Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeReliability Centered Maintenance (RCM) is a strategic approach to maintaining equipment and assets. It focuses on keeping systems running smoothly and preventing breakdowns. RCM helps companies save money, improve safety, and boost productivity by targeting maintenance efforts where they matter most.

This method examines each piece of equipment and determines the best way to keep it working. It’s not about fixing things when they break. Instead, RCM tries to prevent problems before they start. Companies use RCM to make smart choices about when and how to perform maintenance.

Illustration: WorkTrek / Quote: MaxGrip

RCM is different from older maintenance methods. It uses data and careful planning to create a more effective maintenance strategy. .

This approach can lead to better equipment performance and fewer unexpected shutdowns. For businesses that rely on machines and other assets, RCM can be a game-changer.

Benefits of RCM

Reliability Centered Maintenance (RCM) offers several key advantages for organizations. It enhances safety, boosts performance, cuts costs, and improves maintenance planning.

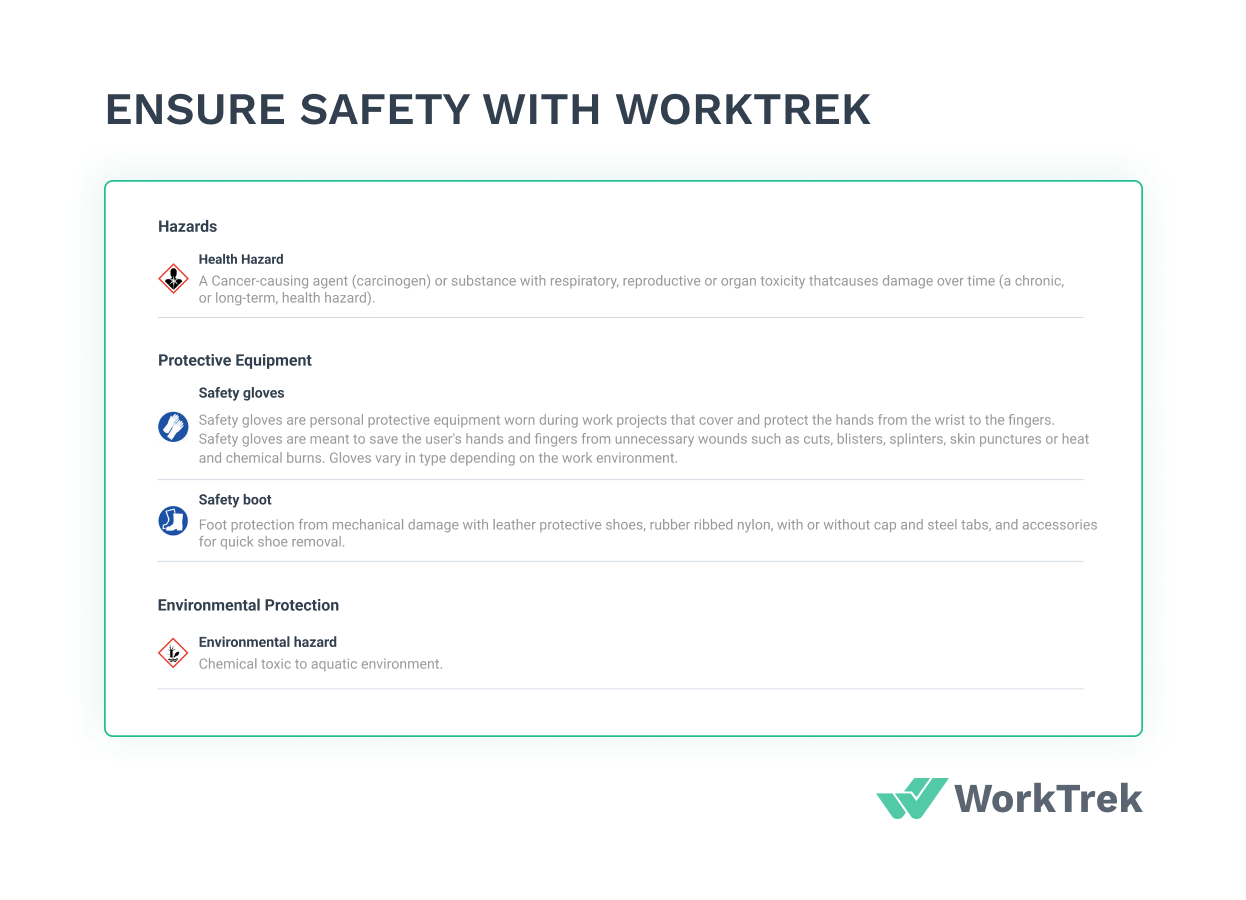

Enhanced Safety and Environmental Integrity

RCM strongly emphasizes safety and environmental protection. It helps identify potential hazards and failure modes that could lead to accidents or environmental damage. By addressing these risks proactively, companies can prevent incidents before they occur.

Source: WorkTrek

RCM promotes a culture of safety awareness among staff. It encourages teams to think critically about equipment failures and their consequences, leading to better safety protocols and procedures.

