Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeMaintenance is crucial for keeping equipment and facilities running smoothly. Two main types of maintenance strategies are preventive and breakdown maintenance. These approaches differ in their timing and goals.

Preventive and predictive maintenance aims to prevent breakdowns before they happen, while breakdown maintenance addresses issues after they occur. Preventive maintenance involves regular checks and upkeep to keep things working well. It helps avoid sudden problems and keeps operations efficient.

Breakdown maintenance, on the other hand, is a reactive approach. It kicks in when something stops working. This method can lead to more downtime and higher costs. Both strategies have their place in a maintenance plan, depending on a business or facility’s needs.

Source: WorkTrek

Understanding Maintenance

Maintenance is vital for keeping equipment running smoothly and efficiently. It involves different approaches to caring for machinery and assets in a business.

Definition of Maintenance

Maintenance refers to the actions taken to keep equipment and facilities in good working order. It includes fixing, replacing, and caring for machinery to prevent breakdowns. The goal is to extend equipment life and ensure it runs at peak performance.

Proper maintenance helps avoid costly repairs and unexpected downtime. It also improves workplace safety. Regular upkeep can spot potential issues before they become big problems.

Types of Maintenance

There are several types of maintenance strategies businesses can use:

- Preventive or Preventative maintenance: Regular, planned care to prevent breakdowns

- Breakdown maintenance: Fixing equipment after it fails

- Corrective maintenance: Addressing issues as they arise

- Predictive maintenance: Using data to predict when maintenance is needed

- Planned maintenance: Scheduled upkeep based on time or usage

- Run to failure maintenance: Allowing equipment to operate until it breaks down

Each type has its own benefits and best uses. The right mix depends on the business and its equipment needs.

Importance of Maintenance for Business Operation

Good maintenance practices are key to smooth business operations. They help:

- Reduced unexpected downtime for critical equipment

- Lower repair costs

- Extend equipment life

- Improve product quality

- Boost productivity

- Reduced emergency maintenance

- Reduced Safety Risks

- Reduced equipment failure

Reduce Maintenance Costs

Proper maintenance can lead to big savings over time. It cuts the risk of major breakdowns that can halt production. Well-maintained equipment also uses less energy, which saves money.

Maintenance is crucial for safety. It helps prevent accidents caused by faulty machinery, protects workers, and avoids legal issues.

What Is Preventive Maintenance?

Preventive maintenance is a proactive approach to equipment upkeep. It aims to prevent breakdowns before they occur through planned inspections and repairs.

Core Principles of Preventive Maintenance

Preventive maintenance focuses on regular upkeep to avoid unexpected failures by employing preventive maintenance strategies. It involves scheduled inspections and maintenance activities to keep equipment running smoothly.

Key principles include:

- Routine checks and cleaning

- Timely replacement of worn parts

- Regular lubrication of moving components

- Adjustments to maintain optimal performance

A well-designed maintenance schedule is crucial. It ensures all equipment receives proper care at the right intervals.

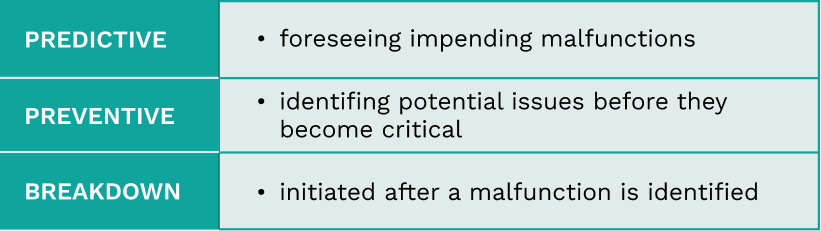

Benefits of Preventive Maintenance Strategy

Implementing preventive maintenance offers several advantages:

- Reduced downtime: Regular care helps avoid unexpected breakdowns.

- Extended equipment life: Proper maintenance keeps machines running longer.

- Improved safety: Well-maintained equipment is less likely to malfunction dangerously.

- Cost savings: Preventing major repairs is often cheaper than fixing breakdowns.

