Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Unplanned CNC machine breakdowns cost 5 times more than implementing a preventive maintenance plan.

- Manufacturing facilities face an average of 800 hours of equipment downtime per year—more than 15 hours weekly.

- Predictive maintenance strategies can reduce CNC cutting machine downtime by up to 50% through sensors and data analytics.

When your CNC machines are down, nothing gets done. It’s that simple.

But here’s what’s not so simple: keeping those computer numerical control powerhouses running smoothly day after day, shift after shift, without unexpected breakdowns that bring your whole manufacturing process to a grinding halt.

Whether you’re running a small machine shop or managing dozens of CNC machines across multiple production lines, the reality is the same: Proper maintenance isn’t optional. It’s the difference between hitting your production targets and explaining to customers why their orders are delayed.

The good news? CNC machine maintenance doesn’t have to be overwhelming.

With the right approach and tools, you can move from reactive firefighting to proactive prevention. This guide walks you through everything you need to know about maintaining CNC equipment, from daily maintenance routines to building a comprehensive preventive maintenance plan that actually works.

Understanding CNC Machines and Why Maintenance Matters

CNC machines are among the most precise and expensive equipment on your shop floor. These computer numerical control systems can achieve tolerances within 0.0001 inches—but only when they’re correctly maintained.

Think about what happens inside a CNC machine during a typical production run. The spindle rotates at thousands of RPM. Ball screws move with incredible precision. Coolant systems pump fluid continuously. Electrical components work in harmony to execute complex machining processes. All of this generates heat, friction, and wear.

Without regular maintenance, small issues compound quickly:

- A slightly worn ball screw affects positioning accuracy.

- Contaminated coolant reduces tool life.

- Dirty air filters cause the cooling system to work harder, leading to overheating.

Before you know it, what started as minor, preventable issues has snowballed into costly repairs and unplanned downtime.

According to research from Aberdeen, 82% of companies have experienced unplanned downtime over the past three years. For CNC equipment specifically, these unexpected breakdowns don’t just halt production; they create a domino effect throughout your entire operation.

The Real Cost of Poor CNC Maintenance

Let’s talk numbers, because that’s where the urgency of proper CNC maintenance becomes crystal clear.

When CNC machine breaks down unexpectedly, you’re not just looking at repair costs. Unplanned downtime can cost manufacturers up to $260,000 per hour, according to industry research. For many operations, even a few hours of machine breakdown means:

- Lost production time that can’t be recovered

- Rush shipping costs for emergency parts

- Overtime labor to catch up on delayed orders

- Potential penalties for missed deliveries

- Damaged customer relationships

The average manufacturer confronts 800 hours of equipment downtime per year. That’s more than 15 hours every single week.

When you multiply that by your hourly production value, the numbers become staggering.

But here’s the kicker: an unplanned CNC machine breakdown typically costs about 5 times more than implementing a preventive maintenance plan. You’re either paying for maintenance on your schedule, or you’re paying much more for repairs on the machine’s schedule.

Beyond the immediate financial impact, consider the operational chaos that follows a machine breakdown.

Your production schedule gets thrown off. Quality may suffer as you rush to catch up. Team morale takes a hit when people are constantly firefighting instead of executing planned work.

The manufacturing process doesn’t wait. Parts need to be machined, deadlines need to be met, and customers expect reliability.

This makes preventive maintenance essential for staying competitive.

Types of CNC Maintenance Approaches

Not all maintenance strategies are created equal. Understanding the different approaches helps you build a preventive maintenance plan that matches your operational needs and budget.

Reactive Maintenance

This is the “run it until it breaks” approach. You perform maintenance tasks only when CNC machine performance degrades or components fail.

While this might work for non-critical equipment, it’s a risky strategy for CNC machines. According to GE research, reactive approaches average 8.43% unplanned downtime annually. This is the highest of any maintenance strategy.

The apparent short-term savings quickly evaporate when you factor in emergency repairs, rush orders for parts, and production losses.

For most operations, reactive maintenance is essentially choosing to fail at the worst possible time.

Preventive Maintenance

This proactive approach involves performing maintenance tasks at predetermined intervals, regardless of whether the machine shows signs of trouble.

It’s like performing regular oil changes for your car to avoid long-term problems.

