Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways

- Clear maintenance goals and structured scheduling form the foundation of effective preventive maintenance programs

- Technology integration and proper team assignments maximize the efficiency and accuracy of maintenance activities

- Continuous performance tracking and safety protocols ensure long-term success and equipment reliability

Manufacturing facilities lose millions of dollars each year due to unexpected equipment breakdowns and unplanned downtime.

What is the most effective way to minimize downtime? Implement a preventative maintenance program.

There is a roadmap for implementing preventive maintenance and reducing downtime. This article highlights the eight key elements of preventive maintenance, which provide a framework that helps manufacturers reduce equipment failures by up to 70%.

When implemented correctly, these eight elements create a comprehensive process that addresses everything from equipment prioritization to performance tracking.

Manufacturers who master these fundamentals often see significant improvements in equipment reliability, worker safety, and operational efficiency within the first year of implementation.

What is Preventive Maintenance in Manufacturing?

Preventive maintenance involves scheduled inspections and repairs to keep equipment running before problems occur. This approach prevents unexpected breakdowns and extends machine life compared to waiting for equipment to fail.

What Is Preventive Maintenance?

Preventive maintenance is a proactive approach that involves regular, planned maintenance of machines and equipment to avoid unexpected failures.

In manufacturing facilities, preventive maintenance is used to inspect, clean, lubricate, and replace parts according to a predetermined schedule.

There are four main types of preventive maintenance: time-based, usage-based, condition-based, and predictive maintenance.

Four Main Types of Maintenance

Time-Based Maintenance

This is when maintenance activities are performed based on predetermined time intervals, such as weekly, monthly, or annually. These maintenance activities are performed regardless of the equipment’s actual condition. Examples include changing HVAC filters every three months or conducting monthly safety inspections.

Usage-Based Maintenance

Maintenance is only triggered based on equipment usage metrics like operating hours, cycles completed, or miles traveled. For instance, changing a vehicle’s oil every 5,000 miles or replacing a printer’s parts after 100,000 pages printed.

Condition-Based Maintenance

This approach uses real-time monitoring of equipment condition indicators to determine when maintenance is needed. Maintenance is performed only when specific indicators indicate a decrease in performance or a potential upcoming failure. Examples include vibration analysis on rotating equipment or thermal imaging to detect hot spots.

Predictive Maintenance

The most advanced form uses data analytics, machine learning, and IoT sensors to predict when equipment failure is likely to occur. This allows maintenance to be scheduled just before failure is expected, optimizing both equipment uptime and maintenance costs.

The Role of Preventive Maintenance in Manufacturing Productivity

It is not a mystery that well-maintained equipment operates optimally. This empowers production teams to focus on meeting goals without interruptions.

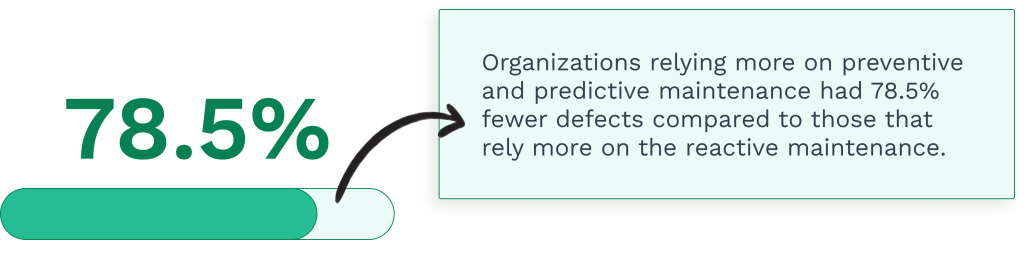

With machines operating with consistent performance, maintenance organizations can enhance product quality and decrease defects.

Improved Production Scheduling

Production scheduling and output become more reliable when equipment failures are rare. Manufacturers can make delivery commitments with confidence. Customer satisfaction improves when orders ship on time.

Increased Labor Efficiency and Work Schedules

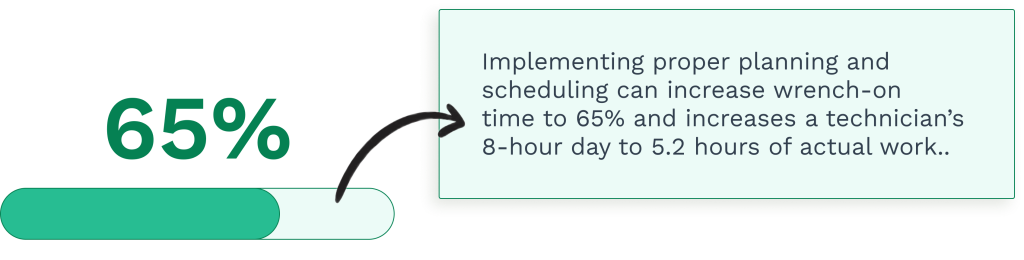

You can increase labor efficiency by allocating maintenance teams to productive tasks instead of emergency repairs.

It will also be easier for maintenance teams to plan their work schedules in accordance with production needs. This level of coordination prevents conflicts between maintenance and production activities.

Improved Quality

Quality control greatly benefits from stable equipment performance. Machines that run within specifications produce consistent results. This reduces waste and rework costs while improving customer satisfaction.

Improved Energy Efficiency

Energy efficiency often improves with proper maintenance and can lead to reduced power bills.

For example, clean, well-lubricated equipment typically consumes less power. This reduces operating costs and supports sustainability goals.

Element 1: Establish Clear Maintenance Goals and Strategies

The first step in the process is to specify maintenance goals that directly support business objectives.

Align Maintenance Goals with Business Objectives

Manufacturing maintenance goals must align directly with company priorities, such as production targets, quality standards, and profit margins.

When maintenance teams understand how routine maintenance tasks impact the bottom line, they make more informed decisions about resource allocation.

For example, some common business-aligned maintenance goals should include reducing unplanned downtime by 25%, cutting maintenance costs per unit produced, or improving equipment availability to 95%.

These goals should be specific, time-bound, and closely tracked via KPI’s.

Production-focused goals

Targets Overall Equipment Effectiveness (OEE) improvements. An OEE increase from 75% to 85% directly translates to higher output, thereby reducing the need for additional equipment investment.

Cost-focused goals

Downtime costs money, and transitioning from reactive to preventive maintenance should result in reduced maintenance costs. A common goal would be for companies to aim for 80% planned maintenance and 20% reactive work, which would help reduce maintenance costs.