The approach also helps meet regulatory requirements more effectively. It ensures that safety-critical systems receive proper attention and maintenance, reducing the risk of fines or legal issues related to safety or environmental breaches.

Improved Reliability and Performance

RCM significantly boosts asset reliability and performance by focusing maintenance efforts where they’re most needed.

Illustration: WorkTrek / Data: ABB

Critical equipment gets more attention, while less important items receive appropriate levels of care.

The method helps identify and address the root causes of failures, leading to fewer breakdowns and longer equipment life. Improved reliability means less downtime, reduced maintenance costs, and more consistent production.

RCM also enhances operational performance. It helps maintain equipment at optimal levels, ensuring peak efficiency. This can lead to higher quality output and improved customer satisfaction.

The approach supports continuous improvement. As teams learn more about asset behavior, they can refine maintenance strategies.

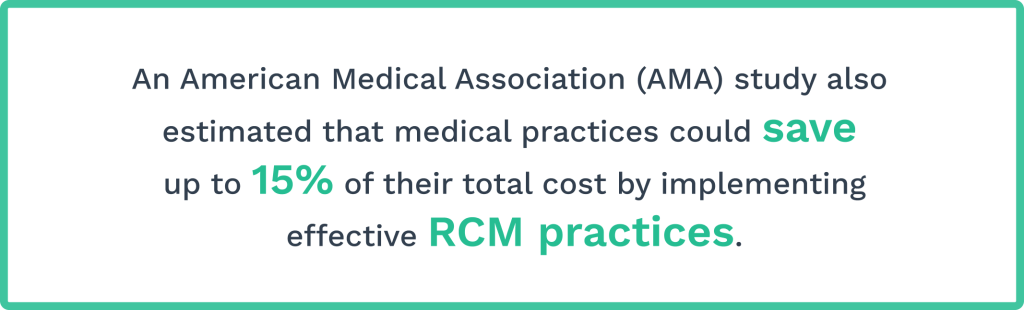

Cost Efficiency

RCM can lead to substantial cost savings for organizations. Focusing on critical assets reduces unnecessary maintenance activities, cuts labor costs, and reduces spare parts inventory.

The method helps prevent costly breakdowns and emergency repairs. Planned maintenance is generally cheaper than reactive fixes. RCM also extends equipment life, delaying expensive replacements.

Improving reliability, RCM reduces production losses due to equipment failures, significantly impacting overall profitability.

The approach also helps optimize maintenance schedules, reducing overtime costs.

Illustration: WorkTrek / Data: Streamline Health

RCM supports better budget planning. It provides data-driven insights into maintenance needs, allowing for more accurate forecasting.

