Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeMaintenance management ensures your business runs smoothly by preventing equipment failures and minimizing downtime. This article highlights the top strategies for maintenance management that can lead to significant savings by optimizing maintenance costs through preventative and predictive strategies.

It’s about planning and controlling maintenance activities effectively. This article will explore key strategies and benefits of effective maintenance management to help improve your operational efficiency.

What do you need to know about maintenance management? Maintenance management is essential for operational efficiency, asset longevity, and safety compliance. It goes beyond simply fixing issues to proactively preventing them.

Different maintenance management approaches include reactive, preventive, and predictive maintenance, each tailored to specific operational needs. These are the cornerstones of proper maintenance management.

Implementing a maintenance management system, particularly with CMMS software, can significantly enhance operational efficiency, reduce costs, and optimize resource allocation.

Introduction

Have you ever marveled at the seamless operation of a sprawling production facility or the reliable services at your favorite hotel? The unsung hero behind this performance is maintenance management. This crucial system ensures operational excellence, whether keeping industrial equipment humming smoothly or the reassuring click of a hotel door locking securely.

Maintenance managers play a pivotal role by assigning tasks to maintenance workers, scheduling contractors, improving employee and asset productivity, and hiring staff to ensure smooth operations.

This approach can improve asset life cycles and transform maintenance operations by enhancing business operations. It can also allow facility and maintenance managers to tailor highly customized maintenance processes.

Understanding Maintenance Management

Explore the core of maintenance management, where comprehensive strategic planning aligns perfectly with seamless execution. This is not just about fixing things when they break; it’s a proactive approach designed to prevent issues before they arise, ensuring operations smoothly.

Definition of Maintenance Management

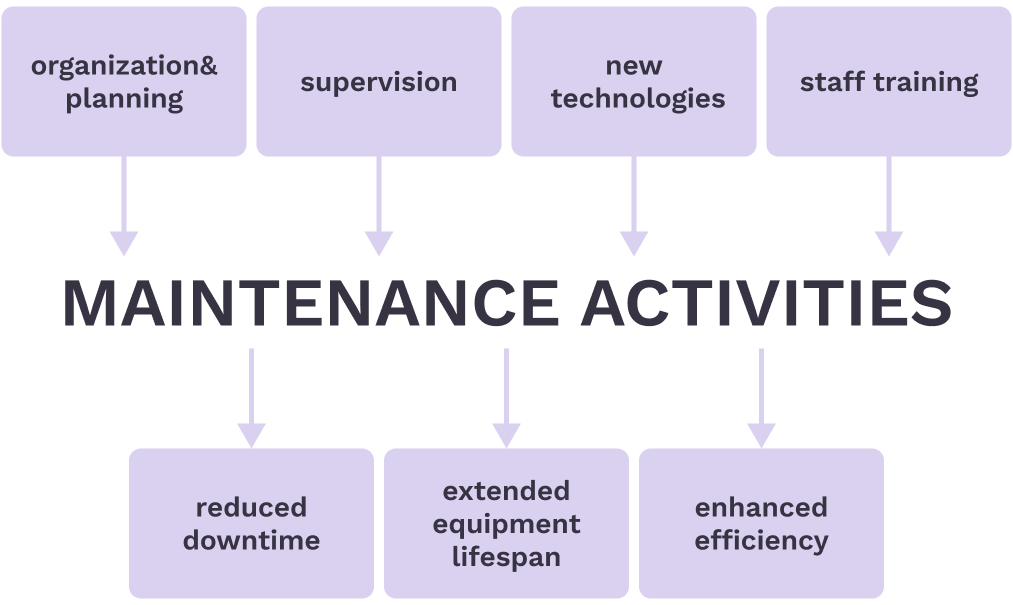

Understanding maintenance management and its best practices is vital for companies to master their maintenance efforts strategically. Through effective organization, planning, and supervision of maintenance activities, they can maintain the performance of a company’s physical assets at peak levels while sidestepping inefficiency traps and the feared downtimes.

Moreover, proficient maintenance operations encompass a range of activities, from routine inspections and preventive maintenance to emergency repairs and predictive maintenance strategies. By integrating these activities into a cohesive maintenance plan, organizations can achieve higher reliability and availability of their assets. This proactive approach helps reduce unexpected downtimes, extend the lifespan of equipment, and optimize overall operational efficiency.

Additionally, proficient maintenance operations require continuous improvement and adaptation to new challenges and technologies. This means regularly updating maintenance practices, investing in staff training, and adopting the latest maintenance management software and tools. By staying ahead of the curve, organizations can ensure that their maintenance operations remain effective and aligned with their strategic goals.

Source: WorkTrek

Importance of Maintenance Management

Maintenance management plays a critical role as it forms the cornerstone of operational efficiency, protecting against excessive costs and ensuring the extended lifespan of assets. It marks the boundary between a flourishing business and one that manages to get by.

