Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeA computerized maintenance management system, or CMMS software, automates work orders, provides asset management, and key API integrations.

CMMS is essential for the coordination of all activities related to the availability, productivity, and maintainability of complex systems.

Modern computer resources have made it possible to considerably improve the effectiveness and efficiency in the field of maintenance through the use of CMMS. CMMS software solution has evolved from relatively simple mainframe scheduling of maintenance activities to multi-user systems that cover a multitude of maintenance functions.

The ability of CMMS to process large amounts of data in a targeted and rapid manner has opened up new possibilities for maintenance, facilitating a more deliberate and thoughtful approach to asset lifecycle management.

What Is A CMMS?

The acronym CMMS stands for Computerized Maintenance Management System. This software package was designed to manage maintenance practices globally on a strategic, financial, and operational level. Today, it is the essential software of the industrial sector. Much more than simple computer programming, it is an assistant for maintenance teams, the cornerstone of industrial efficiency.

Because it can be used to achieve different goals, there are different ways to describe computerized maintenance management software. On the one hand, it is sophisticated software that captures and uses thousands of data points to provide an overview of how a facility is operating or detailed information about individual pieces of equipment.

In terms of functionality, CMMS software allows businesses to monitor inventory levels, manage work orders, set up and schedule preventive maintenance programs, and quickly generate accurate reports. But on another level, it’s just the solution maintenance managers need. Automating processes and streamlining workflows makes your life less stressful by making your workday more predictable.

How Does It Work?

The easiest way to understand how it works is to first look at two old ways of managing maintenance, paper and spreadsheets.

With paper, you always run the risk of losing or corrupting data. Every time you doodle a new work order, you’ll likely include mistakes. And even if you copy everything perfectly, chances are someone will lose that piece of paper, your only copy of that essential data. With spreadsheets, it’s the opposite problem. The risks of copying and pasting insufficient data are still there, but you often have too many copies of the same data now. Why is this a problem? Because as soon as someone updates one copy’s information, all other disconnected copies are out of sync. Ultimately, each team member works from their version of the truth. Everyone is out of it, but no one realizes it.