A solid preventive maintenance system includes:

- Daily checks of coolant levels, lubrication, and machine cleanliness

- Weekly inspections of key components

- Monthly filter replacements and deeper cleaning

- Quarterly reviews of mechanical components

- Annual comprehensive servicing

Preventive maintenance reduces unplanned downtime to about 7.96% annually, according to the GE study.

More importantly, it gives you control. You schedule maintenance during planned downtime rather than having breakdowns dictate your schedule.

Predictive Maintenance

This advanced strategy uses real-time data from sensors and monitoring systems to predict when maintenance is actually needed. Instead of changing a component at a fixed interval, you replace it based on its actual condition.

Predictive maintenance can reduce CNC cutting machine downtime by up to 50% by catching issues before they cause failures. With an unplanned downtime rate of just 5.42% annually, it’s the most effective approach.

The best maintenance programs combine these approaches strategically.

Preventive maintenance forms your foundation, with predictive techniques layered on top for critical systems and expensive components.

Essential CNC Machine Components That Need Regular Attention

CNC machines are complex systems with multiple interdependent components.

The first step is understanding which parts need regular attention. This helps you build practical maintenance tasks into your preventive maintenance plan.

Coolant System

The coolant tank and coolant system work harder than almost any other component. Coolant removes heat from the machining process, lubricates cutting tools, and washes away chips.

But coolant degrades over time. Concentration levels drift, bacteria grow, and contaminants accumulate. A failing cooling system quickly leads to poor surface finish, excessive tool wear, and even damage to CNC machines.

Key maintenance needs:

- Daily checks of coolant level and concentration

- Regular coolant filter replacement

- Periodic complete coolant tank cleaning

- Monitoring for bacterial growth or rancidity, and efficient spare parts management to minimize equipment downtime

Electrical Components and Connections

Electrical systems are the nervous system of your CNC equipment. Loose connections, corroded terminals, or failing components can cause erratic behavior, false alarms, or complete shutdowns.

Regular machine inspection of electrical connections catches problems early. Look for:

To reduce issues such as:

- Loose wiring or connections

- Signs of corrosion on terminals

- Damaged cable insulation

- Overheating indicators on electrical panels

it is important to implement preventive maintenance alongside routine inspections.

Shop vibrations naturally loosen connections over time, making this a critical area for preventive maintenance.

Lubrication Systems and Ball Screws

Ball screws, linear guides, and other mechanical components need proper lubrication to function smoothly. Without adequate lubrication, friction increases, accuracy suffers, and wear accelerates dramatically.

Modern CNC machines often have automatic lubrication systems, but these still need monitoring. Check:

- Oil levels in automatic lubricators

- Manual lubrication points

- Ball screw condition and movement

- Signs of oil leaks or excessive consumption

Cooling Systems and Air Filters

While coolant handles the cutting zone, your CNC machine has separate cooling systems for electronics, hydraulics, and the spindle. These systems need clean airflow to function correctly.

Replace air filters regularly. Dirty filters force systems to work harder, increase energy costs, and can lead to overheating failures.

Tool Changer and Cutting Tools

The tool changer mechanism handles dozens or hundreds of tool changes per shift. It needs to work flawlessly to maintain production flow.

Regular maintenance prevents:

- Tool dropping or mispositioning

- Excessive cycle times

- Damage to the tool magazine

- Spindle contamination

Cutting tools themselves require attention, too. Monitor tool wear patterns, inspect for damage, and replace cutting tools before they fail mid-cut.

CNC Drive Systems

The drive systems, which include servo motors, amplifiers, and feedback devices, control all CNC machine motion. These systems require careful attention because even minor issues affect accuracy.

Watch for:

- Unusual motor sounds or vibration

- Servo alarms or errors

- Degraded positioning accuracy

- Excessive heat in the drive components

Daily Maintenance Tasks for CNC Machines

Daily maintenance forms the foundation of your preventive maintenance program. These quick checks take 10-15 minutes per machine but prevent the most common problems.

Morning Startup Checks

Before running the first part, walk through these essential steps:

Check lubrication levels. Verify the automatic lubrication system has adequate oil. If your machine uses manual lubrication points, apply grease or oil according to the maintenance plan.

