Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

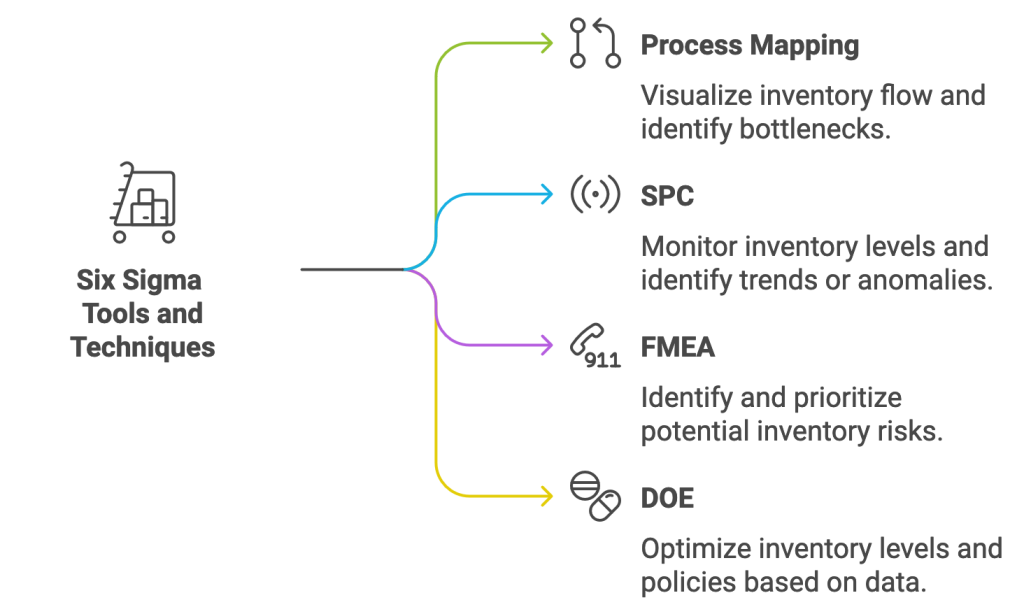

Try for freeAre you tired of losing track of your stock, overspending on storage, or constantly running out of high-demand items? You’re not alone. Below is a guide that will introduce you to 15 types of inventory management methods.

Many businesses face the challenge of inventory management. But fear not! There are proven systems and strategies you can implement to control your inventory and boost your bottom line.

In this guide, we’ll explore 15 different types of inventory management systems companies rely on to streamline operations, cut costs, and keep customers happy.

From basic periodic counting to advanced RFID tracking, there’s a solution for every business need and budget.

Listen to an Audio Version of this Article

1. Perpetual Inventory System

The power and benefit of the perpetual inventory management system is that it gives users an exact inventory count without having to count items or use clunky spreadsheets physically.