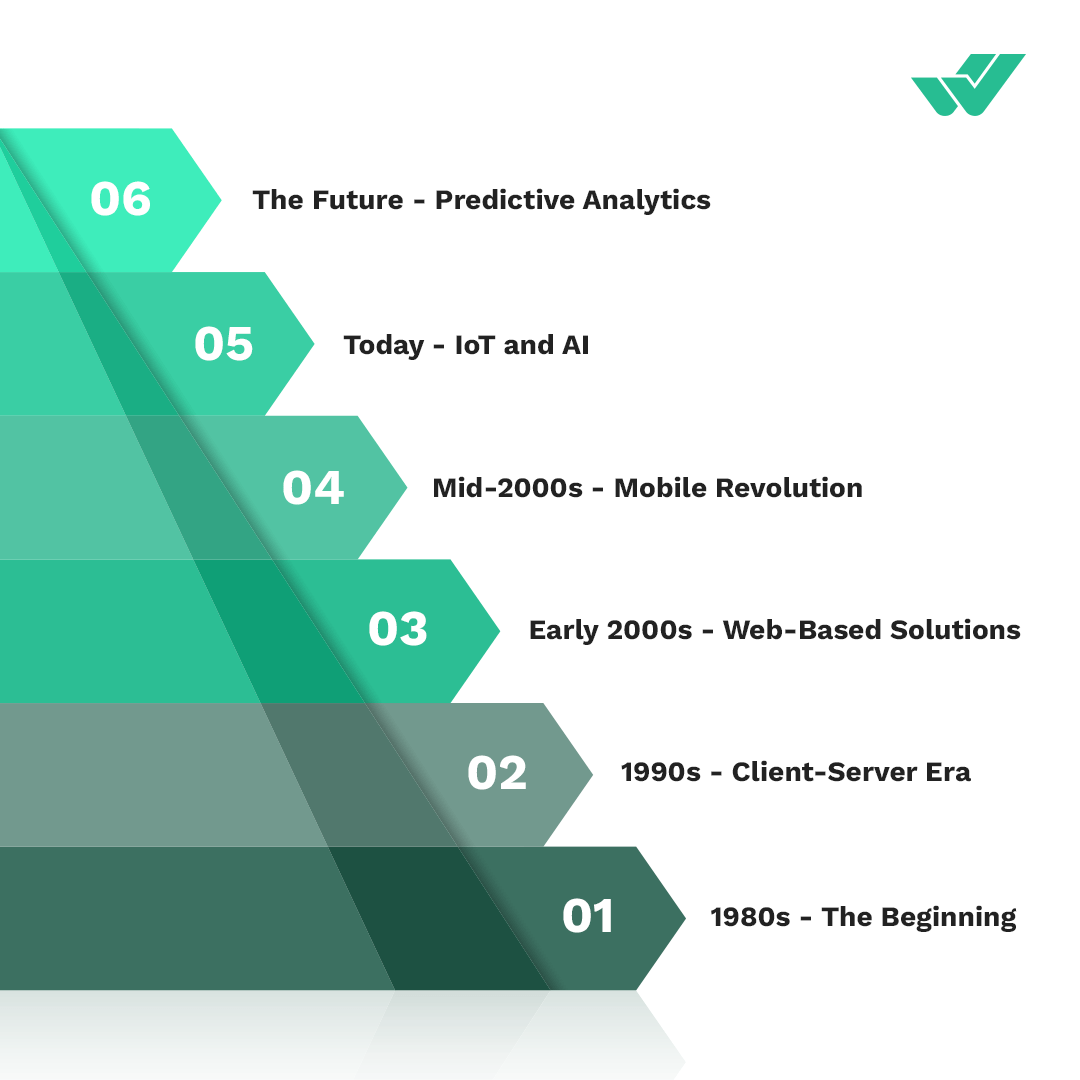

The History

Its origins date back to the 1970s when industrial tools became more complex, with the transition from mechanics to electronics and the emergence of robotics. The industrial sector is becoming more and more demanding. The “zero breakdowns, zero defect” injunctions are everywhere. In the 1980s, it was computerization that transformed the maintenance professions.

The first maintenance management programs appear. The 1990s marked the expansion of CMMS, which was no longer content with serving the industry but also the tertiary sector. It was finally in the 2000s that CMMS software took off. And the web has something to do with it. With reduced hardware investment and reduced installation costs, the entire web CMMS enters the scene and promises great capabilities in terms of ergonomics and functionality. Nowadays, in the era of the Cloud and galloping digitization, the user experience is enriched. A CMMS software solution package is essential for operational teams.

