Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeMaintenance audits are an absolute must for keeping your maintenance operations efficient and cost-effective.

However, the process can be pretty complex.

It involves multiple steps and often even multiple people, so it’s easy to overlook some things or miss some crucial steps.

That’s where this ultimate maintenance audit checklist comes in.

It will walk you through every step you need to take to assess your maintenance procedures and pinpoint potential inefficiencies quickly and easily.

Follow it, and you will never miss a thing.

Review Current Maintenance Policies

Are your current maintenance guidelines and standards transparent and easy to follow?

And how effective are they in the first place?

Review all your documentation, including historical upkeep data such as repair logs, service reports, and downtime records, to get the answers.

This will give you a clear picture of how well the policies are performing and if they’re truly achieving the desired outcomes, such as cutting down on asset downtime or repair costs.

If the results aren’t where you want them to be, the policies in place might need an update.

Another important thing to do at this stage is to ask your staff and management for feedback.

The personnel will give you insight into the policy’s practicality, while the higher-ups can tell you whether your policies align with broader company objectives.

Verify That Your Maintenance Procedures Are Documented

Compared to policies, maintenance procedures offer granular instructions outlining specific steps and protocols for keeping your equipment and systems in optimal shape.

To ensure your staff adheres to them, check if these instructions are well-documented.

Start by ensuring they are comprehensive and up-to-date, reflecting changes in the company’s asset portfolio or organizational needs.

You should have protocols for all maintenance situations: preventive, corrective, and emergency.

These procedures also need to be accessible and easy to understand.

So, test whether your team can easily find the files and ensure they have a consistent format.

This includes standardizing naming conventions, fonts, and headings throughout the documents and ensuring all steps, roles, and tools are clearly and logically detailed.

Assess the Integration of Technology

Maintenance technologies like CMMS can be real game-changers for your operations, but only if they integrate well into the existing workflows.

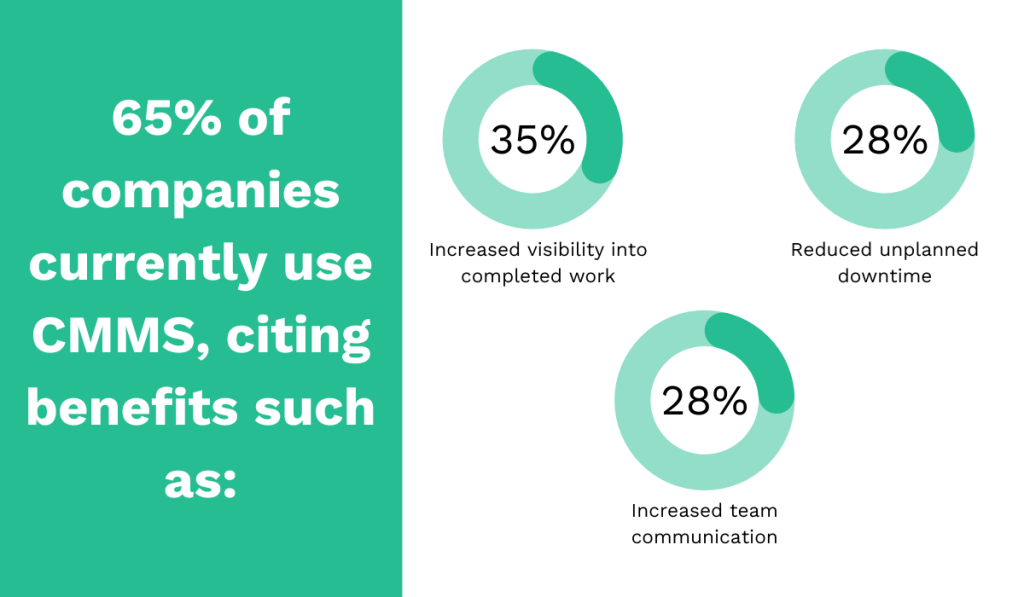

A 2024 UpKeep survey revealed that CMMS solutions help companies increase visibility (35%), reduce unplanned downtime (28%), and boost team communication (28%).

