Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways

- Clear objectives and proper data collection is the foundation of a successful predictive maintenance program

- Building accurate predictive models and real-time monitoring systems enables early detection of equipment issues

- Continuous improvement and optimization help companies scale their predictive maintenance efforts

Equipment failures can be expensive.

From lost production and emergency repairs, traditional maintenance methods often leave businesses scrambling to fix problems after they happen. This can lead to unexpected downtime and higher costs.

Predictive maintenance is the optimum way to reduce equipment downtime and reduce emergency repairs. However, successful predictive maintenance data requires advanced data analytics.

The typical approach to implementing data analytics for predictive maintenance involves the following six steps: defining objectives, collecting and integrating data, processing information, building predictive models, setting up real-time monitoring, and optimizing maintenance schedules.

Companies that master these six steps can reduce machine downtime and improve reliability while cutting maintenance costs. The process requires careful planning and the right technology, but the results can transform how organizations manage their equipment and operations.

Defining Predictive Maintenance and Data Analytics

Predictive maintenance utilizes data analysis tools to anticipate equipment failures before they occur. Modern systems combine AI, IoT sensors, and machine learning to transform how companies maintain their equipment.

What Is Predictive Maintenance?

Predictive maintenance refers to the use of data analysis tools and techniques to detect anomalies in equipment.

These systems can then predict potential failures before they occur. This approach prevents costly downtime by scheduling repairs at the right time.

As opposed to reactive maintenance that fixes equipment after it breaks, predictive maintenance takes action early.

Additionally, unlike preventive maintenance, which follows fixed schedules, predictive maintenance utilizes data to optimize maintenance timing.

Benefits of Predictive Maintenance

Cost Savings:

There are several benefits to predictive maintenance:

- Fewer emergency repairs

- Less spare parts inventory

- Reduced labor costs

- Lower insurance premiums

Operational Benefits:

- Higher equipment uptime

- Better production planning

- Improved safety

- Extended equipment life

Key Predictive Maintenance Technologies: AI, IoT, and Machine Learning

Three main technologies power modern predictive maintenance systems. Internet of Things (IoT) sensors collect equipment data continuously.

AI then processes this data to find patterns.

Machine learning algorithms, which are the foundation of AI, improve predictions over time.

IoT Sensors

These sensors monitor equipment conditions 24/7. They track vibration, temperature, oil quality, and electrical current.

This data is central to systems, such as a computerized maintenance management system (CMMS), like WorkTrek, for analysis.

Artificial Intelligence

It is the layer of technology that processes huge amounts of sensor data quickly.

AI can spot problems that humans might miss. It also handles data from multiple machines simultaneously.

Machine Learning Algorithms

They are the foundational predictive statistical analysis models that empower AI. They also get better at predicting failures as they process more data and evolve.

They learn from past equipment problems to make more accurate predictions for the future. These algorithms help companies predict equipment failures with high accuracy.

Digital transformation is when all of these technologies are integrated into one easy-to-use system. This could be a CMMS like WorkTrek that will ingest all the data collected and provide the analysis to predict failures.

Companies can monitor all their equipment from a single dashboard and get alerts when problems develop.

Step 1: Define Predictive Maintenance Objectives and Strategy

All successful programs start with good planning.

Success in predictive maintenance starts with clear goals and a solid plan.

Setting Maintenance Goals

Companies need to clearly define organizational goals before starting any predictive maintenance program. These goals guide decisions and help measure success later.

The most important goal for any maintenance organization is to reduce unplanned downtime.

Manufacturing facilities lose thousands of dollars every hour when machines are not functioning properly.

One example of a goal would be for a manufacturing company to set specific targets like reducing downtime by 30% in the first year.

Another key goal is cutting maintenance costs.

Traditional maintenance often wastes money on unnecessary repairs. Set a goal to reduce overall maintenance expenses by tracking the required key performance indicators (KPIs).

Equipment lifespan

Every maintenance organization wants to improve equipment lifespan. Use existing data for equipment lifespan and continue to measure that against your predictive maintenance program.

Start by setting arbitrary goals about how much longer equipment should run, based on your historical data.

Don’t forget about safety. Equipment failures can hurt workers.

Companies should set goals to reduce safety incidents through better maintenance timing.

One common approach is for organizations to write down these goals with exact numbers and deadlines.