Quality-focused goals

As the old Ford commercial used to say: Quality is Job 1. Start by linking equipment performance to product defects. Maintaining calibration schedules and precision equipment has a direct impact on product quality metrics.

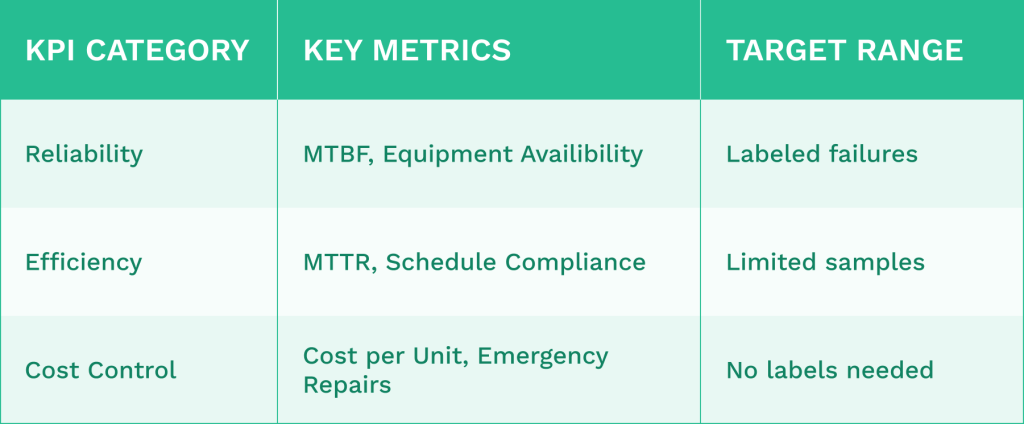

Setting and Measuring Key Performance Indicators

Manufacturing maintenance requires specific KPIs to measure success and drive continuous improvement.

With the right metrics, teams identify problems early and optimize their maintenance strategy.

Equipment-focused KPIs include Mean Time Between Failures (MTBF), Mean Time to Repair (MTTR), and Overall Equipment Effectiveness (OEE).

These metrics directly measure the effectiveness of the maintenance program.

Cost-focused KPIs

Tracks maintenance cost per unit produced, emergency repair frequency, and labor efficiency. These help control spending while maintaining performance.

Schedule compliance

Measures how often planned maintenance happens on time. High compliance rates typically exceed 90% for effective programs.

Regular KPI reviews enable continuous improvement by identifying trends and problem areas. Monthly reviews allow teams to to adjust their strategies and resource allocation based on actual performance data.

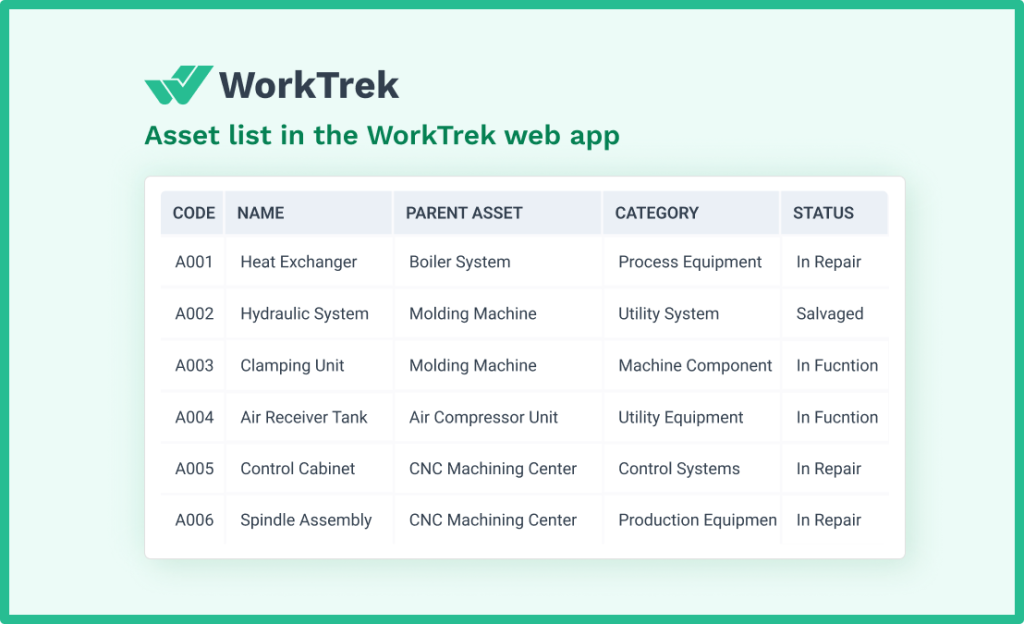

Element 2: Asset Inventory and Critical Equipment Prioritization

Begin by documenting all equipment and systems in detail to ensure optimal operations.

Creating and Maintaining an Asset Inventory

An asset inventory is the starting block of a robust preventive maintenance plan.

It is a process that can help you create a comprehensive list of all equipment and machinery for your facility.

Essential Information to Document:

- Equipment identification numbers and serial numbers

- Manufacturer details and model specifications

- Installation dates and warranty information

- Location within the facility

- Operating specifications and capacity ratings

Maintenance teams must update the inventory regularly to reflect equipment additions, modifications, and retirements. Digital asset management systems streamline this process by allowing real-time updates and centralized data storage.

Accurate documentation prevents equipment from being overlooked during maintenance planning. It also helps maintenance personnel quickly locate equipment specifications and historical data when problems arise.

Criticality Analysis for Equipment

Criticality analysis evaluates how equipment failures impact organizational performance to systematically rank plant assets for work prioritization and reliability improvement initiatives. This process enables manufacturers to focus their resources on the most critical equipment.

Key Factors in Criticality Assessment:

- Impact on production output and quality

- Safety risks to personnel

- Cost of equipment failure and replacement

- Availability of backup systems or redundancy

- Regulatory compliance requirements

Criticality scores are numerical values assigned to assets based on specific criteria that reflect their importance to the organization.

Higher scores generally indicate critical equipment that requires more frequent maintenance and faster response times.

