Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Unplanned equipment downtime costs an average of $25,000 per hour

- Preventive maintenance strategies can reduce maintenance costs by up to 40%

- A computerized maintenance management system like WorkTrek can streamline your preventive maintenance program, with companies reporting up to 70% more PM work order completion

Equipment failures don’t just disrupt operations—they devastate bottom lines. The world’s top 500 companies are losing $1.4 trillion annually to unplanned downtime. The main question isn’t whether you need a preventive maintenance plan, but how quickly you should implement one.

Some think that creating an effective preventive maintenance requires a complete operational overhaul. That is not always accurate.

If you follow a structured approach and leverage the right tools, you can transform your maintenance operation.

This guide walks you through nine essential steps to build a preventive maintenance plan that reduces costs, minimizes downtime, and extends your equipment’s productive life.

What Is a Preventive Maintenance Program?

Let’s start with a sample definition: A preventive maintenance program is a systematic approach that involves scheduled inspections, routine maintenance tasks, and proactive repairs. It is the counter to reactive maintenance, where you fix things after they break.

Think of it like regular oil changes for your car. You wouldn’t wait for your engine to seize before changing the oil.

The same principle applies to your facility’s critical equipment. The data is clear: Organizations that use preventive maintenance report 52.7% less unplanned downtime than their reactive peers.

Why Your Preventive Maintenance Strategy Matters Now More Than Ever

The stakes for maintenance excellence have never been higher.

In 2024, the average cost of one hour of unplanned downtime hovers around $25,000 and can soar to over $500,000 for larger organizations. These numbers represent lost production, emergency repairs, overtime labor, and damaged customer relationships.

Consider this sobering reality: The average plant loses 25 hours monthly to unplanned downtime. That’s three full workdays of lost productivity every month.

For automotive manufacturers, downtime costs can exceed $2.3 million per hour, a twofold increase since 2019.

Yet despite these compelling figures, 58% of facilities spend less than half their time on scheduled maintenance. This gap between knowledge and action represents a massive opportunity for organizations ready to embrace a structured preventive maintenance plan.

