Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways

- Match the maintenance program type to equipment requirements and company resources for best results

- Focus on time-based, usage-based, or condition-based triggers, depending on the asset characteristic

- Regular monitoring and program adjustments ensure continued effectiveness and cost savings

Choosing the right preventive maintenance program can make the difference between costly equipment failures and a productive operation.

Businesses often struggle with equipment breakdowns, unexpected repair costs, and production delays that could be prevented with the right maintenance approach.

So what is the solution?

The key to selecting the right preventive maintenance program lies in matching the program type to specific equipment needs, operational goals, and any available resources.

Developing and building the right program for your facility depends on understanding the preventive maintenance process.

For those companies that implement an effective preventive maintenance program, they can generally see reduced downtime, lower costs, and extended asset life. The right program transforms reactive maintenance into a proactive strategy that protects both equipment and budgets.

Understanding Preventive Maintenance Programs

What is part of a preventive maintenance program? Let’s first start with a definition.

Definition and Core Concepts

Preventive maintenance is the ideal solution for keeping assets in good working order.

PM programs often involve scheduling maintenance tasks, such as inspecting equipment for potential issues before they become significant problems.

In addition, it can include policies, procedures, and tools to regularly maintain company assets. A typical program includes tasks like cleaning, lubricating moving parts, and replacing components before they fail.

Key elements of preventive maintenance include:

- Asset inventory and prioritization

- Scheduled maintenance activities

- Regular inspections and monitoring

- Documentation and record-keeping

PM contrasts sharply with reactive maintenance. In reactive maintenance, equipment is only fixed or maintained after it breaks.

Understanding Your Maintenance Strategy Options

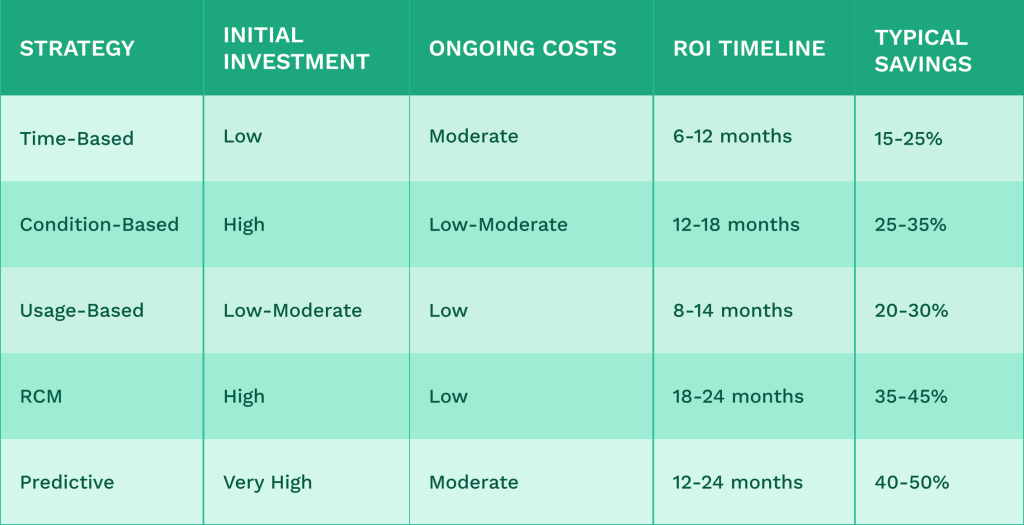

Before you can choose the right maintenance strategy, you need to understand what’s available. Each approach has distinct advantages depending on your equipment, industry, and resources.

