Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways

- Preventive maintenance reduces equipment failures and extends asset life through regular inspections and scheduled maintenance

- Technology solutions like CMMS software help track maintenance schedules, manage inventory, and analyze equipment performance data

- Well-trained maintenance teams combined with continuous improvement processes ensure optimal equipment reliability and regulatory compliance

When manufacturing equipment breaks down, it can cost companies thousands of dollars in lost production time and emergency repairs.

Every minute of unplanned downtime affects the bottom line, making equipment reliability crucial for success.

There is a solution.

Preventive maintenance reduces equipment failures by up to 70%, while extending asset life and significantly cutting maintenance costs.

Smart manufacturers know that fixing problems before they happen costs much less than dealing with emergency breakdowns.

Implementing an effective maintenance management transforms maintenance from a reactive expense into a strategic advantage.

Build a Preventive Maintenance Foundation

As a maintenance manager, what is the most effective way to establish a preventive maintenance foundation?

The first step is to understand the difference in maintenance types, recognize their benefits, and choose the right approach for manufacturing operations.

Defining Preventive Maintenance in Manufacturing

Preventive maintenance involves scheduled activities performed on equipment, generally based on manufacturer recommendations or usage patterns.

There are two primary types of preventive maintenance: time-based and usage-based.

Time-based maintenance occurs at regular intervals, such as weekly, monthly, or quarterly.

Usage-based maintenance, on the other hand, occurs after the equipment has run for a specific number of hours or production cycles.

A typical preventive maintenance programs include routine inspections, lubrication, part replacements, and cleaning procedures. These tasks keep machinery running at peak performance levels.

A preventive maintenance best practice is to document all maintenance activities to track equipment history.

With this data, organizations can identify patterns and optimize future maintenance schedules. Proper documentation also supports warranty claims and regulatory compliance requirements.

Benefits of Preventive Maintenance

The benefits of preventive maintenance are clear. PM reduces unplanned downtime by identifying and addressing problems before they cause equipment failures.

Manufacturing that uses preventive maintenance can generally avoid costly production stops that disrupt delivery schedules and customer relationships.

More importantly, PM can extend the lifespan of equipment. Regular maintenance prevents small issues from becoming major repairs that require expensive part replacements or complete equipment overhauls.

Key Financial Benefits:

- Lower repair costs

- Reduced emergency maintenance expenses

- Extended equipment lifespan

- Improved energy efficiency

- Better warranty protection

Additionally, safety improves significantly with regular maintenance programs. Well-maintained equipment operates within design specifications and reduces workplace accident risks.

This protects workers and minimizes liability concerns.

Quality control also improves with a better maintenance program.

Machines operating properly produce more reliable products with fewer defects. This reduces waste and improves customer satisfaction rates.

Understanding Preventive, Predictive, and Corrective Maintenance

Aside from preventive maintenance, manufacturing maintenance programs incorporate other approaches, including predictive and corrective maintenance.

Preventive maintenance

Follows predetermined schedules regardless of equipment condition. Teams perform tasks like filter changes, belt adjustments, and calibration checks at regular intervals.

Predictive maintenance

Uses sensor data and condition monitoring to determine optimal maintenance timing. Vibration analysis, thermal imaging, and oil analysis identify problems before they cause failures.

Corrective maintenance

Also called reactive maintenance, addresses equipment issues after they occur, but before complete failure.

This reactive approach is more costly than preventive methods, but it may sometimes become necessary.

Ideal Breakdown

Manufacturers typically allocate 60-70% of their maintenance activities to preventive maintenance, 20-30% to predictive maintenance, and reserve 10-20% for corrective maintenance. This balance optimizes costs while maintaining reliable operations.

The main driver of which method you choose depends on the equipment’s criticality and the consequences of failure.

When it comes to critical production equipment, focus on more intensive preventive and predictive approaches than support systems.

Creating a Comprehensive Maintenance Program

Like any important initiative, a successful maintenance program requires careful planning of activities.

This includes creating well-structured schedules with a detailed PM checklist and maintenance intervals that match each asset’s importance to operations.