Step 1: Create a Comprehensive Asset Inventory

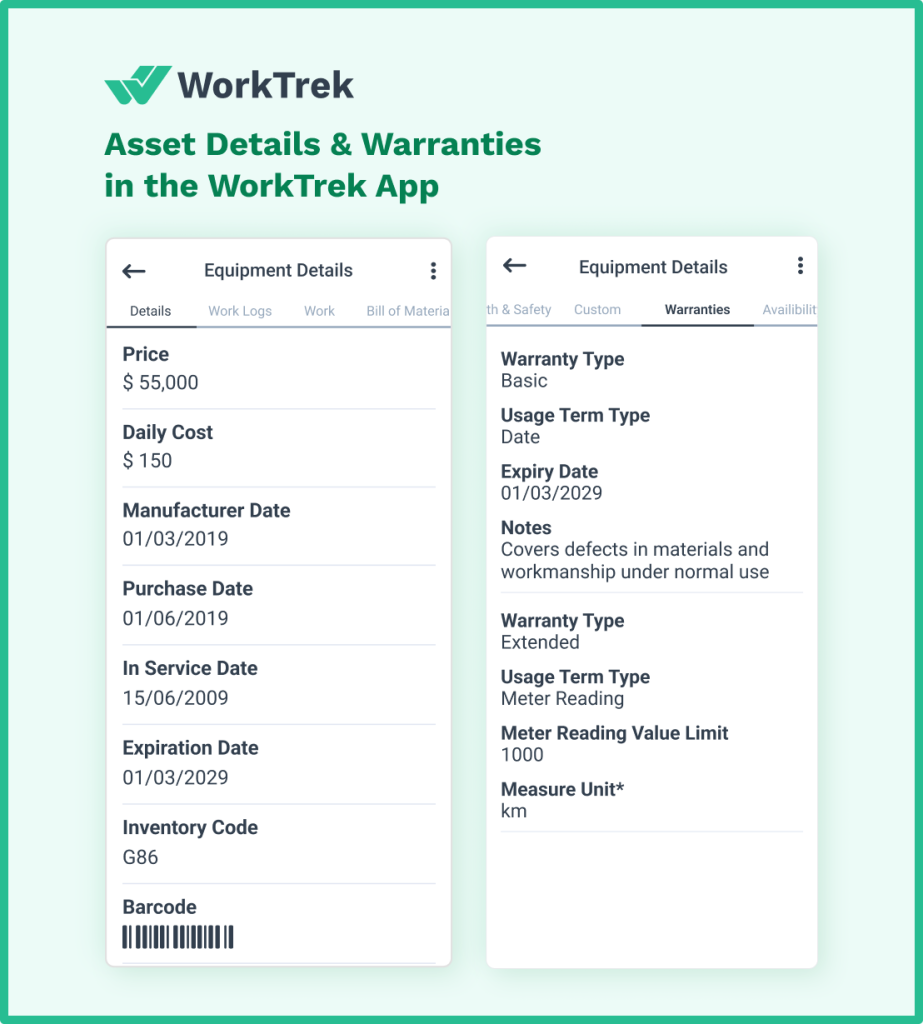

Before you can maintain your equipment, you need to know precisely what you’re maintaining. A comprehensive asset inventory is the first step in the process and is foundational.

Start by documenting all your tangible assets that require regular maintenance.

For each asset, capture:

- Asset identification number and location

- Make, model, and serial number

- Purchase date and warranty information

- Criticality rating (more on this in Step 2)

- Historical maintenance records

- Operating specifications and capacity

- Replacement cost and expected lifespan

Don’t overlook smaller equipment. While that industrial printer might not seem as critical as your production line, unexpected failures of supporting equipment can still cause costly delays. Modern CMMS software like WorkTrek simplifies this process through Excel import functionality, allowing you to build your asset database quickly and maintain it effortlessly.

Step 2: Prioritize Your Critical Assets

Not every equipment needs to follow the same preventive maintenance program.

Some assets directly impact production, safety, or quality, while others play supporting roles.

Understanding this hierarchy helps you allocate maintenance resources where they’ll have the greatest impact.

One of the first steps, and a critical part of a preventive maintenance best practices, should be to perform an asset criticality assessment, which involves evaluating each piece of equipment based on:

- Safety impact: Could failure cause injury or environmental damage?

- Production impact: Would failure stop or slow production?

- Quality impact: Could failure affect product quality or compliance?

- Repair complexity: How difficult and time-consuming are repairs?

- Replacement cost: What’s the financial impact of total failure?

- Redundancy: Do you have backup equipment available?

One popular approach is to rank your assets on a scale (such as 1-5 or A-E) based on these criteria.

Your most critical equipment, typically scoring highest across multiple factors, becomes the initial focus of your preventive maintenance plan.

Step 3: Define Clear Goals and KPIs

A preventive maintenance program without measurable goals is like sailing without a compass. You might be moving, but you won’t know if you’re heading in the right direction.

Setting SMART goals (Specific, Measurable, Achievable, Relevant, Time-bound) transforms vague intentions into concrete targets.

Some examples of goals for preventive maintenance programs include:

- Reduce unplanned downtime by X% within six months

- Achieve 90% preventive maintenance compliance rate

- Decrease emergency repairs by 40% year-over-year

- Extend average equipment life by 20%

- Reduce maintenance costs by 25% within one year

Once goals are established, identify the key performance indicators that will track your progress.

PM completion is the most commonly tracked maintenance KPI, used by 56% of facilities. Other essential metrics include:

Planned Maintenance Percentage (PMP):

The ratio of planned to total maintenance hours. World-class facilities achieve 90% or higher.

Preventive Maintenance Compliance (PMC):

The percentage of scheduled PM tasks completed on time. Target 95% or above.

Mean Time Between Failures (MTBF):

Average time between equipment failures. Higher is better.

Mean Time To Repair (MTTR):

Average time to complete repairs. If, for example, MTTR increases from 49 to 81 minutes, you need to evaluate your maintenance process and find any potential bottlenecks.