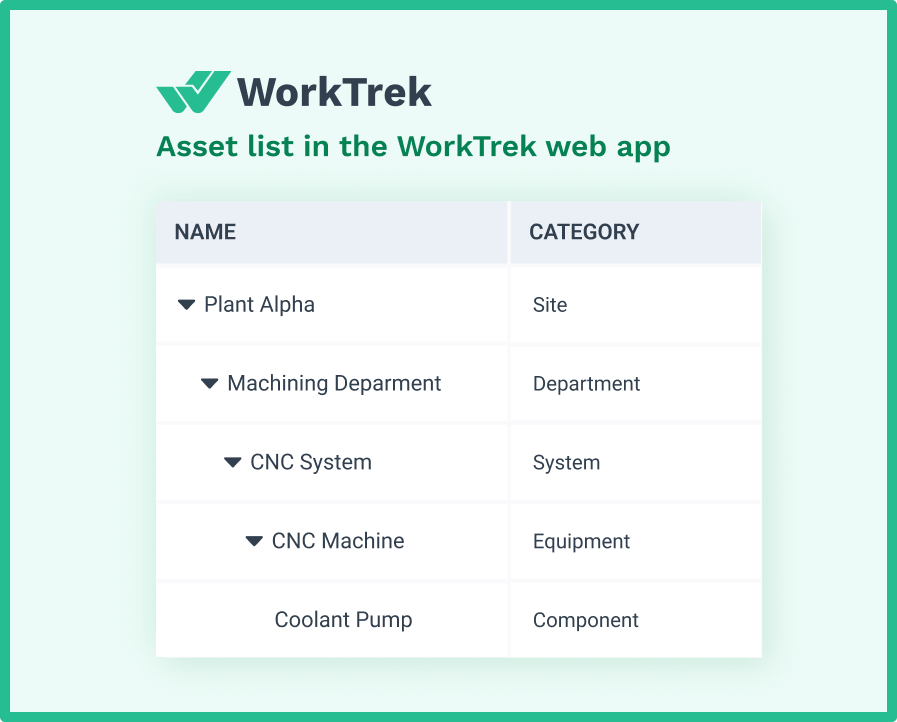

Asset Hierarchy and Classification

Asset hierarchy organizes equipment into logical groups based on function, location, or production line. This structure helps maintenance teams understand the relationships and dependencies among equipment.

Common Classification Levels:

- Site or Facility Level – Main production location

- Area or Department Level – Specific production areas

- System Level – Related equipment groups

- Equipment Level – Individual machines

- Component Level – Parts within machines

Classification systems should align with the facility’s organizational structure and production processes.

Many manufacturers use equipment codes that indicate location, function, and criticality level.

This hierarchy enables maintenance teams to plan work more effectively.

When critical equipment requires maintenance, teams can identify dependent systems that may be affected during the work.

Asset reliability improves when maintenance teams understand how individual components contribute to overall system performance.

Proper classification also facilitates effective spare parts management and efficient maintenance scheduling.

Element 3: Develop a Structured Preventive Maintenance Schedule

Without a well-structured maintenance schedule, implementing a comprehensive preventive maintenance program will be very difficult.

With a preventive maintenance schedule, you can set up a structured plan that occurs at regular intervals, rather than waiting for breakdowns.

Types of Preventive Maintenance Scheduling Methods

There are four popular preventive maintenance scheduling methods:

Calendar-based scheduling

This approach assigns maintenance tasks to specific dates, regardless of equipment usage. Monthly inspections and quarterly overhauls follow a calendar-based scheduling approach. This method works well for equipment that runs consistently.

Usage-based scheduling

Triggers maintenance based on predetermined operating hours or production cycles. For instance, a machine might require service every 500 operating hours or after 10,000 units have been produced.

Condition-based scheduling

Uses real-time monitoring data to determine maintenance timing. Sensors track vibration, temperature, and other indicators, which can then trigger a scheduling event. This happens when the values exceed normal ranges.

Hybrid scheduling

Combines multiple methods for comprehensive coverage. Critical equipment may utilize both time-based inspections and condition monitoring to achieve maximum reliability.

Time-Based and Usage-Based Scheduling

As described earlier in this blog, time-based maintenance schedules tasks according to calendar intervals, such as weekly, monthly, or annually.

The goal is to provide predictable maintenance windows that align with production schedules. This approach can ensure a consistent maintenance intervals.

Advantages of time-based scheduling:

- Simple to plan and manage

- Consistent maintenance intervals

- Easy integration with production calendars

- Predictable resource requirements

Usage-based scheduling benefits:

- More accurate maintenance timing

- Prevents over-maintenance of lightly used equipment

- Accounts for varying production demands

- Better alignment with actual wear patterns

Manufacturing facilities often combine both approaches, leading to a hybrid approach.

For example, emergency generators might receive monthly inspections (time-based) plus service every 100 operating hours (usage-based).

Floating Versus Fixed Schedules

Unlike usage- or time-based maintenance, fixed preventive maintenance schedules establish specific dates for maintenance tasks that cannot be altered.

Monthly inspections, which are part of a preventive maintenance process, are designed to happen on the same date each month, regardless of other factors.

One benefit of fixed schedules is that they provide structure and predictability.

Maintenance teams are aware of exactly when tasks will occur and can follow well-established preventive maintenance checklists.

The biggest benefit is that production lines can plan around these predetermined windows.

Floating preventive maintenance schedules, on the other hand, are adjusted based on equipment condition and operational needs.

Tasks can shift within acceptable timeframes, and most importantly, can be performed without compromising the reliability of critical equipment.

Fixed schedule characteristics:

- Rigid timing requirements

- Consistent planning periods

- Clear accountability

- Potential for unnecessary maintenance

Floating schedule features:

- Flexible timing windows

- Condition-driven adjustments

- Optimized resource utilization

- Reduced maintenance costs

Successful PM schedules incorporate both approaches as part of an effective preventive maintenance strategy.

The optimal strategy is for critical safety systems to use fixed schedules to ensure compliance. At the same time, implement more flexible schedules for less critical items.