Planning and Scheduling Maintenance Activities

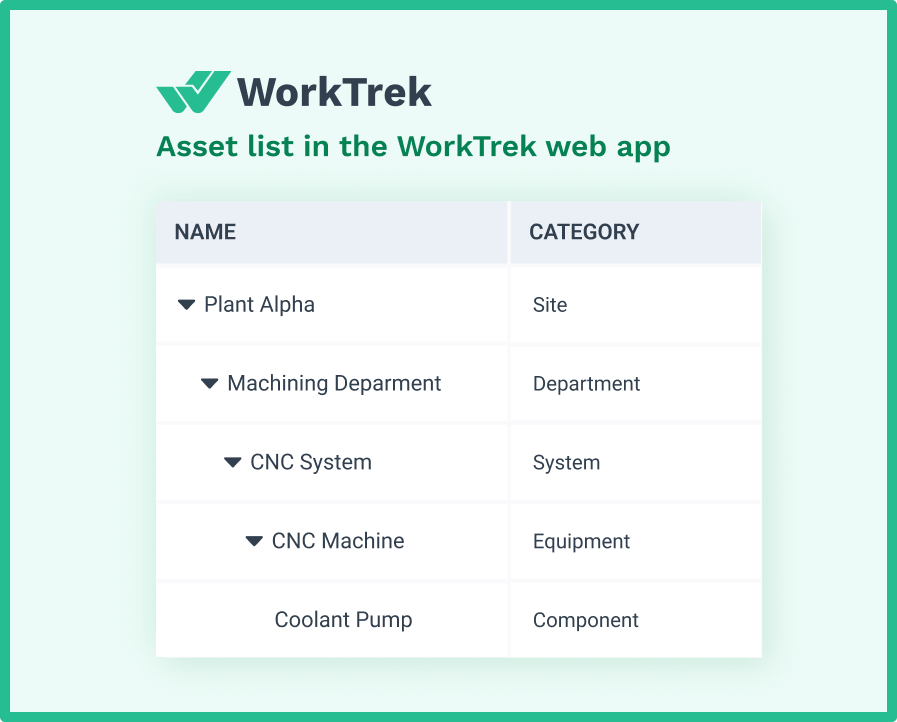

Maintenance planning starts with creating an asset list.

That list should include critical details like manufacturer, model, location, and current condition.

This foundation enables maintenance teams to identify which equipment requires attention and when.

Key Planning Elements:

- Asset identification and categorization, including barcoding

- Resource allocation for labor and materials

- Time estimation for each maintenance task

- Safety requirements and procedures

The goal of maintenance scheduling is to coordinate these planned activities with production demands.

Teams must balance equipment availability with operational needs to minimize disruption.

Production schedules drive timing decisions. Maintenance windows are normally set during planned downtime, shift changes, or periods of low production.

Scheduling Considerations:

- Equipment availability windows

- Technician skill levels and availability

- Parts and materials procurement lead times

- Emergency maintenance buffer time

Developing Maintenance Schedules and Checklists

Maintenance schedules define when routine maintenance is scheduled to occur. This is typically based on specific time intervals or equipment usage.

For example, time-based schedules use daily, weekly, monthly, or annual intervals. On the other hand, usage-based schedules track runtime hours or production cycles.

Typical Schedule Types:

- Daily: Visual inspections, fluid level checks

- Weekly: Lubrication, basic cleaning

- Monthly: Filter changes, belt inspections

- Quarterly: Detailed inspections, calibrations

- Annual: Major overhauls, compliance testing

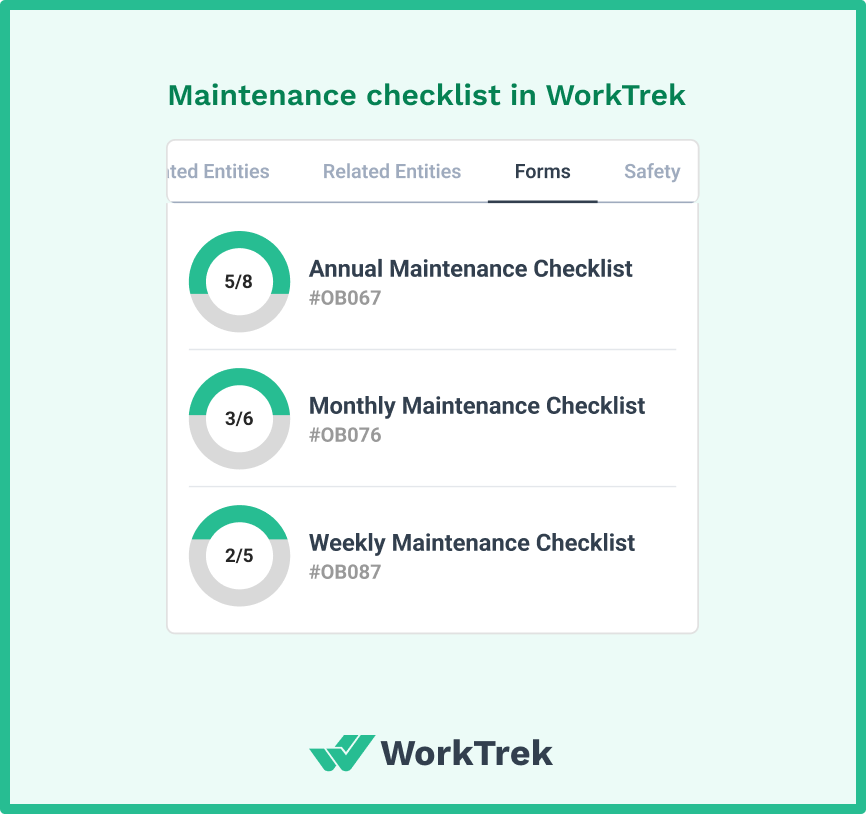

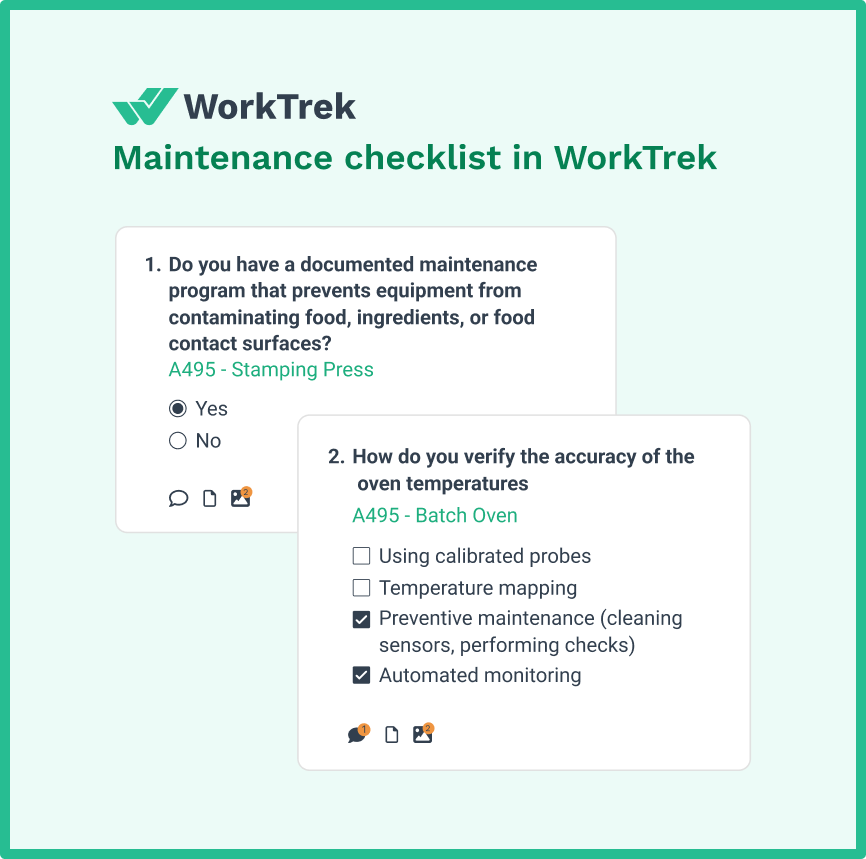

PM checklists ensure consistent execution of scheduled maintenance. Checklists can be designed to break down complex procedures into simple, systematic steps that technicians can follow.

Ideally, checklists include specific measurements, acceptable ranges, and clear pass/fail criteria. They also document safety procedures and required tools for each task.

