If you’re a business owner, you know that keeping your operations running smoothly is essential for success. One way to ensure the optimal performance of your facility is to utilize CMMS tools. CMMS stands for Computerized Maintenance Management Systems, offering a wealth of benefits for your business.

In this blog post, you’ll discover 20 of the main advantages of using CMMS software for your business. Read on to learn more!

What businesses use CMMS?

CMMS, also known as facility management software, can be used in many business environments, including manufacturing plants, retail facilities, restaurants, and healthcare laboratories. These businesses use CMMS to keep track of preventive maintenance tasks, such as oil changes or filter replacements, as well as corrective maintenance activities, like replacing broken parts or performing repairs when needed.

The software also allows businesses to collect data on machine performance, so they can identify potential problems before they become serious issues. Moreover, it enables them to track stock levels so they won’t run out of vital supplies at critical times.

Why do businesses use CMMS?

According to a research study by Whole Building Design Guide, a CMMS allows businesses to track maintenance-related data in real time. This information helps organizations monitor the performance of their machines and equipment, predict potential issues before they arise, and schedule preventive maintenance accordingly.

By utilizing a CMMS optimization program, business owners can save money by avoiding costly downtime due to unexpected repairs or replacements. Additionally, CMMS makes it easier for teams to collaborate on projects across multiple locations or time zones. All information is stored securely in one place, so everyone has access to the same up-to-date information when needed.