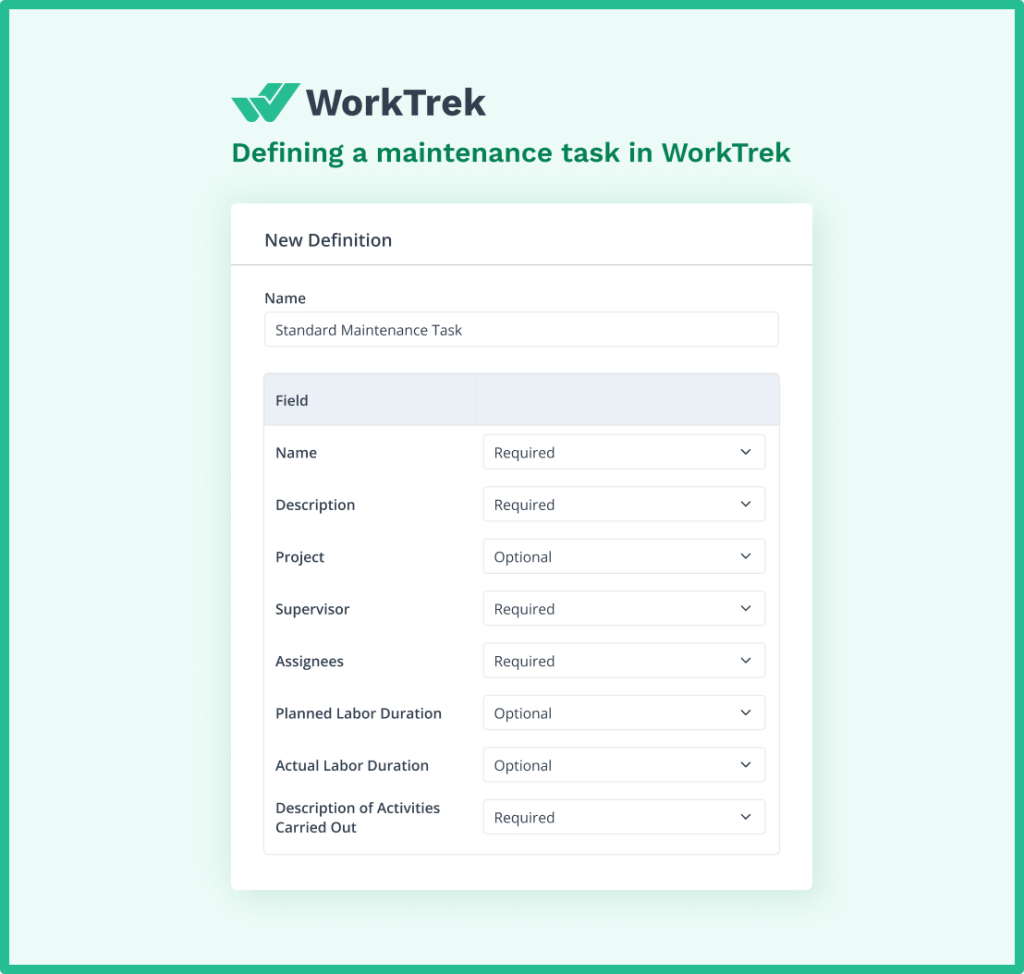

Element 4: Defining Preventive Maintenance Tasks and Procedures

Defining your tasks clearly creates the backbone of effective manufacturing maintenance programs.

Standardizing Maintenance Tasks

With standardized maintenance tasks, organizations can create consistency across all manufacturing operations.

Each task must include specific steps, required tools, and expected outcomes.

Manufacturing facilities can especially benefit from defining preventive maintenance procedures that include task duration and the required skills.

This approach can eliminate confusion during execution and reduce equipment downtime.

Task standardization includes:

- Step-by-step procedures

- Required safety protocols

- Tool and material lists

- Quality checkpoints

- Completion criteria

Creating and maintaining standard procedures reduces training time for new technicians and streamlines the onboarding process.

These procedures also help experienced workers follow the same proven methods every time.

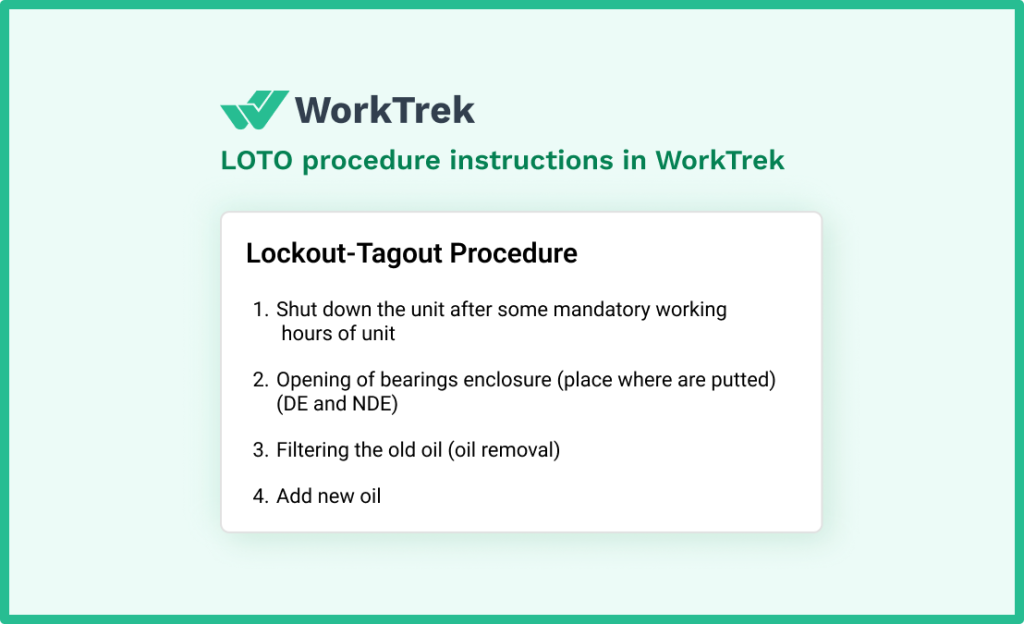

Each standardized task should specify lockout/tagout requirements when applicable. Safety considerations must be built into every procedure from the start.

Routine and Preventive Maintenance Activities

Routine maintenance is the foundation of any preventive maintenance plan.

These activities include inspections, adjustments, calibrations, and component replacements.

Common routine maintenance activities:

- Visual inspections using sight, sound, and touch

- Lubrication of moving parts

- Filter replacements

- Belt tension adjustments

- Cleaning procedures

Documentation of Procedures and Checklists

Don’t forget about proper documentation. Any solid preventive maintenance plan should include thorough documentation of all procedures, which will help maintenance teams perform their jobs more effectively and lead to cost savings.