That’s why this phase is about assessing whether your technology is meeting its primary objective: supporting and improving your maintenance processes.

Compare your performance metrics before and after adopting a digital solution.

If you don’t see similar improvements, it could indicate that the tech is either not being used effectively or is not well-suited to your needs.

Perhaps it’s missing key features, failing to automate some time-consuming tasks, or too complex for your employees to use.

Asking your team for feedback can be helpful here, too.

Evaluate Your Maintenance Planning Process

When gauging the efficiency of your maintenance planning, ask yourself three questions.

✅ 1: “Do I even have a standardized planning procedure?”

This might sound basic, but you should always follow a well-defined series of steps when creating a plan, like defining issues, scheduling tasks, and detailing roles.

Without a clear, repeatable process, it’s too easy to miss important elements and end up with an unsuccessful maintenance plan.

✅ 2: “Does my plan consider broader company goals?”

For instance, if your company aims for higher productivity, your plan should prioritize inspections and maintenance of machines and components that could halt the entire operation, like conveyor belts and hydraulic systems on the production line.

✅ 3: “Are the tools I use for planning and scheduling effective?”

Whichever system you use for this task should speed up the process, not slow it down.

If the answer to all these questions is a “yes” congratulations—the way you plan maintenance should deliver great results and keep your operations running smoothly.

Review Your Preventive Maintenance Schedule

Here, first review the intervals between each maintenance session.

They should be appropriately timed, taking into account factors like:

- Labor and resource allocation

- Parts

- Historical data

- Equipment usage

- Manufacturer’s recommendations

- Training and Communication

Remember, both overly frequent and infrequent upkeep can be a sign of an ineffective schedule.

Next, see if your maintenance schedules are comprehensive, specifying all roles, parts, and tasks needed.

This includes verifying that the maintenance documentation is complete and updated, with detailed records of all past activities and their outcomes.

Finally, to gauge how effective these schedules truly are, examine your expenses and downtime records.

If your preventive maintenance efforts are on point, those documents will show proof of that; fewer disruptions and lower maintenance costs.

Examine the Efficiency of Your Work Order Management

Now it’s time to evaluate how your company manages work orders, from requests to execution.

Start by reviewing the work orders themselves.

Do they include all the important details?

Do they clearly state what needs to be done, who will do it, when it should be completed, what resources are required, and where they are located?

To better understand all the elements an effective work order should contain, we recommend downloading our free maintenance work order template.

It’ll make this step of your audit so much easier.

Then, examine how you assign and manage these work orders.

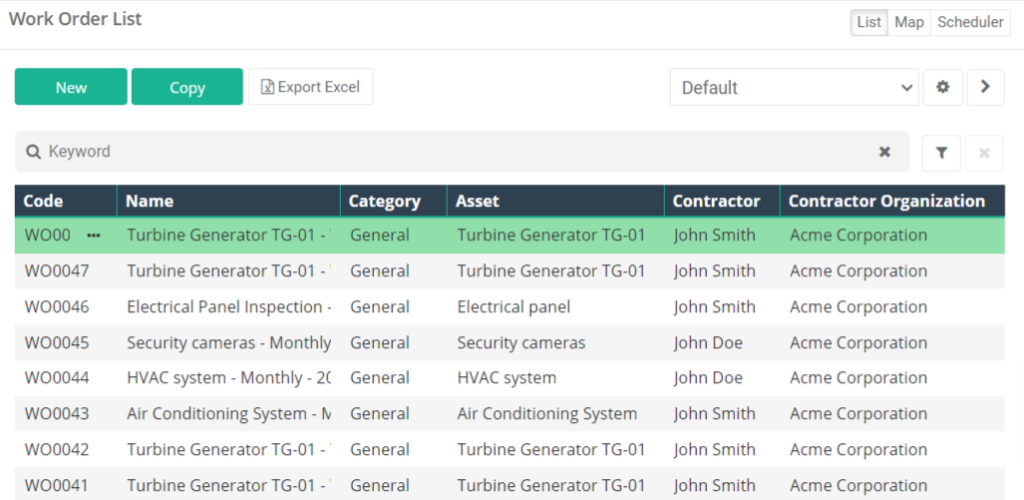

Below, you’ll find the dashboard of our own CMMS, WorkTrek. It’s a good example of what an ideal work order system looks like.

