Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeCreating a high-performance maintenance team is key for any organization looking to minimize downtime and extend the life of your equipment.

A well-executed plan helps your team stay on track from start to finish. By involving key stakeholders during the planning stage, you can quickly address inconsistencies and missed opportunities, achieving a successful execution.

Regular checks and preventive measures, such as routine inspections, can help you identify and fix issues before they escalate. Incorporating an effective preventive maintenance program and prioritizing critical assets can result in exceptional daily performance, regardless of any challenges.

This structure ensures each team member understands their role and how they contribute to the overall success.

Effective maintenance is about preventing problems. A robust preventive maintenance plan and an inventory of critical spare parts can prepare your team for any situation.

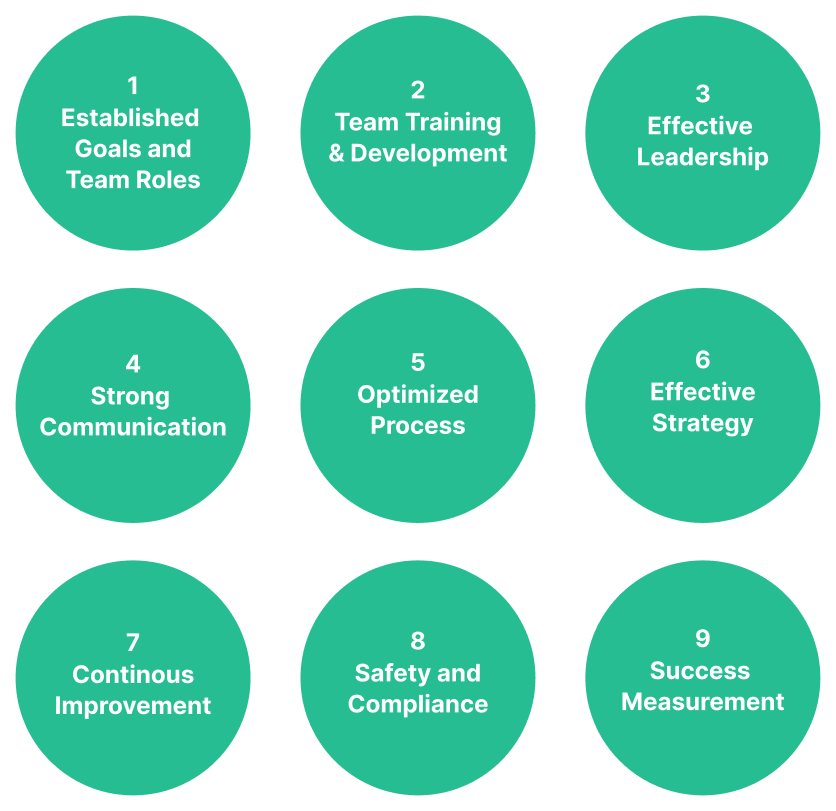

This article highlights the steps you need to build a dependable and high-performing maintenance team.

1. Build the Foundation of a High-Performance Team

Creating a high-performance maintenance team involves setting clear goals and defining each member’s role within the group. Focusing on these essential elements helps align efforts and foster accountability among team members.

Additionally, having a well-defined equipment maintenance strategy is crucial for ensuring preventive maintenance and the longevity of assets.

Defining Team Vision and Goals

You must establish a clear vision and set ambitious, achievable goals to build a high-performance team. Start by discussing what success looks like for your maintenance team. This shared vision should align with the organization’s larger objectives.

A preventive maintenance program is crucial in achieving these goals by ensuring reliability and equipment uptime.