Effective maintenance management involves a strategic approach encompassing various methodologies, including preventive, predictive, and reactive maintenance. By leveraging these approaches, businesses can tailor their maintenance strategies to meet specific operational needs, optimizing performance and reducing the likelihood of unexpected failures.

Technology Integration

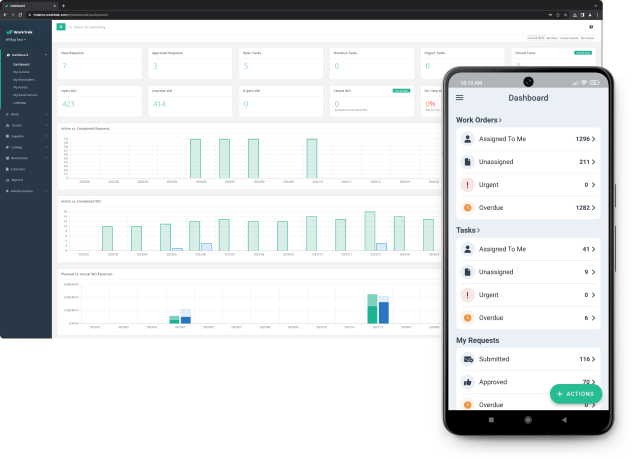

Another critical aspect of maintenance management is the integration of technology. Modern maintenance management systems, such as CMMS (Computerized Maintenance Management Systems), are pivotal in automating and streamlining maintenance activities. These systems provide real-time data and analytics, enabling maintenance managers to make informed decisions and optimize resource allocation.

In summary, maintenance management is a multifaceted discipline that requires a holistic approach to ensure operational efficiency, cost-effectiveness, and asset longevity. It is essential to any successful business strategy, providing a foundation for sustained growth and competitive advantage.

Source: WorkTrek

Key Objectives of Maintenance Management

The quest for excellence in maintenance management revolves around three key objectives: reducing downtime, prolonging asset life, and improving safety and compliance. These are the essential pillars that uphold efficient operations.

Minimizing Downtime

Maintenance management is a reliable shield against downtime. It prevents downtime through oversight and proactive strategies, ensuring that industrial operations and the company’s physical assets remain uninterrupted and efficient.

Extending Asset Lifespan

Physical assets are vital to a company’s health and longevity. Maintenance management ensures these assets have a long and productive life.

Enhancing Safety and Compliance

Compliance and safety don’t happen by chance. By reinforcing these fundamental elements, maintenance management guarantees an operational environment that prioritizes efficiency while safeguarding its most precious resource—its workforce.

Types of Maintenance Management Approaches

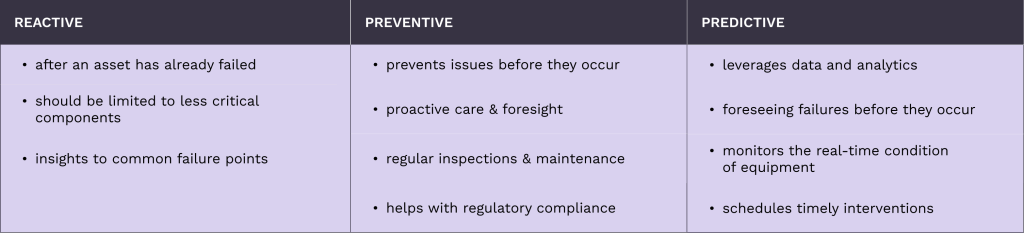

Maintenance management strategies range from reactive to forward-thinking predictive models, catering to various industry requirements. Every plan is customized to meet particular operational demands effectively.

Reactive Maintenance

Reactive maintenance serves as the “emergency response” team in the maintenance world, jumping into action only when an asset has already failed. Ideally, this approach should be limited to less critical components within the broader scope of operational activities.

However, it’s essential to recognize that reactive maintenance, while often viewed as a last resort, can sometimes be thinmlearning experience, offering insights into common failure points and helping to refine overall maintenance strategies.

Preventive Maintenance

A well-designed maintenance program is a crystal ball in preventative maintenance, proactively predicting and addressing potential problems. It also serves as an organized planner for maintenance management, ensuring a seamless experience for everyone involved.

Preventative maintenance is not just about fixing things before they break; it’s about creating a culture of proactive care and foresight. This approach involves regular inspections, routine maintenance tasks, and timely updates to equipment and infrastructure, ensuring that everything operates optimally.

Moreover, preventative maintenance helps in maintaining compliance with industry standards and regulations. Regular checks and updates ensure all equipment meets safety and operational standards, avoiding potential legal issues and fines. This proactive approach also fosters a safer working environment, as potential hazards are identified and mitigated before they can cause harm.

Predictive Maintenance

Predictive maintenance leverages data and analytics to serve in the maintenance world, foreseeing and averting equipment failures before they happen. By leveraging advanced technologies such as IoT sensors, machine learning algorithms, and big data analytics, predictive maintenance can monitor the real-time condition of equipment, predict potential failures, and schedule timely interventions.