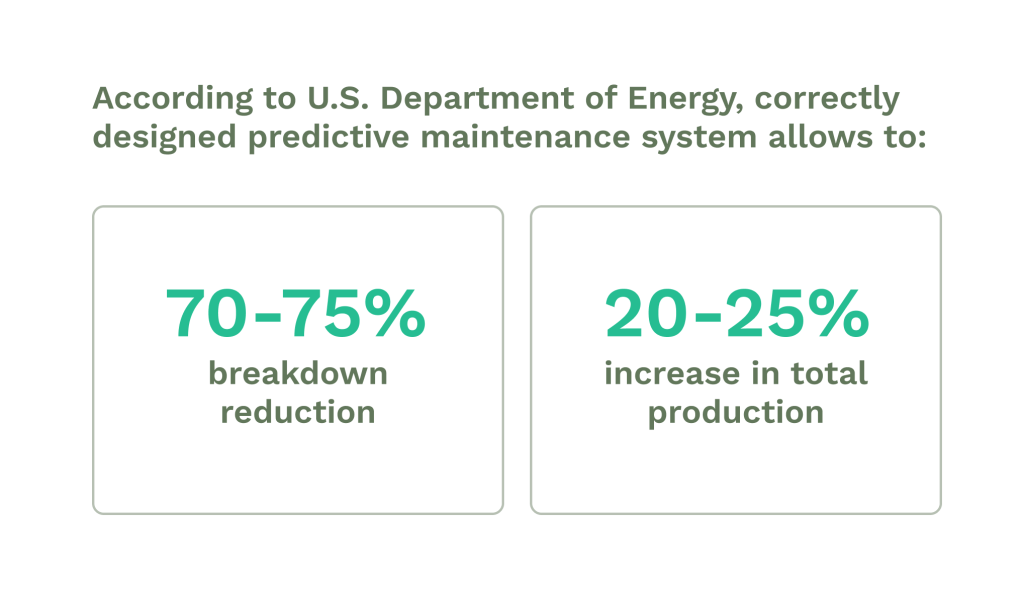

Effective Maintenance Planning

RCM enables more efficient and effective maintenance planning. It helps prioritize maintenance tasks based on criticality and risk.

This ensures resources are used where they’ll have the most impact.

The approach supports predictive maintenance strategies. By understanding failure modes, teams can spot issues before they cause breakdowns, allowing for more proactive maintenance activity scheduling.

Illustration: WorkTrek / Data: TheBlue

RCM improves documentation and knowledge sharing. It creates a structured approach to capturing information on asset performance and maintenance history. This helps teams make better decisions and preserves institutional knowledge.

The method also supports better spare parts management. By understanding equipment needs, organizations can optimize their inventory levels. This reduces carrying costs while ensuring critical parts are available when needed.

Understanding RCM

Reliability-centered Maintenance (RCM) is a strategic approach to asset maintenance. It aims to keep equipment running smoothly while cutting costs. RCM uses data and analysis to make smart choices about maintenance tasks.

Principles of Reliability-Centered Maintenance

RCM focuses on keeping systems working, not just fixing parts. It looks at how equipment fails and what that means for the operation. The main goal is to stop problems before they start.

RCM uses a mix of different maintenance types, including preventive maintenance and proactive repairs.

The method picks the best way to care for each piece of equipment.

One key idea is that not all equipment needs the same care. RCM helps teams decide what’s most important to fix or check, saving time and money by focusing on what matters.

History and Evolution of RCM

RCM was first used in the aviation industry in the 1960s. United Airlines first used it to keep planes safe and on time. The success in aviation led other sectors to adopt RCM.

Illustration: WorkTrek / Data: ramco

Illustration: WorkTrek / Data: ramco

Over time, RCM grew and changed. In 1999, the Society of Automotive Engineers created the JA1011 Standard, which set clear rules for doing RCM right.

Today, many fields use RCM. It helps in factories, power plants, and transport systems. The basic ideas haven’t changed much, but new tech makes RCM easier to use.