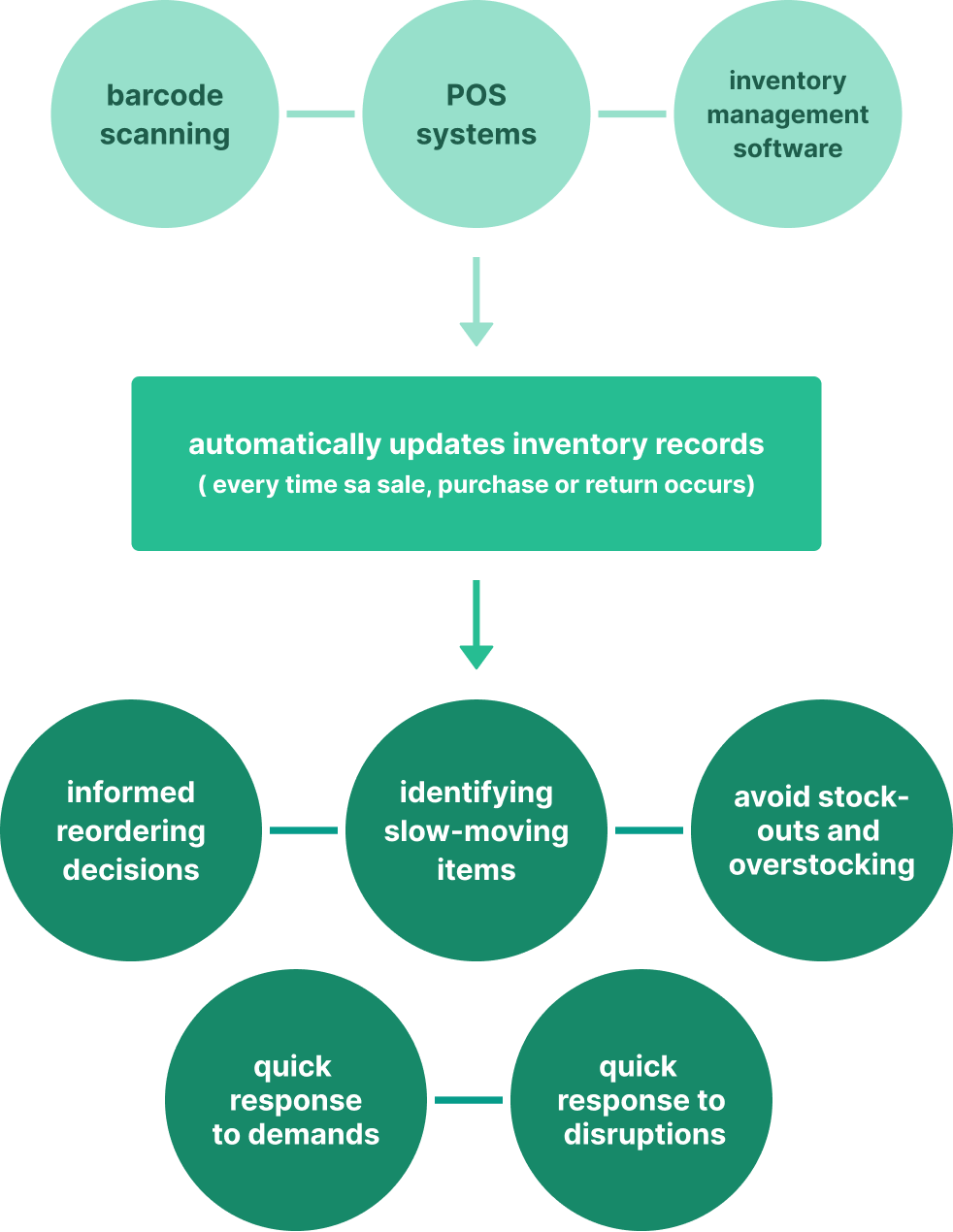

This approach uses technology to automatically update your inventory records every time a sale, purchase, or return occurs.

Source: WorkTrek

Barcode scanning, point-of-sale (POS) systems, and integrated inventory management software provide real-time visibility into your stock levels.

The benefits are significant: With up-to-date data, you can make informed decisions about reordering, identify slow-moving items, avoid stockouts or overstocking, and quickly respond to demand or supply chain disruptions.

2. Periodic Inventory System

A periodic inventory system offers a simpler, lower-tech option for businesses with smaller inventories or less frequent turnover. With this approach, you physically count your inventory at regular intervals—such as monthly, quarterly, or annually—and reconcile the numbers with your records.

Although periodic inventory management generally requires more manual effort and doesn’t provide real-time data, it can still be an effective way to track stock levels and identify discrepancies.

Illustration: WorkTrek / Quote: SFL Worldwide

It’s also less expensive than perpetual systems, making it a popular choice for small businesses or those just starting.

The key to success with periodic inventory management is establishing a consistent counting schedule and sticking to it. Many businesses conduct counts during slower periods or outside regular business hours to minimize disruption.

3. Barcode Inventory System

You see this every time you shop at a grocery store—each product is scanned at the point of sale, mainly for retail businesses.

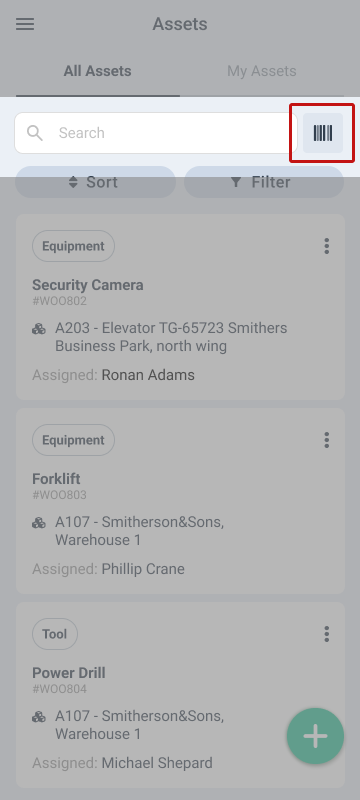

If you’ve ever used a self-checkout lane at a grocery store or scanned a package for shipping, you’re already familiar with barcode technology. But did you know that barcodes can also be a powerful tool for inventory management?

Source: WorkTrek

In a barcode inventory system, each item is assigned a unique barcode that contains key information like the product name, description, and price. When the barcode is scanned, the data is automatically logged into your inventory management software, updating your stock levels in real-time.

Barcoding can automate the inventory process, from receiving to picking and POS.

