Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeIntroduction

The oil and gas industry is the backbone that fuels the global economy. However, it faces many complex and difficult challenges. From a consumer perspective, Oil and gas provide most of the worldwide population’s daily energy needs, such as transportation, cooking, heating and cooling, and electricity generation. Oil and gas raw materials produce fertilizers, fabrics, synthetic rubber, and plastics, which are part of our environment and everything we need to live comfortably.

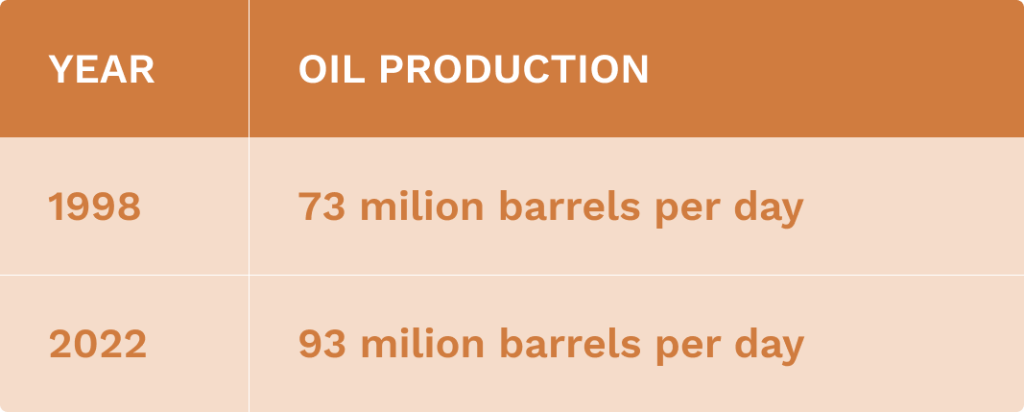

With the growth in electric vehicles and other conservation methods, oil production has grown from 73 million barrels per day in 1998 to 93 million barrels per day in 2022 globally. This explosive growth requires new toolings and efficiencies to streamline fuel delivery to the final consumer. One of those tools is maintenance software.

Source: WorkTrek

What does a CMMS do?

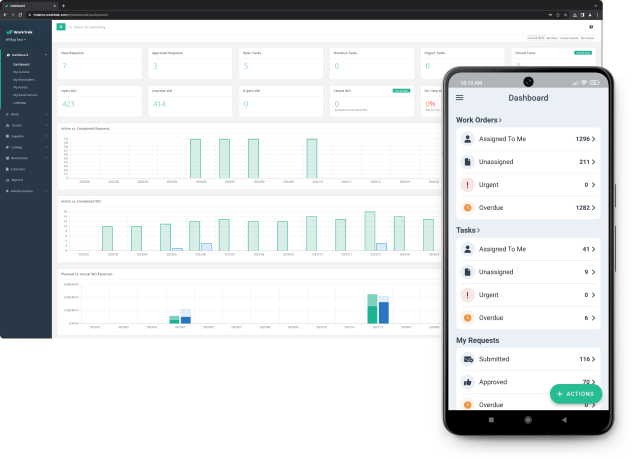

A CMMS solution captures every maintenance detail from anywhere and stores it in a secure, central database. Multiple concurrent users can easily access information from any computer or mobile device, preventing unexpected downtime and other threats to optimal production.

Processes and tasks are streamlined, with access to historical data, essential documents, and real-time updates on work order repairs. This can help maintenance teams reduce equipment downtime, quickly access all service history, reduce machine failure, improve regulatory compliance, and meet the organization’s maintenance needs.

CMMS software will also reduce unplanned maintenance, improve the asset lifecycle, and ensure smooth operations. Users can keep everything in one central, easy-to-access, and secure location.

Source: WorkTrek

What is the Oil and Gas Industry?