Step 4: Develop Detailed Maintenance Tasks and Procedures

Now that you have your assets prioritized and your goals established, it’s time to define the maintenance needed.

Start by transforming general maintenance requirements into specific, actionable preventive maintenance tasks.

Don’t forget to consult the equipment manufacturer’s recommendations. These guidelines provide invaluable baseline maintenance requirements, including:

- Inspection points and frequencies

- Lubrication schedules and specifications

- Replacement intervals for wear parts

- Calibration requirements

- Safety protocols and lockout procedures

However, manufacturer recommendations are just the starting point and should be modified to fit your specific operating needs.

Equipment running two shifts in a dusty environment needs more frequent maintenance than the same machine in a clean, climate-controlled facility with lighter use.

For each preventive maintenance task, document:

- Step-by-step procedures with safety precautions

- Required tools and parts

- Estimated completion time

- Skill level required

- Pass/fail criteria or acceptable measurements

- Follow-up actions for failed inspections

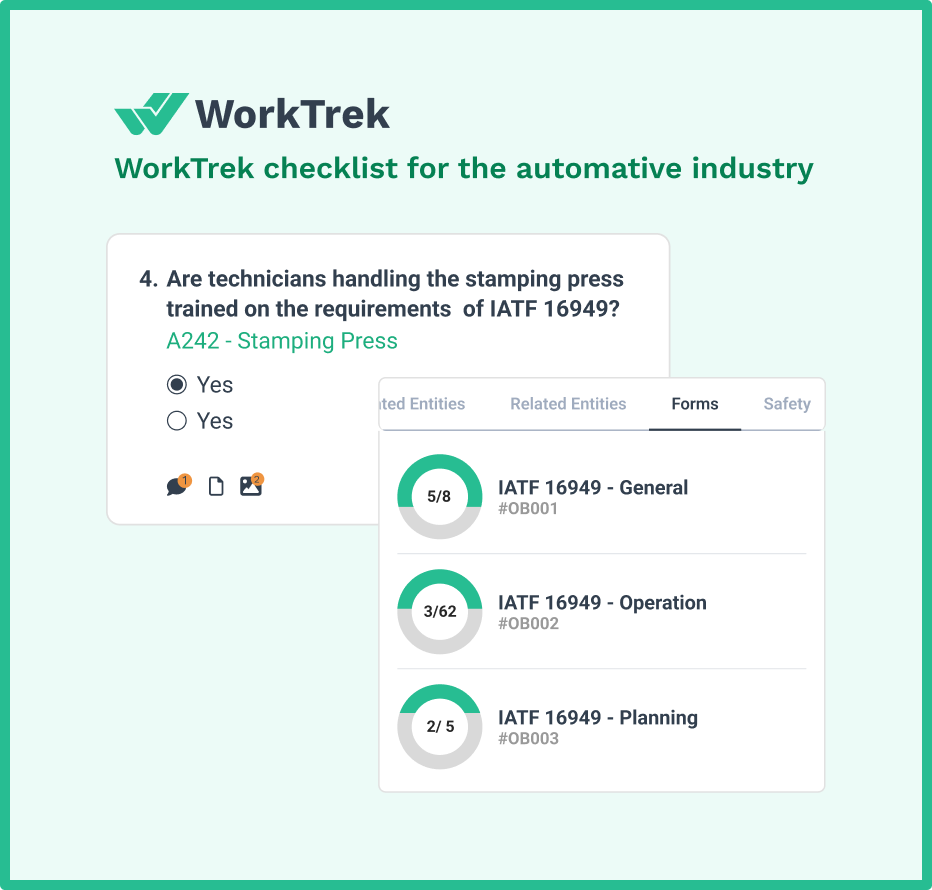

Creating standardized checklists can create consistent preventive maintenance processes regardless of who performs the work.

These checklists are also valuable when training new maintenance technicians or when regular staff are unavailable.

Step 5: Create Your Preventive Maintenance Schedule

Timing is everything in preventive maintenance. Schedule maintenance too frequently, and you waste resources while unnecessarily taking equipment offline. Wait too long, and you risk the very failures you’re trying to prevent.