This approach minimizes unexpected downtime, optimizes maintenance schedules, reduces maintenance costs, and extends the lifespan of critical assets. Companies implementing predictive maintenance can achieve higher operational efficiency, improved asset reliability, and a competitive edge in their industry.

Source: WorkTrek

Benefits of Maintenance Management System

Embracing a maintenance management system can be compared to discovering an abundant cache of maintenance management benefits. Among the valuable assets it offers are enhanced efficiency, reductions in expenditure, and maximizing resource utilization.

Improved Operational Efficiency

Maintenance management systems act as the blueprint for operational efficiency. Automating tasks and refining workflows can help organizations achieve peak efficiency.

Cost Reduction

In business, every penny saved is a penny earned. Maintenance management systems diligently manage resources to minimize maintenance costs while maintaining exceptional quality and performance standards.

Better Resource Allocation

Inventory management systems are the virtuosos of resource allocation, adeptly orchestrating strategic planning to ensure that every moment, ounce of effort, and item in inventory is utilized with utmost efficiency and not a single aspect is squandered.

Maintenance Management Software

In today’s technological era, computerized maintenance management systems (CMMS) software is the foundational pillar of contemporary maintenance management. This instrument harmonizes every component to create a cohesive concert of effectiveness and dependability.

Features of CMMS Software

A CMMS encompasses a variety of features designed to address every detail of maintenance management. CMMS software should offer:

- Issuing work orders

- Managing inventory

- Scheduling preventive maintenance

- Tracking equipment

- Overseeing asset management

A CMMS efficiently coordinates all maintenance activities by integrating work order management, inventory control, preventive maintenance scheduling, reporting and analytics, and asset tracking. This comprehensive approach enhances productivity and reduces the likelihood of equipment failures and unexpected downtime.

Employing a modern cloud-based CMMS system can significantly reduce your maintenance costs, even when considering the average price of CMMS software.

Choosing the Right CMMS for Your Business

Beginning the search for the right Computerized Maintenance Management System (CMMS) is a distinctive journey. Various pathways are offered, tailored to meet specific requirements and goals. The aim is to find the best fit for your organization’s unique environment.

Industry-Specific Maintenance Management Examples

Maintenance management is a diverse field, with each industry adding unique aspects. It effectively adapts from the structured demands of manufacturing to the specific needs of hospitality, demonstrating its flexibility and strength.

Manufacturing

Maintenance management serves as the core of production activities in the manufacturing sector. It guarantees that each piece of machinery and all maintenance procedures operate perfectly to manufacture products that drive global commerce.

Construction

The foundation of the construction industry is robustly supported by maintenance management, with safety and efficiency being as crucial to it as they are to the edifices constructed within this sector.

Hospitality

In the hospitality industry, maintenance management is an unseen force that guarantees each visitor a flawless experience consistent with those before them, crafting enduring memories.

Setting Up an Effective Maintenance Department

The maintenance department serves as the vital core of any organization, functioning as a fusion point for strategic planning and operational execution to forge an entity marked by dependability and high performance.

Staffing and Training

A robust maintenance department relies on the expertise of skilled maintenance personnel, making staffing and training critical to its success. Staying updated with the latest maintenance trends is vital for efficient and effective operation.

Budgeting and Expense Management

Expense management and budgeting are financial navigational tools for a maintenance department. They direct fiscal choices and confirm that each resource is allocated judiciously.

Performance Monitoring

Performance monitoring serves as the observatory for the maintenance team, diligently overseeing operations to guarantee that performance benchmarks are achieved and surpassed.

Source: WorkTrek

Summary

Effective maintenance management is the silent hero in the grand scheme of operational success. This narrative is powered by forward-thinking strategies, the embrace of advanced technology, and an unyielding commitment to excellence.

Frequently Asked Questions

What is the primary goal of maintenance management?

The primary objective of managing maintenance is to enhance the reliability and availability of assets, guaranteeing seamless operations with reduced downtime and optimal efficiency.

How does preventive maintenance contribute to maintenance management?

Preventive maintenance bolsters maintenance management efforts by orchestrating regular tasks through a schedule. Its purpose is to prevent unexpected maintenance and equipment breakdowns, thus prolonging the life of assets while enhancing their overall functionality.

What role does CMMS play in maintenance management?

CMMS enhances maintenance management efficiency by centralizing data, automating task scheduling, monitoring performance metrics, and aiding in informed decision-making.

Can maintenance management impact safety and compliance?

Indeed, maintenance management greatly influences safety and adherence to regulations by conducting periodic reviews, employing software for monitoring activities, and documenting them.

What should be considered when choosing a CMMS?

When selecting a Computerized Maintenance Management System (CMMS), evaluate its functionality, various deployment alternatives, how well it aligns with your company’s requirements, and the total expense of acquiring the software to ensure an informed choice.