Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeEquipment downtime can bring your operations to a screeching halt, costing time, money, and productivity. When machinery breaks down unexpectedly, you’re left scrambling for repairs, delaying projects and driving up costs.

These sudden breakdowns don’t just cause headaches—they can severely impact your bottom line. Missed deadlines, frustrated employees, and unhappy customers are just the start. Without a plan, equipment failure can snowball into expensive repairs, rushed part orders, and costly emergency fixes.

Preventive maintenance is your secret weapon. By routinely servicing your equipment, you can catch issues before they become major problems. Regular maintenance keeps your machinery running smoothly, reduces the risk of unexpected breakdowns, and saves you from the high costs of emergency repairs. With preventive maintenance, you not only extend the lifespan of your equipment but also keep your business running efficiently and profitably.

Understanding Preventive Maintenance

Source: dynaway

Regularly executing maintenance tasks to avert future equipment breakdowns is preventive maintenance. This strategic, proactive method aims to manage assets and upkeep facilities by achieving the following objectives:

- Reduce expenses

- Enhance operational efficiency

- Detect and address potential problems before they lead to system failures

- Minimize periods of non-operation

- Prolong the lifespan of assets

Its primary purpose is clear: to identify and resolve issues before they become major malfunctions, which cuts down on inactive time while increasing asset longevity.

Preventive maintenance extends equipment’s use and fosters a safer environment for employees. Routine evaluations and servicing operations ensure machinery functions at peak performance levels while complying with warranty requirements.

The scope includes maintaining critical building systems such as heating, ventilation, and air conditioning units (HVAC) and safeguarding electrical standards.

It should be stated that despite its effectiveness at minimizing unexpected downtime caused by machine faults, which significantly reduces it, preventive maintenance does not completely prevent these incidents from occurring.

Adopting a blended methodology incorporating reactive measures and preventative actions often constitutes the most successful strategy-wise execution within this domain.

Preventive maintenance schedule and forms

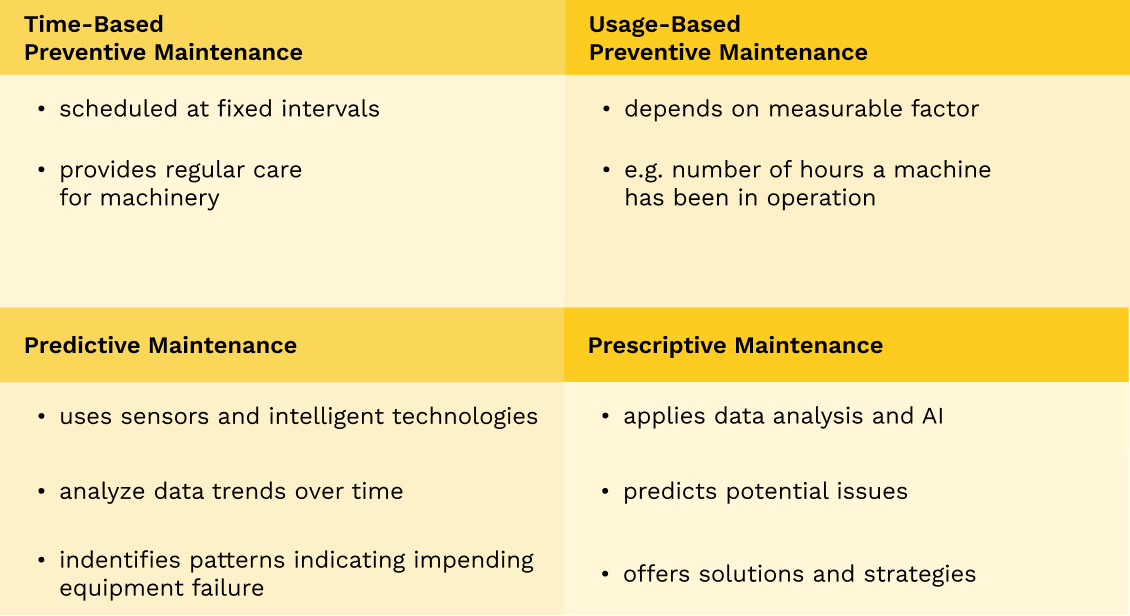

Preventive maintenance has many advantages, which can take various forms to meet specific needs and triggers.

For example, time-based preventive maintenance is scheduled at fixed intervals to provide regular care for machinery. This might include semi-annual reviews of heating, ventilation, and air conditioning (HVAC) units or weekly checks on key production machinery as part of regular maintenance routines.

