Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeFleets can significantly enhance operational efficiency and ensure compliance by integrating Driver Vehicle Inspection Reports (DVIR) with Computerized Maintenance Management Systems (CMMS). Utilizing CMMS software to optimize DVIR processes and automate fleet maintenance processes streamlines inspections, expedites repairs, and reduces downtime.

These tools store inspection data and automate maintenance schedules based on real-time reports, providing comprehensive fleet maintenance solutions.

Using eDVIR devices, fleet managers can more effectively achieve DOT DVIR compliance. These tools simplify documentation and help maintain records effortlessly for the required periods. This ensures safety and enhances vehicle reliability, making fleet operations smoother and more predictable.

Understanding Driver Vehicle Inspection Report (DVIR)

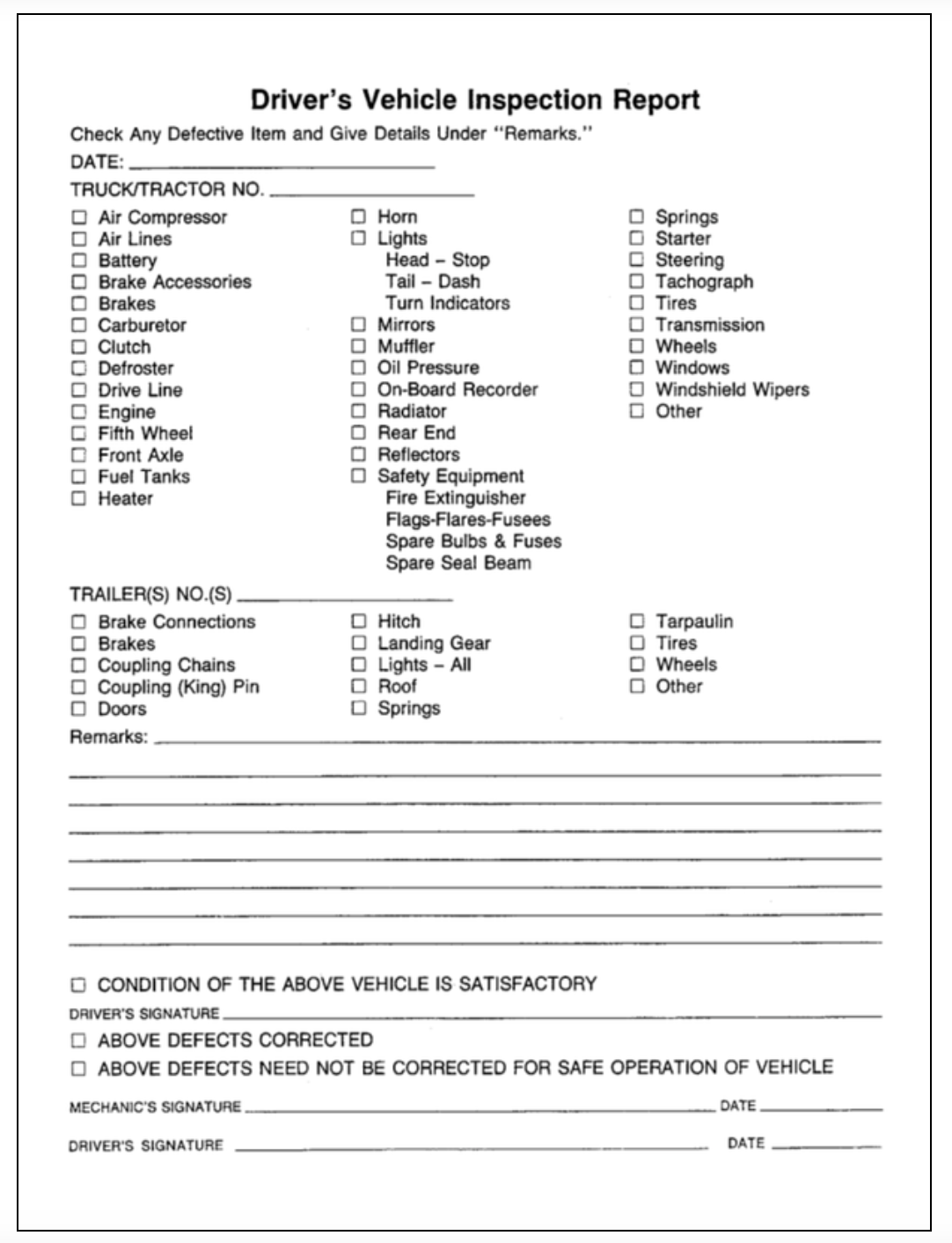

Driver Vehicle Inspection Reports (DVIR) can maintain the safety and compliance of a fleet. They help managers adhere to federal regulations by inspecting and maintaining vehicles properly.