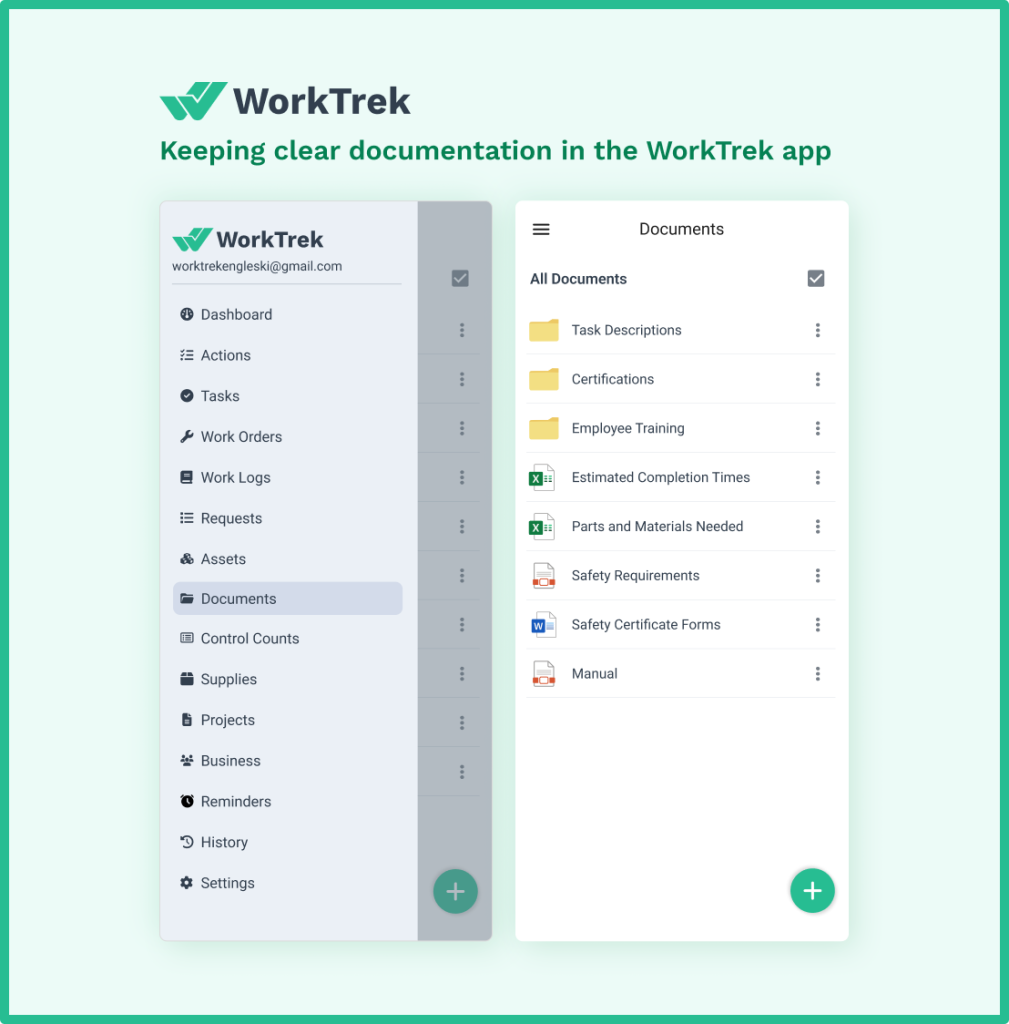

Implementing a CMMS system, such as WorkTrek, can help you organize and digitize all your documentation and processes.

Digital systems are more effective than paper-based methods for tracking and updating procedures.

Maintenance checklists guide technicians through each task step-by-step.

Good documentation includes:

- Clear task descriptions

- Required certifications or training

- Estimated completion times

- Parts and materials needed

- Safety requirements

Digital documentation allows real-time updates when procedures change. It also enables better tracking of completed tasks and identified issues.

Checklists should include spaces for technician notes and observations, as well as any relevant safety guidelines.

This feedback helps improve procedures and identify potential problems early.

Regular review and updates ensure that documentation remains current with equipment changes and new best practices.

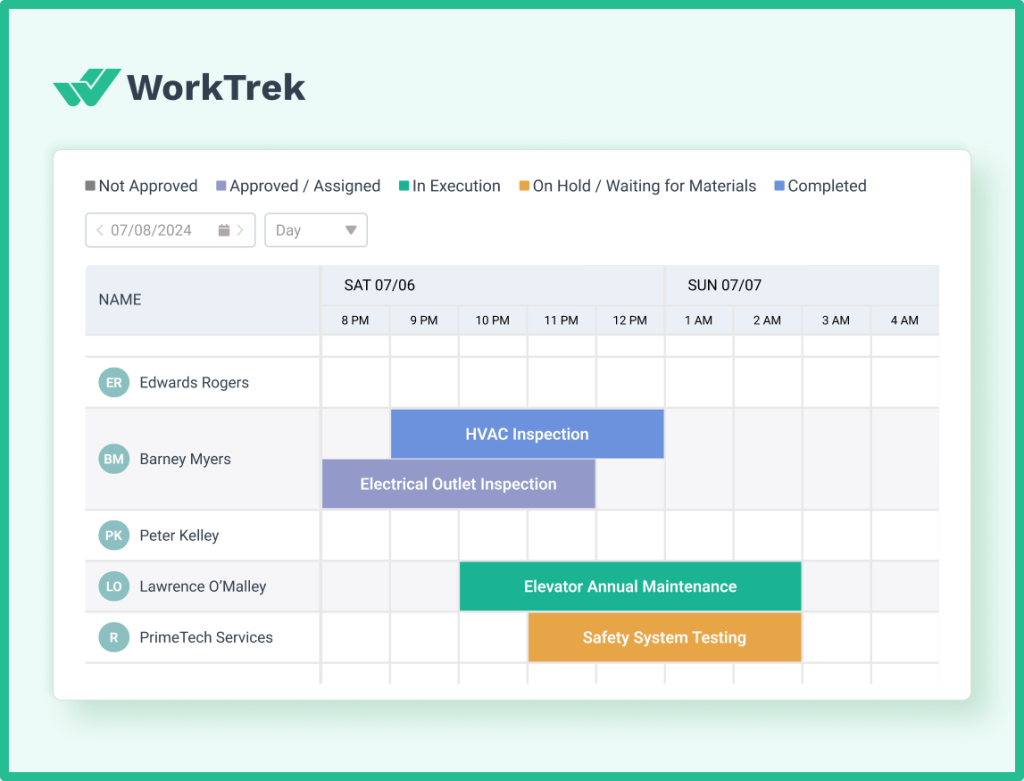

Element 5: Leveraging Maintenance Technology and Data Management

Modern manufacturing relies heavily on technology to streamline maintenance operations and improve equipment reliability.