Key Components of RCM

RCM starts with a deep look at how systems work and fail. This is called RCM analysis. It helps find the most important parts to maintain.

Teams then make a plan to prevent failures. This often includes a mix of tasks:

- Regular checks

- Replacing parts on a schedule

- Watching for signs of wear

RCM also uses data to make choices. It tracks how often things break and why, which helps make better maintenance plans over time.

A big part of RCM is teamwork. It brings together people who run the equipment and those who fix it, leading to smarter decisions about upkeep.

RCM Methodology

Reliability-centered Maintenance (RCM) uses a structured approach to optimizing maintenance strategies. It focuses on identifying and preventing equipment failures to improve reliability and reduce costs.

RCM Process and Implementation

The RCM process starts with defining system functions and performance standards. Teams then identify functional failures and their causes. This collaborative effort involves maintenance, operations, and engineering staff.

RCM implementation follows a Plan-Do-Check-Act cycle:

- Plan: Set goals and define the scope

- Do: Analyze equipment and develop strategies

- Check: Monitor results and gather data

- Act: Adjust strategies based on findings

Successful RCM implementation requires strong leadership support and employee buy-in. Organizations should provide training and resources to ensure proper execution.

Identifying Failure Modes

Failure mode identification is a critical step in RCM. It involves analyzing how equipment can fail and what causes these failures. Teams use tools like Failure Mode and Effects Analysis (FMEA) to examine potential issues systematically.

Key steps in identifying failure modes:

- List all system functions

- Define functional failures

- Determine failure modes for each functional failure

- Identify root causes of failure modes

This process helps teams understand equipment behavior and develop targeted maintenance strategies. It also aids in prioritizing maintenance efforts based on failure likelihood and impact.

Assessing Risks and Consequences

RCM employs a risk-based approach to evaluate the consequences of equipment failures. This assessment considers factors such as safety, environmental impact, and production losses.

Teams assign risk levels to each failure mode based on:

- Probability of occurrence

- Severity of consequences

- Detectability of the failure

This risk assessment guides decision-making on maintenance strategies. High-risk failures receive more attention and resources, while low-risk issues may be addressed with simpler approaches.

Selecting Maintenance Tasks

RCM aims to choose the most effective maintenance tasks for each failure mode. These tasks fall into several categories:

- Preventive maintenance

- Predictive maintenance

- Run-to-failure

- Redesign or modification

Task selection considers factors like technical feasibility and cost-effectiveness. Teams may use decision trees to guide this process.

Condition monitoring plays a key role in many RCM strategies. It involves using sensors and data analysis to detect early signs of equipment deterioration.

The chosen tasks form a comprehensive maintenance plan tailored to each asset’s needs. This approach helps organizations balance reliability, cost, and risk effectively.

RCM in Practice

Reliability-centered Maintenance (RCM) has proven effective across many industries. Companies have seen real benefits from using RCM methods. Building the right culture is key to RCM’s success.

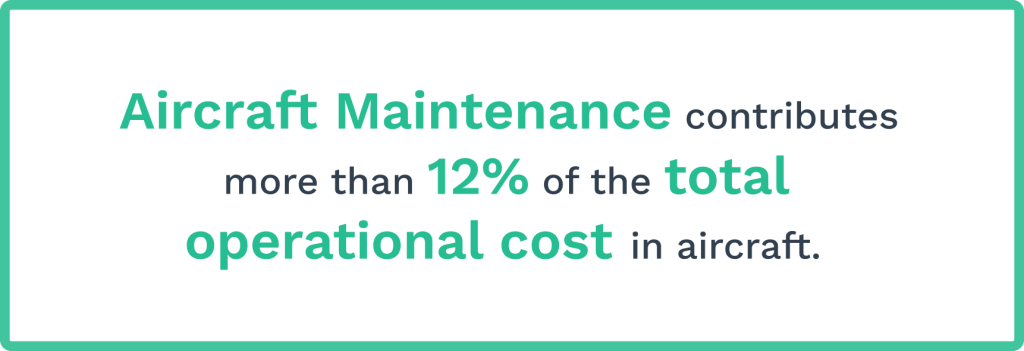

Application in Different Industries

RCM works well in many fields. The aviation industry uses RCM to keep planes safe and on time. Power plants rely on RCM to avoid outages. Factories use it to keep production lines running.

