Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeROI of a CMMS

Let’s say you’re still managing your maintenance processes through traditional methods, such as pen and paper, email outreach, phone calls, or WhatsApp messages.

Naturally, you realize that it is not efficient management, so you finally decide to look for an alternative and more performing solution. Do an internet search, ask around, and collect a few pieces of information wherever you can. You realize that this is interesting.

Sooner or later, however, you will end up asking yourself a question like this: “How much does a CMMS cost me?”

What is the ROI of a CMMS

Soon after, you will ask yourself another question: “What is the ROI of a CMMS?”

If you are reading this article, it is likely that what I have just described is, more or less, the path that has led you here.

In fact, they are both legitimate questions, the only problem is that it is not very easy to answer completely exhaustively. In short, you cannot read this article passively: your help will also be needed.

Why? Well, finally a simple question: because there is neither a precise cost nor (let alone) a single ROI that applies to everyone.

Exactly: when evaluating the final cost or calculating the ROI of a CMMS, there are a number of factors to take into consideration that will decisively affect the result and the price of the CMMS.

What Is ROI?

ROI, the acronym for Return on Investment, is one of the profitability indicators that is part of the economic analysis of a business.

The Return on Investment is taken into consideration when investors and entrepreneurs want to know if it is worth investing in a company because it clearly reports how much that business makes in its core business.

What Is ROI For?

Now we know what ROI means and that it is a profitability indicator, but what is it for?

Return on investment is used to understand if an investment in a particular company is profitable.

In a nutshell, what return will I get if I invest X euros in this company/sector/software? Will I make a profit or a loss?

The Return on Investment shows the answer to this question, so it is essential to calculate it in order to understand whether or not to invest in that particular company/sector/software.

In fact, thanks to the ROI calculation, we will be able to understand the efficiency with which the company/sector/software we are going to invest in will manage our invested capital and its ability to generate income from the investment.

In fact, it is NEVER advisable to analyze just one balance sheet index when evaluating a possible investment.

ROI belongs to a larger group of profitability indicators and it is advisable to analyze them all.

How is ROI calculated?

The ROI, therefore the return on investment, is calculated as a percentage taking into consideration the investment and the turnover.

As with other balance sheet ratios, the ROI calculation will be indicative of your business only if accompanied by other indicators of your company’s structure, both from an equity and economic point of view.

This therefore means that it is not a sufficient parameter to tell you whether your company’s performance is sufficient and profitable or not.

In addition to this, you need to understand how to interpret the ROI data presented, and how much to rely on it to make decisions that can prove decisive for your business.

To calculate your ROI just use a simple formula.

ROI: formula

The formula for calculating the return on investment is given by dividing the net return on investment, calculated by subtracting the turnover from the investment, by the invested capital. The figure obtained will then be multiplied by 100 to calculate the percentage value.

The ROI formula is therefore: [(turnover – investment) / invested capital] x 100

Try our ROI Calculator for Free!

ROI Calculator

Types of ROIs

Based on the value obtained from the calculation of the return on investment, three types of ROI can be identified:

· greater than 0: if the ROI is positive, the business is generating wealth.

· equal to 0: if the ROI is equal to zero, the business is neither generating nor destroying wealth.

· less than 0: if the ROI is negative, the business is destroying wealth.

Six Factors That Influence The Cost Of A CMMS

What are the main cost items of a CMMS?

- Software cost

- Implementation and configuration

- Training, education, and support

- Integrations

- Hardware (when needed)

- Customizations

The cost of CMMS: cloud Vs on-premise

Most CMMS vendors offer two solutions for delivering their software:

- Cloud-based CMMS

- CMMS on-premise

Cloud-based CMMS software is often delivered through a subscription model.

The subscription is often linked to the number of users (therefore to the number of people who will use the software) and is usually paid once a year.

People who only have the possibility of reporting a fault using the appropriate technical intervention request form are not to be considered users.

When you want to determine an estimate for membership fees, you should therefore ask yourself one question: How many people will use the system?

Calculating this cost is the most difficult part, as it varies according to what we want: customizations and integrations are among the most common extras that lead to raising the final price of the CMMS and are usually also the most expensive items. On the other hand, however, they are at the same time the elements that can lead to a higher ROI. So it’s about finding the right balance.

We will examine each of these items more closely in the next paragraphs.

Calculate the costs of a CMMS: implementation and configuration

The cost of implementing and configuring a CMMS includes both direct and indirect installation costs to make the software operational.