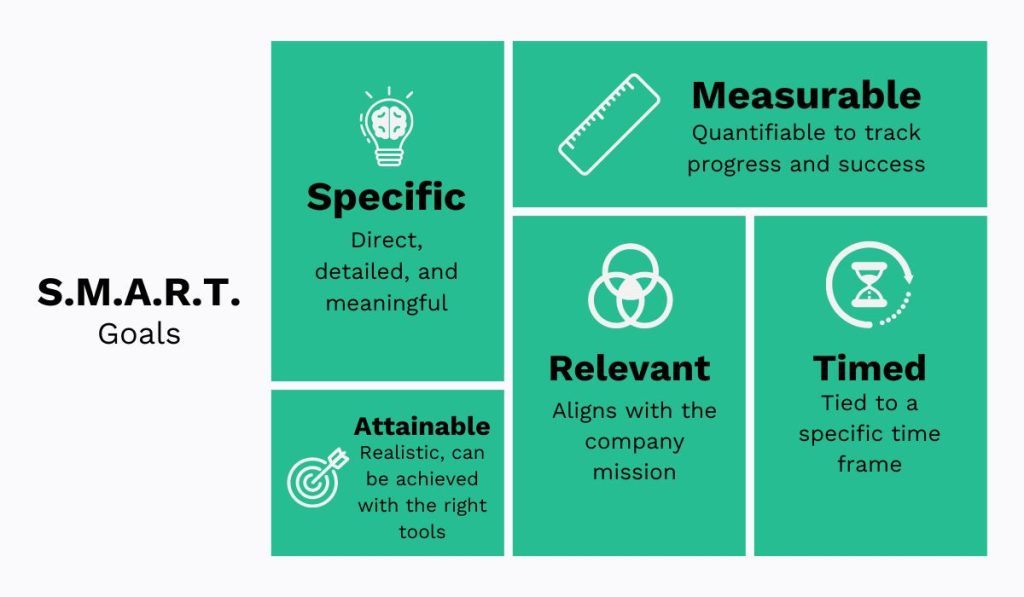

Develop specific goals for the team. These should be SMART goals: Specific, Measurable, Achievable, Relevant, and Time-bound. For instance, if the goal is to reduce machine downtime, set a target percentage for reduction within a specific timeframe.

Revisit these goals regularly and adjust them as needed. Keep everyone informed about progress toward these goals to maintain motivation and accountability.

Source: WorkTrek

Establishing Team Roles and Responsibilities

Clearly defined roles and responsibilities are essential for a high-performing maintenance team. Each team member should understand their specific duties and how they contribute to the overall team’s success.

Create a responsibility matrix to map out who is responsible for what tasks. This can include roles like preventative maintenance, emergency repairs, and inventory management.

Source: Forbes

In addition, cross-training should be encouraged to ensure team members can cover for each other during absences. This not only improves flexibility but also enhances team cohesion and trust.

Review and update these roles regularly to reflect any changes in team dynamics, skills, or organizational needs. Communicating these changes ensures everyone remains on the same page and works efficiently.

2. Invest in Team Skills and Competencies

Enhancing team skills and competencies is crucial to building a high-performance maintenance team. This involves implementing ongoing training programs and promoting cross-functional skill development.

Reliability-centered maintenance can improve skill development by integrating predictive, real-time monitoring, and proactive maintenance practices.

Implement Ongoing Training Programs

Regular training ensures team members stay updated with the latest technologies and keep their skills up to date.

It is crucial to communicate to teams the importance of breakdown maintenance, which is corrective and urgent in contrast to preventive maintenance.

Schedule these sessions frequently to cover new maintenance methods, safety protocols, and equipment usage.

Hands-on workshops can be especially beneficial. Encourage participation in industry conferences and seminars. Online courses and certifications can also provide valuable knowledge without requiring travel.

