Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freePoor spare parts management can cause organizations to struggle with operational inefficiencies and costly downtime. Production delays, extended equipment outages, and increased maintenance costs can severely impact business performance without the right parts available when needed.

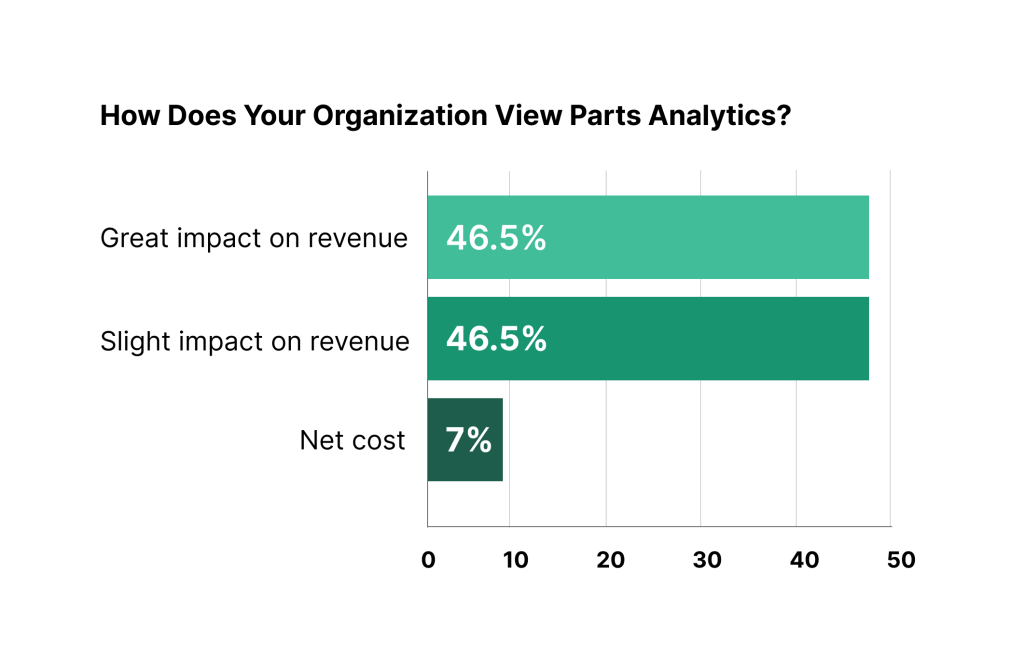

Illustration: WorkTrek / Data: Sparrow

Imagine equipment failing during a critical production cycle; the necessary part isn’t readily available. Every minute of downtime translates to lost revenue, frustrated customers, and strained maintenance teams. Additionally, overstocking parts can lead to excess costs, wasted resources, and storage inefficiencies.

Implementing an effective spare parts management system ensures the right parts are on hand when needed, reducing downtime and keeping operations running smoothly. This approach improves asset reliability, controls inventory costs, and supports a proactive maintenance strategy, ultimately optimizing overall operational efficiency and enhancing profitability.

Understanding Spare Parts Management

Spare parts management can keep equipment running smoothly. It involves stocking and tracking replacement components to fix broken machines quickly.

Importance of Spare Parts in Maintenance

You need working spare parts to fix equipment quickly. Having the right parts on hand lets maintenance teams make repairs immediately, keeping production going and saving money.

Source: WorkTrek

Critical spare parts need special attention. These are components that will shut down operations if they fail. Stocking them is a must to avoid costly delays.

Regular parts are also important. They prevent minor issues from turning into big problems. A good stock of common parts helps maintenance run smoothly.

Challenges in Spare Parts Management

Spare part management can be tricky. One big issue is deciding what to stock and how much.

Too few parts can lead to long repair delays, but too many waste money and space. It is important to find the right balance.

Tracking parts is another challenge. Organizing the spare parts area is crucial. Parts must be easy to find when needed.

Keeping data up to date is also challenging. Part numbers, locations, and quantities change often, and good systems are needed to keep information correct.

Predicting part needs is tough, too. Usage patterns can shift with equipment age and conditions.

Inventory Management Fundamentals

Effective spare parts management relies on solid inventory control practices. Balancing stock levels with costs is key to optimizing operations.