Preventive maintenance can maintain efficiency and save time in the long run. It allows businesses to plan for maintenance costs rather than face surprise expenses.

Illustration: WorkTrek / Data: Plant Engineering

Challenges in Implementing Preventive Maintenance

Despite its benefits, preventive maintenance can face hurdles:

- Initial investment: Setting up a program may require upfront costs.

- Time commitment: Regular maintenance takes time away from production.

- Overcoming resistance: Staff may resist changes to established routines.

Balancing maintenance needs with operational demands can be tricky. It requires careful planning and communication across teams.

Preventive Maintenance Techniques

Effective preventive maintenance strategy uses various techniques:

- Visual inspections: Regular checks to spot early signs of wear or damage.

- Vibration analysis: Detecting unusual vibrations that may indicate problems.

- Oil analysis: Testing lubricants to assess equipment condition.

- Thermography: Using infrared imaging to identify hot spots or thermal issues.

Preventive maintenance software can help manage these tasks. It tracks maintenance schedules, stores equipment data, and generates work orders.

Proper training ensures maintenance staff can effectively perform these techniques. This helps create a robust preventive maintenance system that keeps equipment running smoothly.

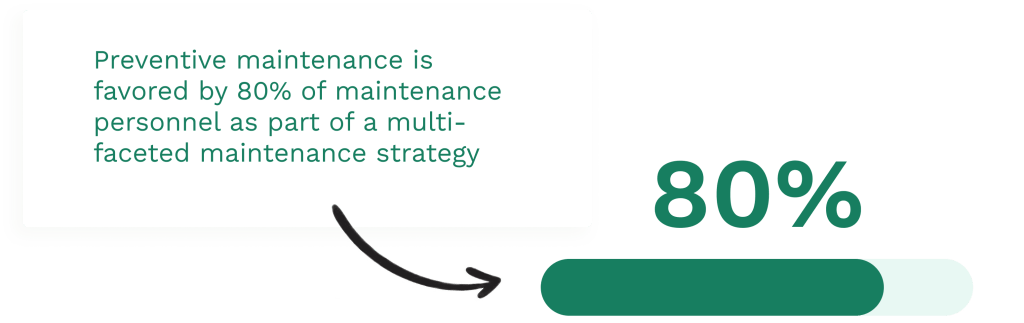

Illustration: WorkTrek / Data: FinancesOnline

What Is Breakdown Maintenance?

Breakdown maintenance strategy is a reactive approach to equipment upkeep. It involves fixing or replacing assets only after they fail or stop working properly. This strategy is used for certain types of equipment and situations.

Nature of Breakdown Maintenance

Unplanned breakdown maintenance is reactive and unplanned. It happens when equipment suddenly stops working, and teams rush to fix the problem quickly.

This type of maintenance often leads to unexpected downtime. It can disrupt normal operations and cause delays. Breakdown maintenance is also called emergency maintenance.

The main goal is to get equipment running again fast. This might mean quick fixes or total replacements.

When Breakdown Maintenance Is Applicable

Breakdown maintenance is best for non-critical equipment, which doesn’t affect key operations if it fails. It’s also suitable for short-life assets that are cheap to replace and generally not part of a scheduled maintenance strategy. This approach can reduce unnecessary maintenance.

Examples include:

- Light bulbs

- Fuses

- Some office equipment

It’s often cheaper to replace these items when they break than to check them regularly.

Ideal Scenarios for Breakdown Maintenance

Breakdown maintenance can work well when:

- Failures won’t cause safety issues

- Downtime won’t hurt production much

- Repair costs are low

Downsides of Breakdown Maintenance

Relying too heavily on breakdown maintenance can cause problems. It often leads to more unplanned downtime, which hurts productivity and increases costs.

Other downsides include:

- Higher repair costs due to sudden failures

- Longer repair times

- Shorter equipment life

- Health and safety risks from unexpected breakdowns

- Stress on maintenance teams

Unexpected failures can also damage other parts of a system. This can make repairs more complex and expensive.