For example: “Reduce maintenance costs by 25% within 18 months” works better than “save money on maintenance.”

Identifying Critical Assets

Not all equipment needs predictive maintenance right away. Companies must find their most important machines first.

Critical assets are machines that cause the biggest problems when they break down. These machines often stop entire production lines or cost the most to fix.

Companies should list all their equipment and rank it by importance.

Some factors to include are:

- Production Impact: How Much Does a Breakdown Slow Down Work?

- Repair Costs: How Expensive Is It to Fix This Machine?

- Safety risks: Could a failure hurt workers?

- Age and condition: Are older machines more likely to break?

Typically, manufacturing plants often find that 20% of their machines cause 80% of their problems. These machines should get predictive maintenance first.

Companies also need to check if machines have the right data available. Some older equipment might need new sensors before predictive maintenance can work.

The goal is to start small with the most important machines. Once you develop experience and see success, you can expand the program.

How to Develop a Predictive Maintenance Strategy

A solid predictive maintenance model connects goals with actions. Start with a clear plan that shows how they will reach their maintenance objectives.

The strategy should match the company’s current abilities and resources. Small manufacturers might start with simple vibration monitoring.

Larger companies could use advanced AI systems right away and integrate other types of IoT sensors.

Implementing a predictive maintenance strategy requires choosing the right technology for each type of equipment.

Not every machine is the same. Different machines need different monitoring methods.

Companies must decide between building their own system or buying one.

Building takes more time and can be risky, but it can potentially fit the organization’s needs. Buying gets results faster but might not match perfectly.

Timeline planning is crucial for success. Most companies take 12-18 months to implement predictive maintenance fully. The strategy should show clear steps and milestones.

Budget planning comes next. Companies need money for sensors, software, training, and staff time. They should plan for both startup costs and ongoing expenses.

The strategy must also cover staff training and change management.

Workers need to learn new tools and methods. Establishing a predictive maintenance program involves getting everyone on board with the new approach.

Step 2: Data Collection and Integration

Sensor data is the foundation of any successful predictive maintenance program. The goal of any program is to gather high-quality data from multiple sources and combine them for analysis.

A successful approach involves integrating data from installed sensors and data from existing maintenance records to create a complete picture of equipment health.

Selecting and Installing Sensors

Maintenance management should select sensors based on the specific equipment they want to monitor, along with the types of failures they want to prevent.

Vibration sensors detect bearing wear and misalignment in rotating equipment like motors and pumps.

Temperature sensors identify overheating components before they fail.

Pressure sensors monitor hydraulic and pneumatic systems for leaks or blockages.

Current sensors track electrical equipment performance and can spot motor problems early.

Sensor Placement

The placement of sensors is critical for accurate data collection. Sensors should be installed at points where they can detect the earliest signs of equipment problems.

For rotating machinery, vibration sensors work best when mounted directly on bearing housings.

Leveraging CMMS and Work Order Data

A computerized maintenance management system like WorkTrek contains valuable historical information about equipment performance and maintenance activities.

This maintenance data includes repair records, part replacement history, and equipment downtime patterns.

Work order history can be analyzed to indicate which components fail most frequently and the typical duration of repairs.

his information helps identify patterns that sensors alone cannot detect.

CMMS software also stores details about maintenance costs, labor hours, and equipment age. These factors influence how quickly equipment degrades and when failures are likely to occur.

Organizations should extract data from their CMMS covering at least two years of maintenance history. This provides enough information to establish baseline performance patterns for each piece of equipment.

The combination of historical CMMS data with real-time sensor information creates a more complete picture than either source alone.

Integrating IoT Devices

IoT integration requires establishing secure network connections and ensuring data flows properly to the analytics platform.

Organizations should verify that IoT devices can communicate with their existing systems.

The devices should be configured to send data at appropriate intervals for data acquisition.

Critical equipment may need continuous monitoring, while less important assets can report status hourly or daily. This will help manage the volume of data.

One benefit of IoT devices is that they enable remote monitoring of equipment in difficult-to-reach locations.

This expands the scope of predictive maintenance programs beyond the plant floor and into hard-to-reach areas.

Step 3: Data Processing and Preparation

Data preparation and processing take up to 80% of project time due to the detailed work required for predictive analytics models.