To give some examples, potential implementation costs concern the payment of services such as system configuration, data migration or data entry, creation of scheduled maintenance, etc.

Most CMMS vendors charge an hourly rate to cover the hours of work required or offer a standard implementation package that includes these services.

Calculate the costs of a CMMS: training, education, and support

The cost of training and support depends on the size, goals, and capabilities of your team.

As with implementation, most vendors offer a specific number of training hours directly with the purchase of a subscription.

Any additional hours are charged by the hour.

While this item is the most tedious part of buying a CMMS, don’t underestimate it. Successful implementation depends on how the people involved use the software.

Accumulate your savings with WorkTrek CMMS!

Book a WorkTrek demo to see how a CMMS can help your business.

Try for freeCalculate the costs of a CMMS: integrations

Being able to integrate your CMMS with other company systems is one of the essential elements to take maintenance to the pro level.

Whether you want to connect the CMMS to the corporate ERP system, to an MES, or to production schedulers, warehouse software, SAP, sensors, meters, and so on, it often represents a decisive argument for achieving the best ROI.

The first step in determining the effective cost of integration is to understand what we want to connect to the CMMS.

Talk to your supplier to understand what the possibilities are and get an accurate idea ofthe final cost.

Calculate the costs of a CMMS: customizations

Customizing your CMMS is not only a smart move but very often a decisive one too.

CMMS software is used in many sectors ranging from facility management to industry. Although CMMS providers very often provide slightly different environments from sector to sector, you will always have needs that are different even from those of your competitor.

However, these customizations are divided into 2 categories: for a first group, represented by simple changes to the interface, it is only a question of modifying some fields, for example removing those that are not needed to make the interface itself cleaner. These customizations are usually done without adding an extra cost unless they become too much.

Other customizations instead require a greater effort for the CMMS provider. Some of them may even involve the development department and, of course, will have to be paid for.

Extra costs: hardware

The purchase of mobile devices represents one of the few costs of a CMMS associated with physical hardware.

One of the main advantages of a CMMS is its ability to access it through smartphones or tablets. This allows you to be able to use the system directly through your own devices, but if the company intends to provide a corporate one, it will be good to calculate the cost in advance.

Calculate The ROI Of A CMMS

The time has come to understand what value a CMMS can offer.

Calculating the ROI of a CMMS depends on many factors including, for example, the objectives we have set ourselves to achieve, or the sector in which we operate.

However, since ours is intended to help calculate ROI, we will focus only on those aspects that are measurable.

Downtime:

Downtime can represent a significant cost item for companies every year. CMMS software can help you reduce this cost in many ways: for a manufacturing company, for example, a CMMS can help reduce the number of unexpected downtimes or help you plan scheduled maintenance more rationally.

A CMMS can also help you:

- Understand the hourly cost of machine downtime.

- Monitor the number of hours of downtime before and after implementation.

- Analyze failure types and evaluate their effects in terms of hours worked per machine and other maintenance metrics.

Eliminate inefficiencies:

Eliminating inefficiencies can save you time and money. The main problem is being able to find them.

CMMS software can give you a big hand in this.

Once you’ve established the average time required to complete a specific task, as well as the required man-hours and man-hour costs, you can begin to find answers to questions such as:

- Does fewer unexpected breakdowns mean fewer additional staff/suppliers?

- Is our preventive maintenance program sufficient to reduce the number of breakdowns?

- Are we saving time by automatically entering data, tracking operations, and compiling the digital end-of-service report?

- Is work being assigned and done faster using the mobile app?

- Does the improvement in communication and dissemination of information lead to shortening intervention times?

- Aspects such as productive time, quality of work, and the total value of working hours are increasing?