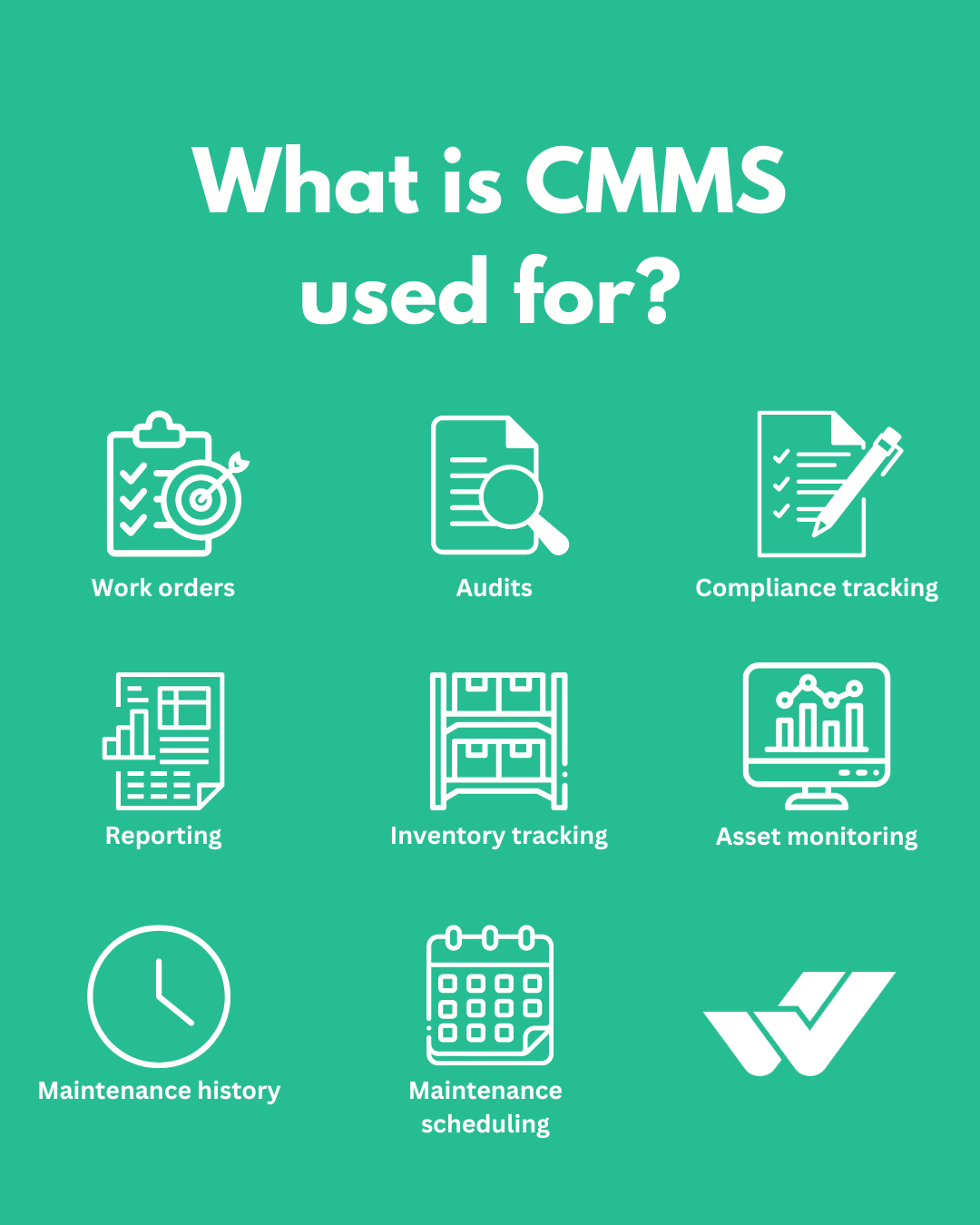

What Is The Role Of A CMMS?

Essential in the industrial sector, the CMMS has many uses. In particular, it allows operational staff and the management team to:

- Knowing, identifying, and managing the equipment to be maintained: inventory, location, and management of relative information by type of equipment.

- Manage maintenance practices: preventive, curative, corrective, and improvement.

- Manage intervention requests.

- Manage spare parts stocks: by keeping the store up to date, better controlling restocking, and paying attention to stock valuation.

- Manage purchases of supplies and services (equipment rental): purchase requests, orders, and supplier invoicing.

- Coordinate staff and schedules: activities, jobs, load plan, forecasts, etc.

- Manage costs and budgets: Prepare budgets, perform periodic monitoring, report variances between forecasts and actual costs, etc.

- Monitor the activity’s performance thanks to the key performance indicators represented in dashboards specifying the requests, statistics, number of alerts, MTTR (Mean Time To Repair), MTBF (Mean Time Between Failures), Pareto’s law, etc.

Who Is Affected By This Type Of Software?

The CMMS concerns several sectors of activity, as long as they involve maintenance of equipment, buildings, or installations. Here is a non-exhaustive list:

- The real estate sector uses it to centralize information related to building maintenance practices.

- The energy sector uses it in the management of network equipment.

- The transport sector uses CMMS to monitor its infrastructures.

- The public sector uses it in the management of public buildings in communities.

- The medical sector uses CMMS to maintain equipment essential for medical operations.

- The industrial sector uses it for the maintenance of automated machines.

Who Uses CMMS?

As said, CMMS software is a key tool for manufacturers, all sectors combined, who seek to maintain their production equipment in operational conditions.