It reduces the risk of manual errors, speeds up counting and reconciliation, and provides a digital trail for auditing purposes.

Implementing barcoding systems costs money, but the investment is worth the time and effort required.

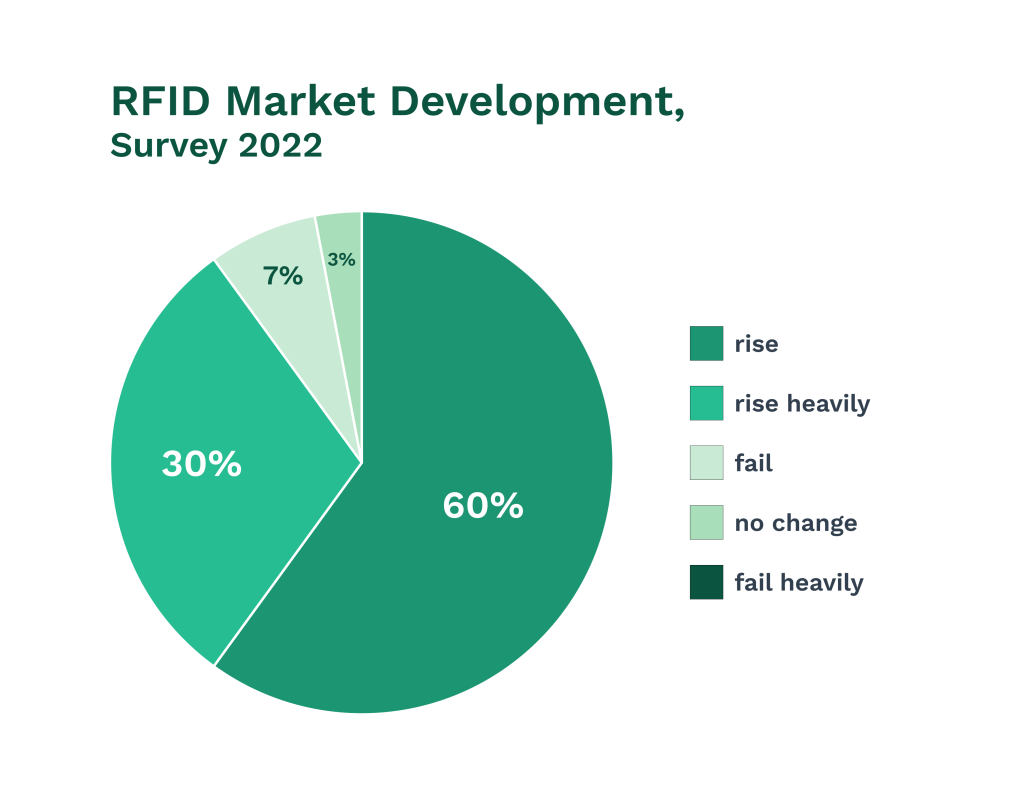

4. RFID Inventory System

Radio-frequency identification (RFID) is like barcoding on steroids. Instead of scanning items individually, RFID readers can automatically detect and track tagged items from a distance, even if they’re not in direct sight.

There are two popular types of RFID devices:

- Low-frequency (LF) RFID devices are also often referred to as passive RFID. They do not have a power source, have a low range, and are only activated when close to a reader. These tags are low-cost and generally used for tagging inventory.

- High-frequency (HF) RFIDHF RFID is widely used across industries due to its balance between range and reliability, especially where proximity is adequate for the application. For example, this is often used to make contactless payments.

Illustration: WorkTrek / Quote: RFID Journal

In an RFID inventory system, each item is tagged with a small chip that contains a unique identifier. When the tag passes near an RFID reader, it transmits that data wirelessly, allowing you to track the item’s location and movement in real-time.

Although passive RFID tags are inexpensive, most businesses use them for high-value items.

RFID has proven to help improve inventory management and reduce theft and loss.