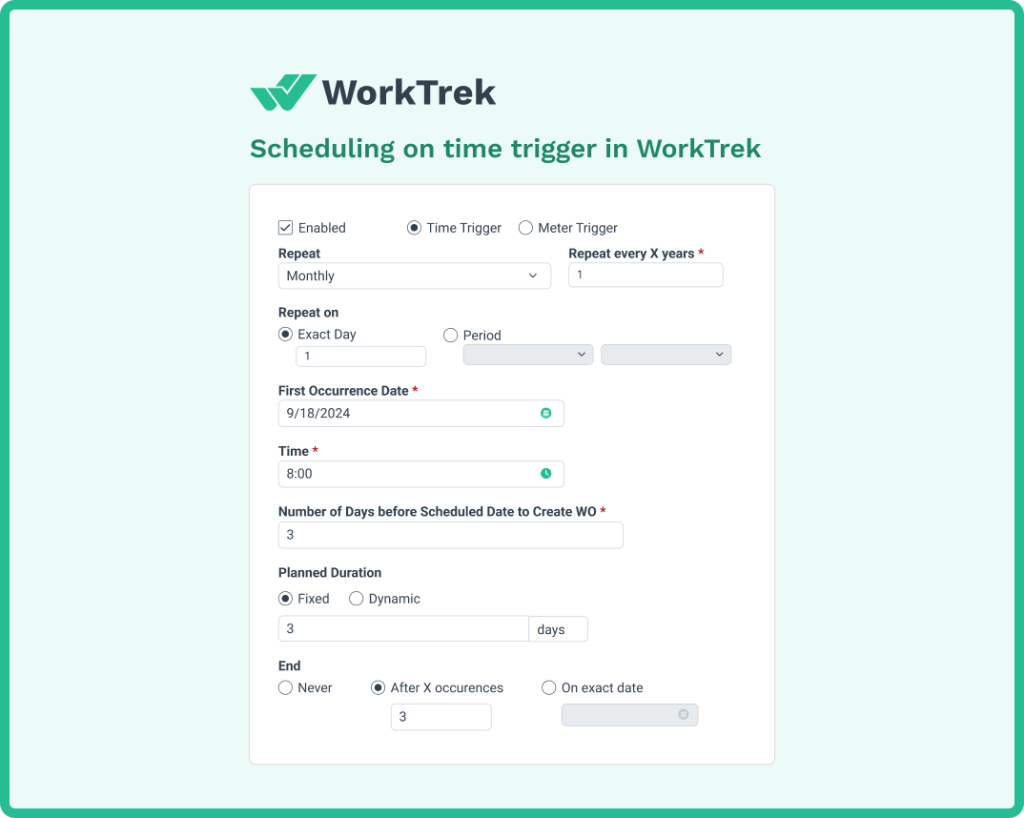

Implementing a CMMS like WorkTrek can streamline preventive Maintenance by centralizing asset data, automating workflows, and generating reports.

Role of CMMS and Maintenance Software

A CMMS is the nerve center of any modern preventive maintenance program.

With a CMMS, maintenance teams can centralize all maintenance activities on a single holistic platform, where they can track work orders, schedule tasks, and monitor equipment performance.

A Computerized Maintenance Management System, can automate routine maintenance scheduling based on time intervals, usage hours, or equipment cycles. Maintenance teams receive automatic notifications when tasks are due, eliminating the risk of missed maintenance windows.

Key CMMS functions include:

- Asset tracking and inventory management

- Work order creation and assignment

- Maintenance history documentation

- Parts and supply management

- Cost tracking and reporting

Preventive maintenance software reduces paperwork and manual tracking errors. Technicians can access equipment manuals, maintenance procedures, and checklists directly through mobile devices on the factory floor.

The maintenance system also generates detailed reports showing equipment performance trends, maintenance costs, and compliance records. This data helps managers make informed decisions about equipment replacement and maintenance budgets.

Using AI and ML in Modern Maintenance Operations

Artificial intelligence and machine learning technologies are transforming how manufacturers approach equipment maintenance. AI algorithms analyze sensor data from machinery to detect early warning signs of potential failures before they occur.

Machine learning models can learn from historical maintenance data to predict when specific components are likely to fail. These predictions allow maintenance teams to schedule repairs during planned downtime rather than responding to unexpected breakdowns.

AI applications in maintenance include:

- Vibration analysis for rotating equipment

- Thermal imaging pattern recognition

- Oil analysis trend monitoring

- Energy consumption anomaly detection

ML algorithms increase in accuracy over time as they’ve processed more data from equipment sensors and maintenance records.

The technology enables manufacturers to transition from time-based maintenance to condition-based maintenance strategies.

Tracking and Analyzing Maintenance Data

Maintenance data collection and analysis are foundational to an effective preventive maintenance program.

Collecting and analyzing large volumes of maintenance data can be daunting without proper systems, making organized data management essential for success.

Manufacturing facilities generate vast amounts of maintenance-related information daily. This includes equipment runtime hours, failure rates, repair costs, and technician time logs.

Critical maintenance metrics to track:

- Mean Time Between Failures (MTBF)

- Mean Time To Repair (MTTR)

- Overall Equipment Effectiveness (OEE)

- Maintenance cost per unit produced

- Planned vs. unplanned maintenance ratios

Using data analytics tools, you can identify patterns and trends that reveal equipment performance issues. For example, analyzing failure data may reveal that certain components consistently fail after a specific number of operating hours.

Regular data analysis enables continuous improvement of maintenance procedures. Teams can identify which preventive maintenance tasks provide the greatest value and adjust schedules accordingly.

Maintenance data also supports regulatory compliance by providing documented evidence of equipment inspections and repairs. This documentation proves essential during safety audits and quality certifications.

Element 6: Assigning Roles and Building a Strong Maintenance Team

Like any initiative, successful preventive maintenance depends on clearly defined team roles, comprehensive training programs, and open communication channels between all stakeholders.

Strong technical expertise, efficient communication, and a proactive approach are critical for teams focused on preventive rather than reactive maintenance strategies.

Defining Team Responsibilities

By defining roles clearly, it can reduce equipment failure and costly repairs. Defining clear roles and responsibilities in maintenance teams is absolutely critical for preventive maintenance work.

RACI Matrix

One approach that successful organizations often implement is known as the RACI Matrix.

RACI provides a practical framework for delegation. RACI stands for Responsible, Accountable, Consulted, and Informed.

This system is designed to clarify who performs each task and when.