Alternatively, usage-based preventive maintenance depends on measurable factors such as the number of hours a machine has been in operation or the number of cycles it has gone through. This type of maintenance includes services like oil changes after a vehicle travels a predetermined distance or taking action based on detected levels of fluid contamination.

Advancements in technology improved predictive and prescriptive approaches to preventive maintenance.

Predictive Maintenance

Predictive maintenance uses sensors and intelligent technologies to forecast when servicing might be necessary. These systems can identify patterns indicating impending equipment failure by analyzing data trends. While predictive maintenance is not the panacea to routine maintenance and improving asset life, it does provide insight into maintenance that cannot be manually acquired.

This allows maintenance teams to address issues before they escalate, preventing costly downtime and extending the life of the machinery. Machine learning algorithms further refine the predictive capabilities, offering a dynamic and responsive approach to maintenance scheduling.

Through the integration of IoT devices, predictive maintenance not only anticipates when a piece of equipment will require service but also diagnoses potential problems, ensuring that maintenance efforts are precisely targeted and more effective.

Reactive Maintenance

Reactive maintenance, as its term suggests, is a response-based approach that kicks into gear after equipment has already failed. A regular maintenance routine has decreased overall maintenance expenses and enhanced asset longevity.

Prescriptive Maintenance

Prescriptive maintenance involves applying data analysis and artificial intelligence to predict potential issues and offer solutions and strategies that mitigate the risks associated with anticipated problems. By leveraging vast amounts of data and advanced analytics, prescriptive maintenance forecasts potential issues and provides actionable recommendations to prevent or minimize their impact.

This approach goes beyond simple predictions, offering a set of steps to avoid future problems, optimize performance, and ensure equipment reliability. It will also greatly reduce instances of unexpected equipment failures, as it takes a more holistic view of maintenance management, integrating it seamlessly with operations to improve overall outcomes.

Source: WorkTrek

Source: WorkTrek

Implementing a Preventive Maintenance Program

The best way to start a preventive maintenance program is to outline clear goals, such as minimizing downtime, enhancing system reliability, or cutting operational costs. Conducting an assessment of asset criticality is crucial for the effective allocation of resources.

This involves identifying which assets are essential to the core operations and which could cause the most significant disruption in case of failure.

By prioritizing assets based on their criticality, organizations can allocate maintenance efforts more strategically, focusing on high-priority areas that could impact safety, regulatory compliance, and operational continuity. This approach greatly reduces unplanned equipment failures and improves the overall maintenance processes.

This targeted approach optimizes resource use and helps formulate a more structured and effective preventive maintenance schedule.

The development of a preventive maintenance schedule is the subsequent phase. The use of a computerized maintenance management system (CMMS) can assist in this process by enabling:

- Precise initiation points that adhere to manufacturer recommendations

- Informed determinations about upkeep needs based on historical data from assets

- Anticipation and scheduling for future requirements regarding equipment upkeep

To ensure the seamless execution of your plan, it’s imperative to gain support from all relevant parties and equip your maintenance team with thorough training.

Doing so will guarantee familiarity and skillfulness within the new preventative maintenance strategy and its associated procedures, thereby solidifying its effectiveness and productivity.

The Role of Technology in Preventive Maintenance

Technology is a crucial factor in contemporary maintenance practices. Utilizing AI and IoT has enhanced the efficiency of maintenance tasks while cutting down on needed resources. IoT devices have empowered proactive maintenance efforts through ongoing monitoring and data gathering regarding machinery operation.