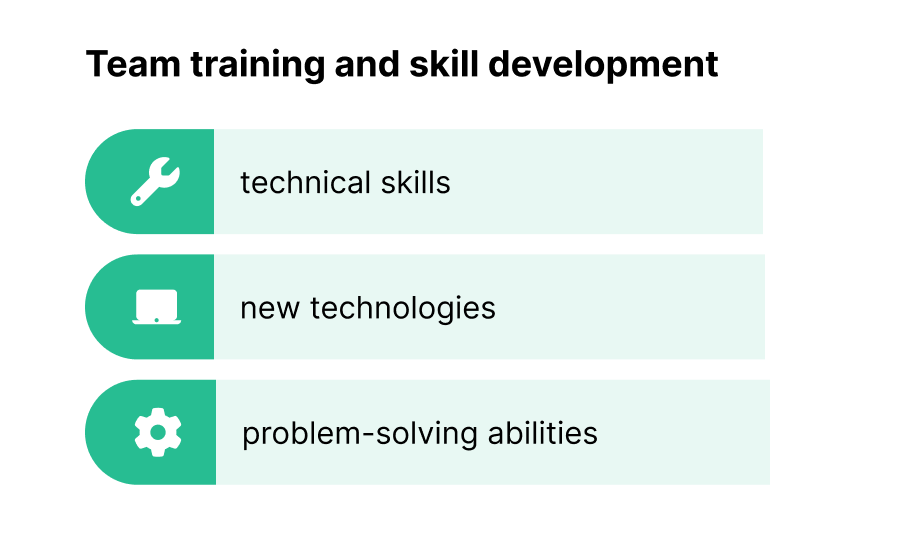

Examples of Training Topics:

- Safety Procedures: Understanding and applying the latest safety standards.

- Technical Skills: Learning advanced troubleshooting techniques and new equipment operations.

- Software Use: Mastering maintenance management software.

Providing consistent training opportunities helps maintain high standards and keeps skills sharp.

Promote Cross-Functional Skill Development

Encouraging team members to develop skills beyond their primary roles enhances versatility. Routine maintenance involves planned and ongoing tasks to prevent problems and is crucial in cross-functional skill development. This makes the team more adaptable and prepares them for varied challenges.

Pair less experienced members with seasoned professionals for mentorship. Create a rotational schedule where team members can try different roles. Offer workshops that cover multiple disciplines within maintenance.

Benefits of Cross-Functional Skills:

- Enhanced Flexibility: Members can step into different roles as needed.

- Improved Problem-Solving: Broader skill sets enable tackling complex issues more effectively.

- Stronger Team Cohesion: Working in various capacities fosters a better understanding and collaboration.

Promoting a multifaceted skill set creates a robust team capable of maintaining high performance under diverse conditions.

Source: WorkTrek

3. Develop Effective Leadership

Developing strong leadership is key to building a high-performance maintenance team. To ensure operational success, focus on empowering leaders and fostering skills among all team members.

Empowering Team Leaders

Empowering team leaders means giving them the authority and tools to make decisions. Leaders should have access to all necessary resources, including training, budget, and personnel. Encourage decision-making by outlining clear goals and expectations, which will help them guide their teams effectively.

Regular communication is vital. Hold frequent meetings where leaders can discuss challenges and share solutions. This not only builds trust but also promotes a collaborative environment.

Participation in leadership development programs is also important, as it helps refine their skills and keeps them updated with modern management techniques.

Recognize and reward exceptional leadership. Positive reinforcement boosts morale and motivates leaders to maintain high performance.

This could be in the form of bonuses, public recognition, or career advancement opportunities. Empowered leaders are more likely to inspire their teams to achieve organizational goals.

Fostering Leadership Skills Among Team Members

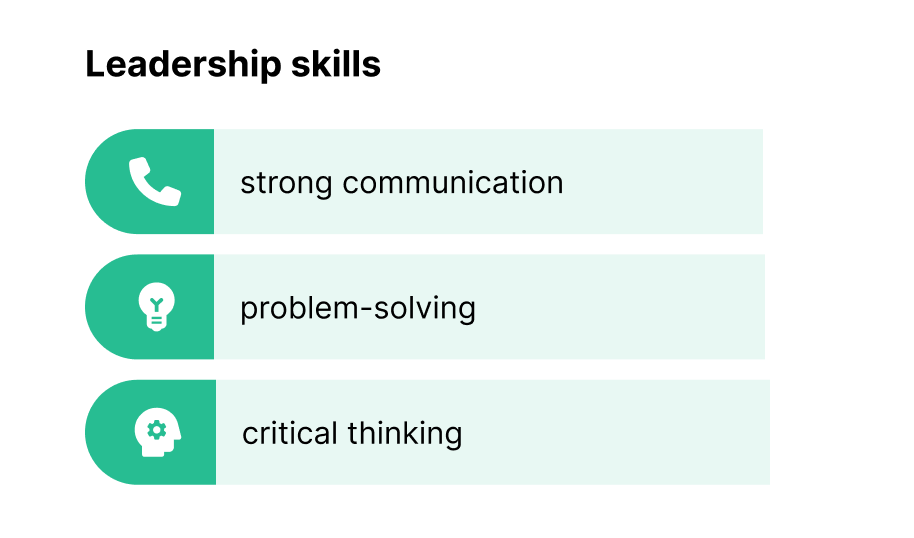

It’s important to develop leadership skills among all team members, not just those in formal leadership roles. Start by offering training sessions on communication, problem-solving, and critical thinking. These skills help team members take initiative and contribute more effectively.

