Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeWork orders guidelines enable you to better organize and oversee your service activities, developing a proper work order greatly contributes to the efficiency of management teams and your field workers, and to smooth communication between all stakeholders.

What is a work order?

A work order is a document by which managers authorize workers to complete tasks. Also known as a work order or service order, work orders are commonly used to manage maintenance operations across industries. They can also be used for follow-up actions on inspections or audits carried out.

The importance of work orders

Work order guidelines are the heart of any maintenance management system. These are not only simple tools for planning and assigning tasks, but also for controlling the variety of resources spent on maintenance. Work orders are important because they play a vital role in standardizing maintenance workflows, including from submitting work requests to closing work orders.

Read also 6 steps to implement a work order process + guide.

What is a work order used for?

A work order contributes to good communication between the field teams, the management teams, and the customers, regarding the nature and the conditions for carrying out the maintenance task. It standardizes workflow and helps streamline the process of planning, assigning, and tracking tasks. It can be used to document resources and track performance.

Therefore, it is also a document with legal significance, which can serve as proof in the event of a customer complaint. Everything is reported there, from the exact schedules for performing the service at the place of its execution, to the equipment used.

In addition to this, the work order has practical utility for all parties involved:

For the technical team:

- have the details of the intervention and previous ones, if any,

- keep track of the hours worked,

- have a document serving as an intermediary between the service provider and the client,

- have the completion of the work validated by the customer’s signature.

For the team leader or the service provider:

- follow up on interventions,

- have traceability of the interventions in case of disagreement with the customer,

- collect reliable data on the hours worked by technicians,

- be proactive about the maintenance services to be provided,

- increase trust in the customer relationship,

- grant more autonomy and responsibility to its teams, while adopting a posture of continuous improvement.

For the customer:

- keep the history of the services obtained,

- easily find the contact of the intervening company,

- have the possibility of giving an opinion on the quality of the service received,

- understand price calculation and invoicing through transparency.

How to make a work order?