Within the company itself, it serves:

- Inevitably, industrial maintenance technicians are the first users of CMMS software.

- The maintenance manager will also actively use the CMMS to monitor interventions, manage his stock of parts and monitor his budget.

- Production teams can also use it to have visibility on past and future interventions.

- The purchasing department can also refer to this tool for negotiations.

- The logistics team will also watch the CMMS to manage the stocks of parts and anticipate possible future supplies.

CMMS Features

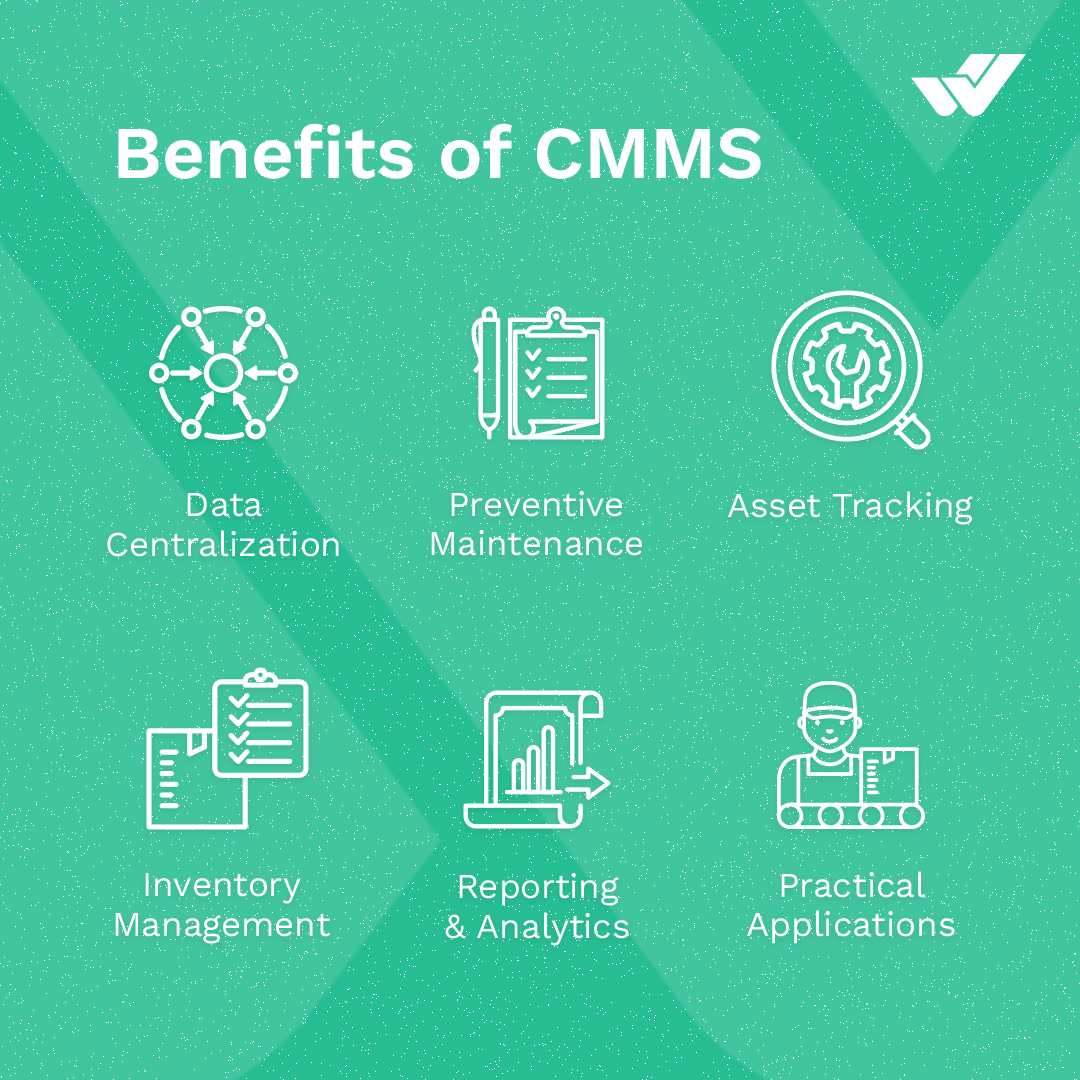

To be completely clear, here are the most used features of CMMS software:

Contract management

It is possible to enter and track all maintenance contracts (maintenance, repair contracts, etc.) in the software.