Organizations must eliminate biases, enhance accuracy, and ensure meaningful insights by implementing thorough data cleaning and robust security measures.

Data Cleaning and Aggregation

Raw sensor data contains noise, duplicates, and missing values that can corrupt predictive models and diagnostic analysis.

Maintenance teams must train statistical models to identify and remove outliers that don’t represent normal equipment behavior.

Common Data Issues:

- Missing timestamps from sensor failures

- Duplicate readings from system errors

- Extreme values from faulty sensors

- Inconsistent measurement units

Data aggregation, from data mining, combines multiple data points into meaningful intervals.

Equipment sensors might collect readings every second, but predictive models work better with hourly or daily averages, depending on equipment type and machine learning models.

One approach that successful organizations follow is to standardize data formats across different equipment types.

Temperature sensors might record in Celsius or Fahrenheit. Pressure gauges could use different measurement scales. This makes standardization critical.

Aggregation Methods:

- Average values for steady-state measurements

- Maximum values for peak performance data

- Trend calculations for degradation patterns

Ensuring Data Security and Quality

Security protects sensitive equipment data from cyber threats and unauthorized access. Follow industry standards, and also consider getting an external security audit for your infrastructure.

Manufacturing companies face increasing risks from data breaches that could expose operational secrets.

Follow industry standard data encryption practices that secure the data both in transit and at rest.

Access controls limit who can view maintenance data and equipment performance metrics.

Security Measures:

- Encrypted data transmission protocols

- Multi-factor authentication (MFA) for system access

- Regular security audits and updates

- Backup systems for data recovery

Data quality checks verify information accuracy before analysis begins. Automated validation rules catch errors that manual reviews might miss.

Quality metrics track data completeness, accuracy, and consistency over time. Poor quality data leads to false alarms and missed failure predictions.

Big Data Management

Predictive maintenance generates massive amounts of sensor data that can be difficult for traditional databases to handle efficiently.

Big data analytics requires specialized tools to process and store information from hundreds of sensors. Some examples, such as Google BigQuery or Amazon Redshift, are well-suited for managing large data sets.

Big Data Characteristics:

- Volume: Terabytes of sensor readings daily

- Velocity: Real-time data streams requiring instant processing

- Variety: Multiple data types from different equipment

Cloud platforms provide scalable storage and processing power for large datasets. Companies can expand capacity as their predictive maintenance programs grow.

Data lakes store raw sensor information in its original format. This approach preserves all available data for future analysis needs that might not be apparent today.

Stream processing analyzes data as it arrives from sensors. This capability enables real-time alerts when equipment shows signs of potential failure.

Step 4: Building and Training Predictive Models

Once you’ve established data sensors and data collection, it is time to start training predictive models.

In this step, the data is cleaned and transformed into actionable insights by selecting appropriate algorithms and fine-tuning their performance.

This step focuses on creating models that can accurately predict equipment failures and identify specific failure patterns.

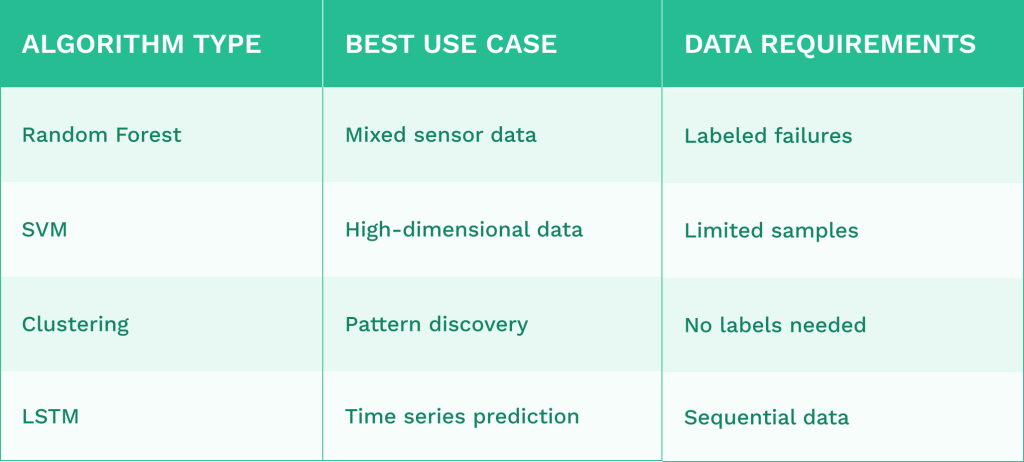

Machine Learning Algorithms

Supervised learning algorithms

These models work best for predictive maintenance when historical failure data exists.