Source: Scribd

Significance of DVIR in Fleet Maintenance Management

DVIRs play a vital role in fleet safety. They help identify defects before they become critical issues. By conducting regular inspections, drivers ensure that vehicles are road-ready, reducing the risk of accidents.

A well-executed DVIR process also minimizes downtime. When vehicles are correctly inspected, needed repairs can be scheduled before issues escalate, keeping the fleet efficient.

Fleet managers can also use DVIRs to track and address recurring problems systematically, which can reduce the total fleet operating costs.

Additionally, integrating computerized maintenance management software (CMMS) can automate fleet maintenance tasks and streamline fleet maintenance processes. This automation saves time, improves communication, reduces downtime, and controls expenses, whether maintenance is managed in-house or outsourced.

Source: Cal/Amp

Compliance with Federal Regulations

The Federal Motor Carrier Safety Administration (FMCSA) mandates strict adherence to regulations regarding vehicle inspections. Compliance with these regulations is essential for legal and operational reasons.

Non-compliance can result in hefty fines and legal complications. Regular DVIRs ensure that fleet managers meet Department of Transportation (DOT) requirements and keep their operations within the law.

As federal regulations stipulate, this includes conducting thorough inspections at the beginning and end of each workday.

Computerized Maintenance Management System (CMMS)

CMMS software helps businesses streamline maintenance tasks and integrate with DVIR processes, enhancing overall efficiency and reducing maintenance costs.

What is CMMS?

A Computerized Maintenance Management System (CMMS) is a tool designed to manage and automate maintenance activities. Maintenance managers utilize CMMS to assign suitable maintenance tasks to the right teams, ensuring accountability, efficient task management, and immediate real-time action when faults are detected.

CMMS handles work orders, schedules preventive maintenance, eliminates manual data entry, improves fleet uptime, and manages assets. It collects data on asset performance, helping to predict and prevent failures.

This system is widely used in asset-intensive industries like manufacturing, utilities, and transportation.

Key Functions:

- Work Order Management: Tracks and schedules maintenance tasks.

- Asset Management: Keeps records of equipment and asset performance.

- Preventive Maintenance Scheduling: Automates routine maintenance to avoid breakdowns and supports preventative maintenance to extend asset life cycles, optimize equipment uptime, and reduce maintenance costs.

By integrating these functions, a CMMS improves maintenance efficiency and reliability.