Inspect coolant levels and concentration. Use a refractometer to verify the coolant mixture is correct. Top off if needed. A proper coolant concentration maintains cutting performance and prevents corrosion.

Review indicator lights and alarms. Make sure no warning lights are active. Address any overnight alarms before production starts.

Test emergency stops. Verify that all e-stops function correctly. This simple safety check could prevent injuries.

Inspect the hydraulic system. Check oil levels and look for leaks. Low hydraulic pressure can cause tool-changer issues and affect machining accuracy.

During Production

Monitor machine sounds. Experienced operators and maintenance staff know what their CNC machines should sound like. Odd noises, like grinding, squealing, or rattling, signal problems that need immediate attention.

Watch chip evacuation. Chips should clear properly from the work area. Chip buildup can damage parts, break tools, or interfere with machine components.

Check coolant flow. Verify coolant is reaching the cutting zone properly. Intermittent flow or pressure issues need investigation and may be managed more systematically with work order software.

End of Shift

Clean machine surfaces. Wipe down the exterior of the machine to remove metal chips and coolant residue. This isn’t just about appearance. Sometimes accumulated chips can work their way into mechanical components, causing damage.

Empty the chip hopper. Full chip hoppers slow evacuation and can cause conveyor problems.

Inspect the work area. Look for coolant leaks, loose tools, or anything unusual that developed during the shift.

Document issues. Note any problems or unusual behavior in your maintenance log. These patterns help identify developing issues before they cause failures.

Weekly Maintenance Requirements

Weekly maintenance goes beyond daily checks, addressing components that require less frequent attention.

Filter Maintenance

Clean or replace air filters. Depending on your shop environment, air filters may need weekly attention. Dusty or dirty conditions require more frequent changes.

Inspect coolant filters. Check for excessive restriction or contamination. Replace if the flow appears reduced or if debris is visible.

Check hydraulic filters. Monitor pressure differentials across hydraulic filters. Replace when indicators show restriction.

Mechanical Inspections

Examine ball screws and ways. Look for signs of wear, contamination, or lubrication problems. Wipe down exposed surfaces and relubricate as needed.

Check spindle condition. Listen for unusual sounds. Feel for vibration or excessive heat. Spindle problems rarely announce themselves until it’s too late. With regular monitoring, issues are caught early.

Inspect the tool changer operation. Run through several tool changes and verify smooth operation. Check gripper fingers, tool retention, and magazine rotation.

Coolant System Maintenance

Test coolant concentration. Weekly testing catches concentration drift before it affects machining quality.

Check for bacterial growth. Rancid coolant smells terrible and damages both parts and machines. Bacterial growth accelerates in warm weather.

Clean coolant tank strainers. Remove accumulated sludge and chips that bypass the main filtration.

Chip Conveyor

Inspect and clean conveyors. Chip conveyors work hard in demanding conditions. Remove any jammed chips, check for proper operation, and lubricate chains or moving parts.

Monthly and Quarterly Maintenance Activities

Monthly and quarterly maintenance addresses components that don’t need constant attention but are too important to neglect.

Monthly Tasks

Deep clean the machine. Go beyond daily surface cleaning. Remove panels to clean internal components, blow out electrical cabinets (with appropriate precautions), and thoroughly clean all accessible areas.

Complete coolant system service. Check coolant lines for leaks or damage. Clean or replace spindle coolant delivery nozzles. Verify coolant pump operation and flow rates.

Inspect electrical connections. Check all accessible electrical connections for tightness. Look for corrosion, damaged insulation, or signs of overheating.

Review and update checklists. Make sure your maintenance tasks list reflects current needs. Update based on any recurring issues or manufacturer recommendations.

Grease chains and conveyors. Apply proper lubricant to chip conveyor chains, pallet changer mechanisms, and other moving parts.

Quarterly Maintenance

Chuck maintenance. For turning centers, remove and thoroughly clean the chuck and jaws. Inspect for wear or damage. This prevents workpiece movement and ensures part accuracy.

Spindle taper inspection. Check the spindle taper for damage, contamination, or wear. A damaged taper can affect tool holding and destroy expensive tooling.