5. Just-in-Time (JIT) Inventory

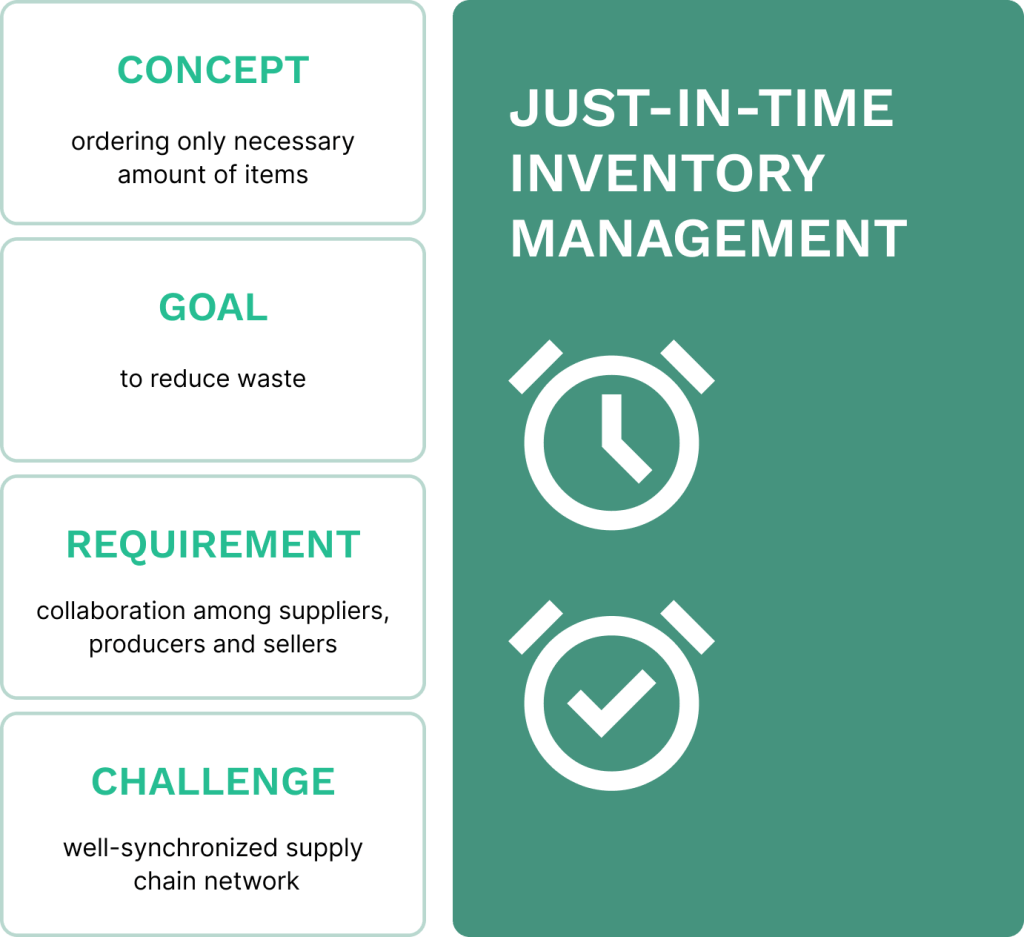

Just-in-time (JIT) inventory management is all about reducing waste and maximizing efficiency, and improving your supply chain management.

Toyota pioneered this strategy to reduce parts storage costs. The goal is to have enough stock to meet demand without storing excess capital or space in inventory.

Source: WorkTrek

JIT requires a close relationship with suppliers. It requires that parts and other inventory materials be delivered on a schedule tied closely to your production schedule.

It is a tricky balancing act, but it can reduce inventory costs, minimize spoilage, and improve cash flow when it works well.

The downside is that JIT can leave businesses more vulnerable to supply chain disruptions or unexpected spikes in demand.

6. ABC Inventory Analysis

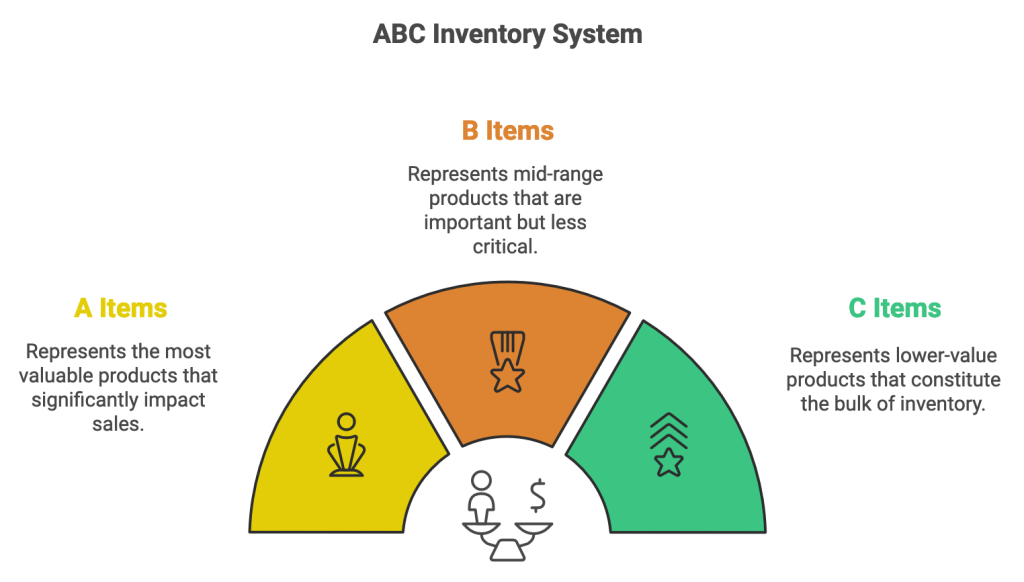

Not all inventory is created equal. Some items are more valuable, faster-moving, or critical to your operations than others. That’s where ABC inventory analysis comes in.