Research shows that as much as 30% of preventive maintenance is performed too frequently.

Successful preventive maintenance programs typically combine multiple scheduling triggers:

Time-based maintenance:

Scheduled at calendar intervals (daily, weekly, monthly, annually). Best for tasks like safety inspections, filter changes, and routine cleaning.

Usage-based maintenance:

Triggered by runtime hours, cycles, or production units. Ideal for equipment with variable usage patterns. A compressor might need service every 2,000 operating hours rather than every three months.

Condition-based maintenance:

Initiated when monitoring reveals deteriorating conditions. While more advanced than basic PM, simple condition monitoring, like vibration checks or oil analysis, can prevent many failures.

When building your preventive maintenance schedule, consider:

- Production schedules to minimize disruption

- Maintenance team capacity and availability

- Seasonal factors affecting equipment stress

- Regulatory compliance deadlines

- Parts availability and lead times

Step 6: Start with a Pilot Program

Launching a full-scale preventive maintenance program across all assets simultaneously is a recipe for disaster.

Instead, start with a pilot program focusing on your most critical equipment. This approach allows you to refine preventive maintenance processes, identify challenges, and demonstrate value before expanding.

Select 2-3 critical assets for your pilot, preferably ones with:

- Clear maintenance requirements

- Measurable performance metrics

- History of failures or high maintenance costs

- Supportive operators who understand PM benefits

Run your pilot for 60-90 days, closely monitoring:

- Task completion rates

- Time estimates versus actual completion time

- Parts and tool availability issues

- Technician feedback on procedures

- Early indicators of improvement (fewer emergency calls, improved performance)

Document everything during the pilot phase. If you use a preventive maintenance software, like WorkTrek CMMS, the documentation will be automated.

Here is what you should look for:

- What worked smoothly?

- Where did technicians struggle?

- Which preventive maintenance tasks proved unnecessary?

- This real-world feedback is invaluable for optimizing your broader program.

Step 7: Train Your Maintenance Team

The best preventive maintenance plan can fail without proper execution.

Your maintenance team needs to understand not just what to do, but why it matters. A popular approach, followed by 61% of companies, is to invest in operator training to reduce downtime.

Comprehensive training should cover:

- Program goals and expected benefits

- New procedures and checklists

- Documentation requirements

- Safety protocols and updates

- Technology tools (CMMS, mobile apps, sensors)

- Communication procedures for issues discovered during PM

Don’t limit training to your maintenance technicians.

Equipment operators who work with equipment daily often notice early warning signs, such as unusual sounds, vibrations, or performance changes. Training them to recognize and report these can help improve equipment reliability.

Consider implementing a mentorship program pairing experienced technicians with newer team members.

97% of companies talk about knowledge transfer among maintenance technicians, while only 55% have established a system

Step 8: Roll Out Your Preventive Maintenance Program

With your pilot program refined and team trained, it’s time for full implementation.

However, resist the temptation to flip a switch and activate everything at once. A phased rollout ensures sustainable adoption while maintaining operational stability.

Phase 1: Critical Assets (Months 1-2)

Expand from your pilot to include all critical equipment. These assets with the highest impact on safety, production, and quality deserve immediate attention in your preventive maintenance program.

Phase 2: Important Assets (Months 3-4)

Add equipment that significantly affects operations but has some redundancy or workaround options. This might include secondary production lines or critical auxiliary systems.

Phase 3: Standard Assets (Months 5-6)

Incorporate routine equipment into your preventive maintenance program. This type of equipment rarely causes major disruptions or interrupts production cycles. Building systems, standard tools, and support equipment fall into this category.

Phase 4: Run-to-Failure Assets

Some equipment doesn’t justify preventive maintenance and should use corrective maintenance. Light bulbs, inexpensive hand tools, and non-critical components might be more cost-effective to replace upon failure.

Throughout the rollout process, maintain open communication channels.

This includes regular team meetings, feedback sessions, and performance updates to keep everyone aligned and engaged. Make sure to address concerns quickly. This will reduce organizational resistance to your program.