Time-Based Preventive Maintenance

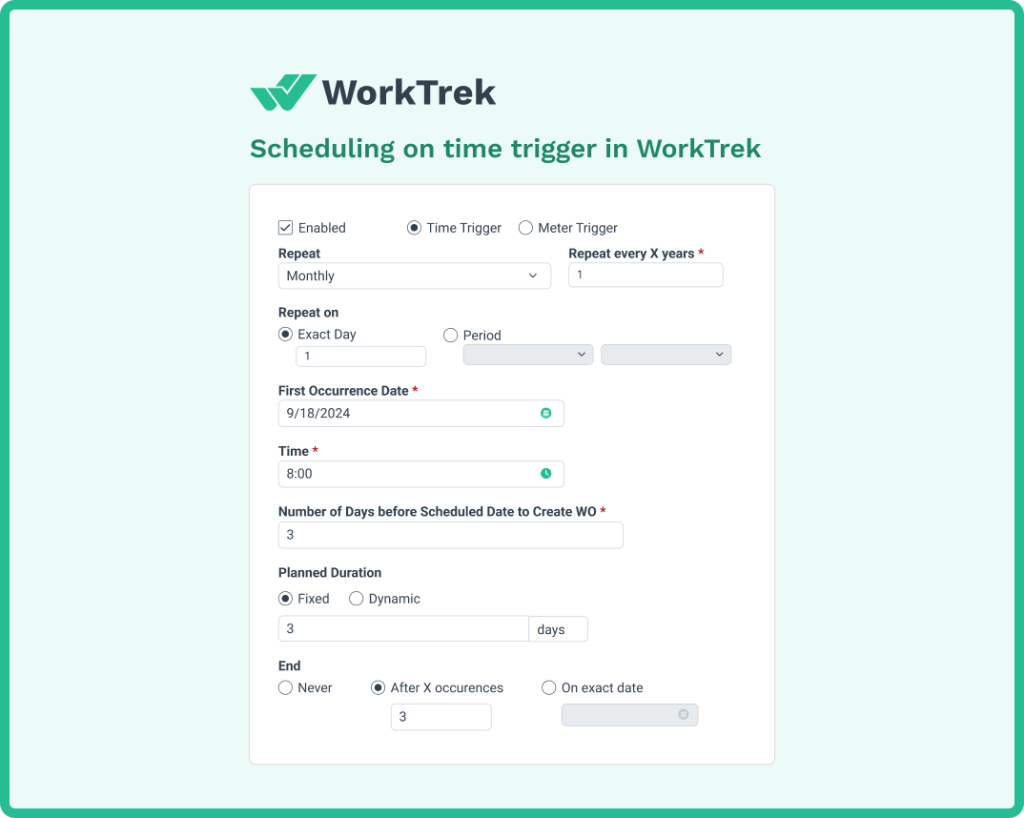

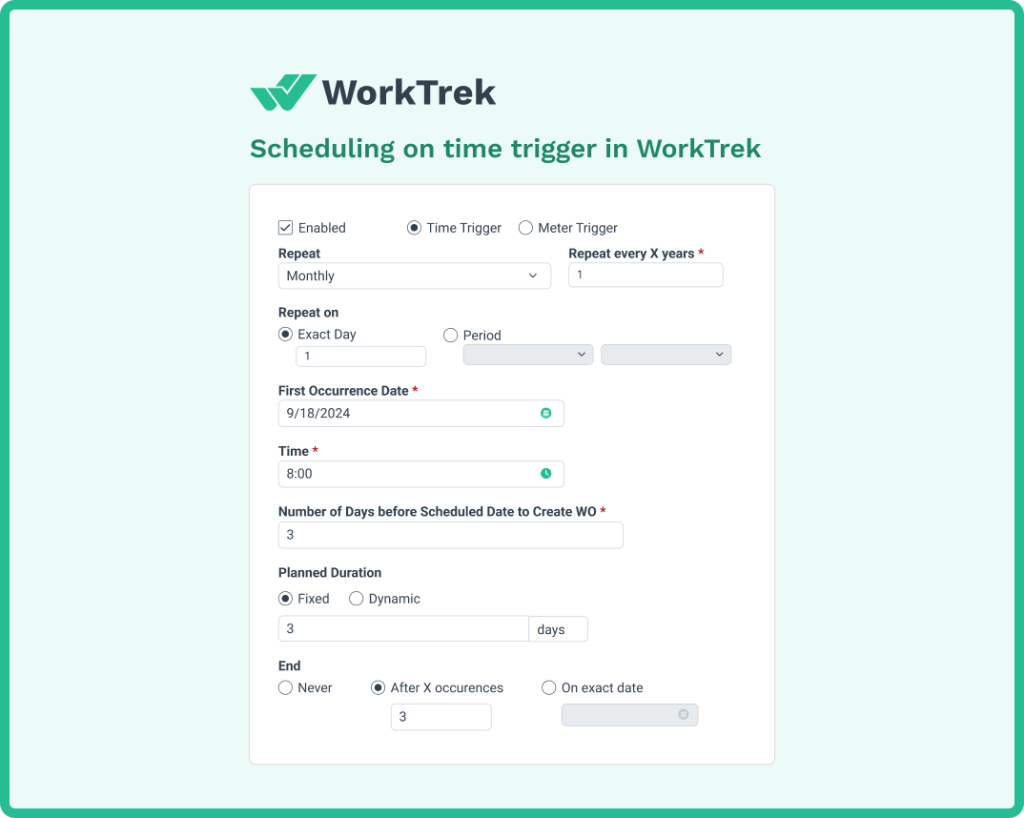

Time-based maintenance schedules maintenance tasks at fixed intervals—daily, weekly, monthly, or annually—regardless of equipment condition or usage.

Best For:

- Equipment with predictable wear patterns

- Assets subject to regulatory requirements

- Operations with consistent usage patterns

- Organizations new to preventive maintenance

Advantages:

- Simple to implement and manage

- Predictable scheduling and budgeting

- Ensures compliance with regulations

- Easy to track and measure compliance

Limitations:

- May perform unnecessary maintenance

- Doesn’t account for variable usage

- Can miss developing issues between intervals

Studies indicate that up to 30% of time-based preventive maintenance is performed too frequently, wasting resources without improving reliability.

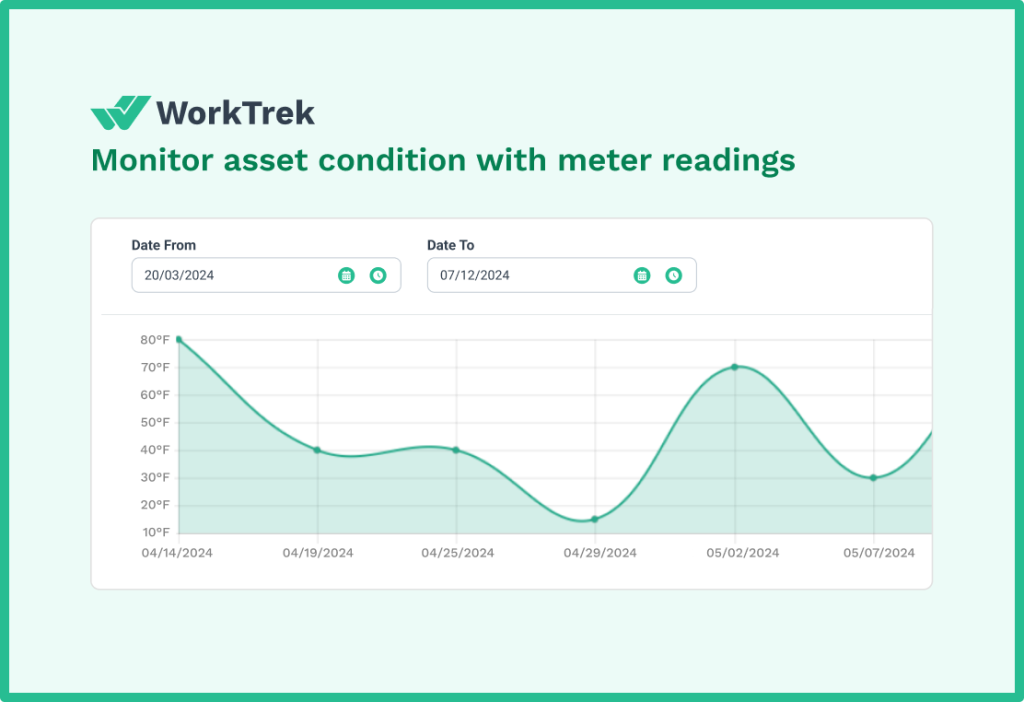

Condition-Based Maintenance (CBM)

Condition-based maintenance monitors equipment performance and schedules maintenance based on actual condition rather than time or usage.