This technique categorizes your inventory into three buckets based on value and importance:

- A items: Your most valuable or critical products, typically accounting for a small percentage of inventory but a large percentage of sales

- B items: Mid-range products that are important but less critical than A items

- C items: Lower-value, slower-moving products that make up the bulk of your inventory

Source: WorkTrek

If you can segment your stock in this way, it makes it much easier to prioritize your overall inventory management efforts.

For instance, you might keep tighter control over A items by counting and restocking more frequently while using a periodic system for C items.

ABC analysis can also help you identify opportunities to streamline your product mix, negotiate better vendor terms, or adjust pricing based on demand and value.

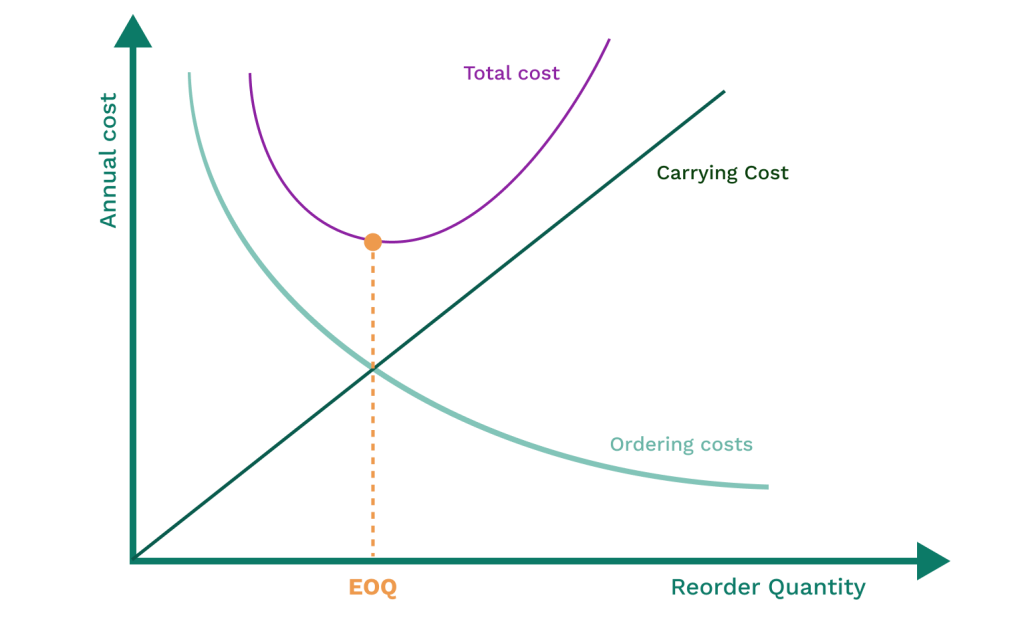

7. Economic Order Quantity (EOQ)

If you manage inventory regularly, you know that one of the biggest challenges is striking the right balance between ordering too much.

Ordering too much stock can tie up valuable cash, and ordering too little risks stocksouts or emergency orders.

That’s where economic order quantity (EOQ) comes in.

This might seem like a high school algebra problem, but we will do our best to simplify it.

Source: WorkTrek

The EOQ formula is:

EOQ = √(2DS/H)

Where:

- D = Annual demand

- S = Fixed cost per order

- H = Annual holding cost per unit

Using EOQ can lead to:

- Lower total inventory costs

- Improved inventory turnover

- Reduced stockouts

To calculate EOQ, you’ll need data on your annual demand, ordering costs per order, and holding costs per unit per year. Plugging those numbers into the formula will give you the ideal order quantity to minimize your total costs.

Of course, EOQ is based on several assumptions, like consistent demand and lead times, and it doesn’t account for factors like discounts or minimum order quantities.

However, it can still be a helpful starting point for optimizing your inventory levels and costs.