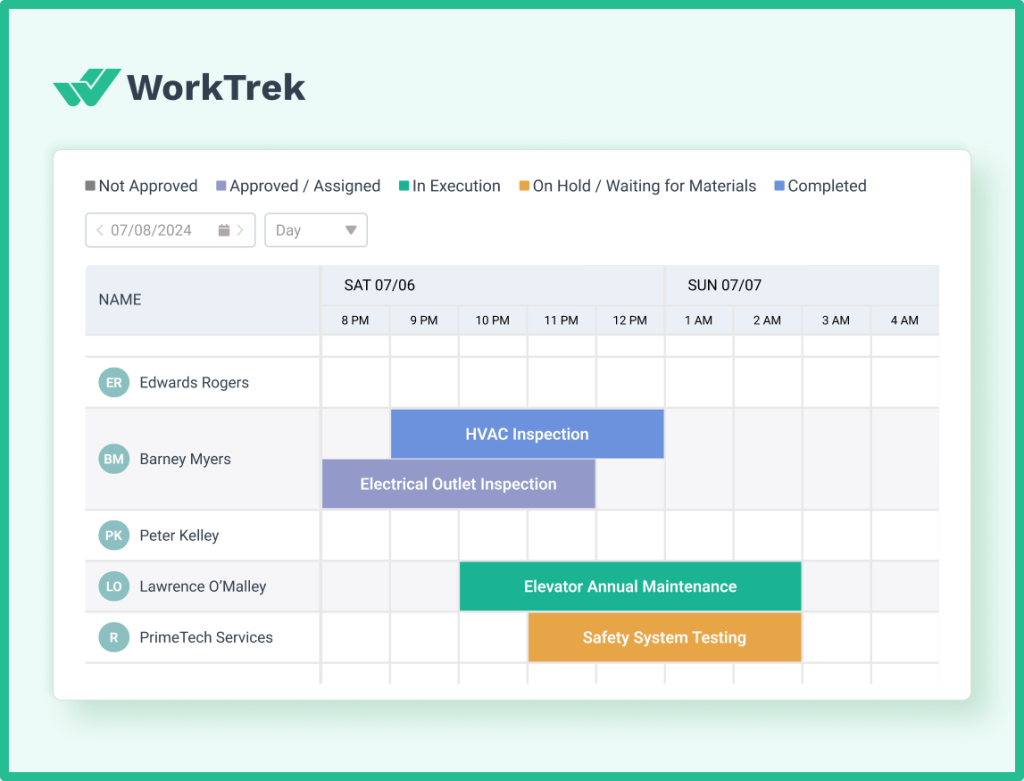

Digital checklists in CMMS platforms, such as WorkTrek, reduce errors and improve data collection.

Technicians can record findings, attach photos, and flag issues immediately and upload them during routine inspections.

Determining Maintenance Interval

The criticality of assets determines the frequency of maintenance.

Critical assets receive more frequent attention because their failure has a significant impact on production.

Criticality Assessment Factors:

- Production impact if equipment fails

- Safety risks associated with failure

- Repair costs versus replacement costs

- Availability of backup equipment

Highly critical assets require shorter maintenance intervals and more detailed inspections. These machines often have redundant maintenance tasks and multiple inspection points to catch problems early.

Medium-criticality equipment follows standard manufacturer recommendations for maintenance intervals. Maintenance teams adjust timing based on operating conditions and maintenance history.

Low-criticality assets may be subject to extended intervals, reactive maintenance, or run-to-failure strategies.

The cost of preventive maintenance must not exceed replacement costs for these items.

Interval Adjustment Triggers:

- Repeated failures between scheduled maintenance

- Operating conditions are harsher than design specifications

- Asset performance is declining despite maintenance

- Changes in production demands or criticality level

Maintenance teams should regularly review and adjust intervals based on asset performance data and maintenance records. This iterative process ensures that maintenance programs remain cost-effective while protecting critical operations.

Leveraging Technology and CMMS Solutions

To successfully implement preventive maintenance, you need a CMMS like Worktrek.

CMMS can optimize equipment tracking and performance, automate scheduling, and predict failures before they occur.

These solutions reduce downtime, cut costs, and enhance the efficiency of maintenance teams across manufacturing facilities.

Implementing a Computerized Maintenance Management System (CMMS)