Best For:

- Critical equipment with high failure costs

- Assets with variable usage patterns

- Equipment where condition indicators are easily measured

- Operations seeking to optimize maintenance costs

Advantages:

- Maintenance only when needed

- Reduces unnecessary maintenance by 25-30%

- Catches problems before failure

- Extends equipment lifespan

Requirements:

- Investment in monitoring systems

- Technical expertise for data interpretation

- Integration with maintenance software

WorkTrek’s condition-monitoring features automatically generate work orders when equipment parameters exceed thresholds, ensuring timely intervention.

Usage-Based Maintenance

Usage-based maintenance triggers maintenance tasks based on actual equipment usage—operating hours, cycles, mileage, or production volume.

Best For:

- Fleet vehicles

- Production equipment with variable schedules

- Seasonal equipment

- Multi-shift operations

Advantages:

- Aligns maintenance with actual wear

- Optimizes maintenance intervals

- Reduces over-maintenance

- Improves cost efficiency

Implementation Needs:

- Hour meters or cycle counters

- Usage tracking systems

- Flexible scheduling capabilities

Reliability-Centered Maintenance (RCM)

Reliability-centered maintenance uses systematic analysis to determine the most cost-effective maintenance strategy for each asset based on failure modes and consequences.

Best For:

- Complex industrial equipment

- High-value critical assets

- Operations with diverse equipment types

- Mature maintenance organizations

Benefits:

- Optimizes maintenance resources

- Reduces maintenance costs by 25-40%

- Improves equipment reliability

- Minimizes safety risks

Challenges:

- Requires extensive analysis

- Higher initial implementation cost

- Needs skilled personnel

- Time-intensive setup

Predictive Maintenance Integration

While technically a separate strategy, predictive maintenance often complements preventive programs by using advanced analytics to forecast failures.

Enhancement Benefits:

- 8-12% additional cost savings beyond preventive maintenance

- 30-50% reduction in machine downtime

- 20-40% extension in equipment life

- 70-75% elimination of breakdowns

Selecting the Right Preventive Maintenance Program

A strong preventive maintenance program requires three core components that work together. These elements create the foundation for reducing equipment downtime and extending asset life through organized planning and execution.

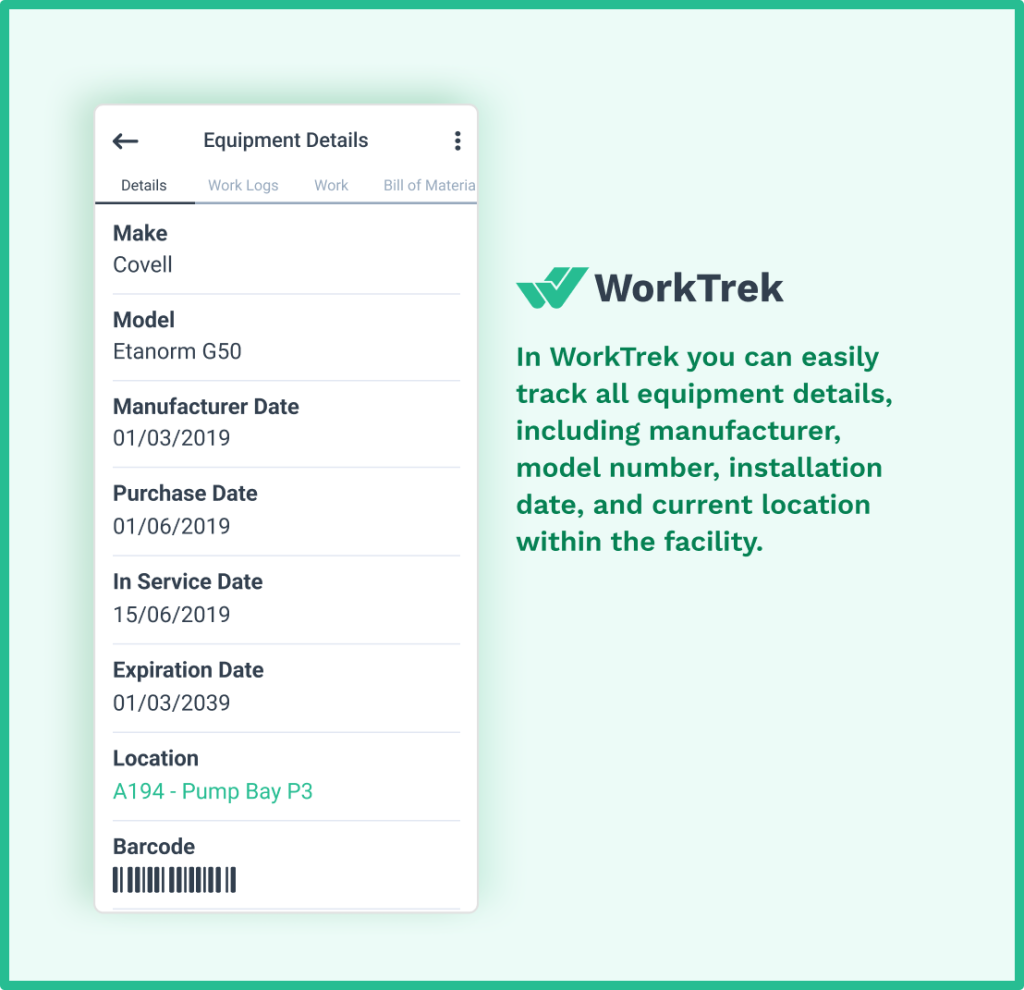

Asset Inventory and Maintenance History

An accurate asset inventory forms the backbone of any effective PM program. Teams must document every piece of equipment with key details, including manufacturer, model number, installation date, and current location within the facility.

Asset inventory systems should capture each item’s warranty status and maintenance history. This data helps maintenance managers make informed decisions about repair versus replacement costs.