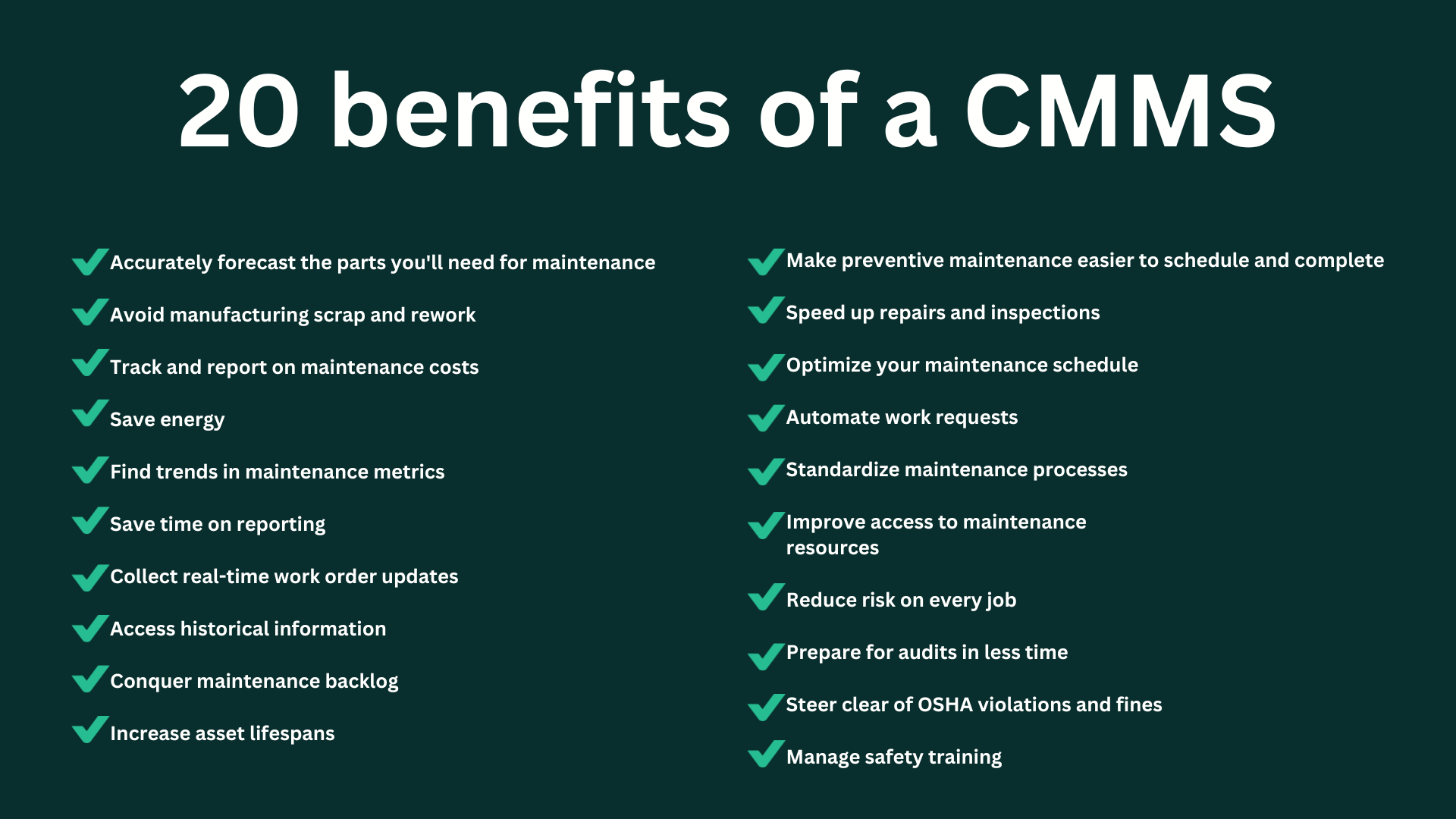

20 Benefits of CMMS software for business

CMMS software can provide a wide range of benefits to business owners, including:

1. Increased visibility over assets

One of the major benefits of using a CMMS tool is increased visibility over assets. With an efficient system in place, it’s easier to track and monitor assets, allowing businesses to stay ahead of potential problems before they become full-blown disasters.

Improved visibility also makes it easier to plan for upcoming maintenance, repairs, and replacements—helping businesses avoid costly downtime or surprises down the line. This can be especially beneficial for operations that may not have the resources or manpower to track every asset manually.

2. Enhanced operational efficiency

Many CMMS examples are designed to help manage equipment maintenance activities, optimize inventory control, and improve scheduling processes. It also has features that allow users to store data on equipment performance and track labor hours for various tasks.

This information can be used by business owners to identify opportunities for improvement in operational efficiency and make the necessary adjustments accordingly. By monitoring these metrics regularly, businesses can ensure they remain efficient and cost-effective while delivering excellent customer service.

3. Easier inventory management

Business owners who employ a CMMS tool will be able to automate the tracking functions related to their inventory. For example, they can use barcodes for quick scanning or make use of auto-replenishment features that notify users when certain items are low.

By integrating your CMMS tool with accounting software like Sage 50 Cloud, you can also set up alerts for particular items when stock levels get too low. You can also try some Sage 50 Cloud alternatives to get greater insight into your inventory.

All this helps ensure that proper stocking levels are maintained without having to manually track every item on a spreadsheet.

4. Improved communication

As per an article by IBM Corporation, CMMS tools provide a centralized point for information sharing, which allows teams to communicate more effectively. This improved communication streamlines maintenance processes and reduces issues, such as missed deadlines and miscommunication between departments.

With improved communication capabilities, CMMS tools provide an invaluable resource for businesses looking to maximize efficiency in their day-to-day operations.

5. Decreased labor costs

As a result of using CMMS tools or top facility management software, business owners can save time in the administrative workload related to managing their facilities. The software helps reduce labor costs by streamlining processes, such as scheduling work orders or tracking materials inventory levels.

Additionally, with automated reminders for scheduled maintenance tasks or notifications when parts need replacing, there’s no need for an additional staff member to monitor these activities. This reduces long-term overhead costs without sacrificing quality or reliability in facility management services.

6. Addressing Maintenance Backlog

While some level of maintenance backlog is inevitable, an excessive backlog can have detrimental effects on your operations. Case in point: the estimated $12 billion cost of backlogged maintenance at US national parks. While this is an extreme scenario, it underscores the critical need to maintain a manageable level of maintenance backlog.

A Computerized Maintenance Management System (CMMS) plays a crucial role in striking a balance between resources and maintenance costs to prevent the backlog from spiraling out of control. The software identifies minor issues that might otherwise go unnoticed and facilitates the scheduling, assignment, and prioritization of maintenance tasks, ensuring that no jobs are overlooked or neglected.