Source: WorldAtlas

The oil and gas industry, often called the energy sector, includes the exploration, extraction, refining, transportation, and marketing of petroleum products. It is a crucial component of the global economy, providing the primary sources of energy that power various industries and meet the energy needs of individuals worldwide. Here are the key elements of the oil and gas industry:

Upstream Sector:

- Exploration: Involves the search for potential underground or underwater crude oil and natural gas reserves.

- Drilling: Once a potential reserve is identified, drilling operations are conducted to extract oil or gas.

Midstream Sector:

- Transportation: Involves the transportation of crude oil and natural gas from production facilities to refineries and other destinations. This can be done through pipelines, tankers, and other means.

- Storage: Facilities are used to store crude oil and natural gas before they are transported to refineries or other end-users.

Downstream Sector:

- Refining: Crude oil is processed in refineries to extract various products such as gasoline, diesel, jet fuel, and petrochemicals.

- Distribution: Refined products are distributed to various end-users through a network of pipelines, trucks, and other transportation methods.

- Retail: The final stage involves selling refined products to consumers through gas stations and other retail outlets.

Petroleum and Petrochemicals:

- The industry also produces a wide range of petrochemicals used in manufacturing various products, including plastics, synthetic materials, and chemicals.

Natural Gas:

- In addition to crude oil, the industry focuses on extracting and distributing natural gas, which is used for heating and electricity generation and as a feedstock for petrochemical processes.

The oil and gas industry has a complex and integrated supply chain and has historically been a critical driver of economic growth. However, it is also subject to challenges, including environmental concerns, fluctuations in oil prices, and the growing emphasis on sustainable and renewable energy sources. As the world transitions toward a more sustainable energy future, the oil and gas industry is actively exploring and investing in cleaner technologies and practices.

What is CMMS for Oil and Gas Industry?

CMMS software stands for Computerized Maintenance Management System, a software solution designed to streamline and optimize maintenance management processes. In the oil and gas industry context, CMMS is used to efficiently manage the maintenance of equipment, facilities, and assets critical to oil and gas operations.

Here are the key features and functionalities of CMMS for Oil and Gas Companies:

Asset Management:

- CMMS for Oil and Gas Companies helps organizations manage and track various assets, including drilling equipment, pumps, pipelines, and other infrastructure.

- It provides a centralized repository for asset information, including maintenance history, specifications, and documentation.

Preventive Maintenance:

- The system allows for the scheduling and management of preventive maintenance tasks, ensuring that equipment is regularly inspected and serviced.

- Preventive maintenance helps identify and address potential issues before they lead to equipment failures or unplanned downtime.

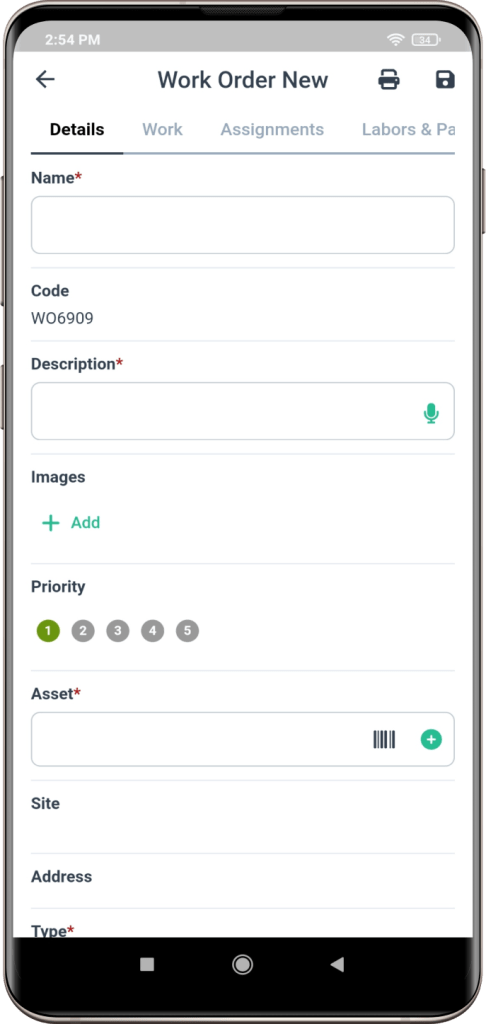

Work Order Management:

- CMMS facilitates creating, assigning, and tracking work orders for maintenance activities.