Stock Levels and Lead Times

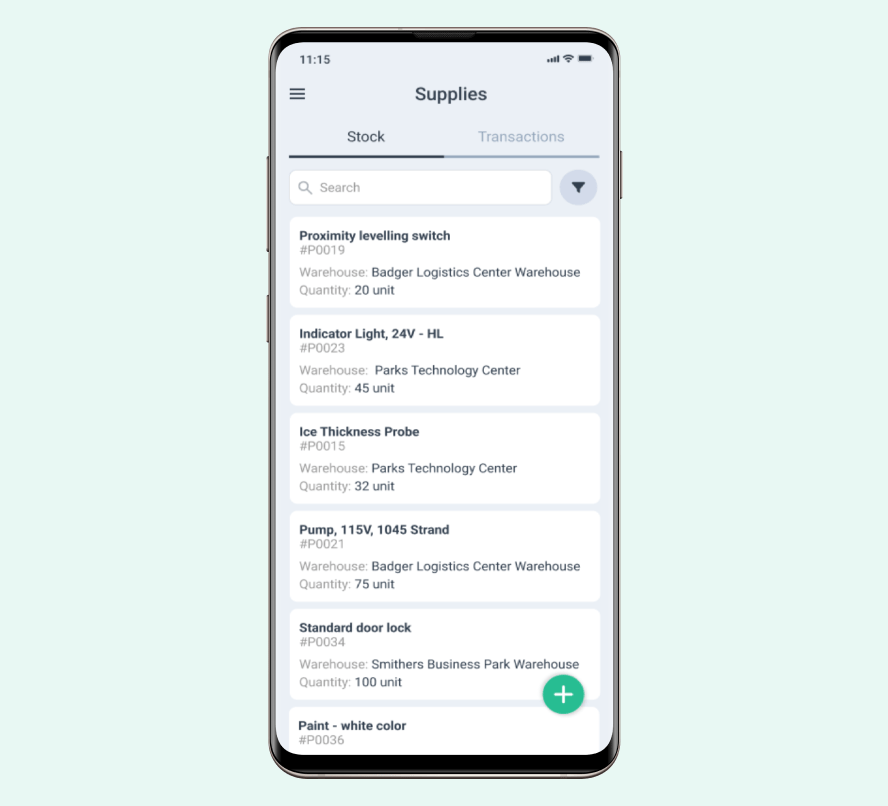

Computerized systems help track and manage parts inventory. These tools monitor stock levels and reorder points. They alert managers when supplies run low.

Source: WorkTrek

Lead times affect inventory decisions. Parts with long lead times may need higher stock levels. This prevents stockouts during critical repairs.

Safety stock acts as a buffer against demand spikes. It protects against supply chain disruptions. The right amount depends on part criticality and usage patterns.

Demand forecasting improves inventory accuracy. It uses historical data and trends to predict future needs.

This helps prevent overstocking or understocking of spare parts.

Inventory Cost Considerations

Holding costs include storage, insurance, and depreciation. These increase with larger inventories. Managers must balance holding costs against stockout risks.

Source: WorkTrek

Ordering costs cover purchasing and receiving parts. Frequent small orders increase these costs. Bulk orders may reduce per-unit costs but tie up more capital.

Centralized storage can lower overall inventory costs. It improves accuracy and accessibility. This approach often reduces duplicate stock across locations.

Obsolescence is a major cost risk for spare parts. Slow-moving items may become outdated before use. Regular inventory turnover reviews help identify at-risk parts.

Spare Parts Inventory Strategies

Managing spare parts inventory requires careful planning and smart tactics. The right approach can save money and keep operations running smoothly. Three key strategies help businesses optimize their spare parts management.

Economic Order Quantity (EOQ)

EOQ helps find the ideal order size for spare parts. It balances ordering and holding costs to minimize total inventory costs.

To calculate EOQ, you need annual demand, ordering cost per order, and holding cost per unit per year. The formula is:

EOQ = √[(2 x Annual Demand x Ordering Cost) / Holding Cost]

Using EOQ can lead to big savings. It reduces excess stock and frequent orders. This method works well for parts with steady demand.

CMMS Systems can help track inventory and calculate EOQ, making it easier to keep the right amount of parts on hand.

Just-In-Time (JIT) Inventory

JIT aims to have parts arrive precisely when needed. This cuts storage costs and reduces waste. It works well for expensive parts or those with short shelf lives.

JIT requires close ties with suppliers. You need fast, reliable delivery. Good forecasting is also key. Without it, you risk running out of critical parts.

Detailed maintenance records help with JIT. They show patterns in part usage. This info helps predict when you’ll need new parts.

JIT can be risky. A single delay can halt production. But when done right, it greatly improves efficiency.

ABC Analysis for Inventory Control

ABC analysis groups spare parts by value and importance. It helps focus management efforts where they matter most.

- A items: These are high-value, critical-to-operations items. They get the most attention because they are for critical equipment. These items are well suited for JIT.

- B items: Moderate value and importance.

- C items: These are low-value and many in number. You can use simpler controls for these items and keep higher inventory counts due to the lower cost of the material.

Illustration: WorkTrek / Data: MarktPilot

Use proper labeling and organization for ABC analysis. Each part should be easy to find and track, making the whole system more effective.

ABC analysis can cut costs and improve service. It ensures that you focus on the aspects of your business that matter most.

Maintenance Management and Planning

Effective maintenance management and planning are key to keeping spare parts in check. Good practices help reduce downtime and costs while boosting equipment reliability.

Preventive and Predictive Maintenance

Preventive maintenance involves regular, scheduled upkeep to prevent breakdowns. This can include tasks like cleaning, lubricating, and replacing worn parts. It helps catch small issues before they become big problems.

Predictive maintenance uses data and sensors to spot potential failures. By tracking things like vibration, temperature, and oil quality, teams can fix issues just in time, reducing unnecessary repairs and parts use.

Both methods help plan spare parts needs better. They make it easier to know what parts to stock and when to order them, leading to less waste and fewer surprise shortages.