Essential inventory details include:

- Asset name and equipment type

- Serial numbers and specifications

- Purchase or installation dates

- Current condition assessments

- Attached manuals and documentation

Maintenance history tracking reveals failure patterns and helps predict future issues. Teams can identify which components fail most often and adjust their maintenance schedule accordingly.

Digital systems work better than spreadsheets for managing large inventories. They allow quick searches and updates across multiple locations.

Defining Maintenance Tasks and Schedules

Clear maintenance tasks and schedules prevent equipment failures before they happen. Each task must specify exactly what work needs to be done and when it should occur.

Maintenance schedules can be time-based, usage-based, or condition-based depending on the equipment type. Time-based tasks happen on fixed intervals like monthly or quarterly. Usage-based maintenance depends on operating hours or production cycles.

Task definitions should include:

- Specific steps to complete the work

- Required tools and replacement parts

- Estimated time for completion

- Safety procedures and lockout requirements

Maintenance managers must balance manufacturer recommendations with actual equipment performance data. OEM guidelines provide starting points, but real-world usage patterns often require schedule adjustments.

Coordination with production schedules ensures maintenance occurs during planned downtime. This approach minimizes disruption to daily operations.

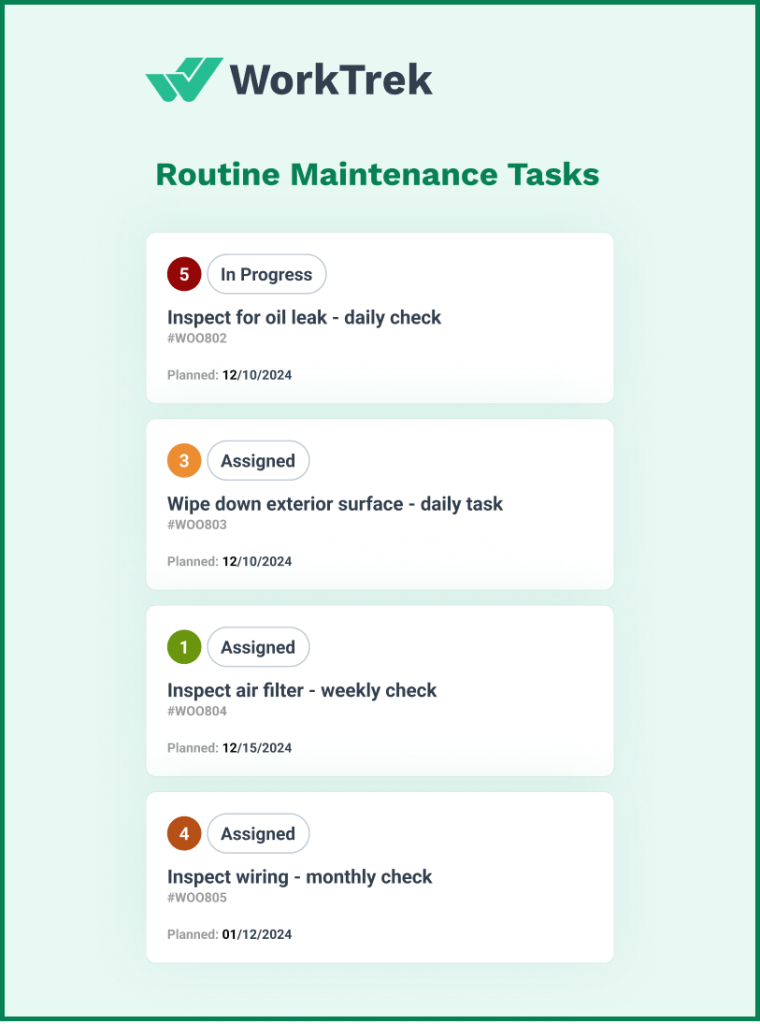

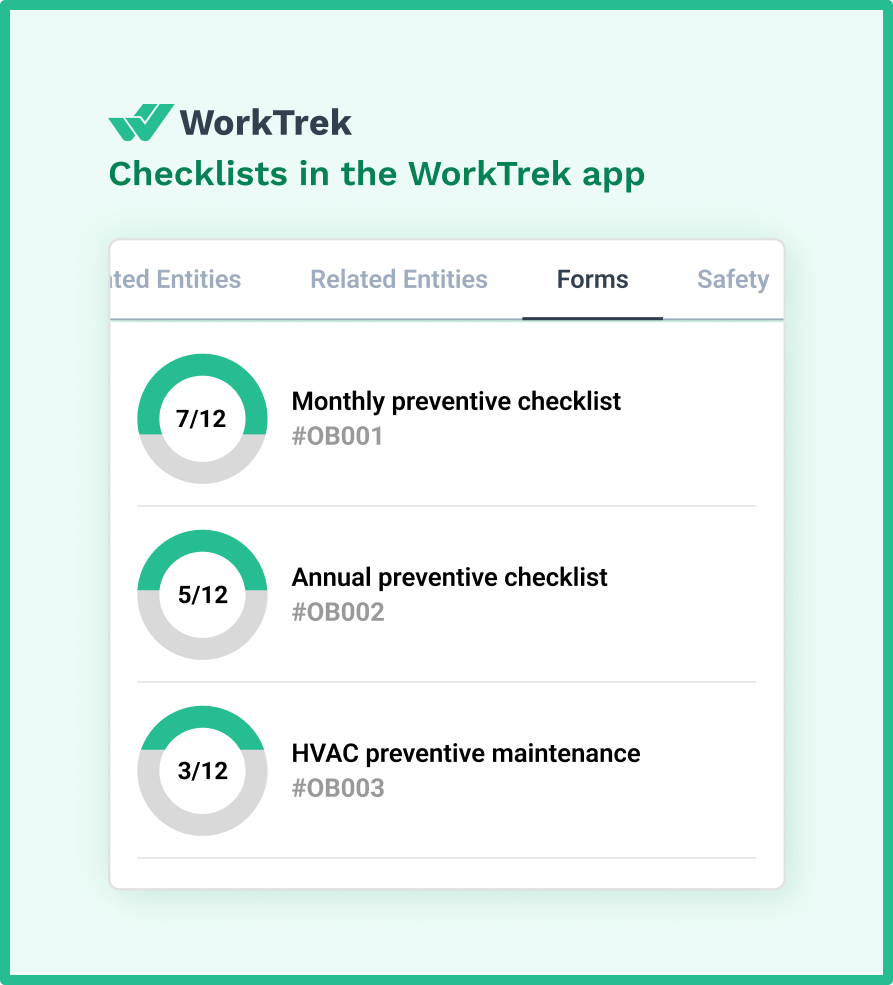

Preventive Maintenance Checklists and Work Orders

Standardized checklists create consistent work quality across different technicians and locations. Each preventive maintenance checklist should break complex tasks into simple, actionable steps.