Random Forest algorithms excel at handling multiple sensor inputs and provide clear feature importance rankings.

Support Vector Machines are supervised models that perform well with high-dimensional sensor data. They work effectively when the data scientist has limited training examples but needs accurate predictions.

Unsupervised learning approaches, such as clustering algorithms, are helpful when failure labels are missing. These methods group similar patterns of equipment behavior.

Anomaly detection algorithms identify unusual equipment behavior that might signal impending failures. Isolation Forest and One-Class SVM algorithms detect outliers in normal operating conditions.

Time series algorithms, such as LSTM neural networks, capture temporal patterns in sensor data. They predict the mean time between failures (MTBF) by learning from historical maintenance cycles.

Model Validation and Tuning

Once the models have been developed, it is time to start testing and tuning them.

Cross-validation techniques prevent overfitting by testing models on unseen data portions.

Time series cross-validation maintains chronological order when splitting maintenance data.

The data scientist must tune hyperparameters to optimize model performance.

Grid search and random search methods systematically test different parameter combinations.

Performance metrics for predictive maintenance differ from standard classification tasks. Precision matters more than recall since false alarms cost money and reduce trust.

Mean Absolute Error measures how accurately the model predicts MTBF values. A lower error indicates better timing predictions for maintenance scheduling.

Building predictive models requires iterative testing and refinement. Models need regular retraining as equipment ages and operating conditions change.

Failure Mode Identification

Multi-class classification

Separates different types of equipment failures. Each failure mode requires different maintenance actions and spare parts inventory.

Bearing failures show different sensor patterns than motor overheating or belt wear. The model learns to distinguish these patterns from vibration, temperature, and current data.

Feature engineering

Creates new variables that highlight specific failure signatures.

Rolling averages smooth noisy sensor readings while trend calculations capture gradual degradation.

Domain expertise guides feature creation for each failure mode. Mechanical engineers understand which sensor combinations indicate specific problems.

Ensemble methods combine multiple models to enhance the accuracy of failure mode predictions. Different algorithms may excel at detecting various types of failures.

Anomaly detection techniques help identify unknown failure patterns that are not present in the training data. These methods flag unusual behavior that requires investigation.

Threshold setting determines when the model triggers maintenance alerts. Conservative thresholds reduce missed failures but increase false alarms.

Step 5: Real-Time Monitoring and Anomaly Detection

Real-time monitoring systems track equipment performance continuously and identify problems before they cause failures.

These systems use sensors to collect data on vibration, temperature, and energy consumption to spot unusual patterns.

Implementing Condition Monitoring

Condition monitoring systems track machine health using multiple sensors placed on critical equipment. Engineers install vibration sensors, temperature probes, and current monitors at key points.

The sensors collect data every few seconds or minutes. This frequency catches problems early while avoiding data overload.

Key sensor types include:

- Accelerometers for vibration measurement

- Temperature sensors for heat detection

- Current transformers for energy monitoring

- Pressure sensors for hydraulic systems

Deploying Real-Time Analytics

Real-time analytics systems process sensor data instantly to identify and address problems. The software uses machine learning models to spot patterns that signal equipment failure.

Anomaly detection systems automatically identify unusual patterns in data tables. They suggest the best algorithms and set up continuous monitoring with automated actions.

Analytics platforms compare current data to normal operating conditions. When readings fall outside expected ranges, the system triggers alerts.

Alert levels typically include:

- Green: Normal operation

- Yellow: Caution – minor deviation detected

- Red: Critical – immediate action required

Real-time anomaly detection in manufacturing helps secure production efficiency and reduce downtime.

Step 6: Predictive Maintenance Scheduling and Optimization

The final step is to transform predictive insights into actionable maintenance plans. This has to then align with automated scheduling systems and performance optimization.

This phase focuses on creating efficient work orders, maximizing equipment uptime, and improving overall operational performance.