Step 9: Monitor, Analyze, and Continuously Improve

A preventive maintenance program isn’t a “set it and forget it” initiative.

Equipment ages, operating conditions change, and new technologies emerge. Continuous monitoring and optimization ensure your program evolves to meet changing needs.

Focus on your established KPIs. Some questions you need to ask are:

- Are you meeting your planned maintenance percentage targets?

- Has equipment downtime decreased?

- Are maintenance costs trending in the right direction?

- Organizations using predictive maintenance report 50% reduction in unplanned downtime

Conduct monthly reviews examining:

- PM compliance rates by asset and technician

- Recurring failure patterns despite PM efforts

- Maintenance task effectiveness (are we preventing failures?)

- Resource utilization and bottlenecks

- Cost per asset trends

Annual program audits should evaluate bigger picture questions:

- Are maintenance intervals optimal?

- Should any assets move between criticality categories?

- Which preventive maintenance tasks provide little value?

- Where could predictive maintenance techniques add value?

- How has the ROI compared to initial projections?

Remember, the goal is not to be perfect. Focus on a continuous improvement process to refine your process as you collect more data.

Even small changes can compound over time, transforming your maintenance operations from a cost center into a competitive advantage.

The power of CMMS Software to Supercharge Your Preventive Maintenance Program

Theoretically, preventive maintenance can be managed with spreadsheets and paper forms. But based on our industry experience, this approach quickly becomes unwieldy as your program grows.

The problem is that while 70% of plants implement CMMS or EAM systems, 49% still use spreadsheets for some of their work.

This is a clear indication that either the team is not trained to use the software or the program is not user-friendly.