Create opportunities for team members to lead projects. This hands-on experience is invaluable for building confidence and competence. Set up mentoring programs where experienced leaders can guide less experienced team members.

This fosters a culture of continuous learning and development.

Feedback plays a crucial role in the development of leadership skills. Provide constructive feedback regularly to help team members understand their strengths and areas for improvement. This can be done through one-on-one meetings or performance reviews.

Encourage a culture where feedback is seen as an opportunity for growth rather than criticism.

Source: WorkTrek

4. Cultivate a Culture of Communication

Clear communication ensures that all team members stay informed, collaborate effectively, and address issues promptly. It is essential for productivity, team cohesion, and efficient problem-solving.

Enhancing Information Sharing

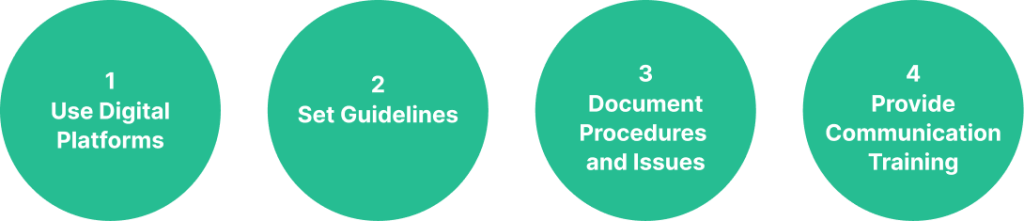

Promote information sharing by implementing shared digital platforms. Tools like Slack or Trello can help keep everyone updated.

Set guidelines on how information should be shared. For example, urgent updates could use a specific channel, while regular updates might use another.

Encourage documenting maintenance procedures and issues. This creates a valuable reference for current and future team members.

Provide training on effective communication techniques. This includes clarity in messaging and understanding how to use the tools provided.

Source: WorkTrek

Implementing Regular Team Meetings

Schedule regular team meetings to go over upcoming tasks and projects. This helps align everyone’s efforts and clarifies responsibilities.

Use these meetings to discuss any roadblocks or issues. This proactive approach can prevent minor problems from becoming significant setbacks.

Encourage participation from all team members during these meetings. Everyone should feel their input is valued and necessary.

Keep the meetings structured but flexible. A well-organized agenda can make discussions more efficient while leaving room for spontaneous, productive conversations.

Source: WorkTrek

Encouraging Open Feedback

Create an environment where team members feel safe giving and receiving positive feedback and constructive criticism.

Implement anonymous feedback tools if necessary. This can help those who are hesitant to speak up in public settings.

Act on the feedback received. Showing that feedback is taken seriously can motivate team members to participate more actively.

Recognize and reward constructive feedback. This can be done through simple gestures like verbal acknowledgment or more formal recognition programs.

Source: WorkTrek

5. Optimize Workflow and Processes

Optimizing workflow and processes ensures your maintenance team operates efficiently and minimizes downtime. Key strategies include streamlining procedures and leveraging technology and automation.

Streamlining Maintenance Procedures

To streamline maintenance procedures, first identify and eliminate unnecessary steps. This makes workflows more efficient.

Begin by mapping out each task your team performs. Point out repetitive or redundant tasks that can be removed or combined.

Implement standardized procedures to ensure consistency. Use checklists and templates to guide your team through each step. This reduces errors and the time spent on each task.

Review and update procedures regularly. Incorporate feedback from your team to continuously improve processes. This keeps workflows relevant and efficient. Streamlined procedures lead to faster turnaround times and greater productivity.