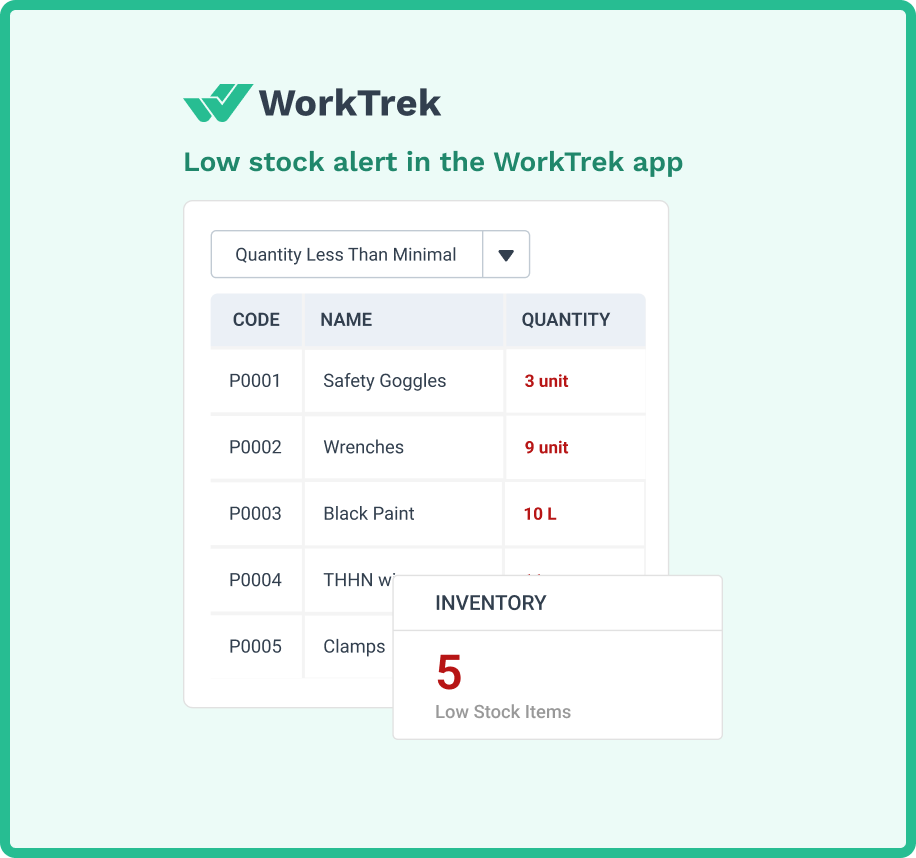

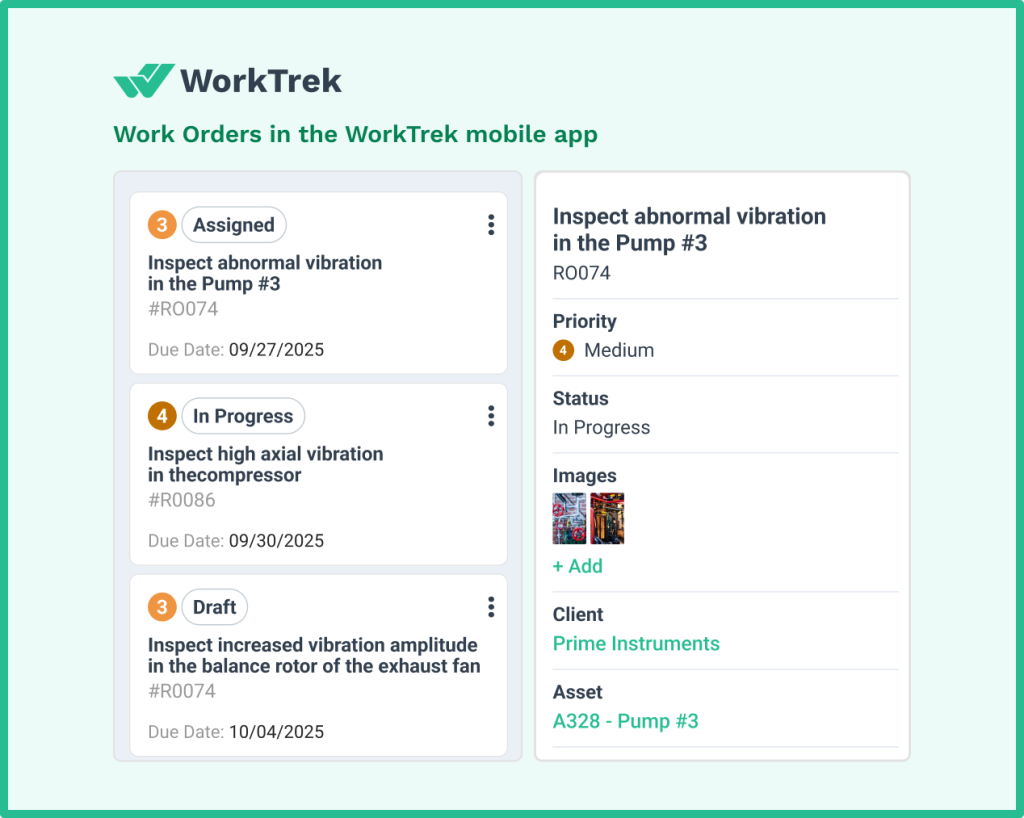

CMMS serves as the central hub for all maintenance operations. The software manages work orders, tracks inventory, and automatically schedules preventive maintenance tasks.

Involving the entire organization ensures a successful implementation of CMMS. Management buy-in and technician training are essential for adoption.

Key CMMS features include:

- Work order management and approval workflows

- Asset tracking with maintenance history

- Inventory management and parts ordering

- Labor tracking and cost analysis

With mobile capabilities, technicians can access the system from anywhere on the factory floor. They can update work orders, request parts, and view equipment information in real-time.

Benefits of CMMS and Reporting

Implementing a CMMS can eliminate paper-based maintenance records and provide instant access to equipment data.

Maintenance teams can monitor asset performance, track repair costs, and identify maintenance trends through automated reporting.

Digital systems provide:

- Real-time equipment status updates

- Maintenance cost tracking by asset

- Compliance documentation storage

- Performance metrics and KPIs

Real-time asset tracking helps maintenance teams monitor hundreds of machines simultaneously.

With this level of visibility, organizations can reduce equipment failures and optimize maintenance schedules.

Custom dashboards track metrics that matter most to manufacturing operations. Mean time between failures (MTBF) and mean time to repair (MTTR) become measurable and manageable.

Digital reporting reduces the time spent on administrative tasks associated with paperwork. Technicians focus more time on actual maintenance tasks rather than documentation.

