets based on a variety of factors such as sensitivity, criticality, value, or compliance requirements.

Collect information

Track various information about the device such as B. Model number, date of purchase, warranty details, serial number, etc. This information also aids in system operations, recalls, maintenance, etc.

Track spare parts and consumables

It is also important to keep track of equipment reserves, such as parts suppliers, parts, and consumables required for various equipment. Organizations try to manage their facilities at the lowest possible cost and in the shortest possible time. To achieve this, there is a great benefit to combining records and providing the above-mentioned assets.

Get device maintenance history

Gathering and recording information about equipment changes, maintenance history, costs incurred, etc. is helpful when replacing equipment. The features and cost of old equipment can be compared with new equipment to make effective purchasing decisions. Likewise, the operational history of calibrations, changes, damage, etc. can be recorded in one place to simplify the verification process while searching for relevant information to resolve issues.

Asset Tracking Best Practices for Maximizing Data Accuracy

Here are nine asset-tracking best practices to follow if you want to simplify your asset management efforts:

Use unique asset IDs

Assign each asset a unique identification number or code for accurate and efficient tracking. This helps avoid confusion and allows easy retrieval of asset information.

Regularly update asset information

Keep an up-to-date record of asset details, including location, status, maintenance history, and any other relevant information that requires manual updates.

Leverage technology

Leverage asset tracking technologies such as barcode labels, RFID tags, or GPS tracking devices to automate data collection and simplify the tracking process.

Conduct periodic audits

Periodic asset audits are performed to verify the physical existence and condition of the assets against the recorded information.

Supercharge your business with WorkTrek CMMS

Book a WorkTrek demo to see how a CMMS can help your asset management.

Try for freeImplement asset movement controls

Establish proper protocols and approval processes for asset movement within the organization. This includes documenting asset transfers, tracking custodians, and ensuring accountability to minimize the risk of unauthorized use or loss.

Train employees

Ensure that all employees understand and apply established follow-up procedures.

Integrate asset tracking with asset management solutions

Integrate asset tracking technology with other related systems such as ERP or CMMS software. This is the best way to ensure seamless data flow, avoid duplicate data entry, and gain complete visibility into asset-related information.

Implement security measures

Protect assets from theft or unauthorized access by implementing security measures such as access controls, monitoring systems, or anti-theft devices.

Continuous improvement and optimization

Regularly assess asset tracking processes, identify opportunities for improvement, and implement necessary changes. This includes analyzing data, gathering employee feedback, and leveraging technological advancements to improve the efficiency and accuracy of asset tracking.

How Helpful Is Asset Tracking In Delivering Functionality Through The CMMS?

Tracking assets using digital technology changes business models as it offers new value-add opportunities that CMMS promises.

Asset Tracking helps organizations to perform various activities such as Maintenance Management, Purchase Requisition, Physical Inspection, Asset Scanning, etc. With asset tracking, a computerized maintenance management system can be easily implemented.

Customizable configuration

Asset tracking is very user-friendly as it can be customized according to business needs. You can also make adjustments and additions if necessary.

Inventory management

The maintenance team also manages inventory levels. Inventory can include extra machine parts, craft supplies, office equipment and materials; hotel bedding, room linens, etc.

CMMS software informs remaining inventory levels, quantities used during maintenance, and reordering of new material. Also, it helps in managing inventory efficiently and controlling inventory-related expenses.