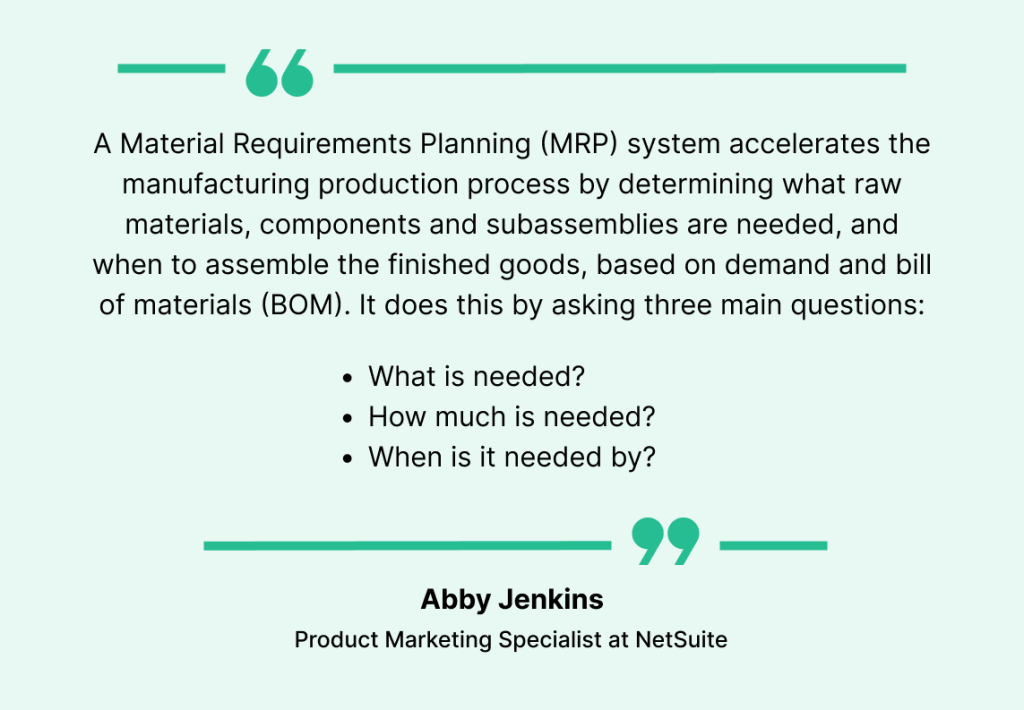

8. Material Requirements Planning (MRP): Getting the Right Parts at the Right Time

As a manufacturer, you must track raw materials, components, and sub-assemblies to meet production demands.

That’s where material requirements planning (MRP) comes in.

MRP is a computerized system that helps businesses plan production and inventory based on sales forecasts, bills of materials (BOMs), and inventory data.

Illustration: WorkTrek / Quote: RFID Journal

It breaks down finished products into parts and generates a schedule of when each part needs to be ordered, produced, or assembled to meet demand.

MRP benefits include reduced inventory levels, improved on-time delivery, and better utilization of resources like labor and equipment.

By synchronizing supply with demand, businesses can minimize stockouts, overproduction, and obsolescence.

The downside is that MRP systems can be complex and expensive to implement. A successful implementation requires significant data management and maintenance.

9. Dropshipping

What if you could sell products without ever handling inventory yourself? That’s the premise behind dropshipping, a fulfillment model where the supplier ships orders directly to the customer on behalf of the retailer.

In dropshipping, retailers sell products on behalf of the manufacturer without ever holding that product in stock.

When an order arrives, the retailer passes it to the supplier, who packs and ships it to the customer.

Illustration: WorkTrek / Date: Coresight Research

Dropshipping can be a low-risk, low-cost way to start an e-commerce business since it requires minimal upfront investment or storage costs.

However, dropshipping also comes with challenges.

You have limited control over product quality, packaging, and shipping times as a seller.

Margins can be lower since the supplier handles fulfillment, and there’s a risk of being out of sync with inventory if the supplier runs out of stock or discontinues a product.

10. Consignment Inventory: Try Before You Buy

In a consignment inventory arrangement, the supplier owns the goods until they’re sold.

This can be a win-win for both parties: the supplier gets access to a new sales channel, while the retailer offers products without the risk of unsold inventory.

Illustration: WorkTrek / Quote: inFlow

Consignment is standard in industries like apparel, home goods, and art, where products may be unique, seasonal, or slow-moving. The retailer typically pays the supplier a percentage of the sale price and keeps the rest as their margin.

Consignment offers retailers lower upfront costs, the ability to test new products or brands, and the flexibility to return unsold items.

For suppliers, consignment can be a way to expand their reach and move excess inventory, but it also carries the risk of delayed payments, damaged products, or slow sales.

11. Cross-Docking

Cross-docking involves transferring incoming goods directly from receiving to shipping, with little or no storage.

The goal is to minimize handling and storage costs while quickly getting products to their final destination.

In a cross-docking operation, goods arrive at a distribution center and are immediately sorted, consolidated, and loaded onto outbound vehicles based on their final destination.