Illustration: WorkTrek / Data: Unlocking Performance

Breakdown Maintenance Scenarios

Common breakdown scenarios include:

- Flat tires on vehicles

- Burnt-out light bulbs

- Broken office printers

- Failed computer hard drives

A non-critical machine might stop working in a factory. If this doesn’t affect the main production line, breakdown maintenance could be used.

A retail store might use breakdown maintenance for its air conditioning. They’d fix it only when it stops working, not before.

Some examples of breakdown maintenance for home appliances like toasters or microwaves. They replace these items when they stop working.

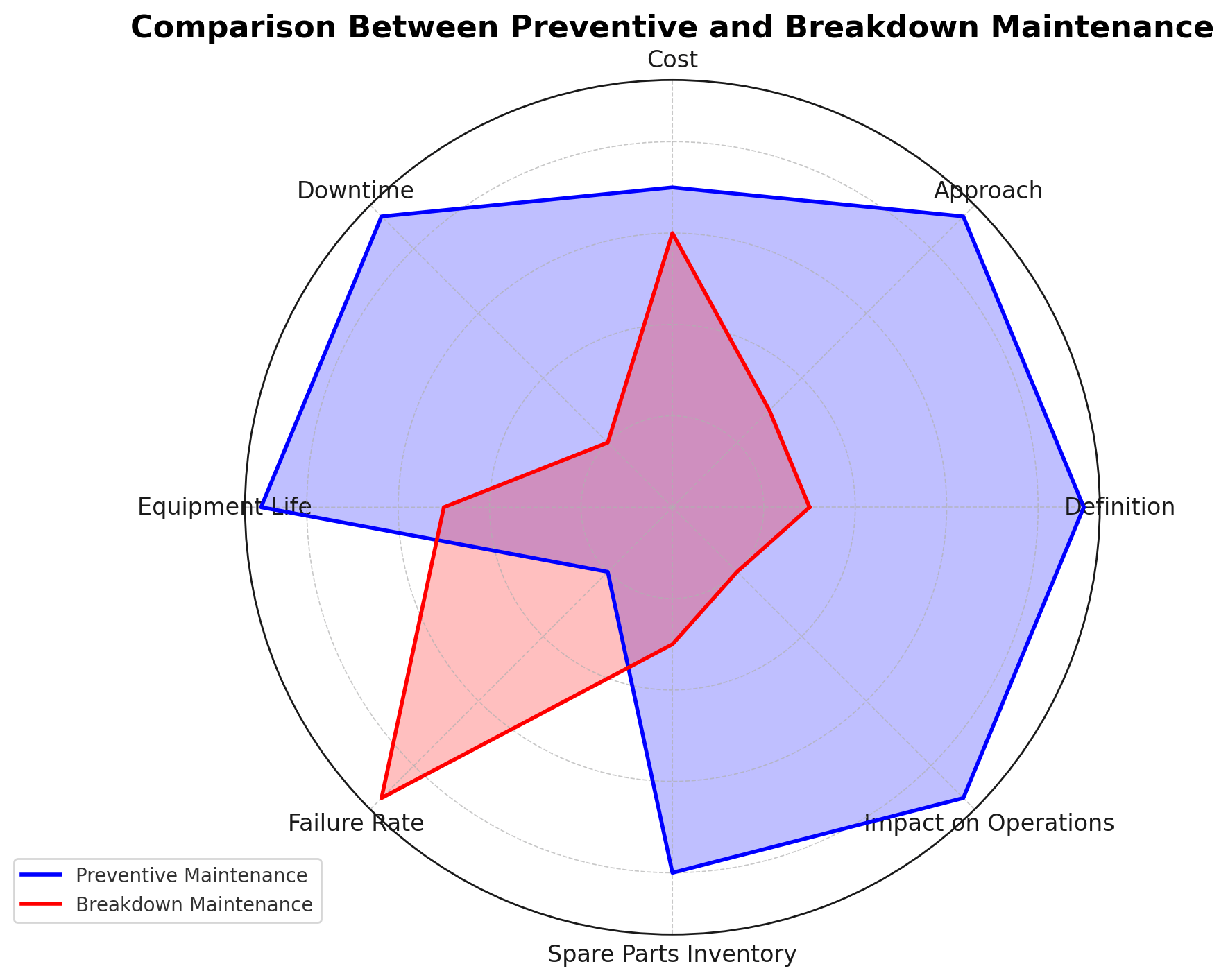

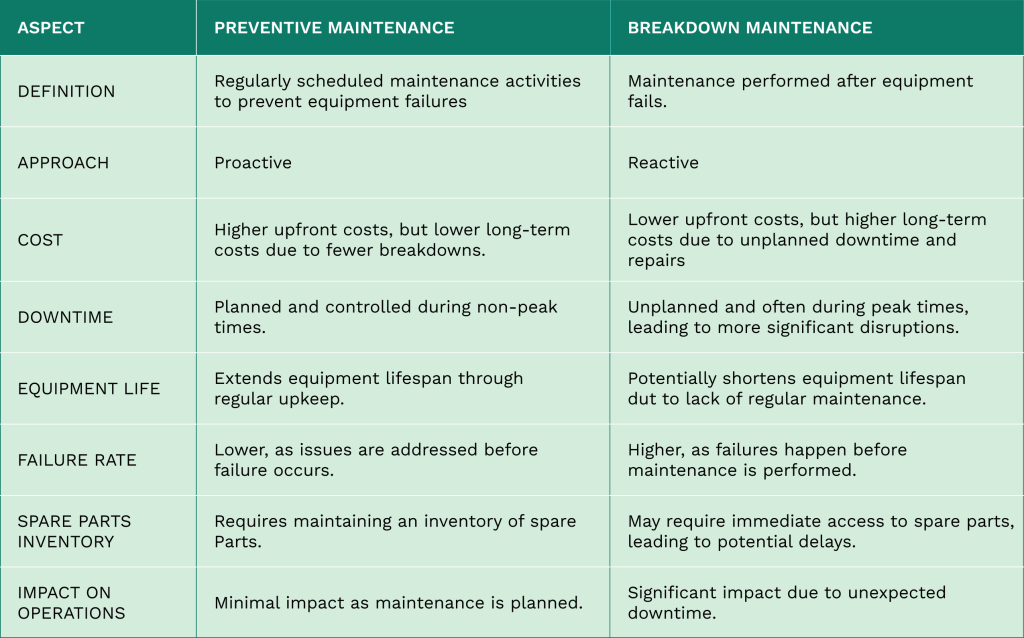

Comparing Maintenance Strategies

Maintenance strategies are crucial in keeping equipment running smoothly. The right approach can save money and boost productivity. Let’s compare preventive and breakdown maintenance.

Source: WorkTrek

Key Differences Between Preventive and Breakdown Maintenance

Preventive maintenance is planned and regular. It aims to stop problems before they start. Breakdown maintenance happens after equipment fails.

Schedules differ greatly. Preventive work follows a set plan. Breakdown fixes occur as needed.

Downtime varies too. Preventive tasks cause short, planned stops. Breakdowns lead to longer, unexpected halts.

The costs show a stark contrast. Preventive work spreads expenses over time, while breakdown repairs often cost more due to emergency repairs.

Equipment lifespan is affected. Regular care extends machine life. Waiting for failures can shorten it.

Source: WorkTrek

Evaluating Maintenance Approaches

Productivity impacts differ. Preventive maintenance keeps machines running well. Breakdowns disrupt workflow.

Quality of output varies. Well-maintained equipment produces better results. Failing machines may create defects.

Health and safety is a key factor. Regular checks catch hazards early. Breakdowns can pose sudden risks.

Costs over time show different patterns. Preventive care has steady, predictable expenses, while breakdown fixes have unpredictable, often higher costs.

- Preventive: Planned, lower long-term costs

- Breakdown: Reactive, higher emergency expenses

Choosing the Right Maintenance Strategy

The best strategy depends on several factors:

- Equipment type and age

- Production demands

- Budget constraints

- Available staff

Manufacturer Recommendations

Manufacturer recommendations guide preventive schedules. Critical machines need more care.