Key maintenance team roles include:

- Maintenance Manager: Plans, schedules, and oversees operations

- Lead Technician: Supervises daily work and troubleshoots complex issues

- Maintenance Technicians: Execute preventive tasks and repairs

- Planner/Scheduler: Coordinates work orders and resource allocation

- Storeroom Coordinator: Manages parts inventory and procurement

A typical maintenance team can range from a couple of on-call maintenance technicians to dozens of full-time professionals. Team size depends on the organization’s size, budget, and the complexity of the equipment.

Maintenance managers typically assign roles based on individual skills and experience. Each person must understand their specific duties within the preventive maintenance program.

Training and Continuous Education

Training empowers maintenance teams to work proactively and access information quickly.

Essential training areas include:

- Equipment-specific procedures and safety protocols

- Preventive maintenance techniques and best practices

- CMMS software operation and work order management

- Root cause analysis and problem-solving methods

- New technology updates and industry standards

Digital resources improve training accessibility. Maintenance operations benefit when manuals, plans, and procedures are digitized into programs accessible from anywhere in the facility.

Regular skills assessments can quickly identify knowledge gaps. Training sessions should address feedback from maintenance team members to build confidence with new technologies and procedures.

Don’t overlook cross-training. It can be flexible within maintenance operations. When technicians understand multiple equipment types, scheduling becomes easier and coverage improves during absences.

Effective Communication Among Stakeholders

Strong communication and practical problem-solving skills are critical in building a maintenance excellence team. Clear communication helps team members understand tasks and expectations.

Regular check-ins and standups build trust and reduce anxiety about performance issues. Frequent communication prevents team members from feeling overwhelmed when discussing roadblocks that keep them behind schedule.

Communication channels should connect:

- Maintenance planning with operations schedules

- Technicians with supervisors and management

- Maintenance teams with procurement and inventory

- Field workers with CMMS systems and documentation

Creating data-driven communication can improve decision-making in maintenance operations. Teams should develop reports based on departmental goals and review them regularly during equipment maintenance cycles.

Feedback loops ensure continuous improvement. When technicians report issues with procedures or equipment, management must respond with training or process adjustments.

Element 7: Ensuring Worker Safety and Preventing Equipment Failures

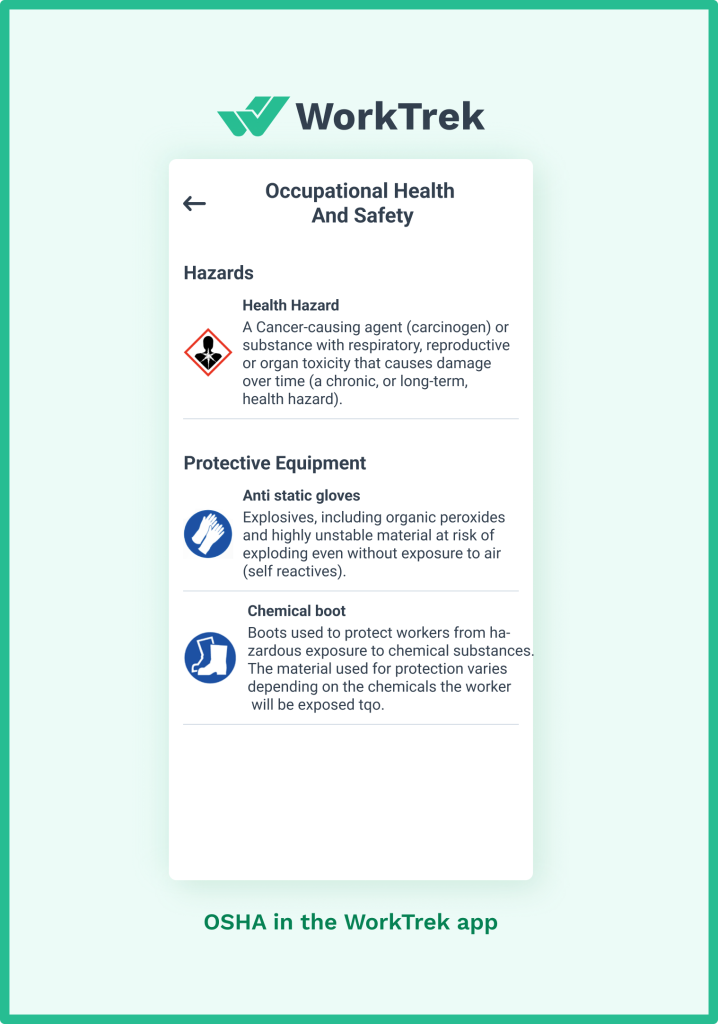

Successful maintenance organizations emphasize safety protocols. They ensure that their maintenance teams have the proper protective equipment, environmental hazards management, and systematic work order processes that prioritize both human safety and asset reliability.

PPE and Safety Procedures

Personal protective equipment is the first line of defense against workplace injuries during maintenance activities. Hard hats protect against falling objects and head impacts during overhead work. Safety glasses shield eyes from chemical splashes, metal shavings, and debris.

Steel-toed boots prevent foot injuries from heavy equipment and falling tools. Cut-resistant gloves protect hands when handling sharp components or metal edges.

Lockout/tagout procedures prevent accidental equipment startup during maintenance work. Workers must isolate energy sources and apply physical locks before beginning repairs. This prevents electrocution, crushing injuries, and equipment damage.

Safety training programs teach workers to identify hazards before they cause accidents. Regular safety meetings review the proper use of PPE and emergency procedures.

These programs can greatly reduce maintenance costs by preventing injury-related work stoppages and equipment damage.

Health, Safety, and Environmental Considerations

Chemical exposure poses serious health risks during equipment maintenance. Cleaning solvents, hydraulic fluids, and lubricants can cause skin irritation or respiratory problems. Proper ventilation systems remove harmful vapors from work areas.

Material Safety Data Sheets (MSDS) provide critical information about chemical hazards and safe handling procedures. Workers should have a clear understanding of these documents before using any chemicals.

Environmental protection prevents costly violations and cleanup expenses. Spill containment systems catch leaked fluids before they reach drains or soil.

Secondary containment around chemical storage areas prevents environmental contamination.

The Safety, Health & Environment pillar integrates workplace safety practices within the operations to achieve zero accidents. This approach can reduce unplanned downtime while cutting environmental compliance costs.