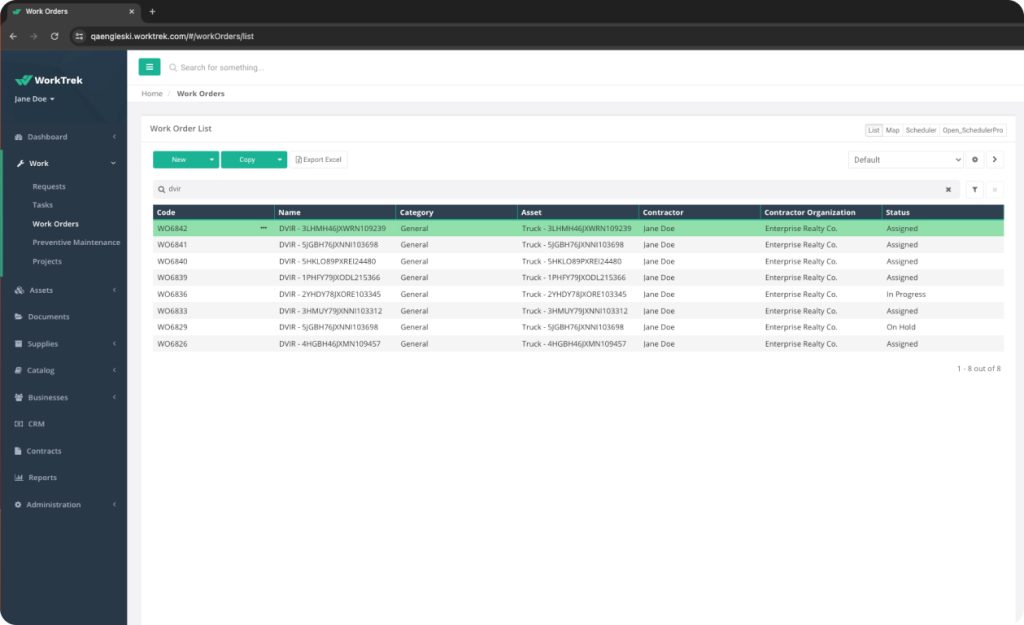

Source: WorkTrek

Benefits of Integrating CMMS with DVIR Processes

Combining CMMS with DVIR (Driver Vehicle Inspection Report) processes brings many benefits.

First, it centralizes fleet maintenance data, combining vehicle inspection records with maintenance schedules. This means fewer missed inspections and repairs, improving vehicle reliability.

It can also directly integrate with a fleet management system to create triggers and automatically track vehicle data, such as mileage.

Second, it automates workflows. When a driver submits a DVIR, the CMMS can create a work order automatically. This speeds up the response to issues, reduces downtime, can improve fleet uptime, and enhances the overall fleet maintenance program.

Third, it enhances compliance. Accurate records of inspections and maintenance activities help to meet regulatory requirements, reducing the risk of fines and improving safety.

By integrating CMMS with DVIR, companies can achieve higher efficiency, control expenses, send diagnostic trouble codes to a central system, and, more importantly, lower maintenance costs and improve regulatory compliance.

Source: WorkTrek

Optimization Strategies

Effective use of CMMS software can significantly improve the performance and efficiency of DVIR processes. Key areas include predictive maintenance, streamlined inspection workflows, and enhanced collaboration between drivers and mechanics.

Leveraging Data for Predictive and Preventative Maintenance

Predictive maintenance relies on data to forecast potential issues before they lead to equipment failure. With CMMS software and cloud technology, organizations can achieve optimized maintenance management by efficiently collecting and analyzing data on vehicle performance, usage patterns, and historical maintenance records. By doing so, they can identify trends and anomalies that signal maintenance needs.

Key Points:

- Data Collection: Use sensors and telematics to gather real-time data.

- Data Analysis: Identify patterns and predict future breakdowns.

- Maintenance Scheduling: Plan maintenance activities to prevent unexpected failures.

Predictive maintenance helps minimize downtime and extends the lifespan of assets, ensuring higher availability of vehicles.

Streamlining Inspection Workflows

CMMS can significantly enhance the efficiency of inspection workflows by automating many tasks and providing a structured inspection process.

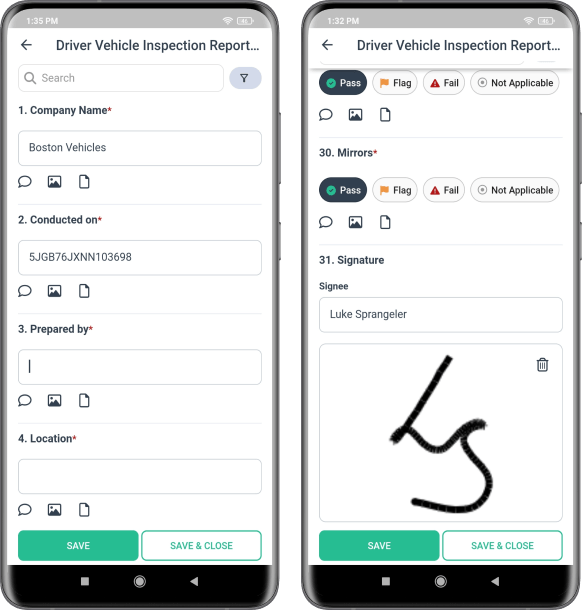

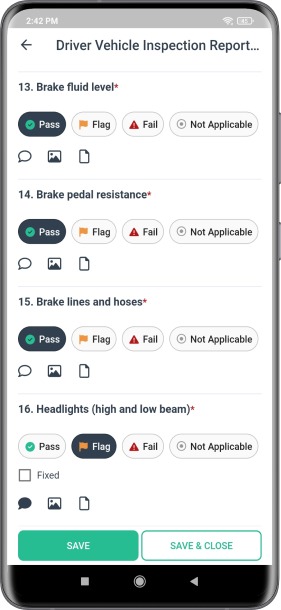

For example, you can use the custom form building features in CMMS software like WorkTrek to create a customized maintenance tasks list for each equipment type.