Utilizing Sensors and Predictive Analytics

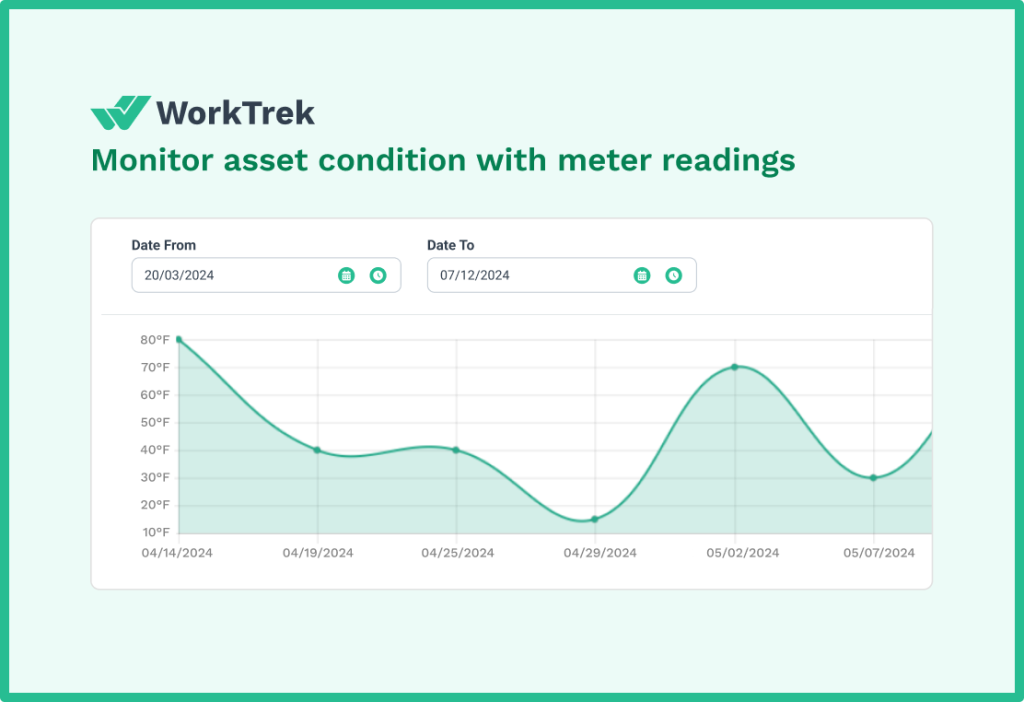

By deploying IoT sensors, organizations can create continuous monitoring of equipment. This is called condition-based maintenance, where repair is only done when sensors detect a data anomaly.

This data feeds into analytics systems that predict when maintenance will be needed.

Sensors used for condition-based maintenance include:

- Motor vibration levels

- Bearing temperatures

- Hydraulic pressure readings

- Belt tension measurements

This data is then fed into predictive maintenance algorithms that analyze sensor data to identify patterns that indicate impending failures.

The system alerts maintenance teams days or weeks in advance of equipment breakdown.

With predictive maintenance, maintenance teams can prevent unexpected downtime and reduce emergency repair costs.

Predictive Maintenance Analytics help optimize:

- Parts inventory levels

- Maintenance staff scheduling

- Equipment replacement timing

- Energy consumption patterns

The combination of sensors and CMMS software enables a comprehensive predictive maintenance program that optimizes equipment reliability.

Building and Training Maintenance Teams

You cannot have a strong maintenance team without clear role definitions, ongoing skill development, and open communication channels.

These elements form the foundation for successful preventive maintenance programs, which can lead to a more efficient organization.

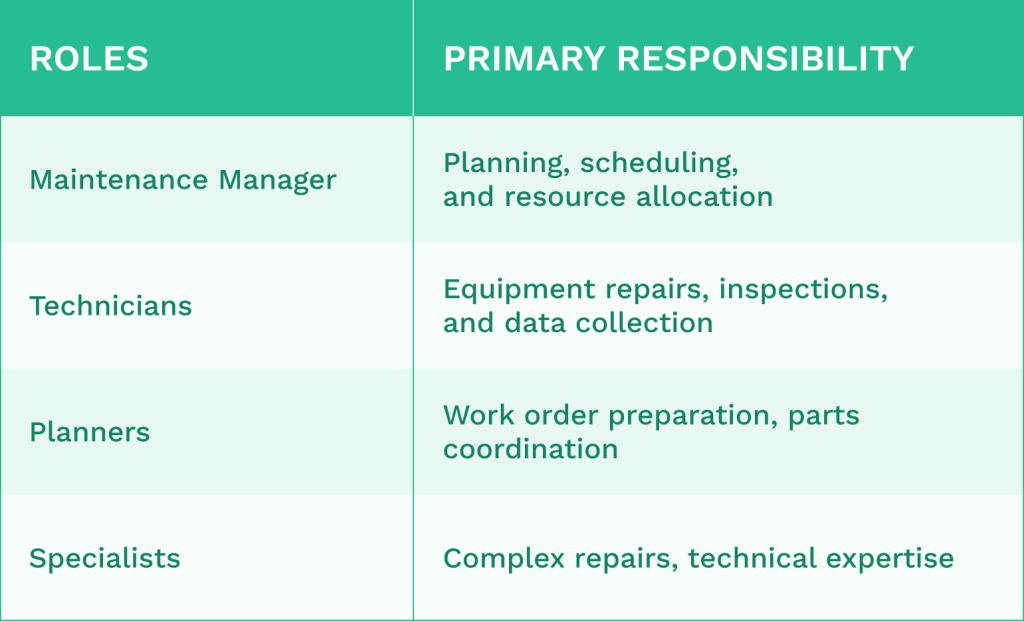

Defining Roles and Responsibilities

Clear job descriptions prevent confusion and ensure all maintenance work gets completed properly. Each team member needs to understand their specific duties and how they fit into the larger operation.