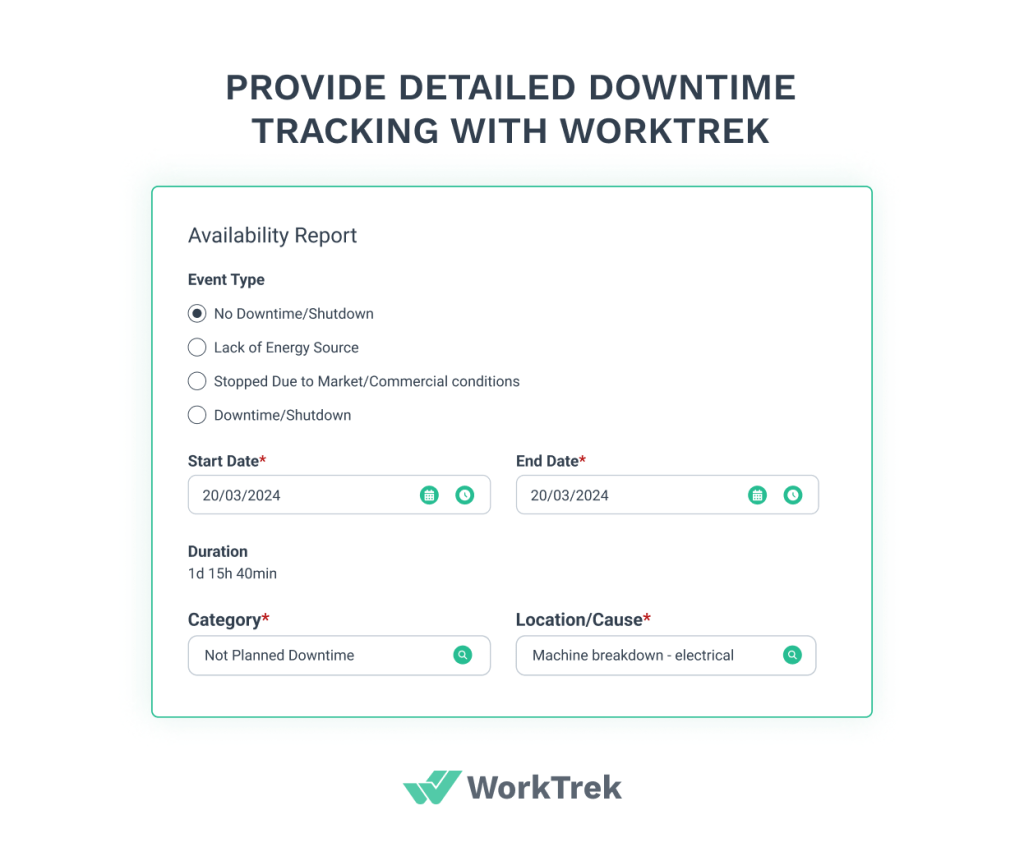

Maintenance Processes and Work Orders

A clear work order process is vital for smooth maintenance. It starts when someone spots an issue, or it’s time for scheduled upkeep. The work order should list the problem, needed parts, and steps to fix it.