Axis backlash testing. Run positioning tests to verify axis accuracy hasn’t degraded. Excessive backlash indicates worn mechanical components that need maintenance.

Review preventive maintenance effectiveness. Analyze maintenance records to identify patterns. Are specific components failing prematurely? Are there recurring issues? Adjust your annual maintenance plan accordingly.

Conduct training refreshers. Schedule training sessions to keep your team up to date on maintenance procedures and safety protocols.

Annual Maintenance Plan Essentials

Your annual maintenance plan represents the most comprehensive service interval. While some tasks can be performed internally, others may require the services of CNC machine manufacturers’ service technicians or specialized equipment.

Major System Overhauls

Complete coolant system service. Remove the coolant tank completely. Clean out all sludge, chips, and contamination. Inspect the tank interior for damage or bacterial growth. Flush all coolant lines and clean or replace filters. Refill with fresh coolant at the correct concentration.

Hydraulic system maintenance. Test hydraulic oil for contamination or degradation. Replace filters. In some cases, completely drain and refill the system with fresh oil.

Lubrication system overhaul. Drain and clean automatic lubrication units. Replace oil with fresh lubricant. Check all delivery lines for proper function. For more guidance on achieving effective maintenance management, review these essential tips.

Mechanical Component Service

Drawbar tension verification. Proper drawbar force is critical for tool holding. Use appropriate tools to verify tension meets manufacturer specifications.

Chuck cylinder inspection. For lathe systems, thoroughly inspect and service the chuck actuating cylinder. Replace seals if needed.

Way and ball screw service. This major task involves carefully cleaning all ways and ball screws, inspecting for wear, and applying fresh lubrication. On machines with replaceable components, evaluate whether parts have reached their service life.

Axis gibs adjustment or replacement. Run diagnostic programs to check for backlash. Adjust or replace X and Y axis gibs as needed to maintain accuracy.

Electrical and Control Systems

Software and firmware updates. Check with CNC machine manufacturers for any recommended software updates. Apply updates during scheduled downtime to improve functionality and address known issues.

Backup critical data. Backup programs, parameters, and configuration data. Store backups securely off-machine in case of failures.

Inspect control panels. Check for any signs of overheating, damaged components, or deteriorating connections inside electrical cabinets.

Documentation and Planning

Update equipment records. Document all maintenance performed, parts replaced, and issues addressed. This history proves invaluable for predicting future needs.

Review machine performance metrics. Analyze uptime, breakdown frequency, and maintenance costs. Use this data to refine your preventive maintenance plan.

Plan next year’s maintenance schedule. Based on usage patterns and performance history, schedule next year’s preventive maintenance activities.

Evaluate machine replacement needs. CNC machines typically provide reliable service for 15-20 years with proper maintenance. Annual reviews help identify when machines approach the end of their useful life.

Common CNC Maintenance Challenges and How to Solve Them

Even with the best preventive maintenance plan, you’ll face challenges. Here’s how to handle the most common ones.

Balancing Production and Maintenance

The eternal conflict: production wants maximum uptime, maintenance knows machines need servicing. When production pressures push maintenance to the back burner, everyone loses.