Automated Maintenance Scheduling

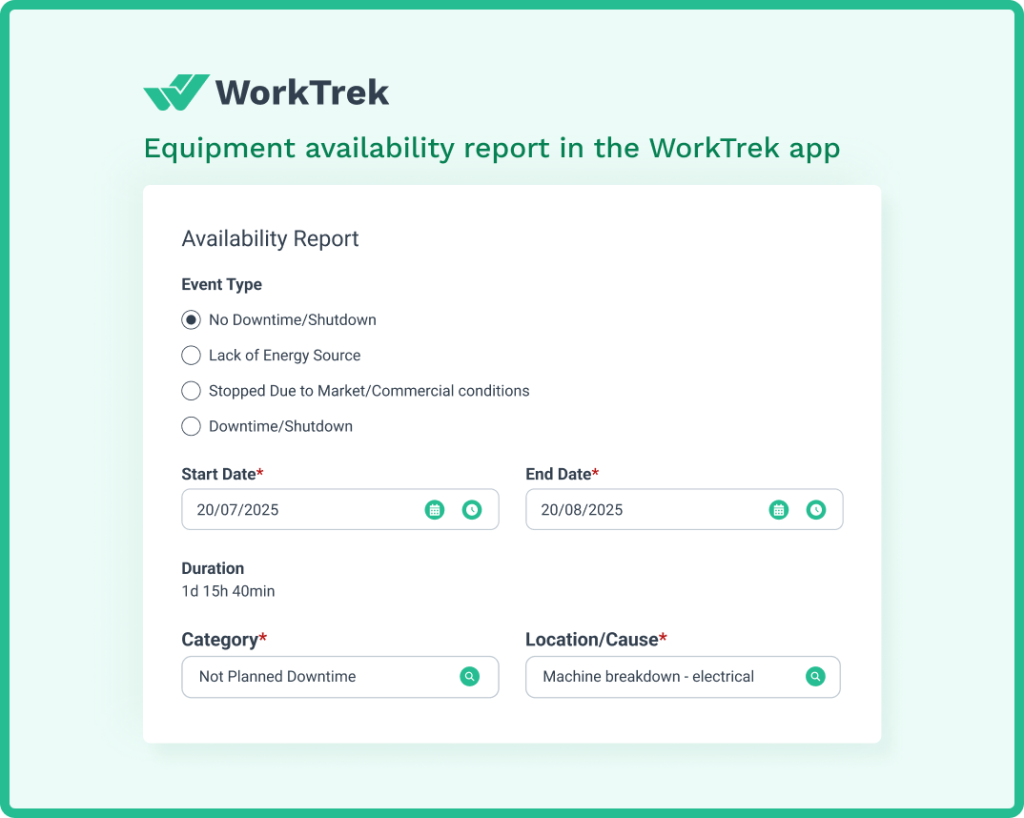

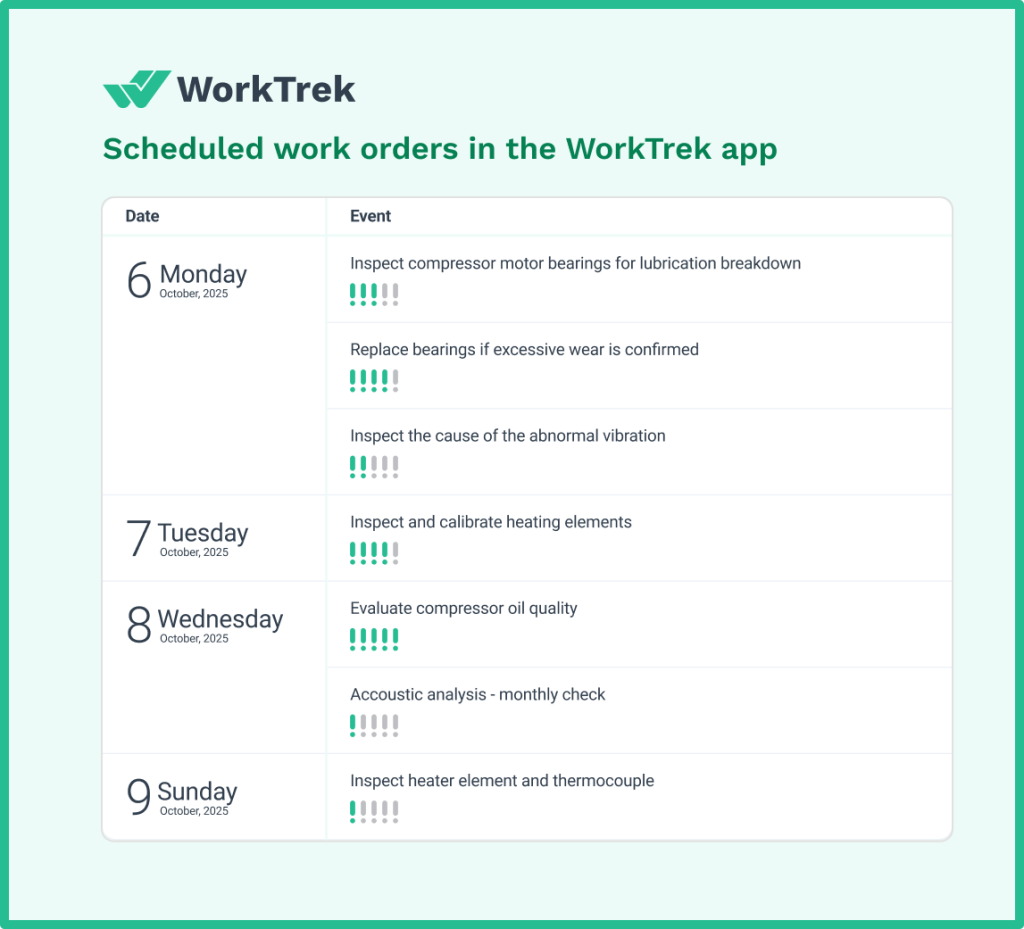

Automated scheduling systems, such as WorkTrek CMMS, utilize predictive data to create optimal maintenance plans.

Maintenance managers don’t need to create work orders manually. These automated systems will detect and issue, auto-generate, and assign the work order to the maintenance technician.

These systems analyze equipment health data and failure predictions to schedule work at the best times.

Key scheduling features include:

- Risk-based prioritization – High-risk equipment gets scheduled first

- Resource availability matching – Systems check technician schedules and parts inventory

- Production impact analysis – Scheduling avoids critical production periods

The system automatically generates maintenance windows based on equipment condition and operational needs. It considers factors like spare parts availability, technician skills, and production schedules.

Predictive maintenance scheduling combines machine learning with decision optimization to create the most effective maintenance plans. This approach reduces conflicts between maintenance needs and production goals.

Smart scheduling also balances workloads across maintenance teams. It prevents overloading technicians during busy periods while ensuring critical equipment receives attention when needed.

Improving Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness measures how well equipment performs compared to its full potential.

Predictive maintenance directly improves OEE by reducing unplanned downtime and optimizing performance.

OEE calculation includes three factors:

- Availability – Percentage of scheduled time equipment operates

- Performance – Speed compared to ideal operating speed

- Quality – Good parts produced versus total parts

Predictive analytics can identify patterns that affect each OEE component.

For instance, vibration data might show declining performance before visible quality issues appear.

The system can track OEE improvements after implementing predictive maintenance. Most companies see 10-20% OEE increases within the first year of proper implementation.

The goal for OEE is to prioritize which equipment needs attention first. Equipment with the lowest OEE scores often provides the biggest improvement opportunities.