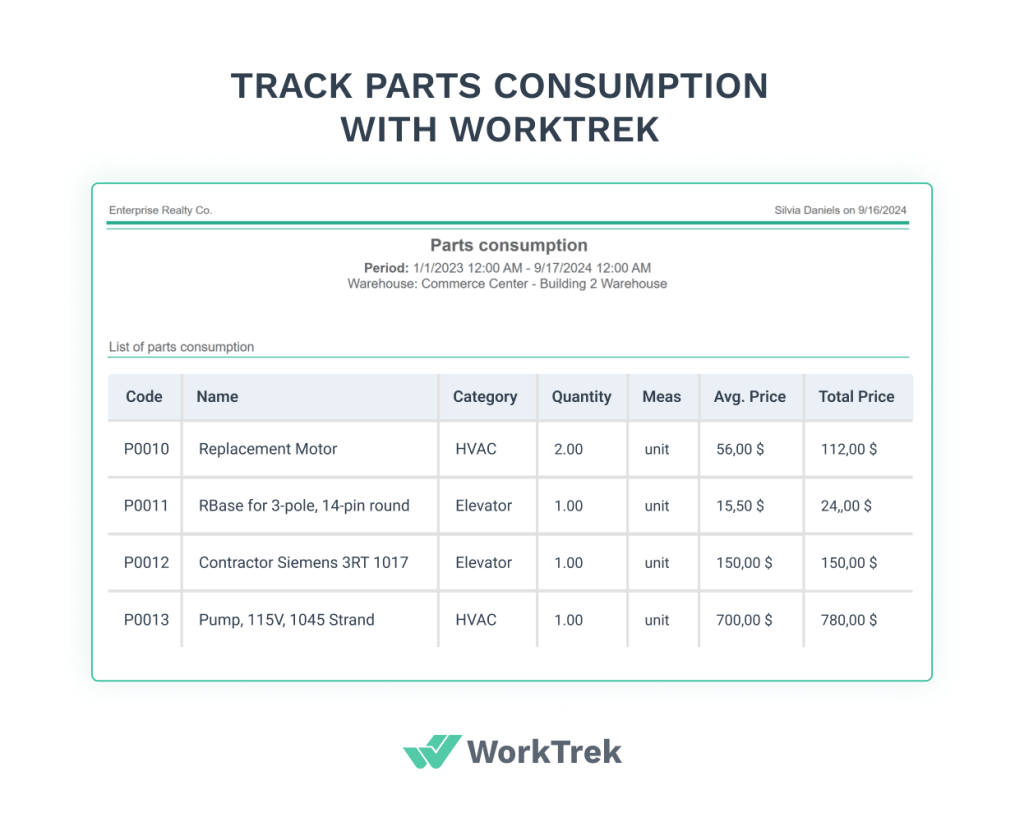

Source: WorkTrek

A computerized system to manage work orders helps track repairs and parts use. This data shows which parts are used most and how often, and it also helps plan future maintenance and parts orders.

Good processes ensure the right parts are on hand when needed. They also help avoid overstocking or running out of critical items. Clear steps for ordering, using, and restocking parts keep everything running smoothly.

Leveraging Technology in Spare Parts Management

Implementing modern technologies can help simplify spare parts management. It helps companies track inventory, plan maintenance, and make smart decisions about parts.

Computerized Maintenance Management System (CMMS)

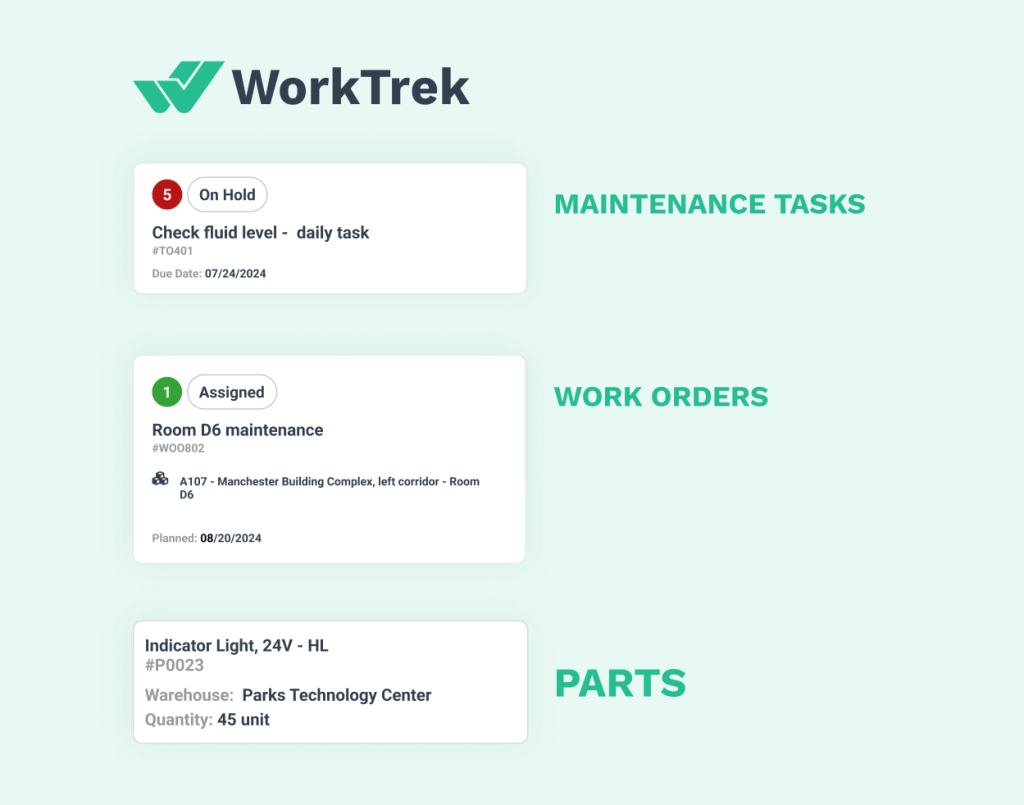

CMMS software is a powerful tool for spare parts management. It helps track parts, schedule maintenance, and manage work orders.

Source: WorkTrek

CMMS systems store data on:

- Part numbers and names

- Quantities in stock

- Locations of parts

- Costs and suppliers

- Usage history

This data helps managers:

- Order parts at the right time

- Avoid stockouts and excess inventory

- Plan maintenance tasks better

CMMS also tracks equipment history. This lets teams see which parts fail often and plan.