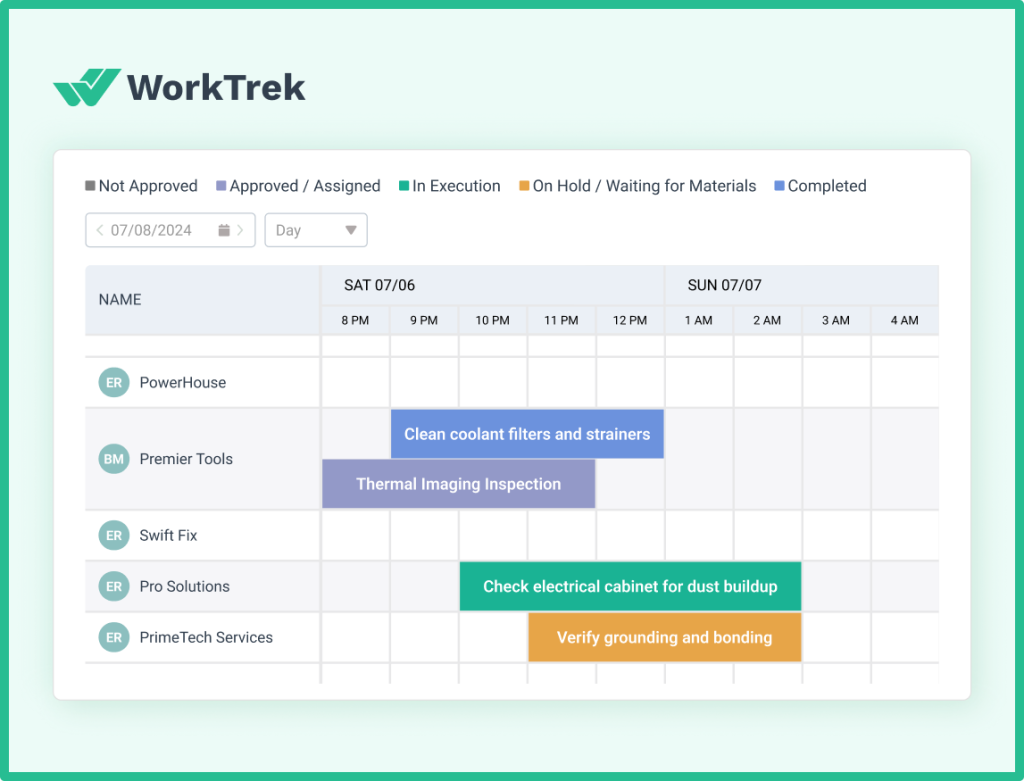

Solution: Schedule preventive maintenance during natural production breaks. This can include shift changes, weekends, or planned low-volume periods. Use a CMMS to demonstrate how preventive maintenance actually improves overall uptime by preventing unplanned breakdowns.

Inconsistent Maintenance Execution

When maintenance tasks depend on individual initiative, things get missed. Different shifts do things differently. Critical checks get skipped when people are busy.

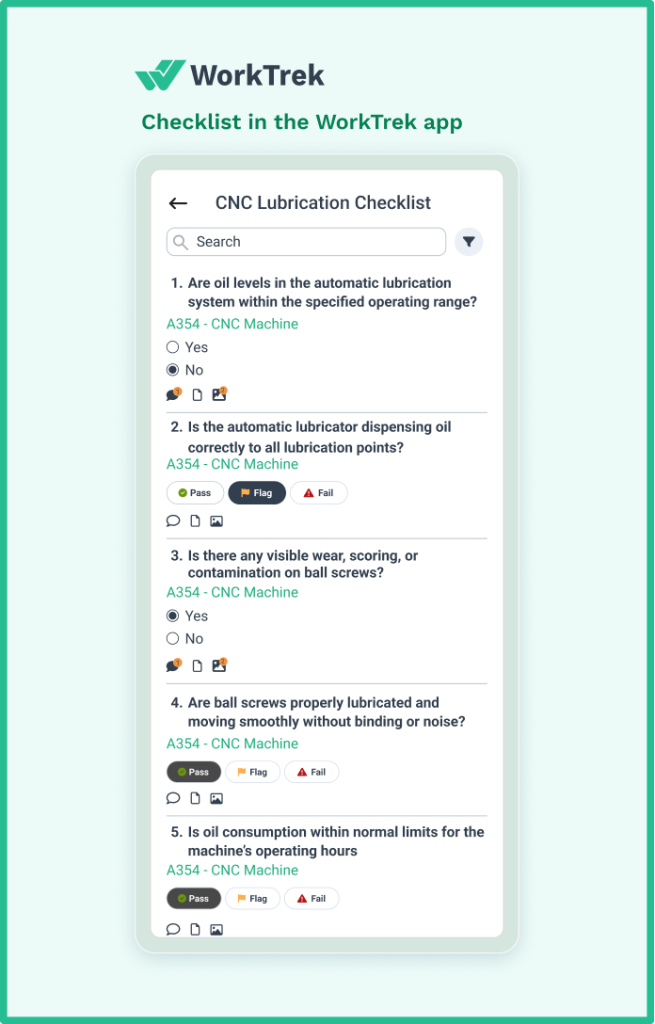

Solution: Implement standardized preventive maintenance checklists accessible via mobile devices. Use a CMMS like WorkTrek to track completion and send alerts for overdue tasks. Make compliance visible to management.