Work orders track task completion and capture important details about the maintenance performed. They create a paper trail that helps with warranty claims and regulatory compliance.

Effective checklists contain:

- Step-by-step procedures in logical order

- Inspection points with specific criteria

- Documentation requirements for findings

- Sign-off spaces for quality control

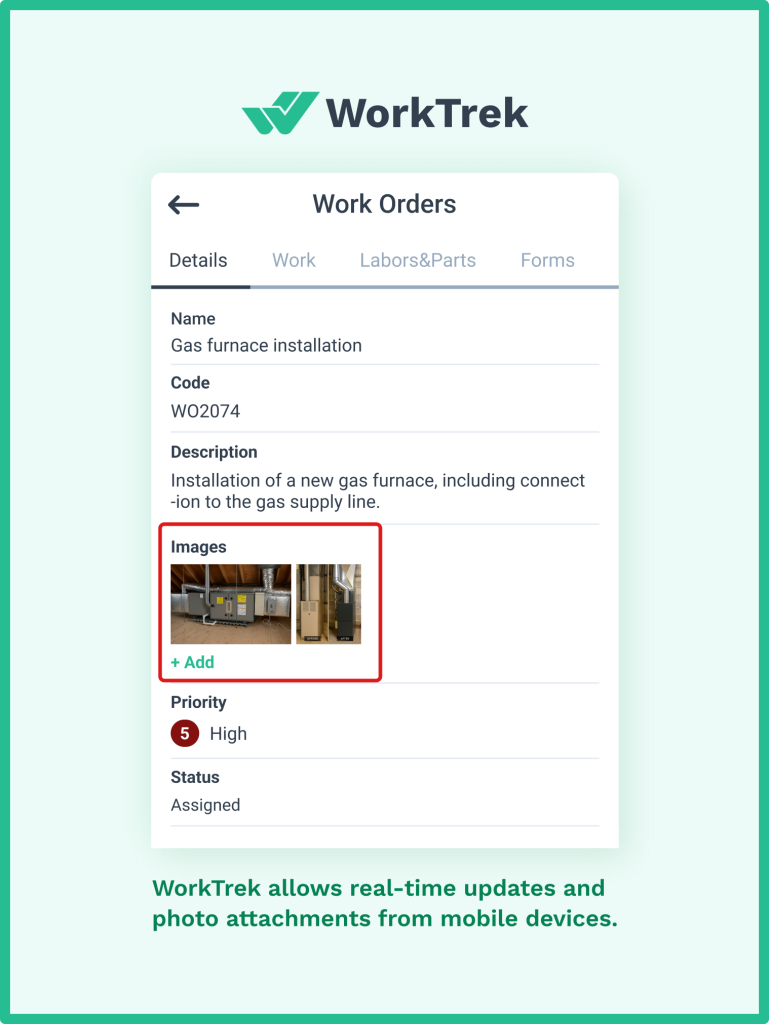

Digital work orders allow real-time updates and photo attachments from mobile devices. Technicians can access procedures, report issues, and request additional parts without returning to the office.

Preventive maintenance programs that use digital checklists report higher completion rates and better data accuracy. The system automatically generates new work orders based on the maintenance schedule and sends notifications when tasks become overdue.

How to Select the Right Preventive Maintenance Program

Selecting an effective preventive maintenance program requires analyzing organizational needs, equipment priorities, and available resources. The decision impacts maintenance costs, equipment reliability, and operational efficiency across all facility operations.

Assess Organizational Goals and Constraints

Start by evaluating budgets, staffing levels, and operational priorities before implementing any maintenance program.

Building the right program for your facility depends on understanding what resources are available for maintenance planning.

Budget constraints can directly influence the complexity of maintenance schedules that facilities can support. Simple time-based programs require fewer resources than advanced condition-based maintenance systems.

Staffing capabilities determine whether organizations can handle internal maintenance or need external service providers. Smaller teams may benefit from streamlined pm schedules rather than complex monitoring systems.

Key organizational factors include:

- Available maintenance budget

- Size of the maintenance team

- Technical expertise of staff

- Regulatory compliance requirements

- Acceptable downtime levels

Companies should also consider their growth plans and whether the maintenance program can scale with expanding operations. A preventive maintenance program that works for current needs may become inadequate as facilities grow.