A mix of strategies often works best. Some items get regular checks. Others run until they fail.

Maintenance teams need proper training for each approach. They must know how to plan and respond.

The correct program balances costs and benefits. It keeps equipment running without excessive downtime or expense.

Advanced Maintenance Practices

Modern maintenance goes beyond simple prevention or repair. New methods use data and technology to predict issues and optimize maintenance tasks.

Predictive Maintenance and Its Advantages

Predictive maintenance uses data to forecast when equipment might fail. It relies on sensors and Internet of Things (IoT) devices to monitor machine health in real-time. This approach can spot problems before they cause breakdowns.

The main benefit is less downtime. Repairs happen only when needed, not on a fixed schedule. This cuts costs and extends equipment life.

Analytics play a big role in predictive maintenance. The software analyzes data from machines to find patterns. These patterns help predict future issues.

Illustration: WorkTrek / Data: McKinsey & Company

Implementing Computerized Maintenance Management Software

New tech tools make maintenance more efficient. Computerized Maintenance Management Systems (CMMS) help plan and track all maintenance tasks. They store equipment info, schedule work, and track parts.

Cloud-based systems let teams access data from anywhere. This improves communication and speeds up decision-making.

Benefits of CMMS

There are several benefits to implementing a CMMS solution. CMMS solutions offer several benefits:

- Automate Work Orders

- Get Real-time status updates

- Spare parts management

- Key Performance Indicators (KPIs)

- Compliance & Control

- Health and Safety Guidelines

- Detailed Reporting

Maintenance Planning and Implementation

Planning and implementing maintenance strategies are key to keeping equipment running smoothly. Both preventive and breakdown maintenance require careful preparation and execution.

Developing a Maintenance Plan

A good maintenance plan starts with setting clear goals. These goals should focus on reducing downtime and costs while improving equipment life.

Next, create a maintenance schedule. This schedule lists when to check and fix equipment, helping prevent unexpected breakdowns.

The plan should also include a system for work orders. Work orders track tasks and who does them, ensuring nothing is missed.

Lastly, assign team roles. Each person should know their job in the maintenance process. Clear roles help avoid confusion and improve efficiency.

Implementing Maintenance Strategies

Train maintenance teams to put the plan into action. They need to know how to perform both preventive and breakdown maintenance.

Use tools to track maintenance tasks. The software can help schedule work and keep records, making it easier to see what’s been done and what needs to be done.

Regular checks are important. They help catch minor issues before they become big problems. This is a key part of preventive maintenance.

Set up a system for quick responses to breakdowns. This might include having spare parts on hand or on-call technicians.

Keep good records of all maintenance work. These records help spot patterns, improve future planning, and minimize downtime.

Legal, Safety, and Economic Considerations

Maintenance strategies have big impacts on workplace safety and company finances. Rules and costs shape choices between preventive and breakdown approaches.

Compliance and Safety Standards

Preventive maintenance helps companies meet safety rules and regulatory compliance. It finds issues before they cause harm, and regular checks keep equipment safe for the maintenance team.

Safety groups often require preventive care, which reduces accident risks and lowers legal troubles from broken rules.

Breakdown fixes can be risky. Rush jobs may skip safety steps, and workers might use unsafe tools to get things running fast.

Some laws demand proof of upkeep. Preventive logs show a company takes care of its gear. This can help if there’s an accident or inspection.

Source: secure frame

Cost Implications and Savings

Preventive care costs money upfront, but it saves cash over time. It prevents big, costly breakdowns and makes machines last longer, too.

Breakdown fixes cost more than prevention. Emergency parts and overtime pay add up fast, and stopped work loses income.

A mix of both types works best for many firms. They often do basic checks but let some less crucial items run until they break.

Smart maintenance planning stretches the maintenance budget, putting money where it helps most and boosting profits in the long run.

Replacing old gear on time saves money. New machines work better and use less power. The trick is knowing when to upgrade.