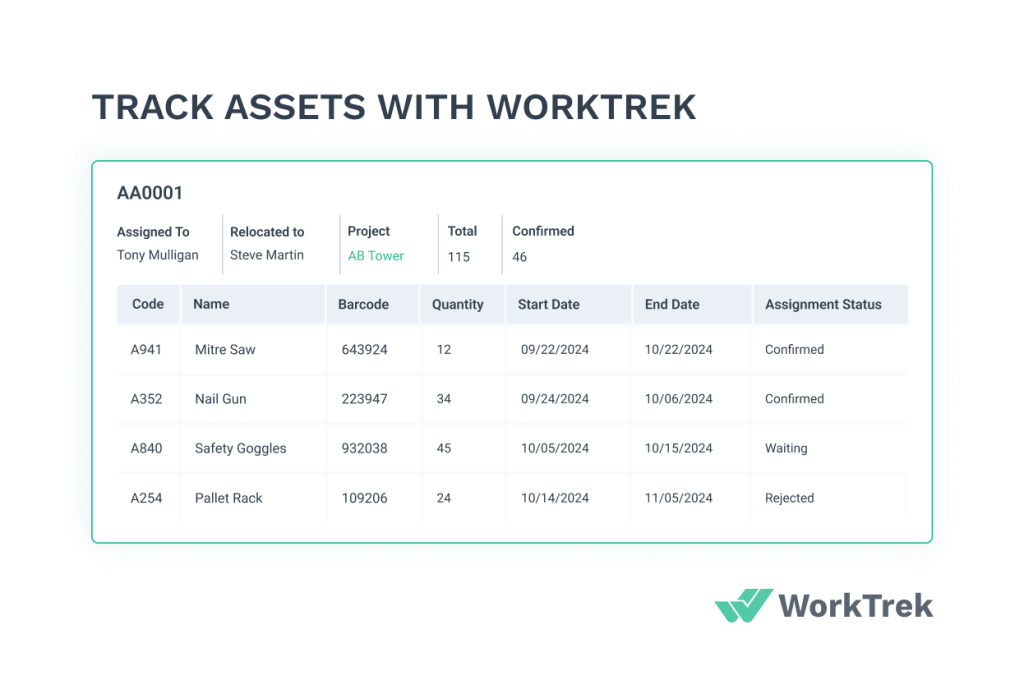

Inventory Tracking Technologies

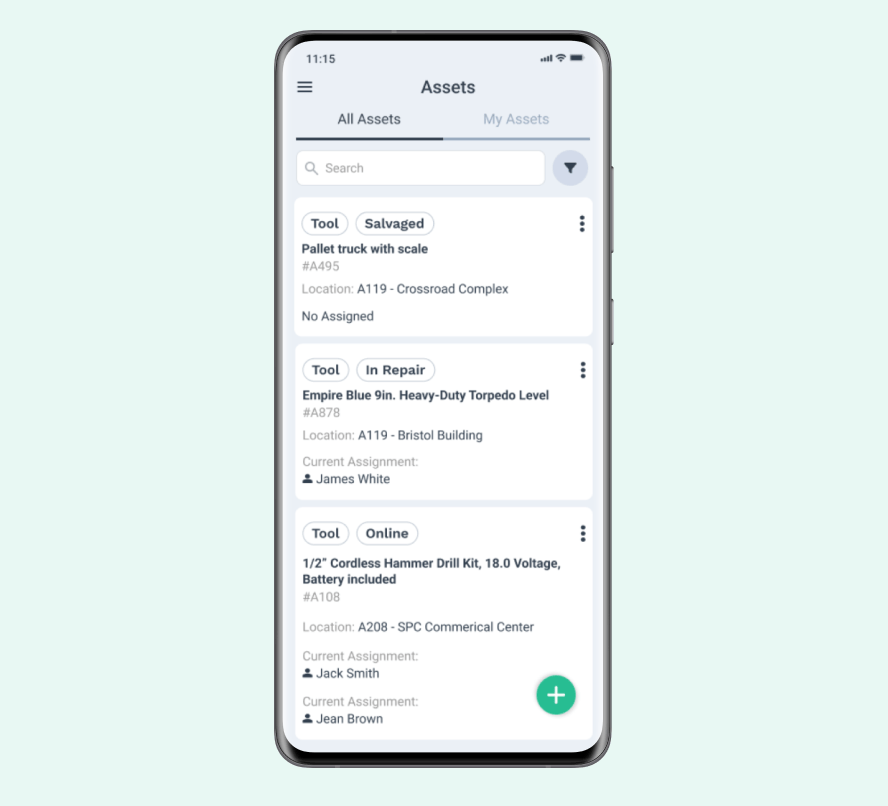

New tech makes tracking spare parts easier and more exact. Automated systems like barcode scanners and RFID tags help count and locate parts fast.

Barcode systems:

- Speed up part check-in and check-out

- Reduce human errors in data entry

- Update inventory counts in real-time

RFID tags go further:

- Track parts without line-of-sight

- Monitor part movements automatically

- Work well in harsh settings like warehouses

These tools give a clear view of stock levels. Managers can set alerts for low stock and track part usage trends. This leads to better forecasting and less waste.

Critical Spare Parts Management

Managing critical spare efficiency can help keep operations running smoothly. Properly managing these components can also prevent costly downtime and production losses.

Identifying and Managing Critical Components

Critical spares are parts needed to fix equipment quickly and avoid extended shutdowns. Common examples include bearings, motors, circuit boards, and valves. To identify critical spares, companies should:

• Review equipment failure history

• Consult with maintenance staff

• Consider lead times for replacements

• Assess impact on operations

Once identified, critical spares need proper management. This involves:

• Tracking inventory levels

• Setting reorder points

• Storing parts correctly

• Regular inspections

Using maintenance management systems can help organize and monitor critical spare parts. These tools provide real-time visibility into inventory and automate reordering processes.