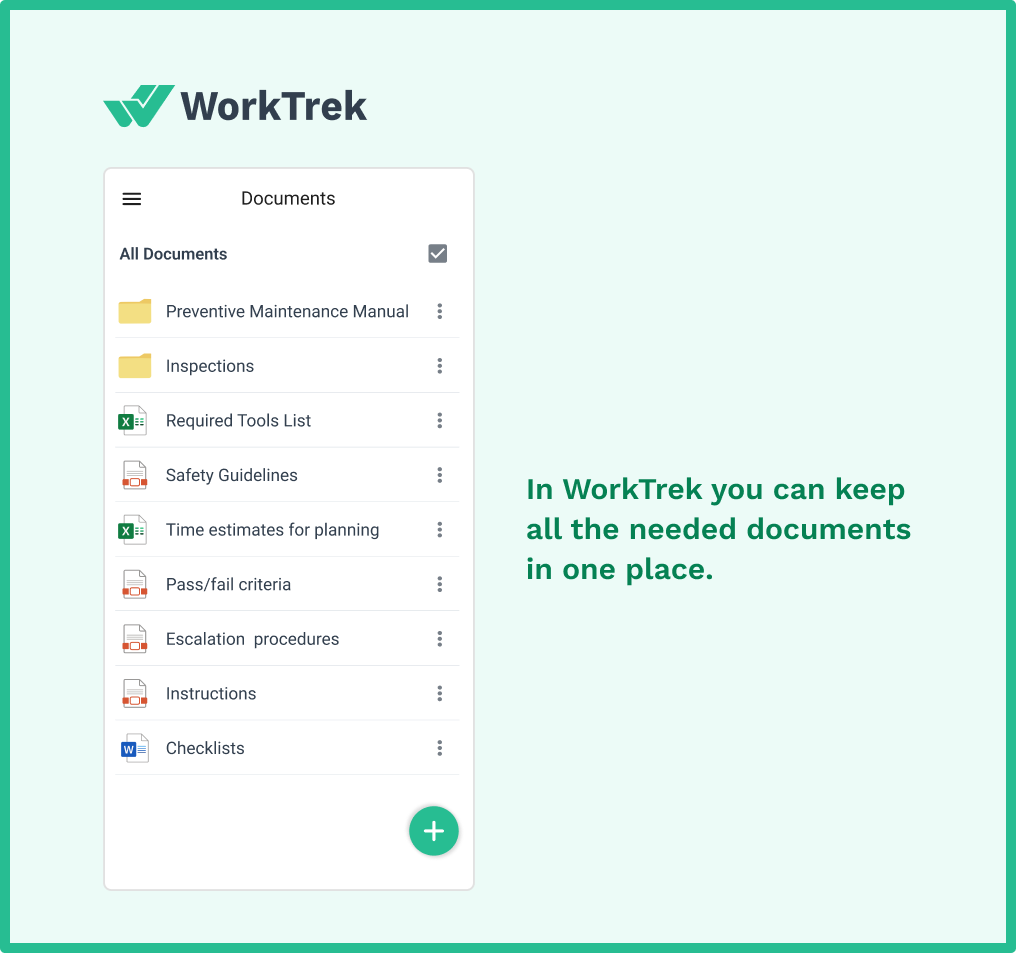

A modern computerized maintenance management system like WorkTrek transforms preventive maintenance from an administrative burden into a streamlined, data-driven process. Here’s how:

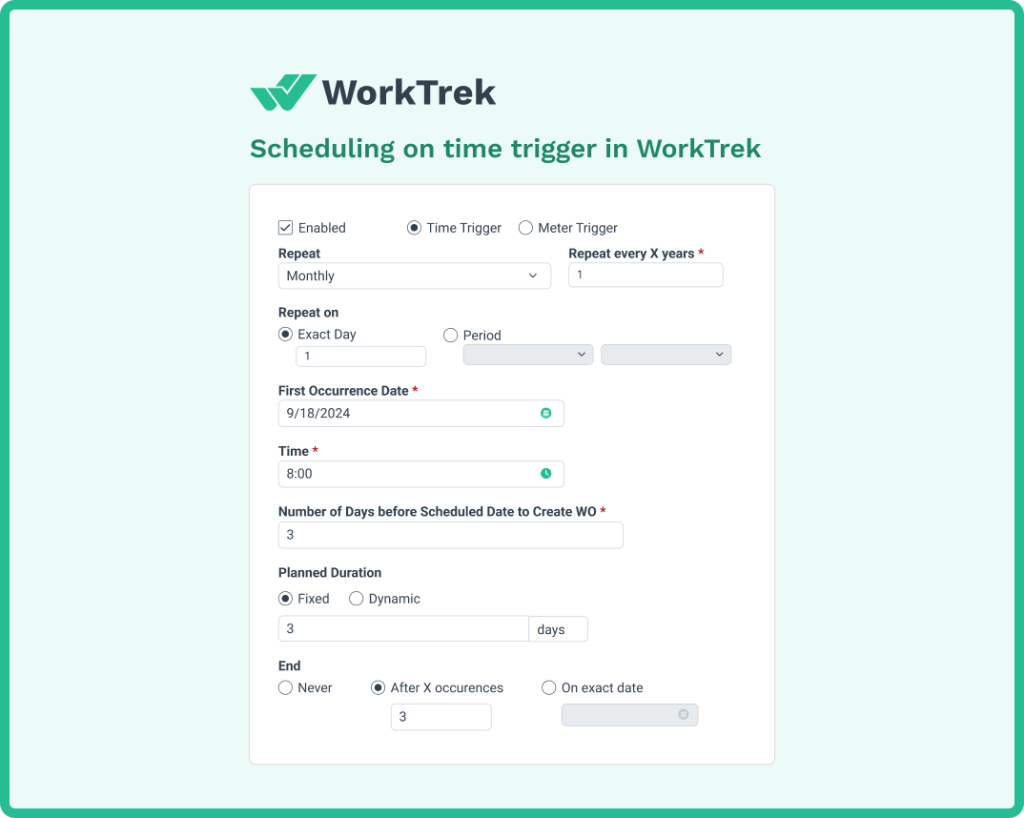

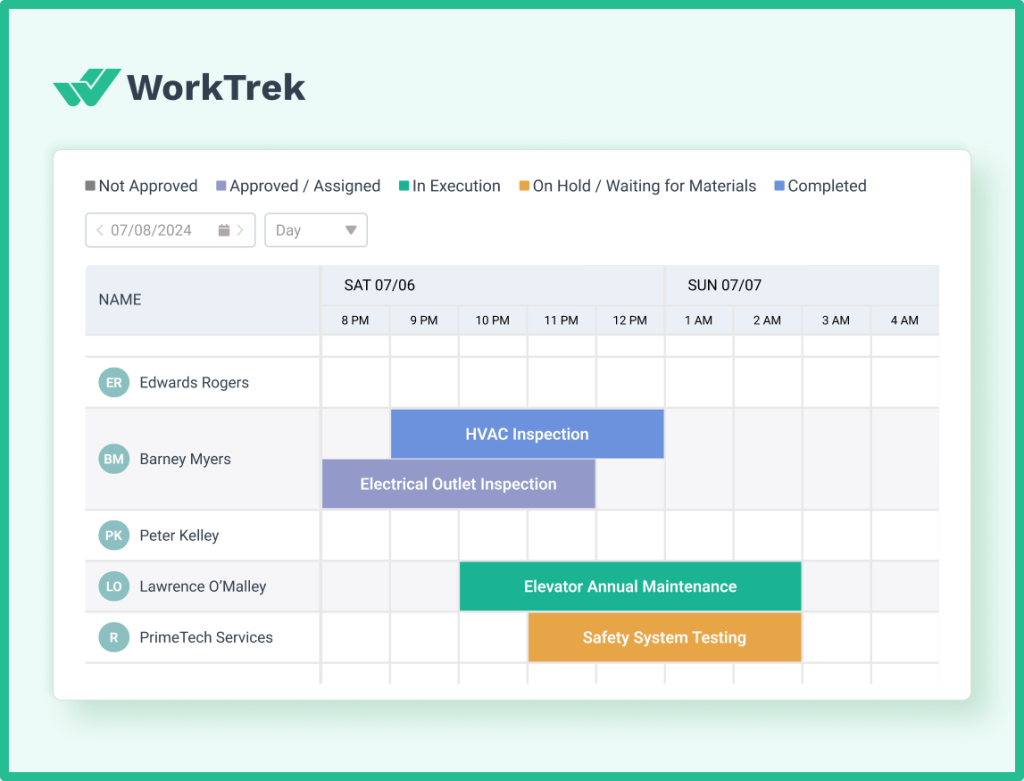

Automated Scheduling and Notifications

WorkTrek can automatically generate work orders based on your preventive maintenance schedule. This can be done with time-based, meter-based, or condition-triggered.

With WorkTrek’s mobile capabilities, maintenance technicians receive mobile notifications, ensuring critical preventive maintenance tasks never slip through the cracks.

No more manual tracking or missed maintenance windows.

Complete Asset Lifecycle Management

Every asset in WorkTrek has its own digital folder containing:

- Complete maintenance history

- Warranty information and documentation

- Parts inventory associations

- Cost tracking and analysis

- Performance trends and failure patterns

This 360-degree view enables data-driven decisions about maintenance strategies, replacement timing, and resource allocation.