See how neatly everything is organized, making it easy to filter and view statuses, assigned technicians, and more?

Clicking on any work order provides details like priority levels, expenses, parts, and more.

Creating new work orders in WorkTrek is just as easy as tracking them.

The system guides you and ensures all the essential information is captured.

This is precisely what efficient work order management is all about: effortlessly overseeing, creating, assigning, and monitoring work orders, transforming your operational efficiency.

Assess the Condition of Key Equipment

Start by thoroughly inspecting your equipment and assessing its physical condition.

Look for noticeable scratches, dents, cracked components, leaks, or loose connections.

Next, put your assets’ operational efficiency to the test.

Are they performing their intended tasks effectively or does something seem off?

Do they seem slower than usual or make excessive noise?

Finally, don’t forget about safety features and mechanisms.

Every emergency stop button, protective shield, and warning sign shouldn’t just be easily visible and fully functional.

Once you’ve examined all these areas, write down your observations and double-check that your equipment records are accurate and up-to-date.

Evaluate Maintenance Personnel’s Skill Levels

Review training records and certifications to see if your maintenance team has received proper training and if that knowledge aligns with the current skill requirements.

They should be well-versed in relevant safety procedures, lockout/tagout protocols, shutdown/startup processes, and other aspects of their roles.

If you find expired certifications or that certain employees haven’t received training recently, note that.

Identifying knowledge gaps and opportunities for additional training is an absolute must for keeping your operations safe and efficient.

Maintenance audits are the perfect opportunity for that.

Check Compliance with Industry Regulations

Are your maintenance personnel bypassing safety features on machinery?

Using non-approved parts?

Neglecting PPE?

If your audit discovers they do, your upkeep activities may be non-compliant with industry regulations, potentially exposing you to hefty fines and legal issues.

To avoid such risks, review all guidelines that apply to your operations.

Regulatory agencies (like OSHA) or government bodies offer detailed resources on their websites, helping you understand the rules you need to follow.

In addition to learning about relevant standards, review all documentation that helps you demonstrate compliance.

Think maintenance logs, inspection reports, and certification records.

Ensuring these documents are up-to-date, complete, and accurate is vital for avoiding non-compliance risks.

This will help you detect non-compliant activities before they become bigger problems, and it will give you confidence during inspections, knowing you have the proof you need to show everything is up to standard.

Benchmark Your Maintenance Against KPIs

Confirming your maintenance activities are compliant is one thing, but checking whether they’re effective is another.

For that, you’ll need to measure maintenance performance using common maintenance KPIs, such as:

- Mean Time to Detection (MTTD)

- Mean Time to Repair (MTTR)

- Mean Time Between Failures (MTBF)

- Overall Equipment Effectiveness (OEE)

- And many others

Start by benchmarking the industry averages of each metric against your historical data to see how you compare.

You may feel like your MTTR is good enough, but after comparing it to the industry standard (which is under five hours, by the way), you may realize there is room for improvement.

These valuable insights can then be used for creating and optimizing your future maintenance strategies.

Analyze How You Handled Previous Issues

There are many things to be considered here.

First, review the response times. Did your team react promptly when an issue occurred?

Did they use specific tools or techniques, such as root cause analysis?

How did the communication flow between teams? Were there any problems due to poor communication?

Then, you’ll need to assess the outcomes of the actions taken.

Did you fix something temporarily or permanently? Did the previous solutions prevent the same issue from occurring?

And what was the impact on operational efficiency? Did it cause any disruption?