This can involve breaking down large shipments into smaller ones or combining multiple small shipments into a larger one.

Cross-docking is commonly used in industries with high-volume, fast-moving products, such as retail, grocery, and e-commerce.

Optimizing truck loads and routes can help reduce lead times, improve inventory turnover, and lower transportation costs.

However, cross-docking requires precise timing, coordination, and information sharing between suppliers, carriers, and customers. Any delays or errors can quickly ripple through the supply chain and cause stockouts or missed deliveries.

12. Backordering

No matter how carefully you plan your inventory, there are times when demand outstrips supply. That’s where back ordering comes in.

Backordering is a fulfillment strategy in which the seller accepts orders for out-of-stock items and ships them when inventory becomes available.

This is a standard inventory optimization method used by small businesses. This approach can improve cash flow and optimize storage space.

This allows businesses to continue selling products even when unavailable rather than losing sales to competitors.

To make back ordering work, businesses must communicate stock status and estimated delivery times to customers and prioritize backorders when inventory is replenished.

They may also need to adjust their pricing or offer incentives to encourage customers to wait for their orders.

Backordering can help manage short-term stock shortages or unexpected spikes in demand, but it’s not a long-term solution.

If backorders become frequent or prolonged, it can damage customer trust and loyalty.

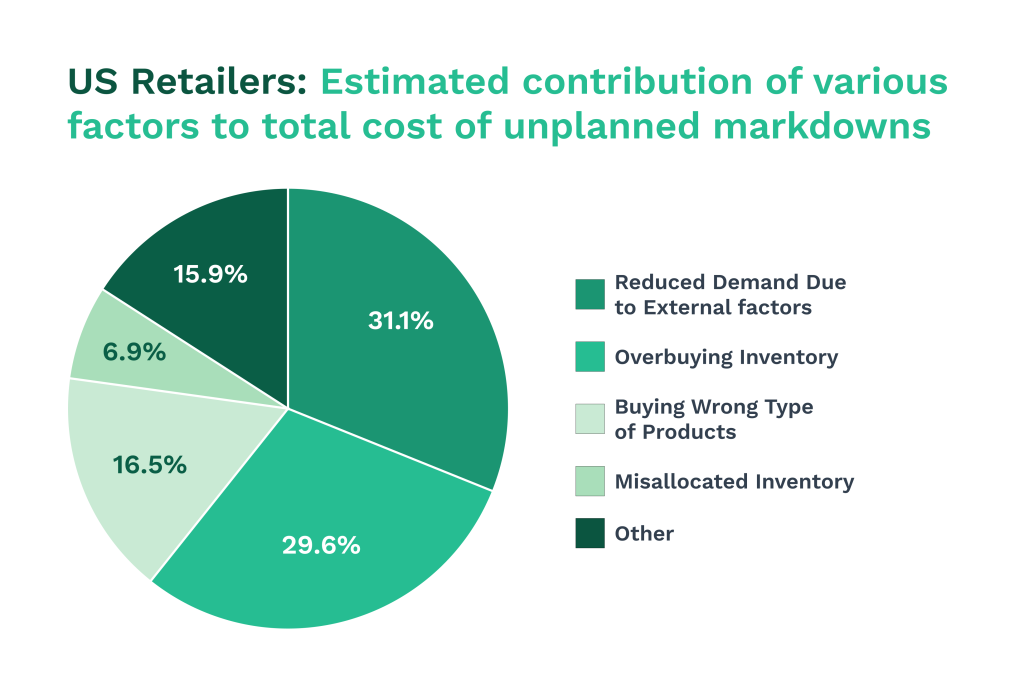

13. Lean Inventory Management

Lean inventory management is a philosophy that originated in manufacturing but has since spread to other industries.

The goal is to eliminate waste and optimize flow by keeping inventory levels as low as possible while meeting customer demand.

Lean principles involve identifying and eliminating non-value-added activities, such as overproduction, waiting, transportation, and excess inventory.

This requires a continuous improvement mindset and a focus on efficiency, quality, and customer value.

In practice, lean inventory management techniques might include things like:

- Using just-in-time (JIT) ordering to minimize inventory holding costs

- Implementing pull systems that only produce or order goods based on actual demand

- Reducing lead times and lot sizes to improve responsiveness and flexibility

- Collaborating with suppliers to improve quality and reliability

- Using visual controls and Kanban systems to manage inventory flow

Lean can help businesses reduce costs, improve quality, and respond quickly to changing market conditions.

However, it also requires a significant cultural shift and a willingness to challenge long-held assumptions about inventory management.