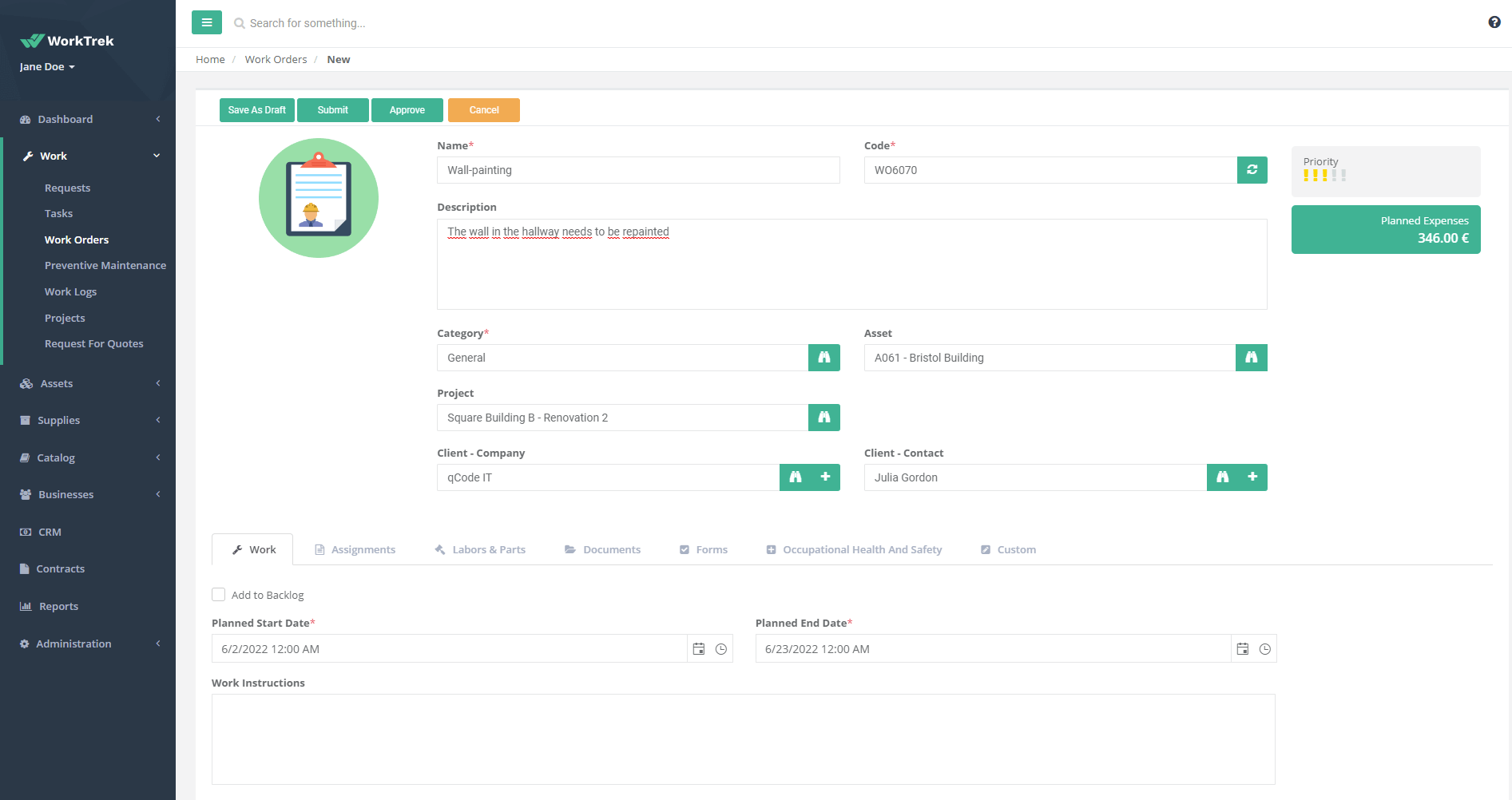

What does a work order contain? There is no standard format because each document can be adapted to the company’s specificities and needs.

Its layout is also very variable, it is above all a communication document so be sure to favor clarity!

Here is the list of the most common information that can be found here:

- the number of the work order,

- the date,

- the place of intervention,

- the coordinates and the contact of the customer,

- the type of service,

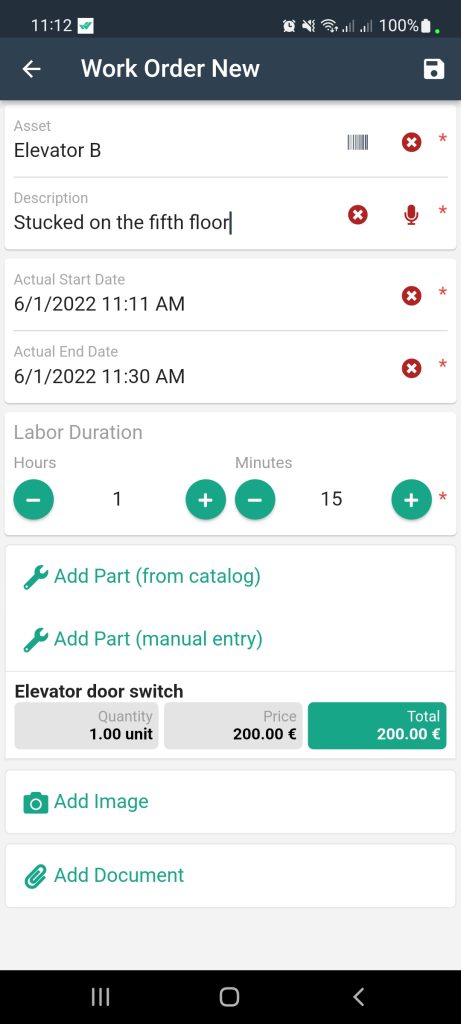

- the detailed description of the intervention,

- the material used,

- schedules: start and end dates/times,

- the total hours worked,

- the history of other interventions previously carried out,

- attachments (photos, plans, diagrams, etc.),

- any concluding remarks.

A few work orders guidelines:

- specify the start/end times of the service,

- add a photo of the work done,

- specify the spare parts needed,

- have the client sign to validate the intervention.

The difference between a work order, a work request, and a purchase order

While a work order is sometimes referred to as a work order or service order in other parts of the world, they are essentially the same thing. However, although related to each other, work orders cannot be used interchangeably with work requests and purchase orders, as each term has a different meaning:

Work order or work request

The difference between a work order and a work request is their source and sequence, i.e. where they originate from and when they are triggered. Typically, work requests come from people who are not maintenance personnel, which leads to the creation of maintenance work orders. For example, machine operators typically first submit a work request for an equipment problem, then maintenance managers approve a designated work order to mechanics.

Work order or purchase order

The difference between a work order and a purchase order is how they are used as part of maintenance work order workflows. While work orders detail specific tasks or services to be performed, purchase orders detail the materials or products needed to complete a work order. Typically, a work order includes a purchase order with the new parts and items to be used when repairing or servicing a piece of equipment.

Read also 10 steps for choosing the right CMMS.