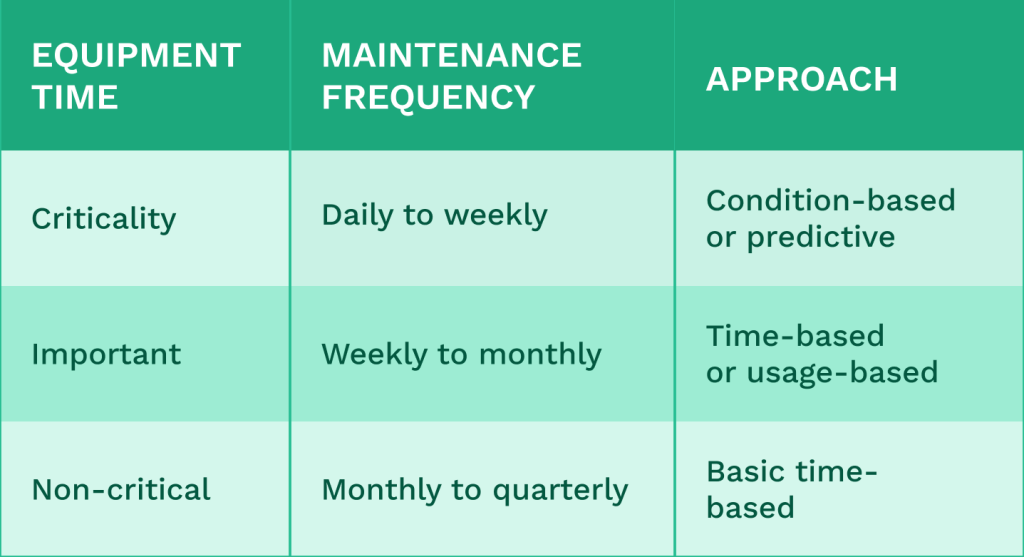

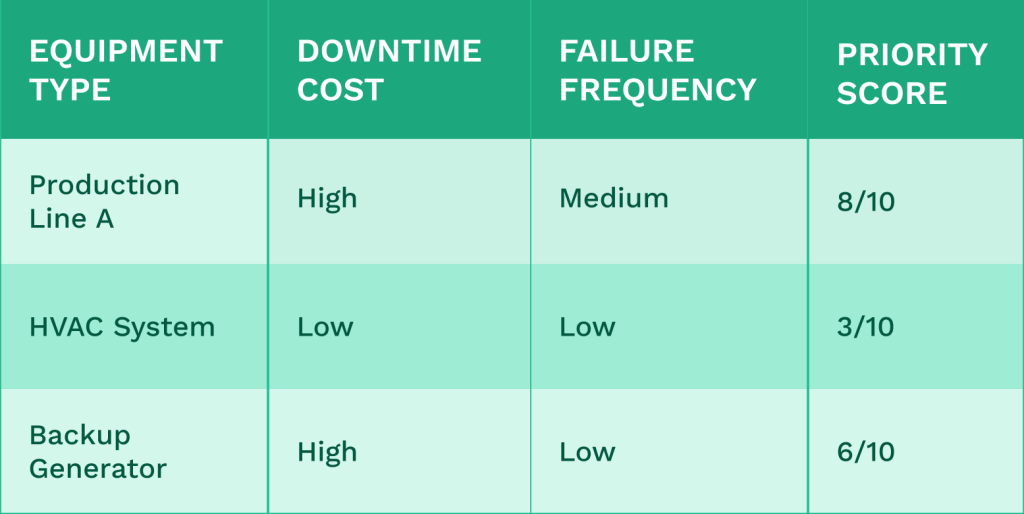

Evaluating Maintenance Needs by Equipment Criticality

The level of equipment criticality determines how much attention and resources each asset should receive in maintenance scheduling. Critical equipment that stops production requires more frequent maintenance than support systems.

Organizations should classify assets into three main categories.

Critical equipment includes production machinery, safety systems, and assets that cause significant downtime when they fail.

Important equipment supports operations but has backup systems or longer acceptable downtime windows.

Non-critical equipment includes office systems and assets that don’t impact core operations.

Reliability-centered maintenance can help identify the most effective maintenance strategy that is based on equipment criticality and failure consequences. This approach ensures resources focus on assets that matter most to operations.

Regular maintenance for critical equipment often requires multiple approaches. Facilities might use condition-based maintenance for monitoring, plus scheduled inspections for comprehensive coverage.

Deciding Between Time-Based, Usage-Based, and Condition-Based Approaches

Time-based maintenance works best for equipment with predictable wear patterns and manufacturer recommendations.

This approach schedules regular maintenance based on calendar intervals, regardless of actual equipment usage.

Usage-based maintenance aligns maintenance schedules with actual equipment operation hours, cycles, or mileage. This method suits assets with variable usage patterns, such as vehicles or production equipment.

Condition-based maintenance uses sensors and monitoring to track equipment health in real-time. This advanced approach reduces unnecessary maintenance while catching problems before they cause failures.

Time-based maintenance benefits:

- Simple to implement and manage

- Works well for regulatory compliance

- Requires minimal technology investment

Usage-based maintenance advantages:

- Aligns with actual wear patterns

- Reduces over-maintenance of lightly used equipment

- Better resource utilization

Condition-based maintenance strengths:

- Prevents unexpected failures

- Optimizes maintenance timing

- Reduces total maintenance costs

Successful maintenance programs follow a hybrid approach.

For example, critical equipment might use condition-based maintenance while support systems rely on time-based schedules.

Your Preventive maintenance strategy should align with equipment characteristics and operational needs rather than using a single approach for everything.

Implementation Steps for Your Preventive Maintenance Program

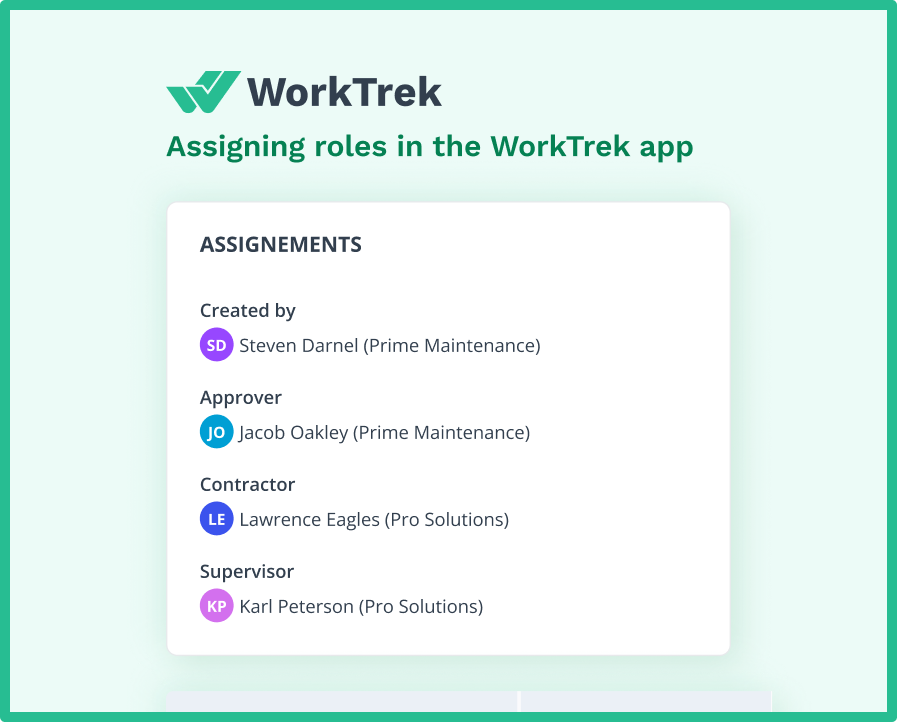

To ensure a successful implementation, you first need to define clear role definitions, properly integrate technology, and provide comprehensive staff training.

