Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeWhat is maintenance metric?

Maintenance metrics serve as essential performance indicators (KPIs) employed to monitor and gauge the efficacy of maintenance procedures. They offer valuable perspectives on the adequacy of asset maintenance, resource allocation, and the effectiveness of strategies in averting equipment breakdowns and operational downtime. Six asset maintenance metrics warrant your attention for comprehensive evaluation.

Any business that uses equipment invests in its maintenance to ensure that the equipment is safe to use and fit for purpose. However, at some point, you need to understand the effectiveness of your service processes and your team and what you can do to improve, which is why maintenance metrics are essential.

The article explains what these measures are and how they can benefit your business.

What Are Equipment Maintenance Metrics?

Metrics are measures you can use to understand how efficient or productive your resources, employees, or processes are. Companies use them to determine where they are doing well and to identify where there is room for improvement. Since equipment, production, and business often depend on resources, maintenance plays a vital role.

It is essential to have productive maintenance, use the correct maintenance method, and allocate resources wisely to ensure that problems are resolved quickly by eliminating downtime and protecting the health and safety of employees.

If you have the numbers to explain how well your team or processes are performing, you can compare them to the standards set for achieving your goal. Once that baseline is established, you can often measure some metrics to understand how well your team is developing over time.

Therefore, you can find the root of a problem and fix it to improve overall metrics and performance.

Leading vs. Lagging Metrics

A standard metrics division is the one between leading and lagging metrics. The first metrics refer to future goals and standards and indicate what needs to be solved to achieve them, while the second ones report results that have already been achieved and take time to measure. To be more precise, leading metrics refer to something that will affect future performance, and lagging metrics report past performance.

An example of a leading metric is the relationship between estimated and actual performance, which indicates what to expect from the article, employee, or process in the future. Downtime is an example of a lagging metric because it measures the hours of inactivity for a given asset or set of assets.

Why are maintenance metrics useful?

Once you have established maintenance metrics in your organization, you will reap many benefits. First, you and your team will understand how each employee’s actions impact the bigger picture and increase efficiency. This knowledge helps keep employees more engaged, more productive, and less likely to leave the company, which is your goal. An employee may not understand the direct impact of their work on the company’s objective. But once you have some metrics in place, it’s easy to explain how, for example, the great work done by the team member on preventative maintenance has a positive impact on a project, on production, and on the company in general.

Maintenance statistics can also help you reduce downtime and improve health and safety. They help you understand how much downtime you have and what’s causing it, so you can develop an improvement strategy. Some preventative service metrics help you determine how efficient you are at preventing damage or breakdowns that could impact the health of your employees.

Additionally, such metrics can help you understand if you are spending more money or time than necessary on certain parts of the process. You get numbers that show how much you’re spending on processes, and you can compare them to the numbers that a new solution or process would bring.

Here are some important maintenance metrics you should track if you want to improve and optimize your maintenance operations:

Planned maintenance percentage (PMP)

As you know, there are two types of maintenance activities: planned and unplanned.

- Planned maintenance is what’s done as part of your preventative maintenance program.

- Unplanned maintenance is what’s done in response to a machine breaking down.

Your planned maintenance percentage is the percentage of total maintenance time that falls into the first category.

PMP = (Planned Maintenance Hours / Total Maintenance Hours) X 100

There is no such thing as 100% PMP — even the best-made machines will break down eventually, but your PMP should be at least 85%.

Inventory Turnover

Inventory turnover represents the rate of inventory flowing through your storerooms or warehouses in a specified period. This metric calculates the cost of purchased stock vs. the cost of items on hand. Tracking inventory turnover helps you evaluate sales and ensure you can meet customer demand.