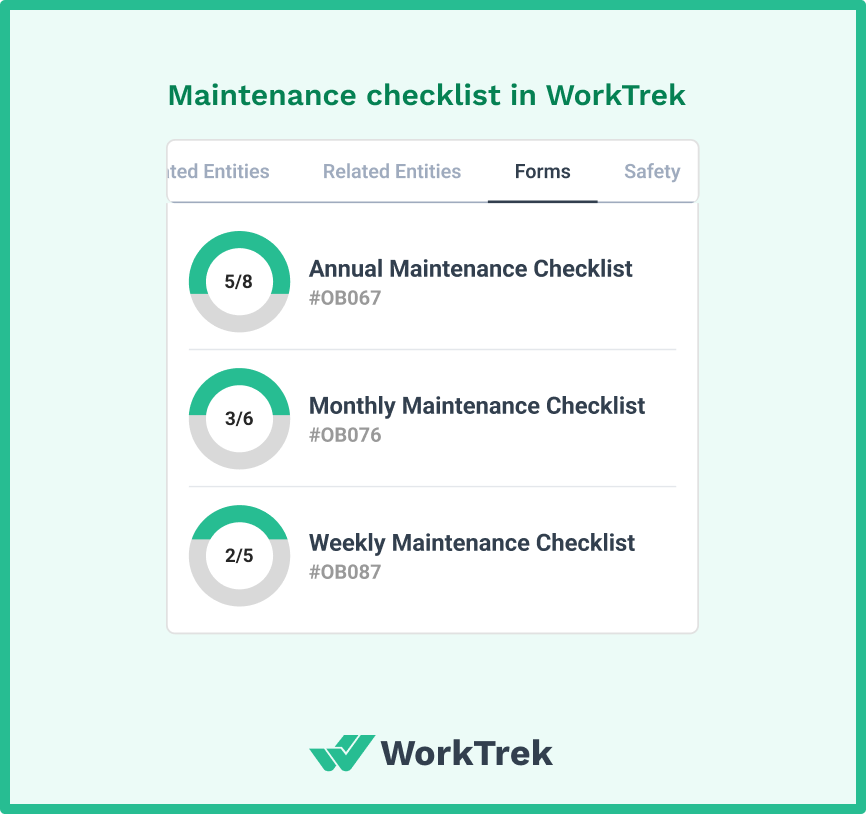

Standardized Procedures and Checklists

WorkTrek’s digital checklists give every technician the tools to follow the same preventive maintenance processes, regardless of experience level.

With detailed step-by-step instructions, required photos, and mandatory fields, eliminate shortcuts and ensure quality work. Completed checklists create an audit trail that proves compliance and identifies improvement opportunities.

Real-Time Reporting and Analytics

Forget manual KPI calculations. WorkTrek’s reporting dashboard provides instant visibility into:

- Preventive maintenance compliance rates

- Maintenance costs by asset, location, or department

- Technician productivity and workload

- Parts usage and inventory levels

- Failure trends and root causes

These insights enable maintenance teams to proactively adjust their preventive maintenance strategy before small issues become major problems.

Mobile-First Design

Maintenance happens in the field, not the office. WorkTrek’s mobile app allows technicians to:

- Access work orders and asset information anywhere

- Complete digital checklists and forms

- Capture photos and notes

- Log parts usage in real-time

- View equipment manuals and schematics

This mobility eliminates paperwork, reduces errors, and accelerates completion of work. Companies using WorkTrek report completing 70% more preventive maintenance work orders compared to manual systems.

Integration Capabilities

It is difficult to have a successful preventive maintenance program in isolation. WorkTrek can easily integrate with existing systems, such as ERP, procurement, and production planning. This can create a unified operational view of your organization.

Common Preventive Maintenance Pitfalls to Avoid

The most well-intentioned preventive maintenance programs can fail. An understanding of common mistakes helps you navigate around them:

Over-maintaining equipment:

More isn’t always better. Excessive preventive maintenance wastes resources and introduces unnecessary failure risks. Follow data, not assumptions.

Underestimating resource requirements:

Preventive maintenance requires dedicated time and personnel. Make sure to understand the requirements and staff accordingly.

Ignoring technician feedback:

Your maintenance team knows what works and what doesn’t. Regular feedback loops ensure continuous improvement.

Neglecting documentation:

Poor record-keeping undermines analysis and improvement efforts. CMMS like WorkTrek makes documentation effortless.

Focusing solely on equipment:

Successful preventive maintenance programs also maintain inventory, tools, and skills. A holistic approach prevents bottlenecks.

Expecting immediate results:

Benefits accumulate over time. Be patient and continue to refine your process.

Conclusion

A preventive maintenance program is more than preventing equipment failure. The goal is to transform your maintenance operation.

By following these nine steps and leveraging modern CMMS technology, you can join the ranks of world-class facilities that have conquered unplanned downtime and turned maintenance into a competitive advantage.

The path from reactive firefighting to proactive maintenance requires commitment, planning, and the right tools.

Your equipment, your team, and your bottom line are all counting on you to make the shift. The blueprint is here. The tools are available. The only question remaining is: When will you start building your preventive maintenance program?