Lack of Proper Documentation

Without good records, you’re flying blind. You don’t know when parts were last replaced, which machines are problem children, or whether your maintenance program is actually working.

Solution: Adopt a CMMS that makes documentation easy and automatic. Every completed work order, every part replaced, every hour of downtime gets recorded without extra effort.

Training Gaps

CNC machines are complex. New operators and maintenance staff need proper training, but training takes time and costs money. The result? People learn on the job, mistakes happen, and maintenance quality suffers.

Solution: Develop structured training programs for both operators and maintenance personnel. Document best practices. Use your CMMS to attach procedures and work instructions to specific maintenance tasks.

Parts Management

Nothing derails maintenance faster than not having the right parts. You schedule a bearing replacement, but the bearing isn’t in stock. Now you’re waiting days or paying premium shipping while the machine sits idle.

Solution: Use your CMMS to track spare parts inventory. Set reorder points for critical components. Analyze parts usage to identify items worth keeping in stock versus ordering as needed.

Machine-Specific Expertise

Maybe you have one technician who really knows your particular CNC equipment. When they’re not available, problems take longer to diagnose and fix.

Solution: Document machine-specific knowledge in your CMMS. Include troubleshooting guides, diagnostic procedures, and lessons learned. Cross-train multiple people on critical equipment.

How CMMS Transforms CNC Preventive Maintenance

A computerized maintenance management system changes everything about how you handle CNC maintenance. Instead of chasing paper checklists, hunting for parts, and wondering if maintenance got done, you have complete visibility and control.

Automated Preventive Maintenance Scheduling

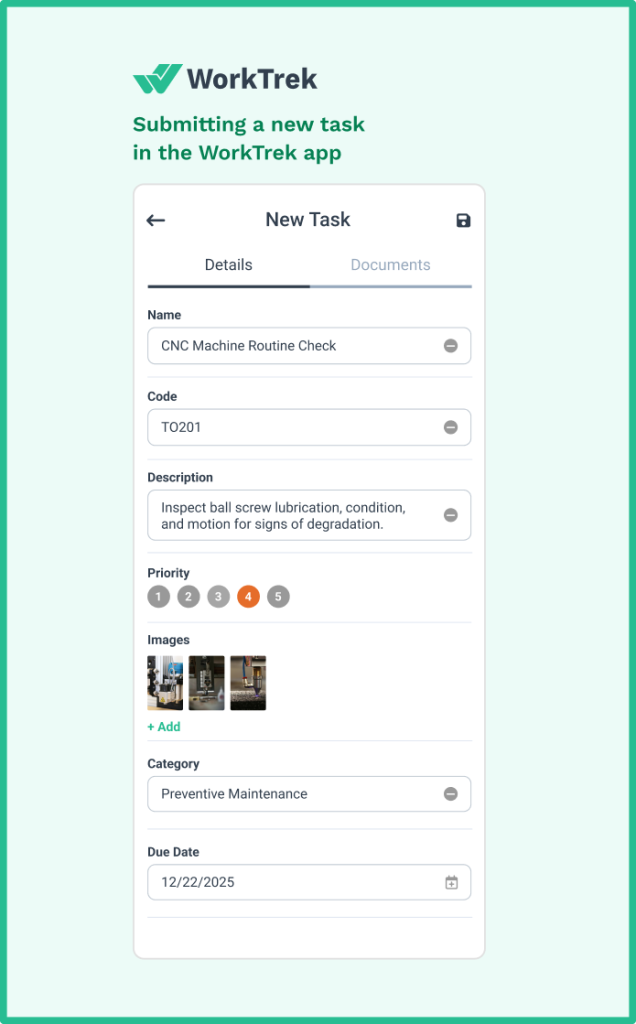

Your CMMS automatically generates maintenance tasks based on time intervals, machine hours, or cycle counts. When a CNC machine hits 500 operating hours, the system creates a work order for the appropriate preventive maintenance tasks. No one needs to remember. Nothing gets missed.