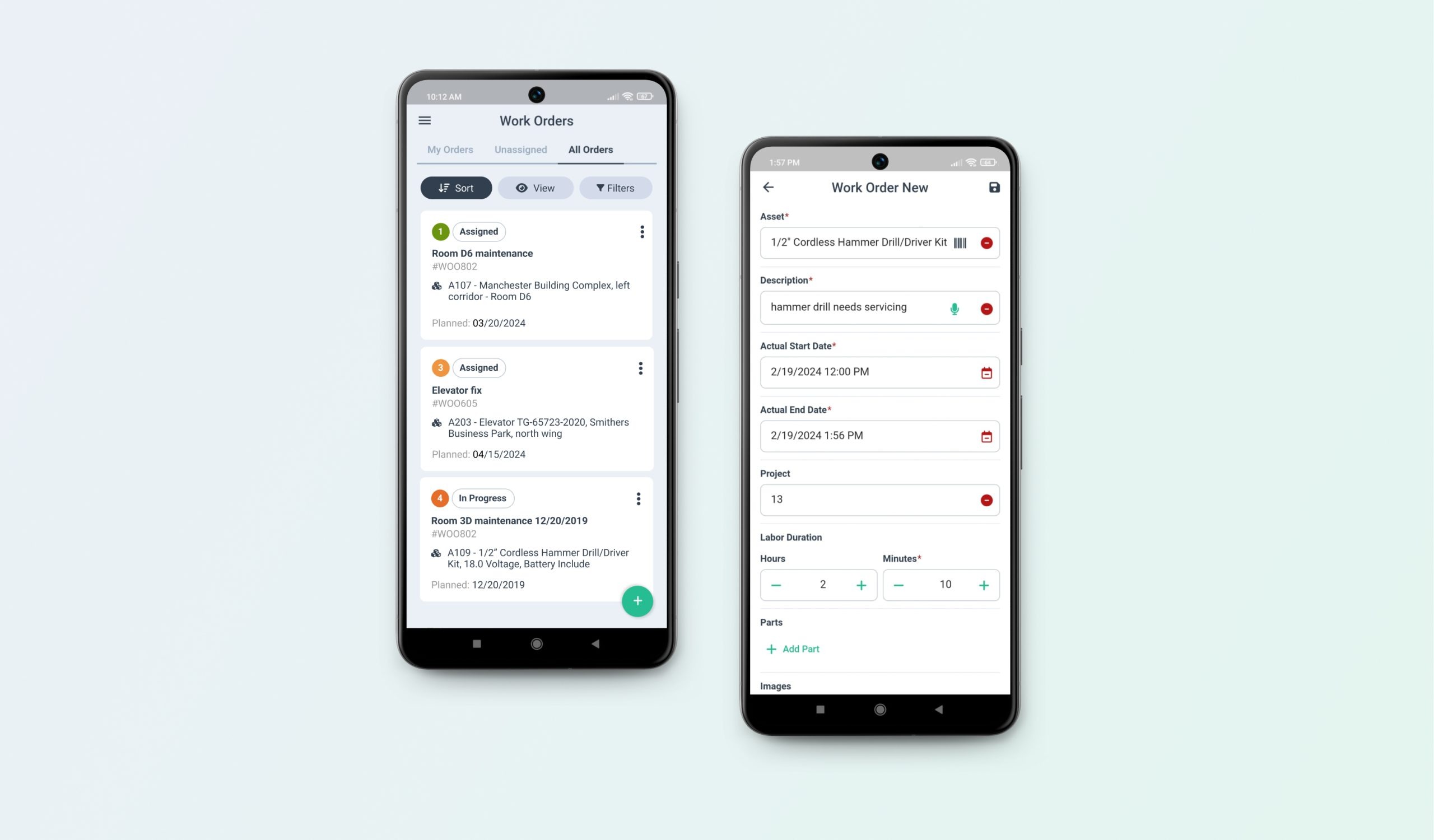

The Computerized Maintenance Management System (CMMS) is crucial for orchestrating preventive maintenance schedules. It assists in several ways, including:

- The allocation of work orders

- Encouraging teamwork within maintenance teams

- Initiating automatic creation of immediate work orders based on real-time inputs from IoT sensors, thus enabling quick reactions to possible equipment malfunctions.

- Creating a preventive maintenance plan

- Reducing equipment downtime and failure

- Reducing costly repairs

- Protecting critical assets

- Simplify schedule maintenance

- Increase asset lifespan

- Prevent equipment failure

- Protect critical assets

By deploying such technologies, organizations can ensure that their preventative measures are scheduled and adaptive to real-time conditions. This will lead to more effective long-term asset management, reduced failure modes, and improved asset maintenance.

CMMS systems also give maintenance managers a singular view of all work being performed and, more importantly, reduce the incidence of unplanned maintenance.

Source: WorkTrek

Source: WorkTrek

Benefits of Using Preventive Maintenance Software

Software designed for preventive maintenance offers many advantages poised to revolutionize maintenance jobs. Central to its capabilities is the ability to simplify work orders, which expedites their generation and enhances the effectiveness with which they’re handled, thereby markedly boosting operational efficiency.

One critical component of this software is its automated scheduling function, which facilitates the forward-thinking organization of tasks such as inspections, cleaning, and lubrication without necessitating human input. It improves spare parts inventory management and utilizes data analysis to bolster decision-making processes related to task implementation.