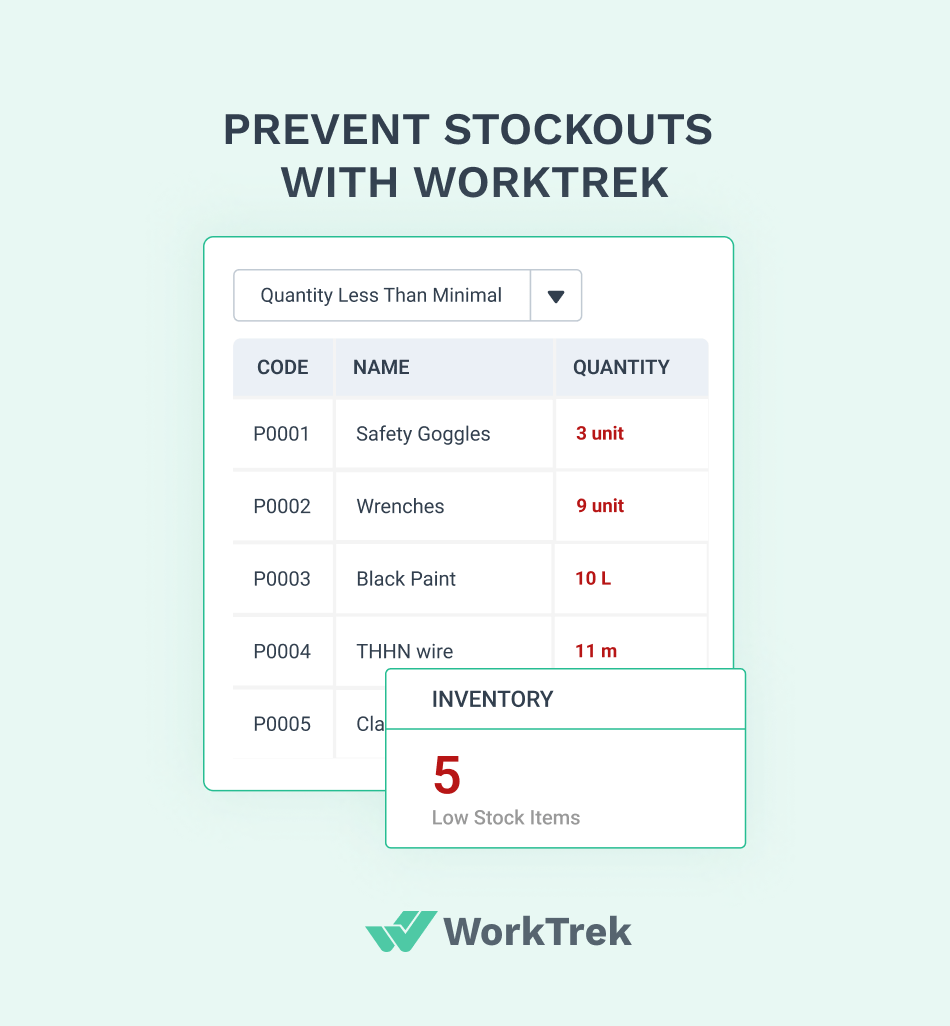

Optimizing Critical Spare Parts Inventory

Balancing inventory levels is key for effective critical spare parts management. Keeping too many parts ties up capital, while too few risk downtime. To optimize inventory:

• Analyze usage patterns

• Use data to forecast demand

• Set minimum and maximum stock levels

• Consider pooling parts across facilities

Critical spare parts management may also involve:

• Partnering with suppliers for quick deliveries

• Exploring refurbishment options

• Using predictive maintenance to reduce part needs

Regular audits help ensure the correct parts are on hand. This protects against obsolescence and identifies opportunities to reduce excess stock.

Procurement and Logistics

Implementing an efficient procurement and logistics of critical spare parts can lead to better outcomes. These processes ensure parts are available when needed while keeping costs down.

Effective Procurement Processes

Companies need clear processes to identify, order, and track parts. Regular audits help maintain optimal stock levels.

Digital systems streamline ordering. They can automate reorders when stock gets low, preventing shortages of crucial parts.

Supplier relationships matter, too. Good ties with vendors can lead to better prices and faster deliveries, so companies should review supplier performance often.

Bulk buying can cut costs for high-use items, but it may not work for all parts. Balance is key to avoiding excess inventory.

Logistics and Supply Chain Considerations

Spare parts logistics involves moving parts from suppliers to where they’re needed. Fast, reliable transport is crucial.

Warehousing is a big part of logistics. Parts must be stored safely and easy to find. Good warehouse management keeps stock organized.