Key maintenance team roles include:

Facilities managers should start establishing accountability measures for each position. This includes setting performance expectations and defining decision-making authority.

Regular performance reviews help identify gaps in coverage. Teams should document who is responsible for handling emergency repairs versus routine maintenance tasks.

Cross-training selected team members creates backup coverage for critical roles. This approach prevents work delays when key personnel are unavailable.

Improving WorkForce Skills Through Training

Creating and implementing a comprehensive maintenance training program equips workers with the technical and safety skills necessary to perform their job effectively.

Training investments directly impact the quality of maintenance and worker confidence.

For new employees, you need to create a structured onboarding that covers equipment-specific procedures.

This includes hands-on practice with actual machinery under supervision.

Continued Workshops and Training

Regular workshops and refresher courses keep maintenance teams updated on the latest techniques and safety protocols.

Without this training, maintenance teams may struggle to keep pace with the evolving technology.

Skills assessments identify individual training needs. Some technicians may require electrical training, while others need knowledge of hydraulics.

Certification programs validate worker competencies. These credentials ensure team members can handle complex maintenance work safely and effectively.

Don’t forget to budget for both internal training and external courses.

Improving Communication and Collaboration

Creating a culture of open communication can prevent maintenance issues from escalating into major problems.

Maintenance teams need reliable methods to share information about equipment conditions and repair needs.

Daily briefings and standups keep everyone informed about priority work and safety concerns. These short meetings coordinate activities and prevent scheduling conflicts.

Digital communication tools, such as a CMMS platform, enable real-time updates on equipment status. Mobile apps allow technicians to report issues immediately from the field.

Cross-departmental collaboration improves maintenance planning. Production teams can provide valuable insights about equipment performance patterns.

Feedback mechanisms and performance reviews create ongoing dialogue between workers and management.

This fosters a culture of accountability and continuous improvement.

Creating documentation standards and standard operating procedures (SOPs) can create standards that can ensure knowledge gets shared across the team.

With Proper record-keeping, teams learn from past maintenance experiences and avoid repeated problems.

Tips to Optimize Maintenance Operations

What are some tips that manufacturing facilities can use to optimize operations, reduce downtimes, and control costs?

Preventive Maintenance Scheduling and Planning

Unplanned downtime costs manufacturers an average of $50,000 per hour across industries.

Preventive maintenance technologies help detect equipment failures before they occur, reducing unexpected breakdowns by 30-50%.

How can you improve equipment reliability? Start with regular inspection, preventive maintenance schedules, and condition monitoring.

Key reliability strategies include:

- Daily operator inspections for visual signs of wear

- Weekly lubrication checks on critical equipment

- Monthly vibration monitoring on rotating machinery

- Quarterly thermal imaging of electrical systems

Another matrix to consider is Overall Equipment Effectiveness (OEE). OEE measures availability, performance, and quality metrics.

World-class facilities achieve OEE scores of 85% or higher. Most manufacturing plants operate at an OEE of between 60-65%.

Implementing real-time monitoring with IoT sensors can alert maintenance teams when equipment parameters exceed normal ranges. This enables organizations to respond promptly before minor issues escalate into major failures.

Reduce Maintenance Costs

Maintenance costs typically represent 15-40% of total production costs in manufacturing.

Preventive maintenance optimization reduces long-term expenses despite requiring an initial investment.

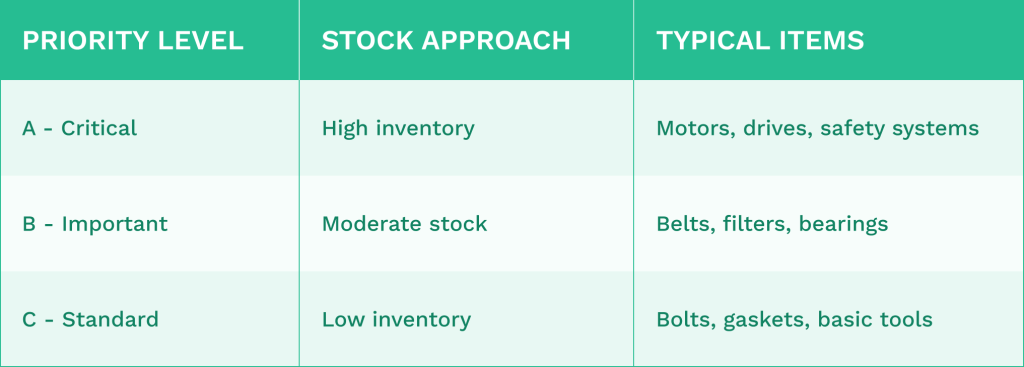

Spare parts inventory management prevents overstocking and keeps critical components available.