Leveraging Technology and Automation

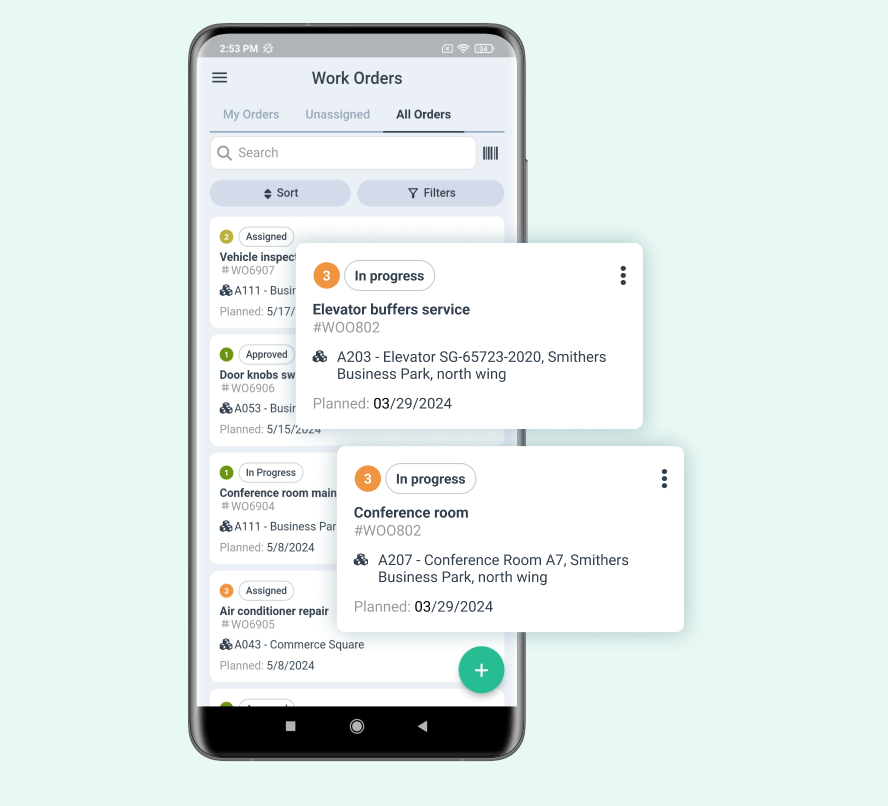

checLeverage technology and automation to take your maintenance processes to the next level. Utilize workflow management software to automate repetitive tasks. This reduces errors and frees up your team for more meaningful work.

Integrate sensors and monitoring tools, such as RFID tags, to detect issues before they become significant problems. Predictive maintenance can notify your team of required maintenance, reducing unexpected breakdowns.

Adopt mobile solutions to enable real-time updates and communication. Use tablets or smartphones with CMMS software to access maintenance records and update work orders. This ensures your team is always informed and can respond quickly.

By leveraging technology, you enhance efficiency, accuracy, and operational effectiveness.

Source: WorkTrek

6. Implement Predictive Maintenance Strategies

Successfully implementing predictive maintenance strategies involves analyzing equipment performance data and scheduling proactive maintenance activities to prevent unexpected failures and improve equipment longevity.

Analyzing Equipment Performance Data

To start, equip your machinery with sensors that collect real-time temperature, pressure, and vibration data. This information helps identify patterns and anomalies. For example, time series process data is commonly analyzed in predictive maintenance.

You should use an analytics engine to process the collected data. Look for trends over time to predict potential issues before they occur.

Ensure data cleansing techniques are applied to remove outliers and fill in missing values, improving the accuracy of your predictions.

Monitor the data regularly and update your predictive models to reflect new findings. This continuous improvement helps in early detection and allows for timely interventions.

Source: WorkTrek

Scheduling Proactive Maintenance Activities

Once you’ve analyzed the performance data, schedule maintenance activities based on the insights gathered and focus on equipment identified as critical during your analysis. This targeted approach ensures resources are used efficiently.

Create a maintenance schedule that aligns with your operational needs without causing significant downtime. This might include off-peak hours or planned shutdowns.

Proactive maintenance reduces the risk of unexpected breakdowns and extends the life of your equipment.

It’s also important to keep detailed records of all maintenance activities. Implementing a CMMS can help automate both data collection and storage.

Documenting helps track the effectiveness of your predictive maintenance strategy and make necessary adjustments.

Regularly review and adjust your maintenance schedule based on new data and evolving operational requirements.