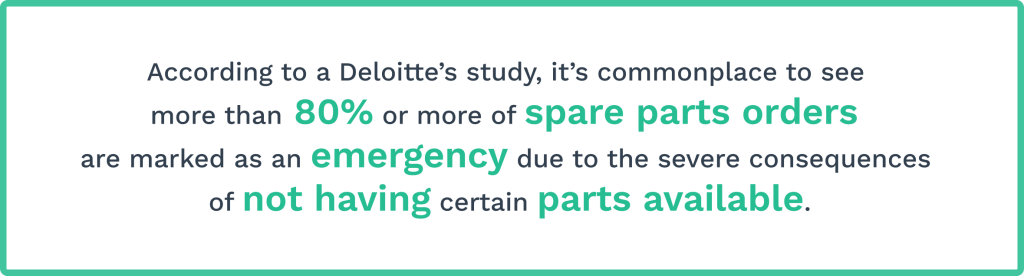

Illustration: WorkTrek / Data: Deloitte

Some companies use regional hubs, which can speed up deliveries to different areas. This is a way to balance central control with local access.

Just-in-time strategies can reduce storage costs. However, they require very reliable suppliers and transport, which is risky for critical parts.

Tech helps track parts through the supply chain. This improves visibility and helps plan better. It can also spot delays early.

Operational and Financial Performance

Good spare parts management impacts a company’s bottom line and daily operations. It affects inventory costs, equipment uptime, and overall asset performance.

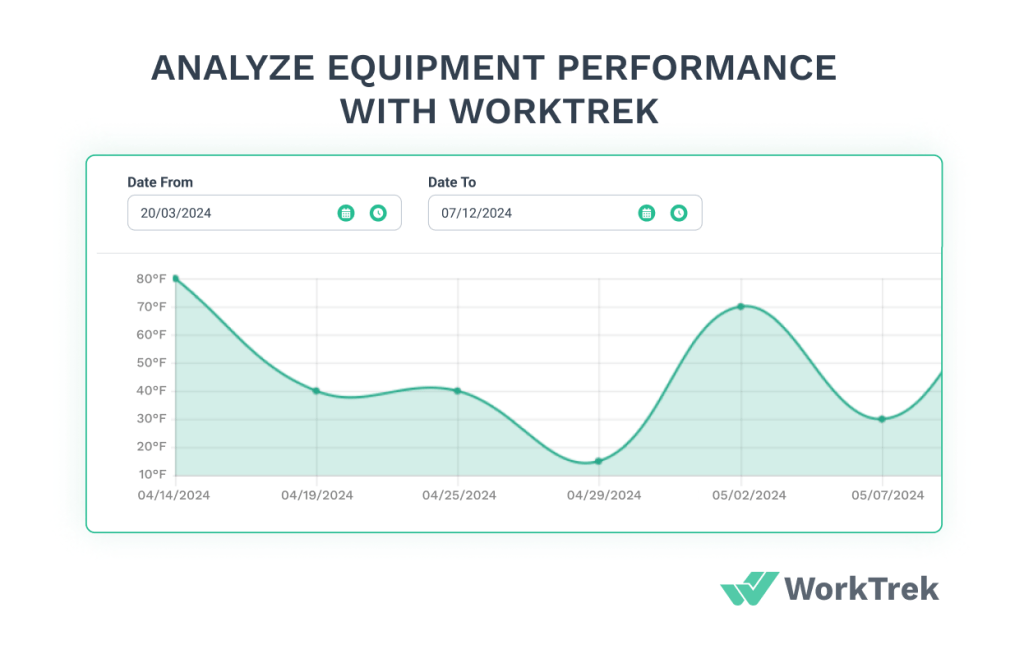

Analyzing Inventory and Equipment Performance

Companies should track parts usage and equipment downtime. This data helps predict future needs and identify problem areas.

Regular analysis of inventory turnover rates is crucial. It shows which parts move quickly and which ones sit on shelves. Fast-moving parts may need higher stock levels, while slow movers might be candidates for reduction or elimination.

Source: WorkTrek

Equipment performance metrics are also important. These include:

- Mean time between failures (MTBF)

- Mean time to repair (MTTR)

- Overall equipment effectiveness (OEE)

These numbers help teams spot trends and make smart maintenance and part-stocking decisions.

Reducing Inventory Costs and Minimizing Downtime

Optimizing spare parts inventory can significantly cut costs. Companies should aim to stock only what’s needed. Too much inventory ties up cash, and too little risks expensive downtime.

Source: WorkTrek

Some strategies to reduce costs include:

- Just-in-time ordering for non-critical parts

- Vendor-managed inventory programs

- Sharing inventory across multiple locations

Businesses must focus on critical spare parts to minimize downtime. These are essential items to keep operations running, and they should always be in stock, even if they are rarely used.

Predictive maintenance also helps prevent unexpected breakdowns. It uses data to forecast when parts might fail, allowing for planned replacements during scheduled downtimes.

Best Practices and Compliance

Good spare parts management keeps equipment running smoothly and helps companies follow important rules. Let’s look at key ways to manage spare parts well and stay compliant.

Spare Parts Management Best Practices

Using software to track parts is a top practice. A Computerized Maintenance Management System (CMMS) helps monitor inventory. It shows what parts are in stock and when to order more.