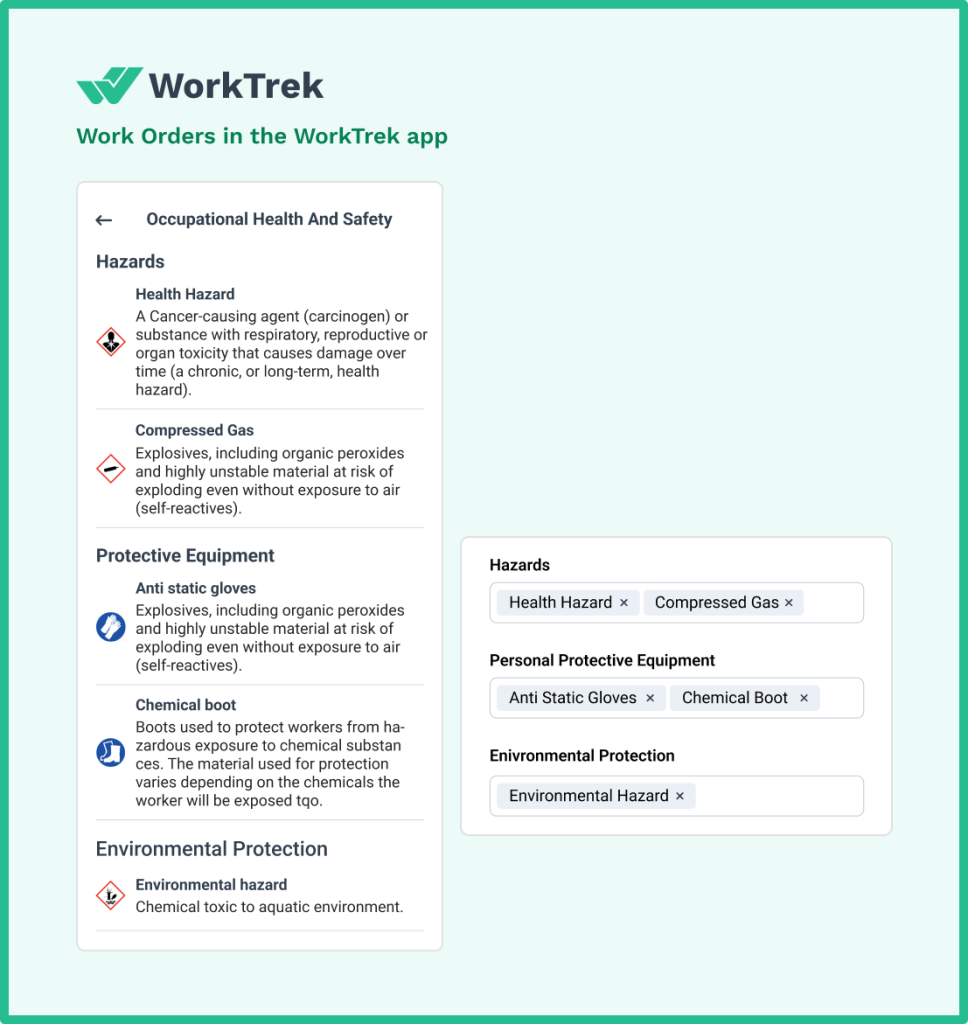

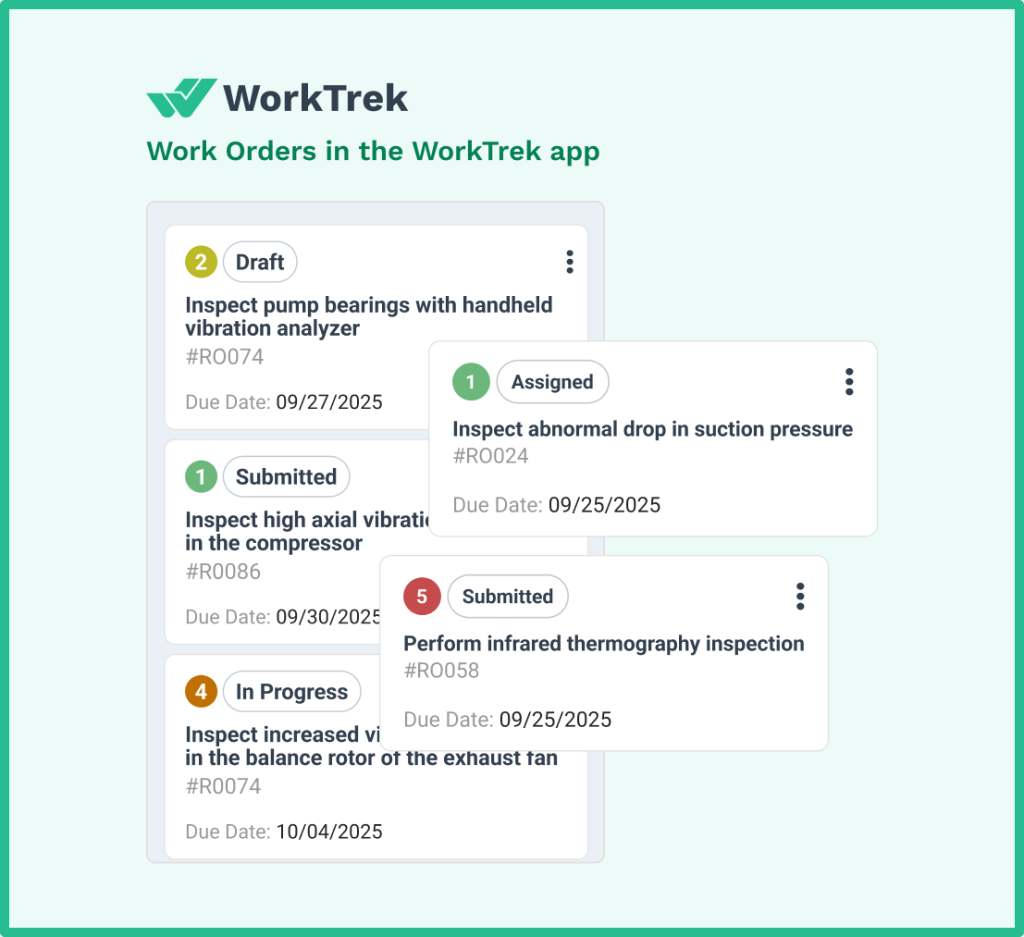

Maintenance Work Order Management

Work order management ensures maintenance tasks get completed efficiently and documented correctly.

Digital work order systems integrate with predictive maintenance platforms to streamline operations.

Modern work order systems provide:

- Automated work order creation from predictive alerts

- Mobile access for technicians in the field

- Parts and inventory integration with supply chain systems

- Digital documentation of completed work

Work orders include specific details from predictive analysis. This might include which components to inspect, what tools to bring, and expected repair procedures.

CMMS tracks work order completion times and effectiveness. This data helps improve future maintenance estimates and resource planning.

Continuous Improvement and Scaling Predictive Maintenance

It will be hard to implement a successful predictive maintenance program without continuous improvement. The models need to be tuned regularly to improve their predictive capability.

Feedback Loops and Model Refinement

Feedback loops help improve prediction accuracy over time.

Set up a regular program on actual equipment failures and compare them to their model predictions.

Key refinement activities include:

- Adjusting algorithms based on false positives and missed failures

- Adding new sensor data sources to improve accuracy

- Updating models with seasonal patterns and usage changes

- Training algorithms with fresh data every 3-6 months

Healthcare facilities often refine their models for medical equipment like MRI machines. For example, they track when their predictions match actual maintenance needs.

Wind turbine operators update their models based on weather patterns and data on blade wear.

Oil and gas companies improve their pipeline monitoring by analyzing past leak predictions.

They can then adjust their models when they find patterns that the system missed.

Model accuracy typically improves by 15-25% within the first year of active refinement. This improvement will compound over the first few years of deployment.