These three foundational elements ensure smooth workflow execution and long-term program success.

Assigning Roles and Responsibilities

A clear role definition prevents maintenance tasks from falling through the cracks. Organizations should designate who will handle scheduling, execution, and oversight of preventive maintenance activities.

Typically, maintenance managers oversee program strategy and resource allocation. Their job is to coordinate schedules, track performance metrics, and ensure compliance with maintenance workflows.

These managers also handle budget decisions and vendor relationships.

Technician responsibilities include:

- Executing scheduled maintenance tasks

- Recording work completion and findings

- Reporting equipment issues or anomalies

- Following safety protocols during maintenance

Facility managers often serve as liaisons between maintenance teams and operations. They communicate downtime schedules and ensure maintenance activities align with business needs.

Some organizations designate maintenance coordinators to handle daily scheduling.

These coordinators manage work orders, track inventory, and coordinate between different maintenance teams. Their goal is to ensure that effective preventive maintenance programs run smoothly.

Leveraging Maintenance Software and CMMS

CMMS platforms like WorkTrek streamline maintenance management by automating schedules and tracking asset performance. The right CMMS makes or breaks preventive maintenance implementation success.

With modern maintenance software, you can automatically generate work orders based on time intervals or usage metrics.

This automation ensures technicians receive timely notifications for upcoming maintenance tasks, eliminating the need for manual scheduling.

Key CMMS features include:

- Asset tracking and history management

- Automated work order generation

- Inventory management integration

- Performance reporting and analytics

CMMS centralizes maintenance data, allowing managers to track costs, completion rates, and equipment performance trends. This data helps optimize maintenance schedules and identify problematic assets.

Mobile CMMS applications enable technicians to access work orders, update task status, and record findings from anywhere. This real-time connectivity improves communication and reduces paperwork delays.

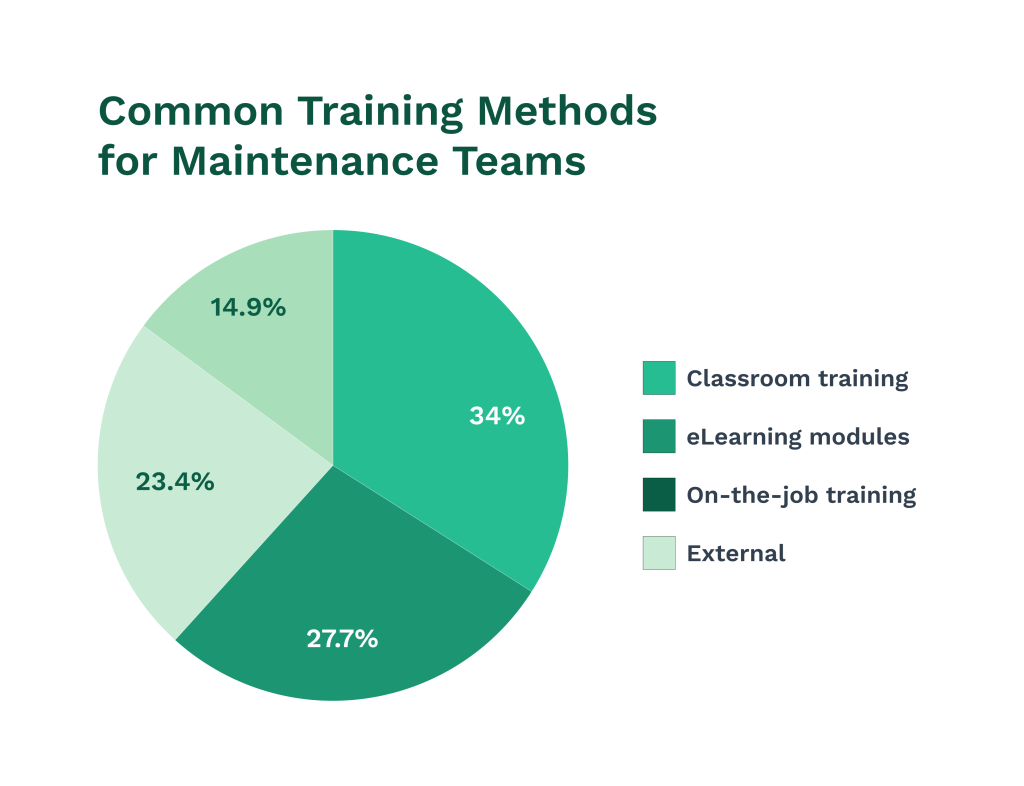

Training Technicians and Staff

With proper training, maintenance teams can perform preventive maintenance tasks safely and effectively. Training programs must cover equipment-specific procedures, safety protocols, and software usage.

Technical training should focus on equipment maintenance procedures, troubleshooting techniques, and proper tool usage. Technicians need hands-on experience with each asset type they will maintain.

Safety training covers lockout/tagout procedures, personal protective equipment requirements, and hazard identification. This training prevents workplace injuries during maintenance activities.

Training components include:

- Equipment-specific maintenance procedures

- CMMS software navigation and data entry

- Safety protocols and emergency procedures

- Quality standards and documentation requirements

Software training teaches technicians how to access work orders, record completion data, and update asset conditions in the CMMS. This ensures accurate data collection and proper execution of the maintenance workflow.