7. Focus on Continuous Improvement

Continuous improvement is critical to maximizing the efficiency and effectiveness of your maintenance team. By adopting lean maintenance practices and utilizing key performance indicators (KPIs), you can ensure long-term success and growth.

Adopt Lean Maintenance Practices

Lean maintenance focuses on reducing waste and optimizing processes. To start, you can adopt strategies like the 5S methodology. This involves sorting, setting in order, shining, standardizing, and Maintaining the workspace to improve efficiency.

Regularly conduct preventive maintenance to avoid unexpected breakdowns. Plan maintenance activities during downtime to minimize impact on production. Training your team on lean principles ensures everyone is aligned and can identify areas for improvement.

Using tools like root cause analysis helps you understand and address the root of problems, preventing recurring issues. Effective communication and teamwork are crucial in lean maintenance, ensuring smooth operations and quick problem resolution.

Utilize Key Performance Indicators (KPIs)

Key performance indicators (KPIs) are essential in tracking and measuring your team’s success. Important KPIs include Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR). These metrics help you understand equipment reliability and repair speed.

Monitor the percentage of planned maintenance versus unplanned maintenance. High levels of planned maintenance typically indicate a proactive approach.

Track overall equipment effectiveness (OEE), which combines availability, performance, and quality metrics to give a comprehensive view of equipment efficiency.

Regularly reviewing these KPIs enables you to make informed decisions and adjustments. Establish clear benchmarks and goals for your team, and use these metrics to celebrate achievements and identify areas needing improvement.

Source: WorkTrek

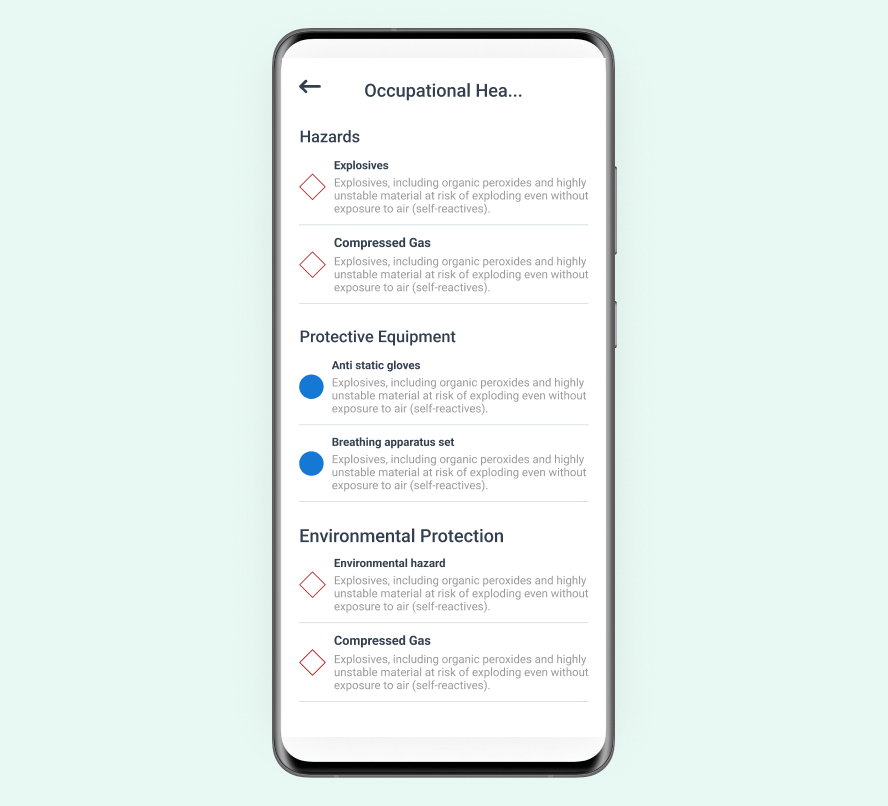

8. Prioritize Safety and Compliance

Maintaining a high-performance maintenance team requires a strong safety and regulatory compliance focus. This ensures that team members work in a secure environment and adhere to necessary standards, which minimizes risks.

Ensuring Adherence to Safety Protocols

Safety protocols are essential to protecting maintenance team members from potential hazards. First, according to the job requirements, everyone should be trained to use personal protective equipment (PPE), such as gloves, helmets, and safety glasses.