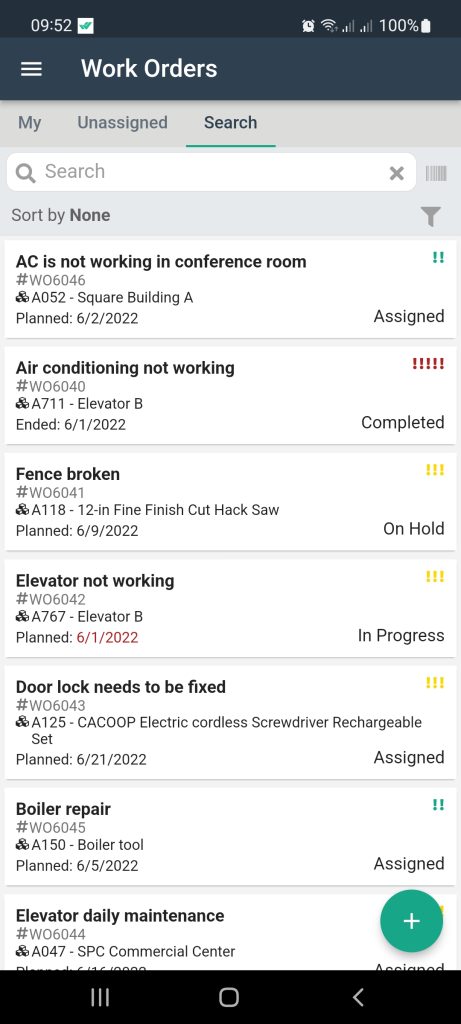

Work Orders guidelines

There are several ways to create a work order, depending on business requirements and customer needs, among other factors. Either way, a streamlined process for opening work orders can ensure that maintenance work gets done on time. Below are some general work orders guidelines to help teams write work orders more effectively:

Understand the work required

Work order writers must not only refer to the details stated in the work requisitions, but they must also gain a thorough understanding of exactly what needs to be done. If in doubt or if some information seems vague, such as equipment symptoms and initial safety considerations, these should be confirmed with the applicant early on to avoid duplication of work.

Consider the resources needed

After having clearly identified the work requested, think about the elements necessary for its realization. Anticipating what tools to use, inventory to check and parts to purchase can help avoid costly delays. Also, it is essential to assess whether the task can be done alone, with another member of the maintenance team, or with colleagues from other departments like engineering and industrial design.

Be specific but succinct

A work order template contains the job description, recipient(s), requester details, cost breakdown, schedule or deadline, and authorized signatures. The key to effective work order writing is to present all the necessary information in a simple manner. Finding the balance between brevity and completeness can help minimize the risk of discrepancies when implementing the work order.

Set realistic estimates and deadlines

When breaking down the cost of labor, materials, and equipment for any job, state reasonable amounts. Asking too much or too little can potentially delay work order processing. Besides budget allocation, one of the biggest challenges of managing work orders is scheduling. Priority levels and due dates should be established based on technician availability, maintenance schedule, and other ongoing tasks.

Use work orders without resorting to paper

Work orders written on paper can be difficult for management to organize, as they tend to be easily damaged and misplaced. A digital work order form, on the other hand, can be filled out on any mobile device, making it easier for teams to write work orders wherever they are. Unlike traditional paper-based service orders, scanned work orders not only minimize data entry errors but also save time and effort when sending them out for authorization.

Sample Work Order System and Procedure

A work order system should allow employees to perform maintenance tasks more efficiently, not slow them down. To streamline work order processing, first, assess business performance using industry benchmarks. Compare your results with the example work order procedure below and identify areas for improvement in the context of the organization:

Step 1

Work request submission and review – Non-maintenance employees submit a work request which is reviewed by their manager. Their managers then validate it with the information entered during previous inspections before sending it to the maintenance department.

Step 2

Approval and creation of a work order – Upon receipt, the maintenance manager determines if the scope of work is necessary. Once approved, management records the work request in the form of a work order with their signature.

Step 3

Work Order Assignment and Scheduling – After giving permission, the manager assigns the job to a mechanic and schedules when it should be done. Applying a dispatch matrix can help ensure that the most qualified technician will be dispatched to work on a particular asset.

Step 4

Work Order Fulfillment and Tracking – In the equipment location area, the maintainer observes physical constraints, identifies environmental conditions, and prepares any type of notes that can help accomplish the work order. When resources become available, work can begin and the manager begins tracking the status of the work order.

Step 5

Work Order Completion and Record Keeping – Once the work is done, the service technician reports the work actually performed and his manager reviews it before closing the work order. Finally, the maintenance manager files the completed work order for future reference.

Conclusion

The work order is the written record that restores the information concerning work between a service provider and a client: what must be done, when, with what material and what labor, and for how much. It is essential in many industries, especially for service and maintenance companies.

For your organization to gain in efficiency and productivity, equip yourself with software to manage your work orders and benefit from digitized information exchanges: readability, reliability, security, and data traceability will be there, both for the workers in the field, their managers and the administrative and accounting departments. Use our Work Order guidelines to succeed.

Read also 10 steps for CMMS implementation.