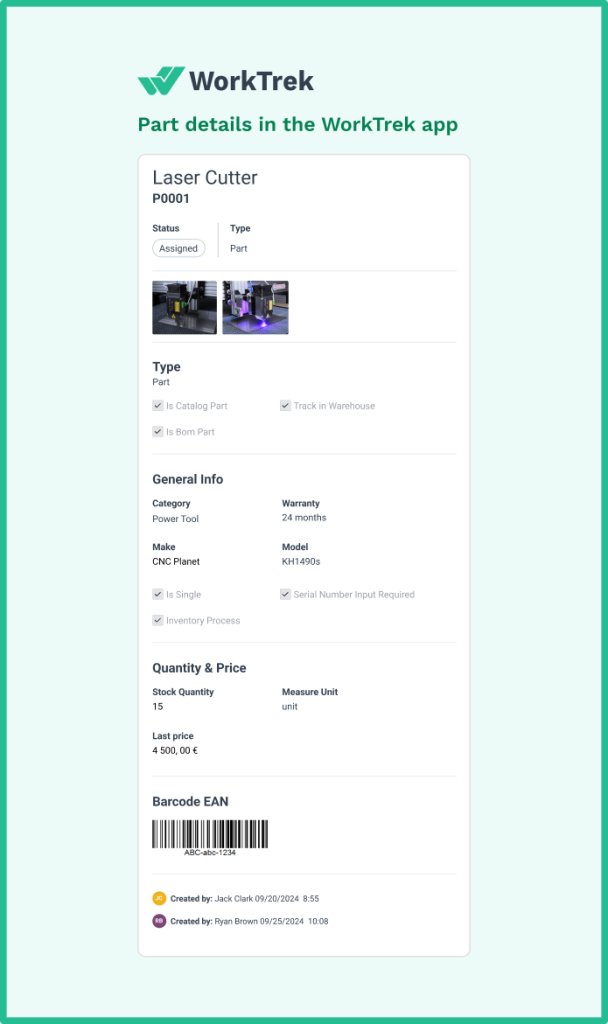

WorkTrek takes this further by supporting both time-based and condition-based scheduling.

If you have sensors monitoring vibration or temperature, maintenance triggers automatically when conditions warrant attention.

Mobile Accessibility for Technicians

With WorkTrek’s mobile app, technicians access everything they need right from their phone or tablet:

- Complete work orders with step-by-step procedures

- Equipment history showing past maintenance and issues

- Parts lists and inventory availability

- Photos and diagrams for reference

- Ability to document work and close tickets on the spot

This eliminates the back-and-forth between the shop floor and office. Technicians start work with complete information and finish with automatic documentation.

Comprehensive Asset Management

Every CNC machine in your operation has a complete digital record in WorkTrek:

- Equipment specifications and serial numbers

- Maintenance history and work performed

- Parts replaced and costs incurred

- Failure patterns and reliability metrics

- Manufacturer documentation and manuals

This centralized information means anyone can quickly understand a machine’s status and history, not just the senior technician who’s been there 20 years.

Parts Inventory Integration

WorkTrek connects maintenance tasks directly to parts inventory. When you create a preventive maintenance work order, the system shows which parts are needed and whether they’re in stock.

As technicians complete work orders and consume parts, inventory automatically updates. Set minimum stock levels for critical components like coolant filters, ball screws, or electrical components, and the system alerts you when it’s time to reorder.