Scaling Across Multiple Assets and Sites

Scaling requires a structured approach to expand predictive maintenance across different locations and equipment types. Be strategic with your approach. Start slowly with a handful of equipment and continue to add more equipment as the process is refined.

Scaling strategies include:

- Standardizing data collection methods across sites

- Creating equipment templates for similar assets

- Training local maintenance teams at each location

- Establishing central monitoring capabilities

One industry is the oil and gas companies, where they scale by equipment type first.

They implement predictive maintenance for all pumps across sites before moving to compressors or valves.

Common scaling challenges:

- Different equipment manufacturers and data formats

- Varying network connectivity at remote sites

- Local regulatory requirements for different regions

- Staff training and change management

Healthcare systems scale by prioritizing critical equipment. They start with life-support devices and later expand to diagnostic equipment.

Automotive plants scale production line by production line. They test predictive maintenance on one assembly line before expanding to paint shops and stamping operations.

Facilities scale by building systems first. They monitor HVAC systems across campus before adding laboratory equipment and IT infrastructure.

Conclusion

Implementing data analytics for predictive maintenance is a transformative opportunity for organizations seeking to optimize their operations and reduce costs.

By following these six strategic steps: defining clear objectives, collecting comprehensive data, processing information effectively, building accurate predictive models, establishing real-time monitoring, and optimizing maintenance schedules, companies can achieve significant improvements in equipment reliability and operational efficiency.

Organizations that successfully implement these practices typically see 10-20% increases in Overall Equipment Effectiveness, substantial reductions in unplanned downtime, and meaningful cost savings within the first year.