Maintenance schedule compliance

Compliance with the maintenance schedule measures the amount of maintenance work performed as a percentage of the planned amount. It’s not as easy as it sounds. Dr. Palmer, who wrote the book on maintenance planning, calls this “the most dangerous measure of planning.” It’s also essential, so here are some tips to get it right:

- Don’t go for 100%. It sounds like a good cause, but consider how easily it can be manipulated. If I plan two activities and complete two activities, my compliance is 100%, not to mention that two activities could only cost me 4 hours when you pay me 40. Palmer suggests loading weekly schedules with 100% of available working hours but only expecting between 40% and 90% compliance. The difference is the amount of unscheduled maintenance that must take place in a given week.

- Measure compliance weekly, not daily. Anything can happen on a normal day and cause maintenance to be postponed. Palmer notes that “focusing on the week as a whole leads to high productivity without committing to the daily bottom line.”

- Measure work orders, not hours worked. Unless you’re a brilliant estimator, working hours may not be indicative of real results, as tasks often take longer than expected. Work assignments are easier to understand and explain.

- Don’t reward or punish employees for extra work. Instead, focus on the success of the original scheme.

Overall equipment effectiveness (OEE)

OEE takes three factors into account: availability, performance, and quality.

OEE % = Availability X Performance X Quality

A 100% OEE would mean your machines are always running at peak performance and every product that comes off your assembly line is perfect. As with 100% PMP, this outcome is impossible, but the calculation can help you assess gaps in your maintenance process.

Mean time between failures (MTBF) and mean time to repair (MTR)

We combined these two metrics because, as a group, they provide an overall picture of how much time manufacturers regularly lose to minor issues like device congestion. While these numbers may be small individually (on the order of minutes), over time they can add up to significant productivity and profit losses.

Mean time to repair

The MTTR metric concerns the time it takes for your service team to find the issue and solve it, and it helps you understand how successful you are at handling unexpected breakdowns. MTTR considers the time that passes between the moment that the problem occurs and the time when you can use the asset again. You can calculate MTTR by dividing the total hours spent on one asset’s upkeep by the number of its completed repairs: MTTR = total maintenance hours/number of repairs. This metric can indicate that an item needs to be replaced instead of wasting hours on repairs, saving you money. It can also be helpful to understand if any equipment had scheduled maintenance before the failure, as this is a clear indication that your maintenance process is flawed. The purpose of scheduled maintenance is to fix minor problems and prevent breakdowns and downtime. If you experience unexpected problems despite regular maintenance, you should investigate the cause of the problems.

Mean time between failures

The MTBF metric helps you measure the time an asset spends working between two unexpected upkeeps. It determines how long you can use an asset before it breaks down again. It does not include scheduled maintenance, as this is not a failure, but a planned activity to avoid resource problems. This metric helps you understand how fruitful your maintenance process is by showing how much time elapses between two failures and how reliable the asset is. If a resource fails often, you won’t be able to use it often and its availability will be low. MTBF can also serve as an indication of faulty equipment or assets that need to be replaced when the value is below normal. To find the average, don’t rely solely on the manufacturer’s manuals. Instead, consider industry standards, equipment health, and maintenance history, which can help you determine acceptable MTBF levels for your assets. Determine the MTBF hours by dividing the total number of operating hours of the asset by the number of failures that have occurred: MTFB = operational hours/failures. The higher the MTBF is, the longer you can expect your system to run without failures. If the number is deficient, you need to find the cause of the issue, whether in equipment or the upkeep process.

Maintenance cost per unit produced

Maintenance cost per unit produced is a simple equation that can tell a lot about the efficiency of your maintenance operations.

For a specific measurement period: Total Maintenance Cost / # Units Produced

If your maintenance costs are too high, check your PMP for the same measurement period – it’s probably below the 85% target.

Conclusion

Maintenance metrics help you understand how productive your equipment or team is and how efficient your maintenance process is. When you perform these checks regularly, you can easily see progress or setbacks in certain areas. Using specific metrics, you can determine exactly where the problems are, so you can focus on that point and fix the problem.