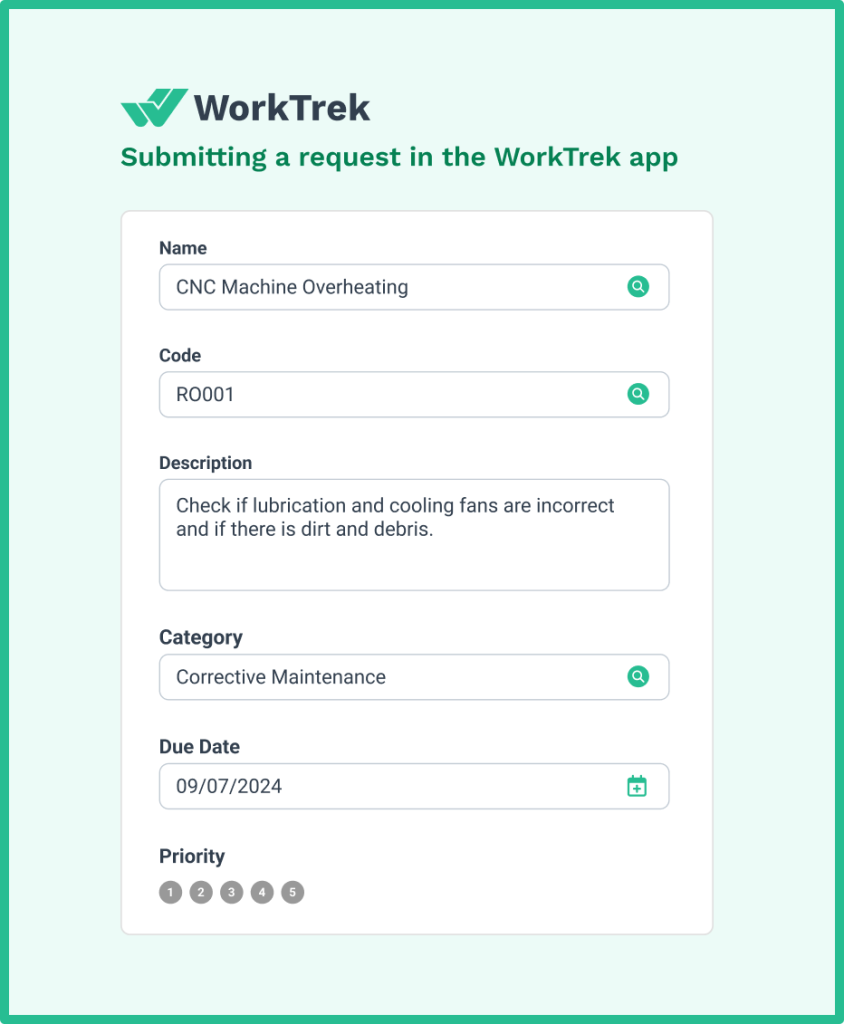

Work Order Management That Actually Works

Traditional paper-based or basic digital systems create more work than they save. WorkTrek streamlines the entire work order lifecycle:

- System automatically generates preventive maintenance work orders

- Work orders route to appropriate technicians based on skills and availability

- Technicians receive mobile notifications

- All work gets documented with photos, notes, and time tracking

- Supervisors monitor progress in real-time

- Completed work automatically updates asset history

No phone tag. No lost paperwork. No wondering if maintenance got done.

Data-Driven Decision Making

WorkTrek turns your maintenance data into actionable insights:

- Which CNC machines have the highest maintenance costs?

- Are preventive maintenance tasks effectively preventing failures?

- How does actual vs. planned downtime compare?

- Which components fail most frequently?

- Where should you focus improvement efforts?

These analytics help you continuously refine your preventive maintenance plan, shifting resources to where they deliver the most value.

Compliance and Documentation

For operations requiring ISO certification, customer audits, or regulatory compliance, WorkTrek provides bulletproof documentation. Every maintenance task, inspection, and calibration automatically generates records showing:

- What work was performed

- When it was completed

- Who did the work

- What parts were used

- Any issues discovered

This comprehensive audit trail eliminates scrambling when inspectors ask questions or customers request maintenance records.

Scalability Across Your Operation

Whether you’re maintaining three CNC machines or three hundred, WorkTrek scales to fit. The same system that handles your milling machines also manages your lathes, grinders, and auxiliary equipment.

As your operation grows, you’re not outgrowing your maintenance management system and starting over with a new one. WorkTrek grows with you.

Conclusion

CNC maintenance isn’t complicated, but it requires consistency and the right tools to succeed.

The stakes are clear: proper preventive maintenance means machines run when you need them, producing quality parts on schedule. Poor maintenance means expensive breakdowns, missed deadlines, and frustrated customers.

The most successful operations have moved beyond paper checklists and reactive firefighting. They’ve implemented systematic preventive maintenance programs supported by modern CMMS technology, such as WorkTrek.

Your CNC machines are major investments that should deliver years of reliable service. Give them the attention they deserve with a comprehensive preventive maintenance plan, and they’ll reward you with optimal performance and minimal unplanned downtime.

The question isn’t whether you can afford to implement proper CNC maintenance. It’s whether you can afford not to.