In healthcare, RCM helps keep vital equipment working. Oil and gas companies use it on offshore rigs, and even IT departments use RCM ideas to manage computer systems.

RCM adapts to each industry’s needs. A hospital focuses on patient safety, while a factory aims for nonstop production. RCM helps both meet their goals.

Case Studies and Success Stories

United Airlines saw big gains with RCM. They cut maintenance costs while improving safety. Downtime dropped, and planes spent more time in the air.

Illustration: WorkTrek / Data: ePlan Blog

Illustration: WorkTrek / Data: ePlan Blog

In 1978, F. Stanley Nowlan (Director of Maintenance Analysis at United Airlines) and Howard F. Heap (Manager of Maintenance Program Planning at United Airlines) produced a seminal report for United Airlines that codified the RCM process.

In the past 40 years, United and other airlines have continued to refine that process. They’ve started using data from IoT devices and advanced analytics tools to better pinpoint the equipment status.

Creating a Culture for RCM Success

RCM needs more than new methods. It needs a new way of thinking. Leaders must show they believe in RCM and explain why it matters.

Training is key. Workers must learn RCM skills and understand how their work fits the big picture.

Teamwork is vital for RCM. Maintenance, operations, and engineering must work together. Open communication helps spot problems early.

Continuous improvement is part of RCM culture. Teams should always look for ways to do better. Celebrate wins to keep people motivated.

Maintaining and Improving the RCM Program

A strong RCM program needs ongoing attention and refinement. Regular monitoring, continuous learning, and integration with broader asset management practices are key to maximizing RCM benefits.

Monitoring and Adjusting the RCM Approach

RCM is not a set-it-and-forget-it process. To stay effective, it requires constant evaluation and adjustment. Organizations should track key performance indicators (KPIs) related to asset reliability, downtime, and maintenance costs.

Regular audits of the RCM process help identify areas for improvement. These may include:

- Equipment failure rates

- Maintenance task effectiveness

- Resource allocation

- Cost savings

Based on these metrics, maintenance teams can fine-tune their strategies. This might involve updating failure modes, adjusting task frequencies, or revising maintenance procedures.

Continuous Learning and Adaptation

The RCM process thrives on knowledge sharing and continuous improvement. Maintenance teams should foster a culture of learning and adaptation.

Key practices include:

- Regular training sessions on RCM principles

- Cross-functional meetings to share insights

- Analyzing root causes of failures

- Staying updated on new maintenance technologies

Sharing learnings across the asset lifecycle helps improve overall system performance. Teams can use this knowledge to refine maintenance strategies and prevent recurring issues.

Integration with Asset Management

RCM should not exist in isolation. It works best when integrated with broader asset management practices. This integration ensures that maintenance efforts align with organizational goals.

Key integration points include:

- Aligning RCM with asset lifecycle planning

- Incorporating RCM data into asset replacement decisions

- Using RCM insights to inform equipment procurement

- Coordinating RCM with other maintenance approaches

By linking RCM to overall asset management, organizations can make more informed decisions about their equipment. This holistic approach helps optimize asset performance and longevity while controlling costs.

Advanced Tools and Techniques in RCM

Modern reliability-centered maintenance relies on cutting-edge tools and methods. These advancements help companies make better choices, spot issues early, and keep equipment running smoothly.