Intervention planning

It is possible to plan maintenance interventions directly in the software, depending on the type of equipment, location, etc.

Managing your equipment

With the CMMS, you optimally manage your equipment. You can inventory and locate them with ease. In addition, the CMMS allows you to manage information dedicated to each type of equipment. You have easy management, whether production equipment, premises, vehicles, etc.. This management also includes technical documentation, such as plans or manufacturer documentation. The CMMS software offers you perfect knowledge of your equipment fleet. Thanks to the creation of this repository and the Full Web CMMS solutions, all your information is easily accessible to you internally and via the Internet.

Managing your maintenance

This is the second strong point of the functionalities of CMMS software. Thanks to the assistance of a CMMS, the maintenance of all of your company’s equipment is guaranteed. The CMMS allows you to manage both corrective and preventive maintenance. CMMS can help you with:

- Set up a new preventive plan based on past events,

- Define the conditions for condition-based maintenance,

- Log and trace each maintenance operation.

Managing your purchases

Regarding your purchases, the CMMS can save you money by taking charge of the purchasing conditions of your suppliers and allowing you to compare them with each other easily. Integrating purchase requests into the CMMS software allows technicians and members of the maintenance department to have optimal follow-up. They always know the current orders, with which suppliers, etc.

Stock management

CMMS software is exciting for a company’s inventory management features. Indeed, the software knows what quantities of products enter and leave the store, what parts are reserved for interventions, and the minimum and maximum quantities of replenishment. The CMMS software also allows recording:

- equivalent items,

- supplier price catalogs,

- links with the equipment tree,

- Etc.

Managing your staff

The CMMS software also manages your teams’ workload schedules with planning assistance tools and the provisional schedule of work requests to be carried out. It also allows the monitoring of time spent by each speaker. By assisting your company’s maintenance department, the CMMS provides considerable assistance and optimizes its productivity while reducing costs, particularly those related to the maintenance and upkeep of your equipment.

Inventory of spare parts

Inventory tracking and control are improved, ensuring spare parts are available when needed and maximizing uptime. Part requests and orders are integrated into the CMMS to obtain better efficiency. Suppliers and their performance are monitored. CMMS data can then be used to accelerate future budgeting and planning efforts.

Maintenance schedule

Preventive and routine maintenance is essential to ensure equipment and supporting facilities are properly functioning. Prior scheduling notices are issued automatically, which allows for better manpower planning. Renewals and terms of service contracts are tracked, and early expiration warnings are produced.

Safety inspections

Visual and instrumental safety inspections are essential for the safe operation of equipment. Computer programming of these inspections guarantees an optimal inspection schedule. In addition, routine computer analyses of inspection results provide warnings of impending safety issues.

Accurate Monitoring Of Industrial Maintenance

The CMMS allows the complete management of the machine park, the organization and planning of regulatory preventive and curative interventions, the analysis and management of the stock and purchases of spare parts, and the overall analysis of the activity through reporting, dashboards, and statistics while taking into account the reality on the ground and its constraints.

Tools that aim to improve the performance and traceability of interventions in real-time. But it is also a turnkey analysis tool that can provide information to experts and cross-reference data from other systems to make better decisions and thus optimize maintenance costs.

In some cases, it acts as a social network, specifically associated with industrial maintenance, making it possible to share knowledge, good practices, or spare parts between experts from the same factory, group, or company.

It also allows for exchange with the platform’s official suppliers to recover technical information to combat machine obsolescence.

CMMS software is, therefore, the key to simple and connected maintenance management.