7. Prolonging Asset Lifespan

The current average age of industrial equipment in the United States has reached levels not seen since the 1940s. While age alone may not always be the primary cause of equipment failure, it frequently contributes to operational issues. Given the financial constraints that may hinder the outright replacement of older models with new ones, the emphasis on proactive maintenance becomes paramount.

Preserving the optimal operational state of equipment over an extended period entails conducting maintenance before any significant breakdown occurs. Relying solely on Original Equipment Manufacturer (OEM) guidelines or guesswork proves inadequate for achieving this objective. By integrating Computerized Maintenance Management System (CMMS) software with sensors, Programmable Logic Controllers (PLCs), Supervisory Control and Data Acquisition (SCADA), and Manufacturing Execution Systems (MES), you gain the ability to monitor an asset’s health in real-time. This integration facilitates the identification of potential failures before they happen, enables diagnostic evaluations of problems, and empowers you to schedule timely maintenance interventions.

8. Streamline Scheduling and Execution of Preventive Maintenance

Preventive maintenance plays a crucial role in identifying defects before they escalate into major issues, ultimately minimizing the occurrence of breakdowns. Maintenance teams recognize the significance of preventive measures in curtailing downtime, but the challenge lies in efficiently scheduling and implementing them.

A Computerized Maintenance Management System (CMMS) provides a comprehensive solution to this challenge through the implementation of automated work orders. Within a CMMS, preventive maintenance (PM) triggers can be established based on factors such as usage, time intervals, or specific conditions. These triggers initiate the generation of a work order, which is then systematically scheduled and assigned. The automation of this process enhances the efficiency of preventive maintenance scheduling, resulting in smoother execution and, ultimately, reducing downtime.

9. Expedite Repairs and Inspections

Downtime becomes inevitable whenever an asset requires repair or inspection, and while complete avoidance may not always be possible, inefficient processes for repairs and preventive maintenance (PM) can significantly prolong downtime. The cumulative impact of these inefficiencies translates to substantial time and financial losses for your facility in terms of disrupted production.

Implementing a Computerized Maintenance Management System (CMMS) streamlines the repair and inspection processes, minimizing downtime to the bare minimum. Technicians gain the flexibility to access a mobile CMMS app from any location, enabling them to review an asset’s history, diagrams, spare part locations, and other pertinent details for expedited work completion. Moreover, CMMS software provides the capability to identify work orders that are taking too long, pinpoint the cause of the delay, and rectify it promptly, ensuring swifter task completion.

10. Minimize Risk in Every Job

The expeditious completion of a job holds little significance if it compromises safety. Failing to integrate safety into the planning process elevates the risk of accidents. Ensuring the safety of every task introduces additional steps in the work order creation process, but the investment is worthwhile in preserving the well-being of your team.

A Computerized Maintenance Management System (CMMS) simplifies the creation of work orders with a focus on the maintenance team’s safety. Incorporating checklists, material safety data sheets, safety procedures, and required Personal Protective Equipment (PPE) ensures that technicians execute tasks safely, mitigating potential risks.

11. Streamline Audit Preparation

Navigating audits can prove challenging without the right tools and expertise. Failing an audit entails significant complications and the potential loss of substantial financial resources.

CMMS software provides a more efficient and cost-effective approach to audit preparation. It facilitates inspection rounds and enables seamless searches within the system for maintenance records related to specific assets or time periods. The documentation of compliance activities becomes more straightforward with CMMS, offering the capability to generate reports and store relevant photos.

12. Avert OSHA Violations and Penalties

Safety violations not only contribute to increased accidents but also incur substantial financial penalties, potentially costing businesses millions of dollars. Such violations often result from missing information, unclear expectations, and breakdowns in communication.

A CMMS emerges as a solution to these challenges. Safety procedures become more accessible and visible through checklists and asset profiles. Technicians can swiftly access these procedures on their mobile devices, ensuring they never overlook crucial safety instructions that could lead to a violation.