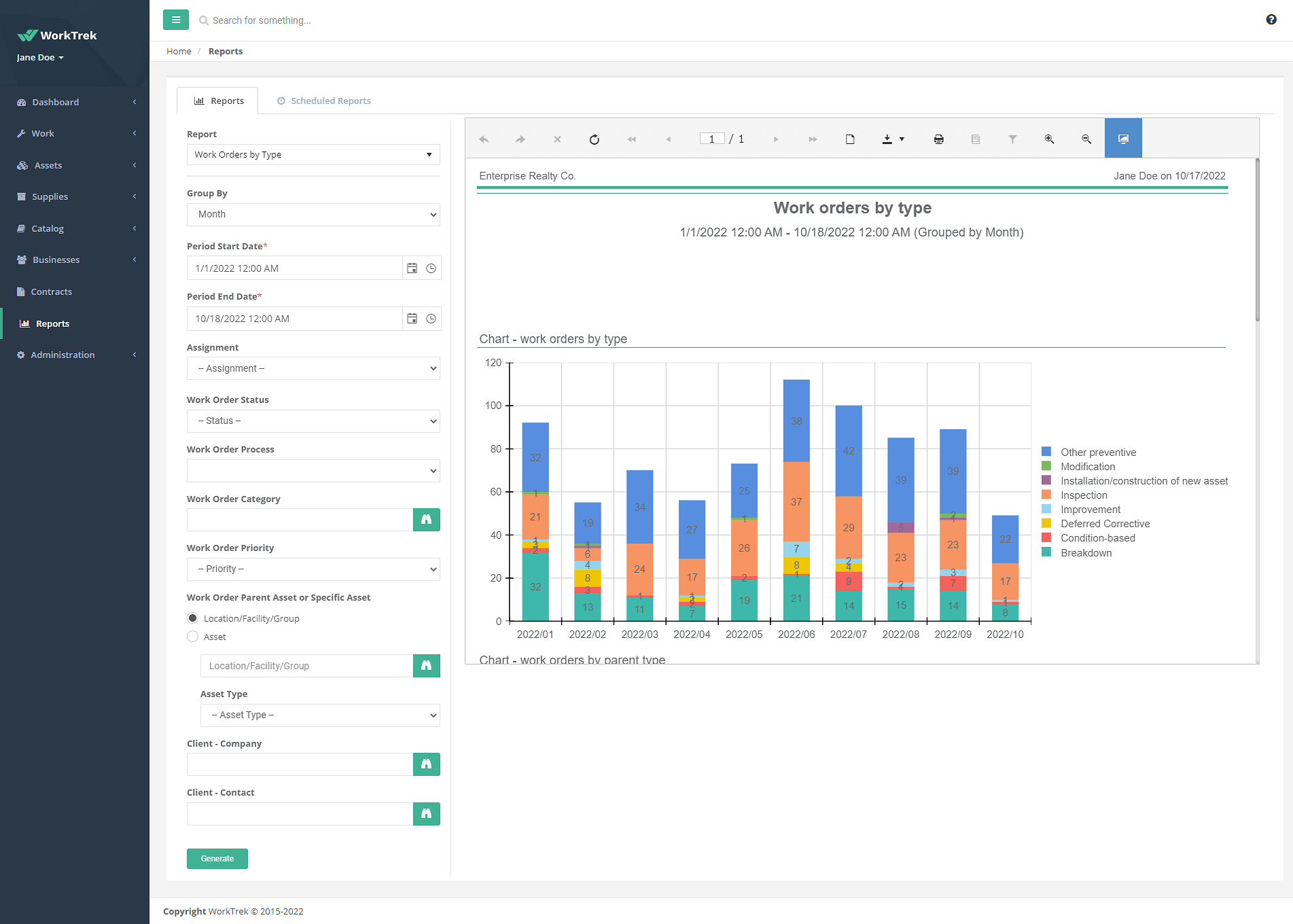

Software that tracks the factors needed to calculate maintenance statistics is a much better solution than pen and paper. It gives the entire team access and understanding of processes, resources, and maintenance, making everyone more productive and informed.