Based on your analysis, you can identify your process’ strengths and weaknesses.

Maybe gaps in knowledge or unclear procedures were the cause of the delays in problem resolution.

Or, on the flip side, perhaps vigilant inventory management ensured all the right parts were on hand just when you needed them, leading to a disruption-free repair process.

Overall, this step will show you which practices to keep and which to change to prevent the recurrence of certain issues and boost your efficiency.

Review the Maintenance Budget Allocation

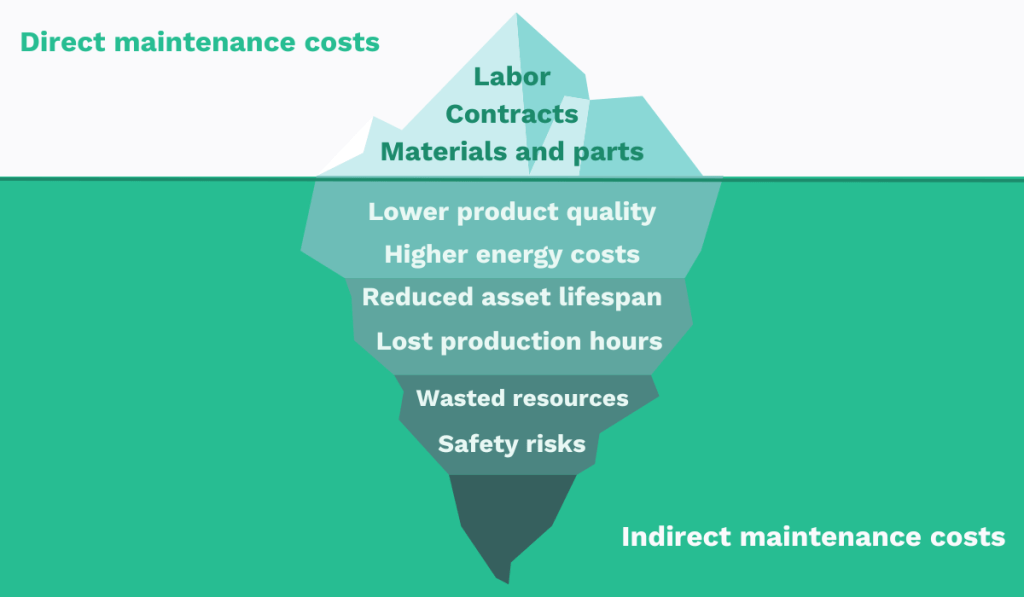

For this step, you’ll need to thoroughly review your financial records and gather all data on your maintenance expenses, both direct and indirect.

Confirm that funds are allocated appropriately across different maintenance categories—preventive, predictive, and corrective—and that you’re not overspending in certain areas.

While you’re at it, also check if your upkeep strategies are providing good value for the money spent.

Take a look at the benefits of various procedures or tools you’ve implemented, and then compare them to their cost.

If specific processes are not yielding significant results but cost a lot, consider redirecting your spending to more effective areas.

Evaluate Your Preparedness for Emergencies

Start with relevant documentation.

Your emergency response procedures should be easily accessible and your staff should know how to use them.

These documents should also be fairly detailed, outlining processes, responsibilities, and available resources.

Plus, if any emergency drills and exercises were conducted in the past, those should be recorded, too, including details on what went well and what didn’t.

Once you confirm your plan is solid, move on to the resources.

Check that all emergency response equipment is available, calibrated, and fully operational.

Identify if anything’s missing or if certain assets need more frequent inspections.

Remember, even the best strategy falls short if the tools and resources required to execute it aren’t up to par.

Conclusion

Don’t maintenance audits now seem far more manageable?

Sure, there’s a lot of data and documentation to review, but with this checklist, you’ll breeze through the whole process.

Think of it like this: maintenance audits are the door to improving your entire upkeep regime, leading to greater efficiency and significant cost savings.

This checklist is, then, the key that opens that door.