Objectives Of CMMS

The objective of the CMMS is to allow an industrialist to better manage the maintenance operations of his installations, thus increasing his efficiency and profitability. Fewer breakdowns on the machines mean more production, customer satisfaction, and turnover. Thus, the CMMS allows the maintenance manager to follow all the key elements for managing his scope. It is an essential tool for setting up and respecting a maintenance plan.

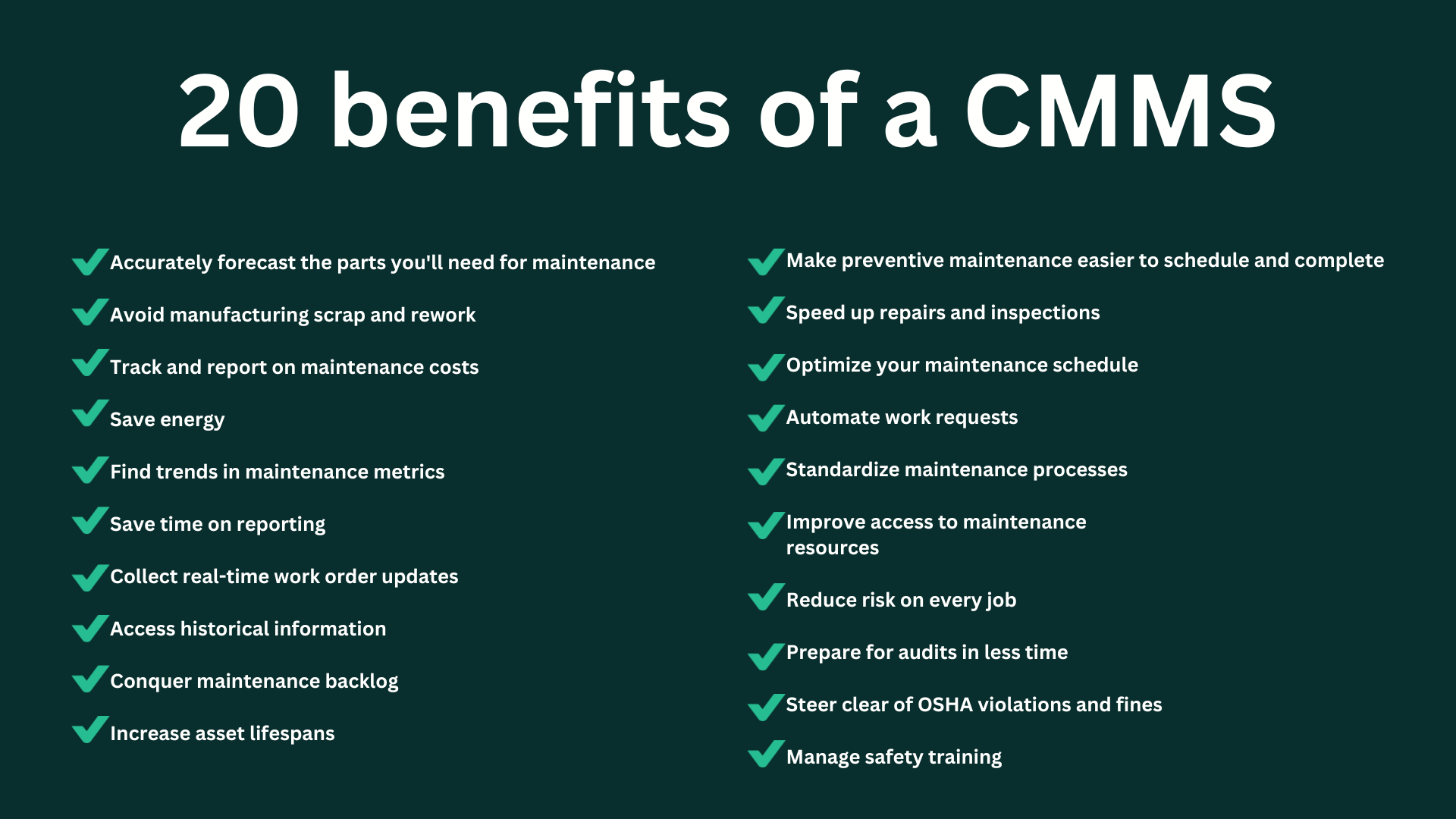

Benefits Of CMMS

The CMMS offers several advantages to manufacturers who decide to implement this solution in their computer system in particular:

- Improvement of equipment availability rate and better analysis of its lifespan and long-term depreciation.