Monitoring, Optimization, and Continuous Improvement

Successful preventive maintenance programs require ongoing tracking of performance metrics and regular adjustments based on data analysis. Organizations must establish measurement systems and foster improvement mindsets to reduce operational costs and maximize equipment reliability.

Tracking Key Performance Indicators

Organizations need specific metrics to assess the effectiveness of their preventive maintenance programs. The most critical KPIs include equipment downtime, mean time between failures, and maintenance costs.

- Equipment downtime during unplanned maintenance

- Mean time between equipment failures (MTBF)

- Preventive maintenance compliance rates

- Maintenance cost per asset

- Overall equipment effectiveness (OEE)

Teams should track PM labor hours versus emergency maintenance hours. This ratio shows whether preventive efforts are reducing reactive work.

Monitoring key performance indicators helps identify areas that need improvement in maintenance strategies. Companies can spot patterns in equipment failures and adjust their approach accordingly.

Monthly KPI reports should compare current performance to baseline measurements. This data reveals whether the maintenance program is meeting its goals.

Analyzing Data to Refine the Maintenance Process

Data analysis transforms raw maintenance information into actionable insights. Teams must review equipment history for the past 30, 60, and 180 days to identify trends.

Key Analysis Areas:

- Root causes of critical equipment breakdowns

- PM frequency, accuracy and effectiveness

- Rework patterns and recurring issues

- Maintenance procedure effectiveness

The maintenance process improves when teams examine PM compliance rates against equipment performance. Low compliance often correlates with higher failure rates and increased operational costs.

Organizations should regularly review their current maintenance procedures. Some may need complete rewrites, while others require frequency adjustments based on actual equipment performance.

Encourage a Culture of Continuous Improvement

Effective maintenance teams need structured processes for ongoing improvement. Cross-functional teams —including operators, technicians, and engineers —should collaborate on optimization efforts.

Team Roles for Continuous Improvement:

- Operators: Provide daily equipment observations

- Maintenance technicians: Share hands-on repair insights

- Engineers: Analyze technical data and trends

- Planners: Coordinate improvement implementations

Teams should establish clear expectations and measurable goals for improvement initiatives. Regular progress reviews keep everyone focused on results.

Continuous improvement in maintenance operations requires less reactive firefighting and more proactive planning. This approach ultimately leads to lower maintenance costs and improved safety.

Organizations should share improvement results with the entire team.

Common Challenges and How to Overcome Them

Companies face three major hurdles when implementing preventive maintenance programs: employee resistance to new processes, limited budgets for technology and training, and overwhelming amounts of maintenance data that don’t lead to clear action steps.

Overcoming Resistance to Change

Resistance to change remains one of the most significant barriers to the success of preventive maintenance programs. Employees often prefer reactive maintenance because it feels familiar and easy to perform.

So, how to overcome the resistance?

Show concrete benefits to maintenance teams. Present data on how preventive maintenance reduces equipment downtime by 30-50% compared to reactive approaches. Highlight reduced emergency repair calls and less stressful working conditions.

Start with willing participants. Identify maintenance staff who embrace new methods and use them as program champions. Their positive experiences will influence skeptical colleagues.

Provide hands-on training rather than just theory. Let technicians practice new procedures on non-critical equipment first. This builds confidence and competence before moving to essential machinery.

Create clear accountability measures. Use maintenance workflow tracking to show individual and team performance improvements.

Don’t forget to track technician compliance with automated work-order systems that reduce manual tracking errors.

Address workload concerns directly. Many technicians worry that preventive maintenance adds to their existing duties. Show how planned maintenance actually reduces emergency calls and overtime hours.

Managing Budget and Resource Limitations

Budget constraints force many organizations to delay preventive maintenance programs. Innovative implementation strategies can overcome these financial barriers.

Start small with critical equipment. Focus on high-impact assets first rather than attempting company-wide implementation. Target machines that cause the most equipment downtime when they fail.

Demonstrate return on investment quickly. Track maintenance costs before and after program implementation. Most companies see 15-25% reduction in maintenance expenses within the first year.

Use existing resources creatively. Train current staff instead of hiring specialists. Many maintenance technicians can learn preventive procedures with proper guidance.

Prioritize based on failure impact. Create a simple scoring system:

Phase implementation over 12-18 months. This spreads costs while building momentum through early successes.

Avoiding Data Overload and Ensuring Actionability

Modern CMMS systems generate massive amounts of data. Without proper structure, this information becomes overwhelming rather than helpful.

Focus on key performance indicators that drive decisions. Track equipment failures, mean time between failures, and planned maintenance completion rates. Avoid collecting data that doesn’t lead to specific actions.

Set up automated alerts for critical thresholds. Program systems to notify managers when equipment approaches failure points or maintenance tasks fall behind schedule.

Create simple dashboards for different audiences. Technicians need detailed work instructions while managers need summary reports. Customize data presentation based on user needs.

Establish regular review cycles. Schedule weekly equipment performance reviews and monthly program assessments. This prevents data from accumulating without analysis.

Use predictive analytics selectively. Start with condition-based monitoring on the most critical equipment before expanding to comprehensive predictive maintenance programs.

Train staff to interpret data correctly. Many maintenance teams struggle to translate reports into actionable improvements to the maintenance workflow. Provide specific examples of how data should influence scheduling and resource allocation decisions.

Conclusion

The difference between organizations that thrive and those that struggle often comes down to the selection of a maintenance strategy. The right preventive maintenance program can:

- Reduce equipment failures by 70-75%

- Extend equipment lifespan by 20-40%

- Cut maintenance costs by 25-40%

Yet many organizations continue using ineffective strategies simply because “that’s how we’ve always done it.”

Don’t let tradition or inertia dictate your maintenance future. The data, tools, and knowledge exist to choose and implement the perfect preventive maintenance program for your needs.

Start with an honest assessment. Match strategies to equipment characteristics. Invest in appropriate technology like WorkTrek’s comprehensive CMMS platform.

Monitor results relentlessly. Adjust based on data.

Your equipment is waiting. Your budget is ready. Your competitive advantage depends on it.