Preventive Maintenance Best Practices

Implementing best practices is crucial for the success of a preventive maintenance program. Conducting routine preventive maintenance tasks, such as systematic inspections and oil changes, helps prevent equipment failures while ensuring safety and maintaining operational efficiency.

Simple maintenance tasks, such as cleaning machinery to remove debris like dust, cannot be overstressed since they significantly extend the equipment’s life expectancy. Similarly, periodic lubrication is vital in protecting machine parts from excess wear, which can lead to unexpected downtime during production processes.

Continuous training for maintenance teams enhances their abilities, making them more effective at preventive maintenance work. Engaging trained, skilled engineers in formulating preventative maintenance ensures these strategies are more efficient.

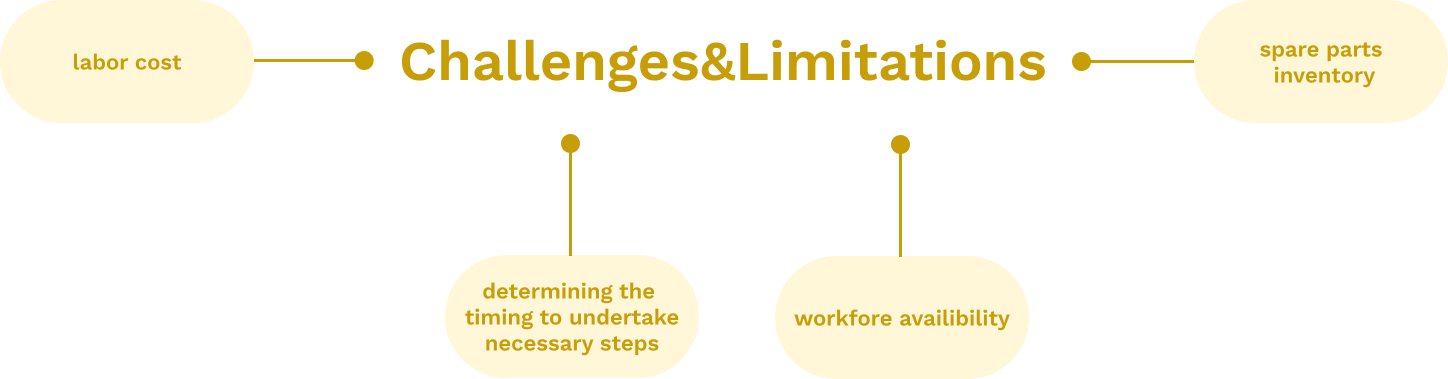

Challenges and Limitations of Preventive Maintenance

While preventive maintenance has benefits, the initial and continuous investment it demands can also hinder it. This financial pressure is exacerbated when cutting-edge digital solutions for maintenance or the additional labor costs are perceived as costly, particularly in scenarios where keeping maintenance expenses under control is a key concern.

Another hurdle is determining the precise timing of inspections and necessary upkeep tasks to prevent equipment failure. Overcommitting to preventive maintenance schedules may lead to an undue amount of planned downtime devoted solely to standard cleaning and repairs that might not suit a particular facility’s distinct requirements.

To avoid fiscal waste, resources like workforce availability, spare parts inventory, and time allocation need to be carefully managed. Complicating matters are instances where scheduled maintenance efforts stack up—often referred to as “pyramiding tasks”—resulting in excessive servicing that interrupts essential preventative actions intended to prevent equipment malfunction.

Source: WorkTrek

Measuring the Success of Preventive Maintenance

Assessing the effectiveness of a preventive maintenance program is essential for its ongoing refinement. Critical performance metrics specific to preventive maintenance should include aspects such as:

- Efficiency

- Ratio of Planned Maintenance

- Adherence to Preventive Maintenance Schedules

- Frequency of Missed PM Tasks.

Evaluating these metrics can provide deep insights into how well your program functions.

Analyzing data consistently is key to enhancing a preventive maintenance program’s efficiency. Regularly examining historical data helps refine processes and foresee upcoming maintenance requirements, promoting informed strategic actions.

A comprehensive preventive maintenance checklist is an effective method for monitoring KPIs. It facilitates thorough evaluation and necessary modifications within the preventive management scheme, ensuring it retains relevance and contributes positively to organizational operations.

Preventive Maintenance Across Industries

Preventative maintenance plays a critical role across a range of industries. For instance, educational institutions maintain an environment conducive to safety and comfort for learning activities. In fleet management, proactive maintenance is essential to prevent vehicle breakdowns that could interfere with daily business activities.