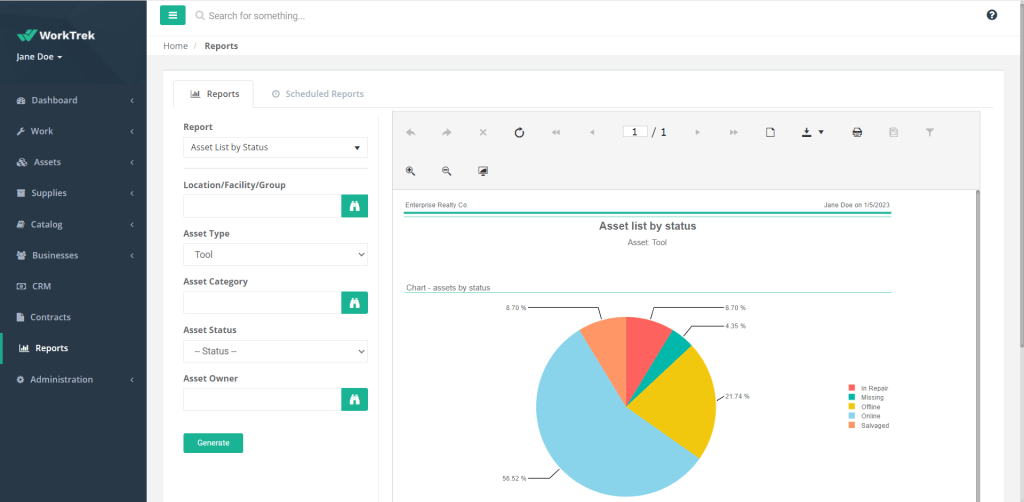

Analysis and efficiency:

One of the central aspects of a CMMS is the ability to analyze stored data and provide advanced reporting to make it easier to read and therefore actionable.

Some reports and KPIs can also give us an indication of the return on investment of our CMMS. These reports can help us answer questions that, without data in hand, would remain unanswered.

- Are we doing too much (or too little) scheduled maintenance? Indeed, if it has been demonstrated that optimal maintenance planning can cost 3 to 4 times less than reactive maintenance, it is also true that an excess of scheduled maintenance leads to a significant loss of efficiency which has repercussions on management costs and times.

- How much does a machine downtime cost on average (and specifically)? Has the average number of total machine stops (or for each plant) dropped or is it dropping?

- Which assets are our staff or suppliers spending the most time on?

- What are the most expensive assets in terms of downtime or maintenance?

- What is the backlogging rate (maintenance backlog)? Is it decreasing?

- Is the mean intervention time (wrench time) decreasing?

Answering these questions will help you find the CMMS ROI in relation to labor costs and labor time.

Inventory and spare parts warehouse:

Optimal management of spare parts and materials in the warehouse can lead to a significant reduction in costs.

You can measure these savings by calculating the amount you spent on inventory before and after implementing a CMMS.

Here are some examples of how CMMS software can help you better manage your parts warehouse inventory.

- You can save on purchasing spare equipment through maintenance planning.

- You can track the usage of spare materials and equipment in your warehouse in just a few clicks, and set minimum thresholds so you don’t overstock.

- Identifying the materials needed for a work order allows you to reduce time and labor costs.

Durability and asset efficiency:

Part of the ROI of CMMS software also comes from ensuring that the assets receive adequate maintenance in order to make them last longer and maintain initial productivity standards.

This will allow your company to save a nice nest egg in the long run.

All of this obviously has a major impact on the ROI of a CMMS. In particular, because it allows you to:

- Increase the availability and efficiency of your plants

- Extend the natural life cycle of resources

Sustainability and safety:

A CMMS can also provide a high ROI in terms of efficiency and sustainability. Here are some examples:

- Better maintenance helps keep machines in like-new condition, reducing utility costs.

- CMMS software simplifies the management of audits and inspections, as well as contributes to compliance with safety procedures.

- Through processes that automate maintenance planning, the CMMS contributes not only to comply with the required regulatory standards.

Integration with business systems:

In addition to integration with ERP systems, a CMMS can also be integrated with much more complex systems, such as BMS, BEMS, and BIM, by sharing the collected data. This possibility, very often, is able to generate an even higher ROI because even in maintenance unity is strength.

Costs and ROI of a CMMS: finding the right balance for your Business needs

The CMMS software market has evolved in recent years, both in terms of available features and in terms of its cost.

Today, CMMS software is available at a much lower cost than in the past, and even some open-source experiments are available. See WorkTrek pricing here.

Each of these has different characteristics, different capabilities, and, of course, different ROIs.

Understanding the cost of a CMMS and the value it brings to your company requires careful analysis and a definition of the objectives that we want to impose on ourselves through the implementation of maintenance software.

It is important to carefully consider each of the elements, talk to the different suppliers, and get a complete picture, since the cost structure of a CMMS, more often than not, is also an indication of the necessary effort and services behind the product but which can turn out to be an ace in the hole and an extra gear to achieve success.

ROI is a fundamental index for evaluating the profitability of a company’s investments.