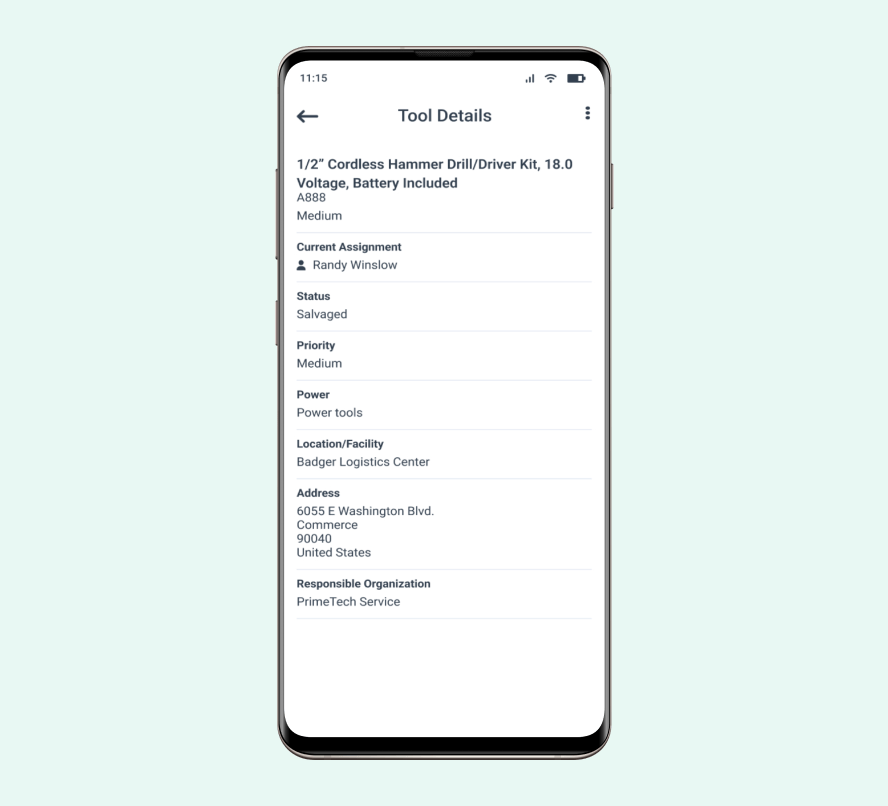

Technological Advancements in RCM

Implementing a CMMS system like WorkTrek can help provide you with real data and status on each piece of equipment.

Source: WorkTrek

Source: WorkTrek

Reliability-centered maintenance can also use smart sensors and the Internet of Things (IoT). These tools gather real-time data on machine health, allowing companies to track vibration, temperature, and other key factors.

Artificial intelligence (AI) and machine learning boost RCM efforts. These systems can predict when parts might fail, helping prevent breakdowns before they happen.

Mobile apps let workers check and update maintenance information on the go, speeding up response times and improving efficiency.

Virtual reality (VR) is changing how technicians train. They can practice complex repairs in a safe, virtual setting.

Data-Driven Decision Making

RCM thrives on good data. Modern systems collect vast amounts of info from machines and processes.

Big data analytics help make sense of all this information. Companies can spot trends and patterns humans might miss.

CMMS system system dashboard can give managers a clear view of asset health. They can see which machines need attention at a glance.

Predictive algorithms use past data to forecast future issues. This lets teams plan maintenance at the best times.

Data-driven RCM helps companies decide which assets to fix or replace. It eliminates the guesswork in big choices.

Analytical Methods in RCM

Failure Mode and Effects Analysis (FMEA) is a key RCM tool. It helps teams find weak points in systems before they cause problems.

Fault Tree Analysis (FTA) maps out how small issues can lead to major failures, helping prevent major breakdowns.

Root Cause Failure Analysis digs deep into why problems happen. It goes beyond symptoms to fix underlying issues.