Advanced CMMS leverages modern digital maintenance practices and offers a paradigm shift in maintenance practices through sophisticated data gathering and analytical techniques.

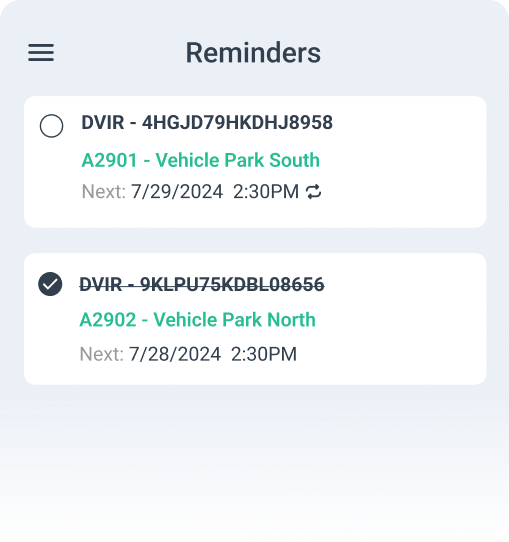

Automated notifications remind drivers and mechanics when inspections are due, ensuring no missed inspections.

Key Points:

- Automated Reminders: Ensure timely inspections with computerized alerts.

- Digital Checklists: Use electronic forms to standardize inspections.

- Centralized Records: Store all inspection data in a single, accessible location.

- Cost Reporting: Customer reports to provide detailed cost reporting

- Asset Report: Customized asset downtime reporting

- Parts: Notifications for critical spare part shortages

Such features reduce the administrative burden and reduce errors, leading to faster inspection processes and better compliance with regulations.

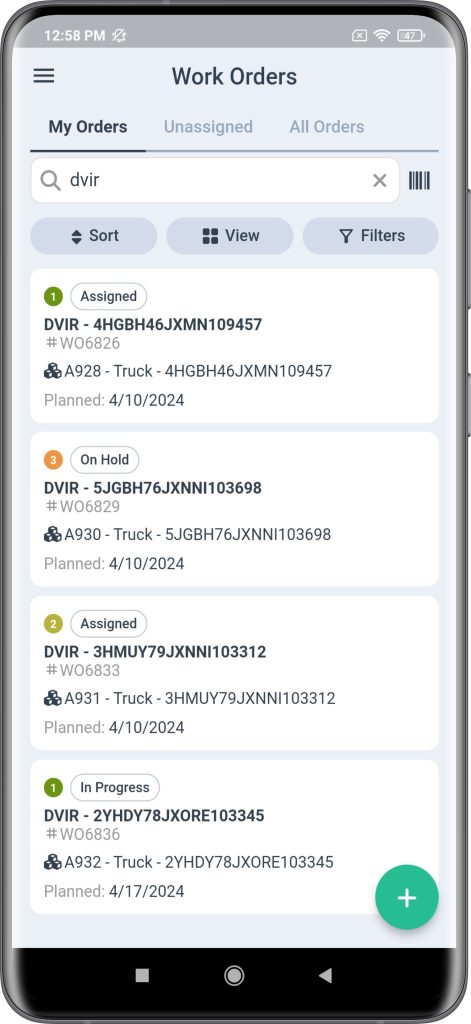

Source: WorkTrek

Enhancing Driver and Mechanic Collaboration

Improved collaboration between drivers, mechanics, and maintenance managers can increase the success rate of any maintenance program. CMMS platforms provide tools that facilitate communication and information sharing.

Key Points:

- Instant Reporting: Drivers can report issues in real time via mobile apps.

- Task Management: Assign and track maintenance tasks quickly.

- Feedback Loops: Create channels for drivers to provide feedback on repairs.

- Repair Status: List of all repairs completed

This collaboration ensures that problems are quickly reported and addressed, leading to more efficient maintenance and better vehicle performance. Mechanics and maintenance managers are alerted to faults.

They can take immediate action in real-time, leveraging the benefits of CMMS techniques to streamline maintenance processes for enterprises of all sizes.

Technological Advancements

Innovations in CMMS software are enhancing how Driver Vehicle Inspection Reports (DVIR) are managed. The industry is seeing significant improvements through electronic DVIR (eDVIR) and mobile apps.