Work Order Management to Support Safe Operations

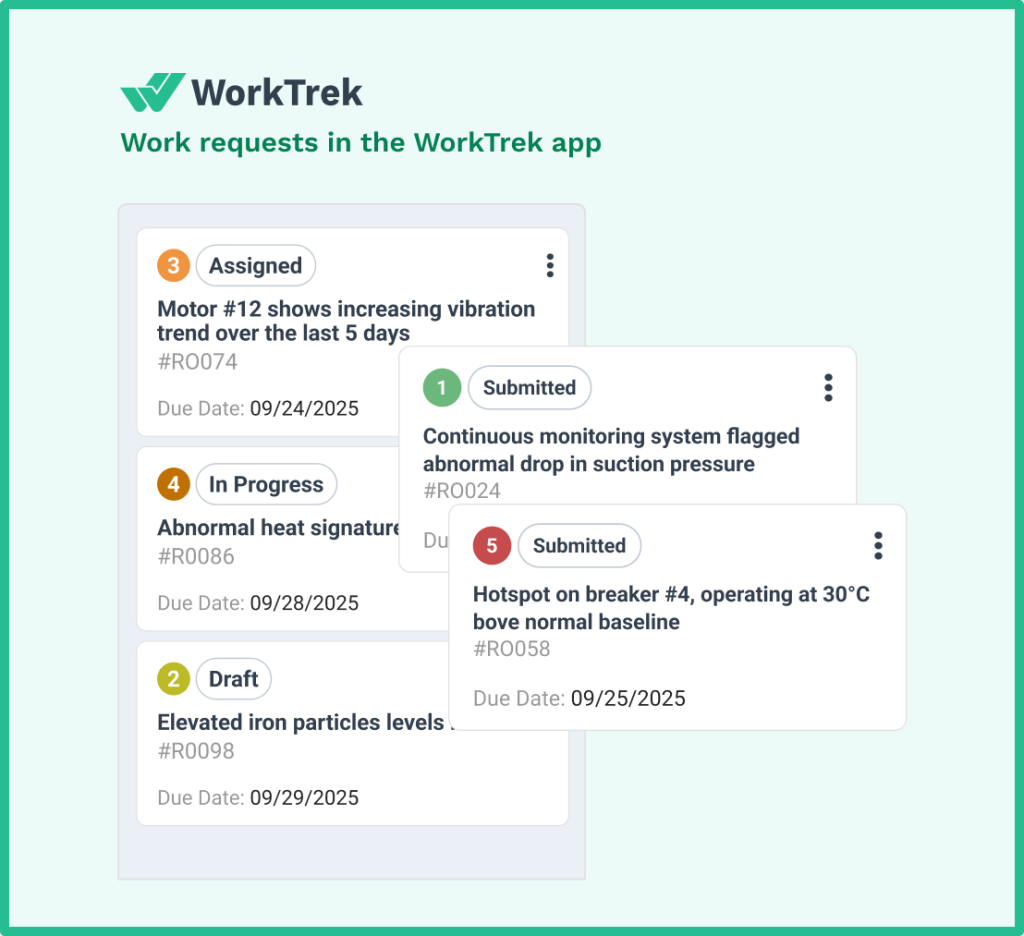

Preventive maintenance checklists and work orders should include all mandatory safety checkpoints as part of the repair process.

Each work order should specify the required PPE, safety procedures, and hazard warnings. This prevents workers from starting dangerous tasks without proper protection.

Safety permits authorize high-risk work, such as confined space entry or hot work. These documents verify that safety measures are in place prior to work commencing.

Priority systems ensure safety-critical repairs receive immediate attention. Equipment failures that pose safety risks get urgent scheduling to prevent accidents. This systematic approach prevents minor safety issues from becoming major incidents.

Digital work order systems track safety compliance and training requirements. They alert supervisors when workers lack required certifications for specific tasks. This prevents unqualified personnel from performing dangerous maintenance work.

Element 8: Tracking Performance, Continuous Improvement, and Optimization

A successful preventive maintenance process requires measuring program effectiveness through Key Performance Indicators (KPI’s).

Teams must systematically analyze equipment failures and adjust maintenance plans based on real-world performance data to maximize uptime and minimize costs.

Monitoring KPIs for Equipment Effectiveness

There are specific KPIs that manufacturing teams should track to measure the success of any preventive maintenance plan.

Critical maintenance KPIs include:

- Equipment uptime – percentage of time machines run without problems

- Mean Time Between Failures (MTBF) – average time equipment works before breaking down

- Mean Time to Repair (MTTR) – average time needed to fix equipment failures

- Maintenance costs per unit of production or per asset

Teams should set target values for each metric.

For example, world-class manufacturers often achieve OEE scores above 85%.

Tracking these numbers every month helps teams identify trends before they become major problems. Equipment with declining MTBF scores needs more attention in the maintenance plan.

Root Cause Analysis and Condition Monitoring

When equipment fails or performs poorly, maintenance teams must identify the root cause of the issue.

Root cause analysis examines beyond obvious symptoms to identify the underlying reasons why failures occur.

Common analysis methods include:

- 5 Whys technique – asking “why” five times to dig deeper into problems

- Fishbone diagrams – mapping potential causes across categories like materials, methods, and machines

- Failure mode analysis – studying how different parts can fail

Teams should examine recurring work orders to find patterns. Equipment that needs the same repair multiple times likely has an underlying issue that standard maintenance misses.

Adapting the Maintenance Plan for Continuous Improvement

Smart maintenance teams regularly update their plans based on performance data and equipment behavior.

Static maintenance schedules often waste time on unnecessary tasks while missing critical needs.

Teams should review maintenance intervals quarterly. Equipment that consistently performs well between scheduled services might need less frequent attention.

Machines with frequent failures may require more intensive care.

Key improvement actions include:

- Adjusting task frequency based on actual failure rates

- Adding new maintenance tasks for recurring problems

- Removing tasks that don’t prevent failures

- Training staff on better maintenance techniques

Preventive maintenance optimization focuses resources where they create the most value.

Teams analyze which maintenance activities actually prevent failures and which ones consume time.

Successful programs also incorporate feedback from equipment operators. They often notice small changes in machine behavior that maintenance schedules might miss.

Conclusion

The eight key elements of preventive maintenance provide a comprehensive roadmap for transforming manufacturing operations from reactive to proactive maintenance strategies.

When implemented systematically, this framework can reduce equipment failures by up to 70% while delivering measurable improvements in reliability, safety, and operational efficiency.

However, success requires commitment across all organizational levels. It all starts with clear goals, prioritizing critical assets, leveraging advanced technology, and fostering a culture of continuous improvement.

Maintenance organizations that treat preventive maintenance as a strategic investment rather than a cost center can achieve significant returns while building more resilient, efficient manufacturing operations.

Source: WorkTrek

Source: WorkTrek