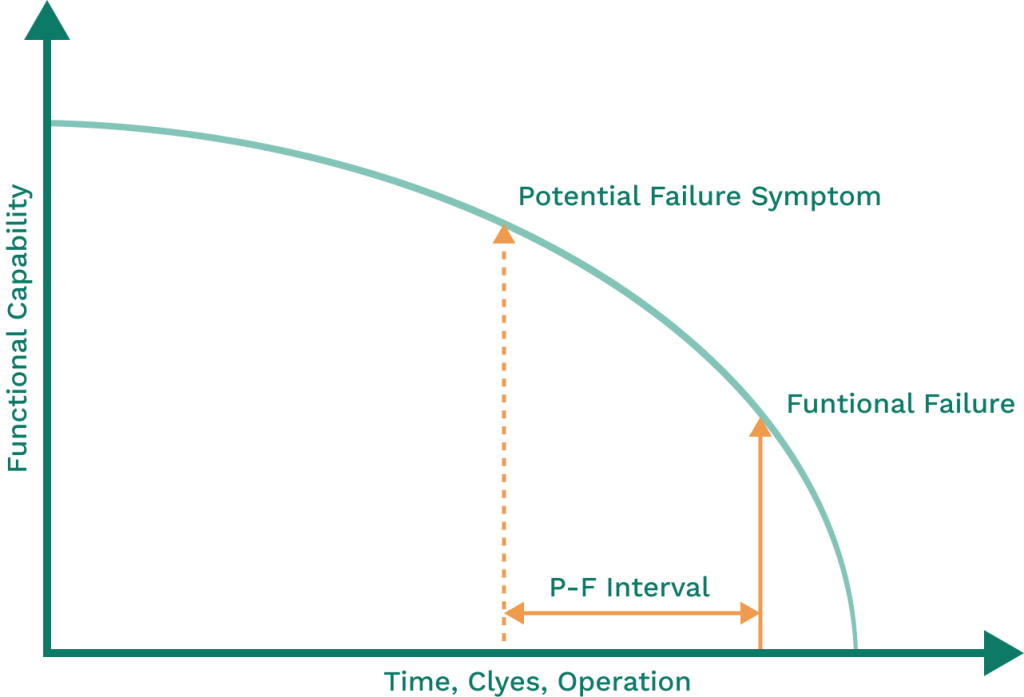

The P-F Curve shows how equipment health changes over time. It helps teams decide when to act to prevent failures.

Source: WorkTrek

Condition monitoring uses tools like vibration analysis and oil testing. These methods catch small changes that signal future problems.

Challenges and Considerations in RCM

Reliability-centered Maintenance (RCM) has many benefits, but it also has challenges. To succeed with RCM, organizations must navigate hurdles, weigh costs against benefits, and address misconceptions.

Overcoming Implementation Hurdles

RCM implementation can be complex. It requires strong leadership and teamwork, and many companies struggle to get buy-in from all levels of staff.

Training is crucial. Workers need to understand new processes and tools. This takes time and resources.

Data collection and analysis can be daunting. RCM needs accurate information to work well, and companies may need to upgrade their systems to gather the right data.

Change management is key. Shifting from reactive to proactive maintenance is a big change, and some staff may resist new working methods.

Balancing Costs and Benefits

RCM can save money long term, but upfront costs can be high. Companies need to invest in:

- Training programs

- New tools and technology

- Data systems

These costs can be a barrier for some organizations.

RCM may lead to more planned downtime at first. This can impact production in the short term.

It’s important to track ROI carefully. The benefits of RCM may take time to appear in financial reports.

Addressing Common Misconceptions

Some think RCM is only for big companies. In reality, businesses of all sizes can benefit.

There’s a myth that RCM means doing more maintenance. It often leads to less but more targeted work.

Some believe RCM is too complex. While it does require learning, the basic principles are straightforward.

A common error is thinking RCM replaces other maintenance strategies. It works best when combined with preventive and predictive maintenance.

RCM isn’t a quick fix. It’s an ongoing process that needs constant refinement.