The Role of Electronic DVIR (eDVIR)

Electronic DVIRs (eDVIRs) streamline the inspection process. They help drivers submit reports electronically, reducing paperwork and errors. eDVIRs ensure that inspection data is accurate and timely.

Electronic Logging Devices (ELDs) integration capabilities enhance data collection and compliance. CMMS systems help manage and track these digital reports efficiently. This integration translates to better maintenance schedules and quicker issue resolution.

Using eDVIRs can also improve accountability. Drivers and maintenance teams can easily access reports, ensuring all issues are documented and addressed promptly.

CMMS Mobile Solutions: Apps and Cloud-Based Tools

CMMS Mobile apps provide access to DVIR features on the go. Apps available on iOS and Android allow drivers to complete inspections using their smartphones.

Cloud-based tools ensure data syncs across multiple devices. This is crucial for real-time updates and decision-making.

CMMS mobile apps, like WorkTrek Mobile, also support offline functionality, allowing drivers to complete reports without internet access.

Integration capabilities enhance these systems’ utility. Data collected through mobile solutions can feed directly into the CMMS, ensuring a seamless workflow. This reduces manual data entry and speeds up the maintenance process.

With these mobile solutions, companies can ensure thorough inspections and compliance with regulations. They also provide a user-friendly interface for drivers, making the inspection process more efficient and reliable.

Operational Implementation

Optimizing DVIR (Driver Vehicle Inspection Reports) with CMMS (Computerized Maintenance Management System) software involves several essential practices. Key elements include customizing inspection lists, scheduling and notification systems, and ensuring proper training and user adoption.

Customized Inspection Lists and Automation

Customizing inspection lists allows companies to tailor their DVIRs to specific needs. A CMMS can help create detailed, automated inspection checklists that reflect the unique requirements of different vehicles and operations.

Automated workflows can ensure that inspection tasks are consistently completed and recorded. This improves accuracy and saves time by eliminating manual data entry. Important aspects, such as brake checks and tire pressure, can be systematically monitored.

CMMS software can also store historical data, enabling maintenance teams to track patterns and predict when specific components might fail. This proactive approach enhances overall vehicle safety and performance.

Source: WorkTrek

Scheduling and Notification Systems

Scheduling regular inspections and maintenance tasks is pivotal in maintaining vehicle health. CMMS software excels at creating and managing these schedules, ensuring no inspection is missed.

Automated notification systems alert maintenance teams and drivers when an inspection or maintenance task is due. These notifications can be customized based on the urgency and type of task.

Such proactive notifications ensure timely inspections and mitigate the risk of vehicle breakdowns. Also, they provide a clear overview of maintenance schedules, helping to balance workload and resource allocation efficiently.

Training and User Adoption

Ensuring that users are well-trained and comfortable with CMMS software is crucial for successful implementation. Training should cover both the software’s technical aspects and the specific procedures related to DVIR.

Hands-on training sessions, user guides, and continuous support can facilitate smoother adoption. Training programs should focus on correctly inputting data, interpreting inspection results, and responding to alerts.

Highlighting the benefits of CMMS software in simplifying tasks and improving accuracy can further encourage user adoption. Engaged and informed users are more likely to embrace the new system, leading to better maintenance practices and compliance.

Maintenance Management

Optimizing maintenance management is crucial for improving operational efficiency and reducing costs. Key areas include scheduling, asset tracking, maintenance efficiency, cost reduction, inventory management, and work orders.

Maintenance Schedules and Asset Tracking

Maintaining an efficient schedule is essential for preventing unexpected breakdowns. CMMS software can help plan and automate vehicle maintenance schedules, ensuring that tasks are completed on time and resources are utilized effectively.

Asset management is another critical aspect. Knowing each asset’s current condition helps in planning preventive maintenance, which reduces downtime and prolongs asset life. Advanced tracking features, including GPS integration with fleet management software, provide real-time asset location and status updates.

Evaluating Maintenance Efficiency and Cost-Reduction

Evaluating the efficiency of maintenance activities helps businesses identify areas for improvement. CMMS software generates detailed reports that offer insights into maintenance efficiency. These reports highlight which tasks take the most time and which assets require frequent repairs.

Effective maintenance can significantly reduce costs. By monitoring and analyzing maintenance data, companies can implement cost-reduction strategies.

Predictive maintenance uses data to predict failures before they happen, resulting in fewer emergency repairs and lower maintenance costs.