- Cost reduction.

- It improved stock management.

- Optimization of the technical service organization thanks to the recording of operating modes, the monitoring of interventions, and the increase in preventive actions.

- Inventory of equipment, incident prevention, planning, and monitoring regulatory controls.

- Control of the quality of the unit’s customer services and monitoring of the evolution of the breakdown rate thanks to the indicators delivered by the software.

- Centralization of technical, administrative, and financial documentation for equipment and traceability of history and costs related to maintenance operations carried out on each piece of equipment.

- Improved decision-making on equipment renewal, the internal and external maintenance budget to be allocated to equipment, the choice of partners (suppliers, subcontractors, and manufacturers), etc.

Why Invest In Plant Maintenance

Investing in proper maintenance of a building means guaranteeing greater:

- safety (think of the importance of correct management of the alarm or fire prevention system),

- comfort,

- energy efficiency,

- duration over time.

In large buildings, many systems and structures are subject to maintenance, and their management is often complicated. Exploiting technology’s advantages means facilitating the achievement of those benefits and anticipating problems.

Continuous maintenance prevents breakdowns and malfunctions and prolongs the useful life of a system. All this also translates into lower costs, both for regular management and for any unforeseen events. Thus, we move from corrective maintenance, which solves a problem, to preventive or predictive maintenance.

The Evolution Of CMMS

If the CMMS is an asset in the industrial sector, it is, however, not deployed optimally in all companies. Nearly half of the players in the industrial sector do not have it in a complete and sufficiently structured way. Remember that CMMS software is a giant step towards the modernization of the information system and an undeniable competitive advantage.

The CMMS and EAM have not reached the end of their possibilities.

It can be coupled with an EAM (Enterprise Asset Management) solution to manage the life cycle of an organization’s physical assets.

Digitization allows mass data processing and makes the tool even more efficient. Artificial intelligence gives it a more sophisticated dimension. With ever more autonomous and intelligent software, maintenance is entering the 4.0 era.

What Is The Difference Between EAM And CMMS?

CMMS and EAM (Enterprise Asset Management) systems have similar goals and some of the same functionality, although EAM systems offer a wider range of functionality. What really sets them apart is philosophy and scope.

A CMMS system focuses on support, while an EAM system takes a holistic approach, integrating multiple business functions. The CMMS begins to provide follow-up after the purchase and installation of an asset. On the other hand, the EAM system can follow the entire life cycle of an investment, starting with design and installation. A CMMS system is designed to handle a single site or offer limited multi-site support. The EAM system has extensive functions to manage multiple sites and companies.

An EAM system is much more than a reinforced CMMS. It is a comprehensive tool for managing physical assets and optimizing their performance across the enterprise. EAM is a CMMS combined with an inventory management system, a purchasing management system, a document management system, an accounting system, a project management system, multi-site management tools and performance management, all in one integrated software.

What Does A CMMS Software Implementation Look Like?

Once a team chooses CMMS software, it must understand its implementation process. On-premise CMMS software is often painful to implement compared to cloud-based systems. Indeed, for an “on-premise” CMMS software, consider the following characteristics:

- You must either wait for the vendor to send you CDs or download the installation files from their website.

- Your IT staff should verify that the software is compatible with your operating system and network.

- Check if, following an update of your computer, there is a risk of compromising compatibility with the CMMS software.

- Access to the software is limited to that specific computer.

- If the CMMS provider does an update, you need to do the subsequent upgrades, which will bring us back to the original process.

- You will rarely be on the latest version, and keeping up to date manually will be challenging.

Not sure if our CMMS services are right for you? Read our blog or take our quiz to learn more! This quiz will help you determine if our CMMS platform is a good fit for your needs and provide you with personalized advice on the next steps. It only takes a few moments to fill out, so why not find out today if our CMMS is right for you?