Source: WorkTrek

Having a clear work order process is crucial. This means deciding who starts work orders and how to label parts. It also includes getting supervisor approval when jobs are done.

Controlling inventory is key. Companies should:

- Keep only needed parts on hand

- Store parts in a clean, organized space

- Check stock levels often

- Use data to predict when parts will be needed

Training staff on proper parts handling improves quality. It helps avoid damage and ensures parts work when needed.

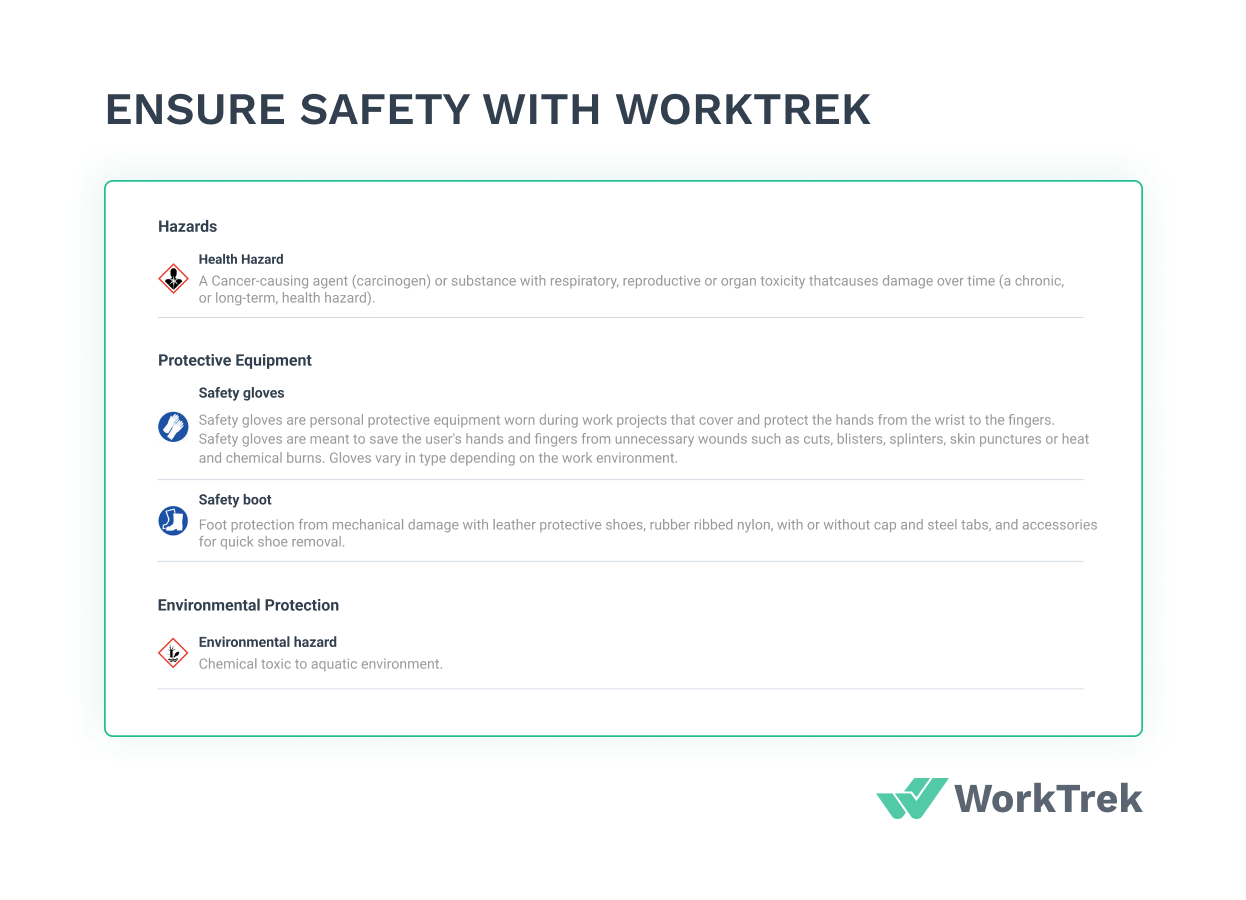

Compliance with Industry Regulations

Following rules keeps operations safe and legal. Companies must know which regulations apply to their industry. Common areas include:

- Safety standards for storing and handling parts

- Environmental rules for disposing of old parts

- Quality control measures for critical components

Source: WorkTrek

Regular audits help ensure compliance. These checks can find issues before they become big problem

Proper documentation is a must. This includes keeping records of:

- Parts purchases and usage

- Maintenance activities

- Safety inspections

Companies should stay up-to-date on changing regulations. This might mean joining industry groups or working with compliance experts.

Concluding Thoughts on Spare Parts Management

Proper inventory storage prevents damage and makes parts easily accessible when needed. This ensures quick repairs and minimizes equipment downtime.

Balancing stocking levels is key. Too little inventory can lead to costly delays, while excess inventory ties up capital and storage space. Regular analysis helps determine the right balance.

Effective spare parts management contributes to extended equipment lifespan. Regular maintenance and timely repairs, facilitated by readily available parts, keep the machinery running smoothly for longer.