13. Streamline Safety Training Management

Safety training is a pivotal component, shown to reduce injuries by 24% and mitigate unforeseen costs. However, challenges such as timing and the need for specialized skills can impede the implementation of well-intentioned safety plans.

CMMS software acts as a facilitator in overcoming obstacles to proper safety training. It allows for the storage and tracking of health and safety information for technicians, including certifications. Furthermore, CMMS enables the extraction of safety reports, aiding in the prioritization of necessary training initiatives.

14. Uncover Patterns in Maintenance Metrics

Maintenance metrics act as a numeric translation of actions, enabling the measurement of everyone and everything’s performance within your operation. They serve as a bridge between cause and effect, facilitating informed decision-making and operational improvement.

Effective metrics tracking demands the right combination of tools, processes, and personnel. The instrumental ‘tools’ in this equation are provided by CMMS software, which captures and tracks metrics over time, offering a comprehensive, long-term perspective on performance. Additionally, CMMS software streamlines metric analysis, empowering you to fine-tune strategies based on valuable data insights.

15. Streamline Reporting and Save Time

Maintenance Key Performance Indicators (KPIs) play a pivotal role in identifying persistent equipment issues and benchmarking against industry standards. However, compiling KPI reports using manual methods like Excel or pen and paper can be laborious and prone to errors.

CMMS software transforms this process by enabling the collection of data from various facets of your maintenance operation and synthesizing it through reporting templates. Many CMMS platforms offer automated report delivery to your inbox on a predetermined schedule. A clearer understanding of your KPIs empowers you to enhance value and mitigate risks through strategic adjustments. Swiftly analyze trends, identify recurring problems, track costs, and more with the efficiency of CMMS reporting capabilities.

16. Receive Real-Time Work Order Updates

Efficient tracking of work order progress is pivotal for minimizing backlog, establishing effective schedules, planning production, and managing budgets. Lack of visibility into work orders for key personnel can result in increased downtime, elevated costs, and uninformed decision-making.

CMMS serves as a safeguard against such scenarios by providing real-time work order updates, including priority status, assigned personnel, and duration of tasks. This information allows for proactive resource allocation if required. Additionally, CMMS notifies production staff when assets are back online, ensuring a prompt return to work. The system’s ability to identify work orders causing delays or incurring additional costs empowers you to address and rectify underlying issues promptly.

17. Access Comprehensive Historical Information

Effectively managing an asset throughout its lifecycle necessitates a thorough understanding of its history. Even with technicians possessing extensive knowledge about an asset’s past, the risk of losing this information forever looms due to high turnover and retirement rates.

CMMS acts as a bulwark against this knowledge loss by providing unique records for each asset, documenting all relevant details from repairs to inspections, labor hours, and more. Technicians can readily access these records for preventive maintenance or troubleshooting, ensuring that critical historical information remains accessible and valuable.

18. Streamline Work Requests Through Automation

Maintenance managers often contend with work requests arriving through various outdated channels such as phone calls, sticky notes, whiteboards, or word of mouth, creating inefficiencies in the process. These antiquated methods compel maintenance teams to invest unnecessary time in creating work orders and manually inputting data.

CMMS software addresses these challenges by automating the work request process. Employees can effortlessly log work requests, establish preventive maintenance (PM) triggers, or integrate with sensors to generate work orders based on real-time asset conditions. This automation eliminates the need for translating work orders, chasing down operators, or sifting through physical files, saving valuable time and streamlining the entire workflow.

19. Standardize Maintenance Processes for Efficiency

Efficiency in maintenance is often achieved by employing proven tools and methods tailored to specific situations. Starting from scratch with each preventive maintenance (PM), repair, or report can result in prolonged timelines, increased downtime, and higher costs.

A CMMS empowers you to standardize maintenance processes by creating checklists, workflows, reporting templates, and more. These resources are digitally accessible, ensuring that everyone has access to the same information, follows consistent best practices, and completes tasks efficiently.

20. Enhance Access to Maintenance Resources

A lack of centralized knowledge often translates to the need to track down individuals, sift through physical documents, or navigate computer files to find solutions for breakdowns. These seemingly minor inefficiencies can cascade into more significant issues, including increased downtime and failed audits.