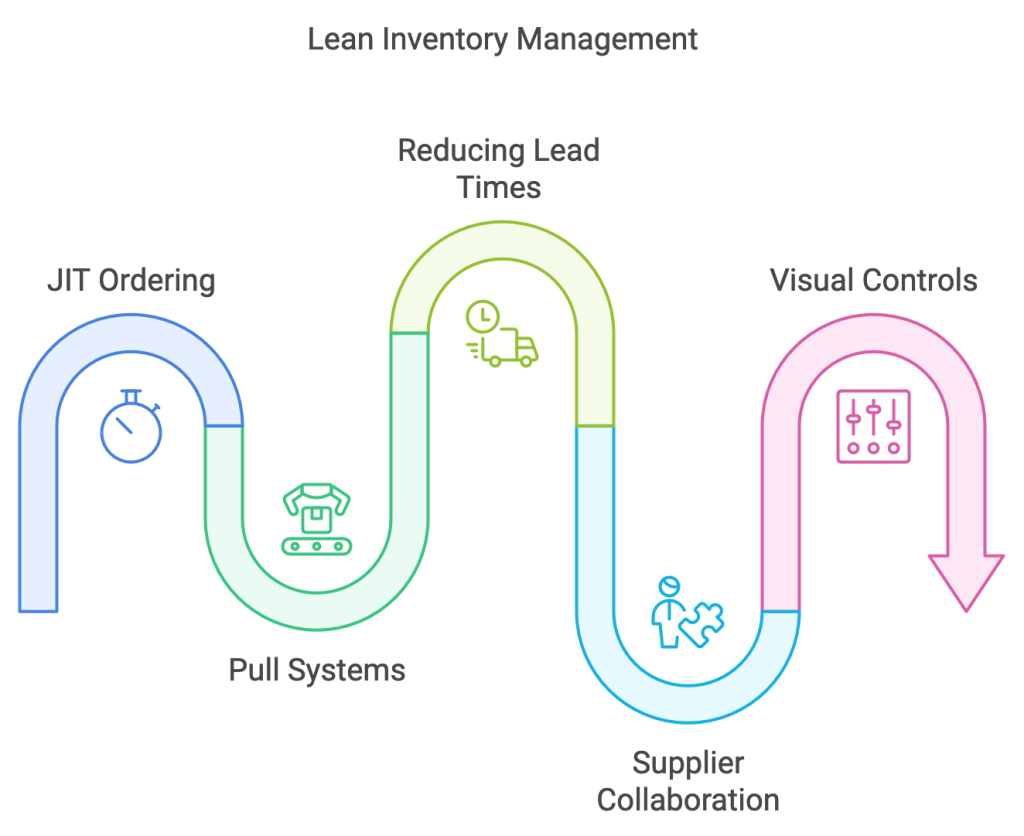

14. Six Sigma Inventory Management

Six Sigma is a data-driven approach to quality management that aims to reduce process defects and variability.

The goal is to achieve near-perfect performance by systematically identifying and eliminating sources of waste and error.

In a Six Sigma inventory management system, businesses use statistical tools and techniques to measure and analyze inventory data, identify root causes of problems, and implement solutions that improve efficiency and accuracy.

Some standard Six Sigma tools and techniques used in inventory management include:

- Process mapping to visualize inventory flow and identify bottlenecks

- Statistical process control (SPC) to monitor inventory levels and identify trends or anomalies

- Failure mode and effects analysis (FMEA) to identify and prioritize potential inventory risks

- Design of experiments (DOE) to optimize inventory levels and policies based on data

Source: WorkTrek

Six Sigma can optimize inventory control but requires specialized training and expertise and may be overkill for smaller or simpler inventory systems.

15. Demand Forecasting

At the heart of effective inventory management is the ability to predict future demand. Demand forecasting involves using historical sales data, market trends, and other factors to estimate how much inventory will be needed to meet customer needs in the coming weeks, months, or years.

Accurate demand forecasting is essential for businesses to avoid stockouts, minimize excess inventory, and plan for seasonal or promotional spikes in demand. It can also help companies to make better pricing, production, and resource allocation decisions.

Illustration: WorkTrek / Quote: inFlow

Different methods and tools are used for demand forecasting, ranging from simple moving averages to complex machine-learning algorithms. Some common approaches include:

- Time-series analysis to identify patterns and trends in sales data over time

- Regression analysis to identify the key drivers of demand and predict future sales based on changes in those factors

- Collaborative forecasting that involves input from multiple stakeholders, such as sales teams, marketing, and suppliers

- Predictive analytics that use advanced algorithms and big data to generate more accurate and granular forecasts

Effective demand forecasting requires a combination of data, domain expertise, and judgment. It’s an ongoing process that needs to be continuously updated and refined based on actual sales data and changing market conditions.