Inventory and Work Order Management

Managing inventory is key to ensuring that the necessary parts are always available. Inventory management modules within CMMS software track stock levels, order history, and parts usage. They automate reorder processes to prevent stockouts, ensuring smooth maintenance operations.

Work order management is equally essential for streamlined maintenance processes. CMMS software allows for easy creation, assignment, and tracking of work orders.

This helps prioritize maintenance tasks based on urgency and resource availability. With real-time updates and notifications, maintenance teams can stay informed and efficient.

CMMS software in these areas leads to better-organized, cost-effective, and efficient maintenance operations.

Ensuring Safety and Compliance

Ensuring safety and compliance in fleet operations involves consistently monitoring vehicle components and strict adherence to safety standards. Together, these practices help reduce accidents and enhance regulatory compliance.

Monitoring Vehicle Component Performance

Regular vehicle inspections are essential to maintaining safety. Checking components like brake connections, windshield wipers, lights, mirrors, and emergency equipment ensures they function correctly. Using a Computerized Maintenance Management System (CMMS), fleet managers can schedule and monitor these inspections efficiently.

Digital inspection reports provide a comprehensive record of each check, making it easier to identify recurring issues. For example, regular checks of the brake system and reflectors can prevent accidents and breakdowns. Tracking the performance of vehicle parts helps detect wear and tear early, allowing for timely maintenance and reducing the risk of failures.

Adhering to Safety Standards and Protocols

Compliance with safety standards and regulatory protocols is crucial. The Driver Vehicle Inspection Report (DVIR) process, mandated by the Federal Motor Carrier Safety Administration (FMCSA), requires pre-trip and post-trip inspections of each vehicle. This ensures that issues are addressed before they compromise safety.

CMMS software can streamline this process by facilitating the creation and submission of electronic DVIRs. This enhances compliance and makes record-keeping more accurate and less time-consuming. Detailed documentation of inspections, including checks of wheels, horns, and other critical components, is essential for meeting regulatory requirements and ensuring vehicle safety.

By investing in these technologies, fleet operators can ensure their operations remain safe and compliant.

Source: WorkTrek

Comparative Analysis: Before and After CMMS Implementation

Before CMMS Implementation:

- Inefficient paper-based DVIR processes

- High maintenance backlog

- Frequent unplanned downtime

- Manual data entry tracking of fleet vehicles

After CMMS Implementation:

- Digital DVIR processes are streamlined

- Reduction in maintenance backlog

- Proactive maintenance scheduling minimized downtime

- Real-time tracking and reporting for fleet managers

- Real-time maintenance data

- Improved vehicle performance

- Improved asset maintenance

Frequently Asked Questions

Integrating CMMS software with DVIR processes can streamline inspections, improve maintenance tracking, and ensure compliance with transport regulations. Here are some common questions about optimizing DVIR with CMMS software.

How can integrating CMMS Software improve DVIR process efficiency?

CMMS software automates many tasks in the DVIR process. It helps schedule inspections, notify teams of issues, and create repair tickets immediately. This reduces the time spent on manual tasks and speeds up maintenance.

What features of CMMS Software are most beneficial for managing DVIRs?

Key features include automated scheduling, real-time notifications, and detailed reporting. These tools help ensure that inspections are carried out on time and any issues identified are addressed promptly. The software also maintains a comprehensive log of all inspections and repairs.

Can CMMS Software track and optimize the maintenance schedules based on DVIR outcomes?

Yes, CMMS software tracks all DVIR data and uses it to optimize maintenance schedules. By analyzing DVIR reports, the system can adjust maintenance schedules to focus on recurring issues or prioritize critical repairs, reducing machinery downtime.

What are the best practices for implementing CMMS Software for DVIR management?

To implement CMMS software effectively, companies should provide thorough user training, integrate the software with existing systems, and establish clear protocols for using it. Regular reviews and updates are also essential to ensure the system remains effective.

How does CMMS Software ensure compliance with transport regulations through DVIRs?

CMMS software helps maintain compliance by automatically recording all inspections and repairs. This creates an audit trail that can be reviewed if needed. The software also ensures that inspections are scheduled and completed on time, meeting regulatory requirements.

What metrics should be monitored within CMMS Software to evaluate DVIR effectiveness?

Important metrics include the number of completed inspections, the time to resolve reported issues, and the frequency of recurring problems. Monitoring these metrics helps identify areas for improvement and ensures that the DVIR process is efficient and effective.