Next, conduct regular safety drills. These help team members practice emergency procedures and familiarize themselves with the actions needed in hazardous situations.

Routine inspections are another key measure. Check tools and machinery for defects that could pose risks. Create a checklist that inspects electrical cords, power tools, and other equipment for wear and tear.

Implement a transparent reporting system for safety issues. Make it easy for team members to report unsafe conditions or incidents promptly. Encourage a culture of openness where safety concerns are taken seriously and acted upon immediately.

Staying Updated with Regulatory Standards

Keeping up with regulatory standards is crucial for compliance. Review and update your team’s safety manuals and protocols regularly based on the latest regulations.

Make it a point to subscribe to industry newsletters and updates from relevant authorities.

Training sessions should be scheduled to educate team members about any regulation changes. This keeps everyone informed about new compliance requirements. Assign a dedicated compliance officer to oversee these updates and ensure practices align with current standards.

Perform internal audits regularly. These audits help identify areas where your team might not meet regulatory requirements. Based on audit findings, take corrective actions to close any gaps in compliance.

Use software tools, such as WorkTrek CMMS, to track compliance. These tools can keep records of training, certifications, and safety inspections, ensuring that nothing falls through the cracks. This method also provides a reliable way to demonstrate compliance during external inspections or audits.

Source: WorkTrek

9. Measure and Celebrating Success

To ensure the effectiveness of a high-performance maintenance team, it is crucial to measure and celebrate their successes. This involves setting clear milestones and recognizing the team’s achievements to foster continued excellence.

Setting Achievable Milestones

Setting achievable milestones is the first step in tracking success. Break down larger goals into smaller, more manageable tasks. This makes progress more straightforward to monitor and allows the team to stay focused.

Consider using Key Performance Indicators (KPIs) such as:

- Response Times: Measure how quickly the team responds to maintenance requests.

- Downtime Reduction: Track the reduction in equipment downtime over a specified period.

- Completion Rates: Monitor the percentage of maintenance tasks completed on time.

Review these milestones regularly to ensure they align with the team’s objectives. Adjust them as necessary to keep the team motivated and on track.

Recognize and Reward Accomplishments

Recognizing and rewarding accomplishments is essential for maintaining team morale. Celebrate small wins and significant achievements to show appreciation for the team’s hard work.

You can recognize accomplishments through:

- Public Appreciation: Announce achievements during team meetings or in company newsletters.

- Incentives: Offer rewards such as bonuses, gift cards, or extra time off.

- Career Development: Provide opportunities for further training or professional growth.

Regularly engaging in these practices helps create a positive work environment. It encourages the team to maintain high performance and strive for continuous improvement, making them feel valued and appreciated.

Source: WorkTrek

Frequently Asked Questions

How do you structure a maintenance team?

A maintenance team should be structured with clear roles and responsibilities. Typically, it includes technicians, skilled tradespeople, and maintenance managers. Organizing staff by specific areas like electrical, mechanical, and plumbing can improve efficiency and focus.

What is the hierarchy of maintenance management?

The hierarchy usually starts with maintenance technicians at the base, followed by supervisors or team leaders. Above them are maintenance managers, who report to directors or vice presidents. This structure ensures clear lines of communication and responsibility.

How can you organize a maintenance department to maximize productivity?

Implementing a robust preventive maintenance plan is critical. Setting SMART goals and continuous training also play crucial roles. Efficient communication channels and involving key stakeholders in planning stages help streamline processes and reduce downtime.

What are the roles and responsibilities within a maintenance team?

Maintenance technicians, supervisors, planners, and managers play roles. Responsibilities range from performing routine checks and repairs to managing spare parts inventories and overseeing large projects. Providing ongoing training is essential for keeping skills up-to-date.

What key factors define a high-performance maintenance team?

Strong technical expertise, efficient communication, and a proactive approach are crucial. Teams should focus on preventive rather than reactive maintenance and regularly update their knowledge through training. Engaging team members in planning and goal-setting also contributes to high performance.

In what ways can the effectiveness of a maintenance team be measured?

Effectiveness can be tracked using metrics such as downtime reduction, response time to issues, and completion rates of planned maintenance tasks. Regularly evaluating these metrics helps identify areas for improvement and reinforces successful strategies.