- Work orders can be prioritized, assigned to specific personnel or teams, and monitored to ensure timely completion.

Source: WorkTrek

Mobile Accessibility:

- Many modern CMMS solutions offer mobile access CMMS, enabling field personnel to access, update, and complete work orders in real time using mobile devices.

What Problems Does the Oil and Gas Industry Face?

The oil and gas industry faces various economic, environmental, technological, and geopolitical challenges. Some of the fundamental problems include:

Price Volatility: Oil and gas prices are highly volatile and can be influenced by geopolitical events, supply and demand fluctuations, and economic conditions. This volatility can impact the profitability of companies in the industry.

Environmental Concerns: Fossil fuel extraction, processing, and burning contribute to environmental pollution and climate change. This has increased scrutiny and pressure for the industry to adopt cleaner and more sustainable practices.

Transition to Renewable Energy: The global shift toward renewable energy sources challenges traditional oil and gas companies. As countries and industries increasingly adopt cleaner technologies, the oil and gas sector must diversify and invest in renewable energy solutions.

Addressing these challenges requires a combination of innovation, strategic planning, and collaboration with stakeholders. Many companies in the oil and gas sector are actively working on diversification, digital transformation, and sustainability initiatives to navigate these complex issues.

Solving Oil and Gas Maintenance Challenges with a CMMS

In many equipment-dependent industries, computerized maintenance management systems (CMMS) are used to plan, track, and improve a company’s maintenance activities throughout production. This is especially important for an oil and gas company. Utilizing CMMS software will reduce maintenance costs, improve asset performance, centralize maintenance data, and, most importantly, reduce equipment failure.

The popularity of CMMS systems in equipment-intensive enterprises is mainly due to their maintenance and cost-saving features. They can increase uptime on production-critical machinery, reduce repair and replacement costs, and improve safety and compliance, to name a few benefits.

As oil stock prices fluctuate worldwide, oil and gas companies must operate at peak efficiency. This means increasing production while minimizing costs, such as maintenance costs.

Benefits of a CMMS for Oil and Gas Companies

A CMMS benefits the oil and gas industry by helping streamline maintenance processes, enhance asset management, and improve operational efficiency. Here are some key benefits:

Improved Asset Management:

-

CMMS enables better tracking and managing of assets such as drilling equipment, pipelines, and other critical infrastructure.

-

It helps schedule preventive maintenance tasks to prolong the lifespan of assets and reduce unplanned downtime.

Reduced Downtime:

-

By implementing a CMMS, organizations can schedule maintenance activities more efficiently, reducing the risk of unexpected breakdowns and minimizing downtime.

-

Timely preventive maintenance helps identify and address potential issues before they lead to equipment failures.

Optimized Work Order Management:

-

CMMS allows for creating, assigning, and tracking work orders in a centralized system.

-

Work orders can be prioritized, assigned to the right personnel, and tracked to ensure timely completion of maintenance tasks.

Inventory Management:

-

Efficient inventory management is crucial in the oil and gas sector, where spare parts and equipment are often expensive and critical for operations.

-

CMMS helps manage inventory levels, reorder supplies, and track spare parts usage.

Cost Savings:

-

By reducing unplanned downtime, improving asset reliability, and optimizing maintenance processes, CMMS can contribute to significant cost savings over time.

-

Efficient resource utilization and inventory management also lead to cost reductions.

Mobile Accessibility:

- Many modern CMMS solutions offer mobile accessibility, allowing field personnel to access and update information in real time, improving communication and response times.

Conclusion

In summary, CMMS for Oil and Gas Companies plays a crucial role in managing and maintaining assets, ensuring regulatory compliance, optimizing maintenance processes, providing visibility for the maintenance manager, providing easily accessible historical data, and ultimately contributing to the efficient and reliable operation of oil and gas facilities.