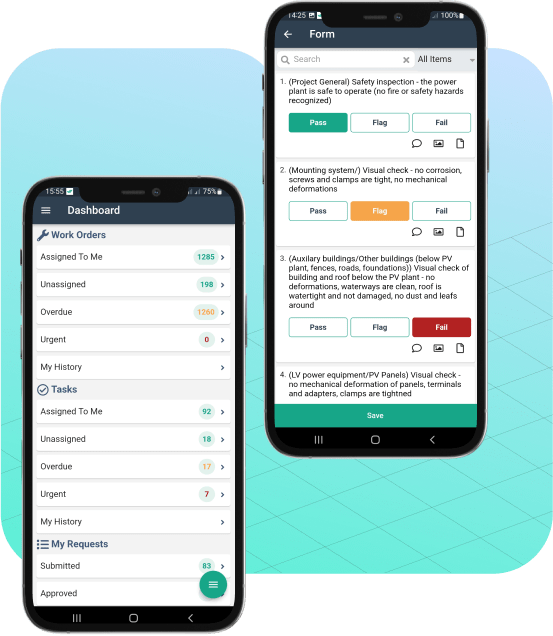

Mobile platform for Asset Tracking

The asset tracking mobile app behind CMMS provides 24/7 access and convenience. If you want to know where your assets are, just use your smartphone and access the app software.

Mobile technology provides the opportunity to ask questions, solve problems, and ensure on-time operations. Search for updates and information even when users are away from their desks.

Preventive maintenance

PM is a periodic inspection program with the goal of “finding and fixing small problems before big ones arise.”

It is an essential part of a CMMS because it can be scheduled in advance. It also sends out alerts and notifications to take over scheduled tasks.

The goal of preventive maintenance is to maintain the machine or equipment in the absence of breakdowns. This includes performing some or all maintenance, oil changes, lubrication, etc. at specified intervals.

Preventive maintenance can save up to 20-30% in maintenance costs.

Purchasing and Requisition

Procurement and requirements processes have also become more efficient in achieving consistent results. The digital procurement process is easy to set up because it is computerized and multiple operators are responsible for handling large amounts of data dynamically.

The purchase requisition process interfaces with the purchase requisition software in the asset tracking system to provide stock level notifications before stock levels reach minimum stock and backorders are required.

Required processes will be verified against relevant existing invoices and purchase orders before approval. Reports are generated without blocking and delays. So you have a real-time vision. Cloud-based storage is centralized with easy and seamless access to the system and approval requests.

Security check

Security is one of the least considered aspects. Unmaintained equipment or its sudden failure may result in personal injury. Fortunately, this situation can be avoided if the right precautions are taken.

Maintenance management software tracks maintenance and lets you know when the last maintenance was performed and when the next maintenance is due. A computerized maintenance management system allows supervised access to prevent safety hazards. The right people can access the application.

This also reduces insurance costs, since preventive measures aim to prevent accidents and injuries.

Work plan and arrangement

Many companies employ computerized software to manage their work orders and streamline their maintenance operations.

In the application, you can easily get detailed information about the ticket. Important data such as work order status, machine status, work order assignments, and work order history can also be retrieved.

Comparison of CMMS and EAM Asset Tracking & Management

Some companies use hardware maintenance software called CMMS, short for “computerized maintenance management system” but also called “computer-assisted maintenance management software”.

CMMS and EAM systems have similar goals and some of the same functionality, although EAM systems offer a wider range of functionality. What sets them apart is philosophy and scope.

A CMMS system focuses on support, while an EAM system takes a holistic approach, integrating multiple business functions. The CMMS begins to provide follow-up after the purchase and installation of an asset. On the other hand, the EAM system can follow the entire life cycle of an asset, starting with design and installation. A CMMS system is designed to handle a single site or offer limited multisite support. The EAM system is equipped with extensive functions to manage multiple sites and companies.

An EAM system is a comprehensive tool for managing physical assets and optimizing their performance across the enterprise. EAM is a CMMS combined with an inventory management system, a purchasing management system, a document management system, an accounting system, a project management system, multi-site management tools, and performance management, all in one integrated software.

Asset maintenance management is very helpful for CMMS to make operations simpler and more efficient. It simplifies asset management, makes company operations robust, and provides a comprehensive reference guide for the future. A CMMS enables management teams to make informed decisions based on operational efficiencies and asset cost savings, thereby increasing company savings.