In the oil and gas sector, preventive maintenance is especially important due to the potentially catastrophic impacts failures can have on the environment and local communities.

As such, entities within this field are keenly focused on instituting strategies for proactive equipment monitoring, often leveraging remote technology as one of its distinct advantages.

Industries rich in physical assets stand to gain from employing maintenance management software through several key enhancements.

- Smoothing out asset management processes

- Elevating productivity levels

- Boosting system uptime

- Enhancing return on investment

Oil and Gas Industry

Across many industries, preventive (and, by extension, proactive) maintenance is an indispensable cornerstone of their operational infrastructure. This approach is not merely a set of tasks; it’s a philosophy permeating the fabric of an organization’s approach to asset management.

Healthcare and Aviation Industry

From the care of medical equipment in healthcare facilities to the rigorous safety checks in the aviation industry, preventive maintenance is universally acknowledged as a critical practice.

It ensures the smooth operation of systems, the safety of personnel, and the reliability of services provided. By prioritizing maintenance, industries can avoid equipment failure’s costly and disruptive consequences, safeguarding their reputation and ensuring customer satisfaction.

Preventive maintenance (PM)

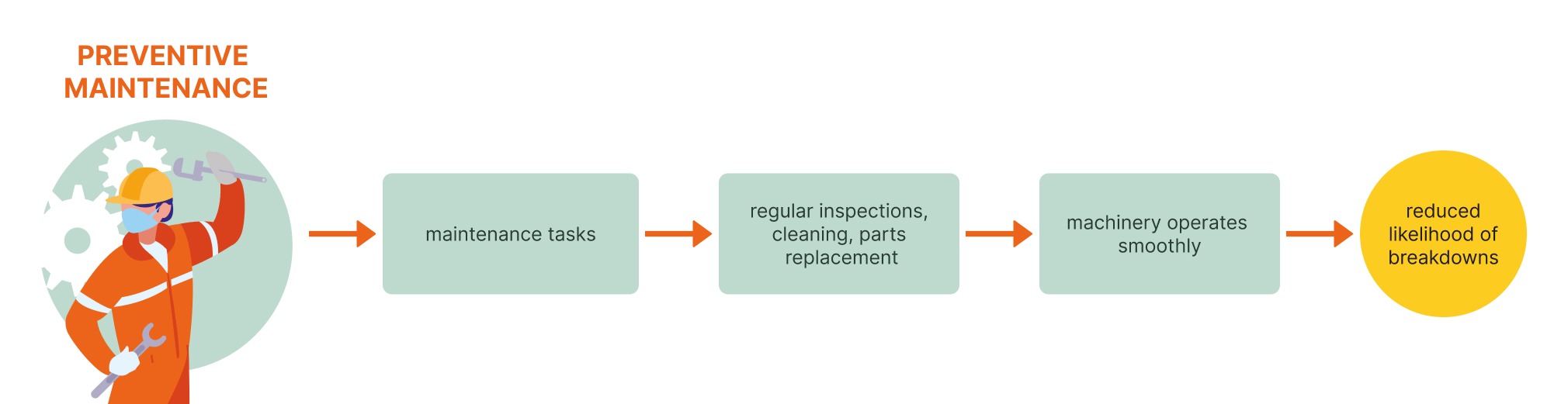

Preventive maintenance (PM) is a strategic approach that involves scheduling and performing maintenance tasks to prevent equipment failures before they occur. By conducting regular inspections, cleaning, and parts replacements, PM helps ensure that machinery and systems operate smoothly, reducing the likelihood of unexpected breakdowns.

This proactive form of maintenance enhances the reliability and efficiency of equipment and extends its lifespan, leading to significant cost savings. Furthermore, PM contributes to a safer work environment by identifying potential hazards and rectifying them promptly. In essence, preventive maintenance is an investment in the longevity and productivity of an organization’s assets.

Source: WorkTrek

Source: WorkTrek

Summary

Implementing a preventive maintenance strategy is crucial in prolonging the life of assets, cutting down expenses, and boosting operational effectiveness. This approach involves establishing an extensive plan incorporating technology and following industry best practices to forestall equipment failures, promote employee safety, and increase productivity.

While it’s important to acknowledge the complexities and constraints associated with preventive maintenance, such as considerable investment demands, strategic development needs, and ongoing refinement efforts, the advantages provided by this proactive measure considerably surpass its costs, thus rendering it an indispensable procedure for maintaining high-efficiency levels within various sectors.