Another approach is ABC analysis, which categorizes parts by importance and usage frequency.

Labor optimization focuses maintenance efforts on equipment that has the greatest impact on production. Critical machinery receives priority scheduling and skilled technician assignments.

Planned maintenance costs 3-5 times less than emergency repairs, by reducing both parts and labor costs.

Organizations save money by scheduling work during planned downtime rather than responding to failures.

Measure with Lean Manufacturing and Six Sigma

Lean manufacturing principles are shown to reduce waste in maintenance operations.

It accomplishes that through standardized procedures and visual management systems. These principles incorporate lean tools like 5S workplace organization.

Six Sigma methodologies reduce variation in the maintenance process through data-driven decision-making. DMAIC (Define, Measure, Analyze, Improve, Control) helps identify root causes of recurring equipment problems.

Lean maintenance tools include:

- 5S organization for tool and parts storage

- Visual controls showing equipment status

- Standard work procedures for common tasks

- Continuous improvement through employee suggestions

Six Sigma projects focus on addressing specific maintenance challenges with clearly defined, measurable goals. Teams analyze failure patterns to prevent future occurrences rather than just fixing problems.

Performance metrics track improvement over time. Mean time between failures (MTBF) and mean time to repair (MTTR) provide clear benchmarks for operational efficiency gains.

Driving Continuous Improvement and Regulatory Compliance

A successful preventive maintenance program requires ongoing analysis of performance data to identify opportunities for optimization.

Manufacturing facilities should maintain strict adherence to safety standards while building sustainable processes that deliver consistent results over time.

Leveraging Data and Analytics

Performance Metrics drive meaningful change in maintenance operations.

Key indicators to track include equipment downtime, mean time between failures, and maintenance cost per unit of production.

Teams should track these metrics monthly. Compare current performance with historical data to identify trends and areas for improvement.

Data Collection Systems capture real-time information from equipment sensors and maintenance activities.

Modern CMMS platforms, such as WorkTrek, store this data automatically and generate actionable reports.

Manufacturing teams can boost maintenance efficiency by analyzing patterns in equipment performance. This helps predict when components will fail before they break down.

Root Cause Analysis identifies the reasons why problems occur repeatedly. Document each failure mode and its underlying causes to prevent similar issues.

Regular data review meetings enable maintenance teams to adjust their schedules and procedures. Focus on equipment that generates the highest downtime costs first.

Safety and Regulatory Standards

Industry Compliance requires that maintenance organizations follow specific maintenance protocols for different types of equipment.

For instance, food processing facilities must meet FDA standards while chemical plants follow EPA guidelines.

Document all maintenance activities to prove compliance during inspections. Keep detailed records of who performed the work, when it occurred, and the procedures used.

Safety Protocols protect workers during maintenance tasks. Lockout/tagout procedures prevent accidental equipment startup during maintenance and repair operations.

Personal protective equipment requirements vary depending on the task type. Establish clear guidelines for when workers need respirators, safety glasses, or other protective gear.

Training Requirements ensure technicians understand both safety procedures and regulatory standards. Schedule regular refresher courses to keep skills current.

How to Sustain Long-Term Maintenance Success?

Clear resource planning ensures adequate staffing and budget allocation for ongoing maintenance activities. Plan and budget for equipment upgrades and replacement cycles in advance.

Cross-train multiple technicians on critical equipment. This prevents maintenance delays when key personnel are unavailable.

Standardize your processes to create consistent results across different shifts and technicians.

Develop detailed preventive maintenance checklists for each maintenance task.

Continuous Feedback from operators and maintenance staff reveals opportunities for improvement. Schedule quarterly reviews to discuss what is working well and what needs adjustment.

Track the financial impact of maintenance improvements. Calculate how reduced downtime and lower repair costs contribute to overall profitability.

Conclusion

Preventive maintenance is transformational for manufacturing operations. By implementing the eight best practices outlined in this guide, facilities can reduce equipment failures by up to 70%, extend asset lifespans, and significantly lower maintenance costs.

However, success requires three essential elements: a well-structured maintenance program with optimized schedules, modern CMMS technology that enables data-driven decisions, and skilled maintenance teams committed to continuous improvement.

When combined with proper planning, regular training, and adherence to safety standards, these practices create a sustainable competitive advantage.