CMMS serves as a solution by providing a centralized hub for maintenance resources, making information readily available to anyone at any time. Attach videos, manuals, task lists, accident reports, inventory requirements, and more to specific equipment or work orders within the CMMS. This accessibility enables technicians to complete tasks more efficiently, reducing downtime and contributing to overall operational success.

Top 3 CMMS software features

Do you want to make the most of your CMMS software system? With so many different features to choose from, it can be hard to know which ones will give you the highest return on investment. To help narrow down your choices, here are the top 3 CMMS software features:

1. Asset tracking

This feature allows you to keep an accurate and up-to-date record of all assets in your business. With this data at hand, you can streamline operations, improve performance, reduce maintenance costs, and ensure compliance with industry standards.

2. Preventive maintenance (PM) scheduling

PM scheduling enables businesses to stay ahead of potential breakdowns by pre-emptively checking equipment and replacing parts as needed before they fail. This helps reduce repair costs while improving safety conditions for workers and customers alike.

3. Powerful reporting capabilities

These features should include intuitive report customization for greater accuracy and flexibility, built-in templates for quickly generating reports, interactive charts for deeper analysis, and automated email notifications so you’re always up to date with the latest information.

Leverage CMMS tools to grow your business

CMMS tools have huge potential to improve the efficiency and profitability of businesses. With their ability to store data, track maintenance, schedule tasks, and forecast costs, they can save time and money and help ensure better outcomes for customers.

Business owners should take advantage of these powerful tools to bring more success and prosperity to their operations. Ultimately, investing in a reliable CMMS tool will be an investment that pays off for many years to come.

Not sure if our CMMS services are right for you? Read our blog or take our quiz to learn more! This quiz will help you determine if our CMMS platform is a good fit for your needs and provide you with personalized advice on the next steps. It only takes a few moments to fill out, so why not find out today if our CMMS is right for you?

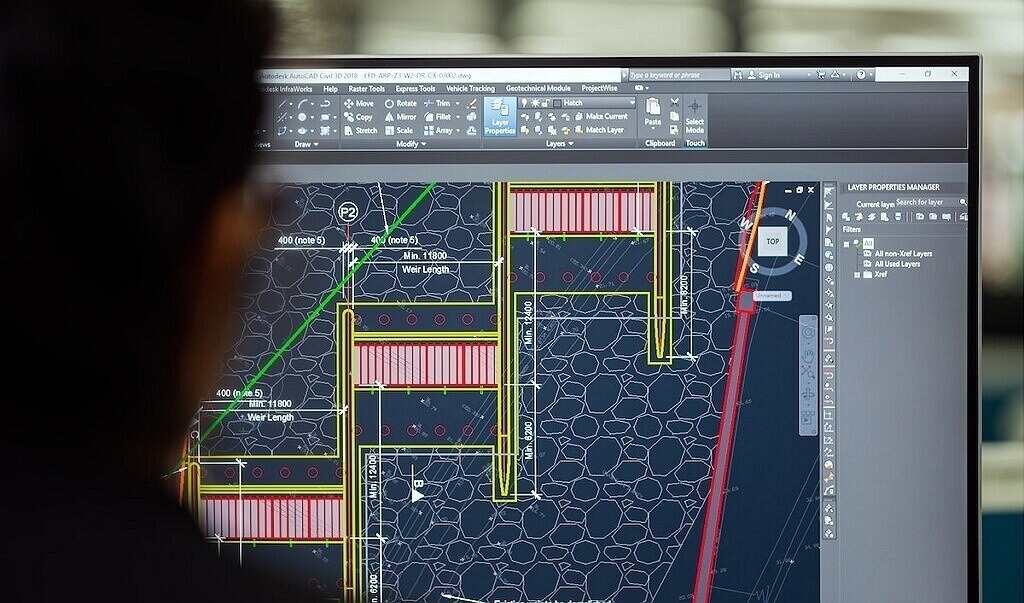

Photo by ThisIsEngineering on

Photo by ThisIsEngineering on