Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeAre you looking to reduce downtime and streamline maintenance tasks in your manufacturing operations? Manufacturing maintenance software is designed to address these challenges, offering features that elevate production efficiency.

This article explores the software’s pivotal role, from preventive maintenance to advanced analytics, and how your plant can reap tangible benefits with its adoption.

Key Takeaways

- Preventive maintenance software automates maintenance tasks, minimizes equipment downtime, and integrates with other systems for improved efficiency in manufacturing operations.

- Advanced analytics in maintenance software provide actionable insights to reduce equipment downtime, optimize spare parts inventory, and offer predictive insights for maintenance teams.

- Manufacturing maintenance software enhances asset management, empowers maintenance teams with critical features like customizable schedules and mobile access, and delivers long-term benefits, including cost savings and improved production efficiency.

Maximizing Uptime with Preventive Maintenance Software

In the manufacturing industry, preventive maintenance software is essential for maximum uptime. It streamlines maintenance tasks by automating them, keeps records of equipment history, and works in harmony with other systems to guarantee that equipment maintenance processes are conducted smoothly.

This approach leads to a marked decrease in equipment downtime, immensely beneficial for manufacturing entities aiming to enhance efficiency and sustain uninterrupted production.

Scheduling Preventive Maintenance Tasks

By utilizing manufacturing maintenance software, operations can efficiently time preventive maintenance tasks to ensure a harmonious blend of regular upkeep and the agility to respond to immediate repair needs.

This strategic scheduling facilitates optimal resource use while fulfilling maintenance goals and minimizing any interruption in manufacturing production activities.

Source: ClassPoint

Tracking Maintenance Histories

Maintenance professionals are empowered to examine historical data and logs, allowing them to foresee potential problems and take preventive measures before these issues worsen.

Such a strategy leverages data in equipment maintenance software, shifting from merely reacting to issues as they arise to predicting them and improving maintenance goals through proactive upkeep work on equipment.

System Integration for Seamless Operations

Establishing a unified digital solution by implementing a system integration of preventive maintenance software connects with real-time equipment sensors and other departments within the facility.

This innovation affords maintenance teams immediate access to vital data, simplifies interactions between different sectors, and improves user-friendliness.

As all pertinent information is presented on one dashboard, this integration becomes an indispensable tool for boosting overall productivity in the manufacturing environment.

Source: WorkTrek

Streamlining Plant Maintenance with Advanced Analytics

Plant maintenance software, empowered by advanced analytics, is transforming the landscape of manufacturing maintenance. Interpreting extensive data sets into valuable insights gives maintenance professionals the tools to minimize downtime and optimize their operations for increased efficiency.

These cutting-edge analytical capabilities have become essential for plant managers seeking to advance their manufacturing operations. With such technology, they can drive improvement within maintenance and foster overall operational enhancements in manufacturing facilities.

Analyzing Equipment Downtime Causes

Investigating the reasons for equipment downtime, maintenance software enhanced with advanced analytics provides a detailed perspective that identifies obstacles in manufacturing equipment maintenance.

Such thorough scrutiny facilitates the formulation of preventive maintenance tasks aimed at directly tackling the underlying causes of downtime problems, which results in improved inventory management and more efficient production processes.

Predictive Insights for Maintenance Teams

Advanced analytics offer predictive insights that enable maintenance crews to:

- Anticipate and prevent potential failures in equipment

- Minimize the downtime of machinery

- Boost the dependability of production line operations

- Guarantee that all maintenance tasks align with overarching objectives to enhance efficiency.

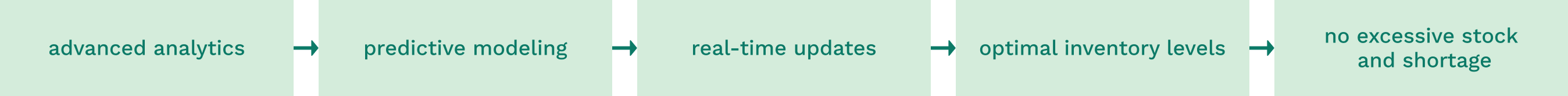

Optimizing Spare Parts Inventory

Advanced analytics are crucial in manufacturing maintenance to manage spare parts inventory effectively. Maintenance software utilizes predictive modeling and provides real-time updates to maintain optimal inventory levels, thus preventing excessive stock and shortages.

This enables well-planned bulk ordering, ensuring that maintenance operations run smoothly without interruption.

Managing spare parts inventory is critical to maintenance operations for manufacturing facilities. CMMS software is invaluable, offering features that track inventory levels and usage patterns. It provides automated alerts when parts fall below predetermined thresholds, ensuring that maintenance teams can reorder components promptly.

This proactive approach prevents the scramble for parts during critical repairs and minimizes the risk of production delays due to unavailable components. By maintaining an optimal inventory level, CMMS software helps avoid excess stock, which ties up capital, and shortages, which could lead to costly downtime.

Source: WorkTrek

Enhancing Asset Management on the Plant Floor

An effective asset management strategy reduces equipment downtime and optimizes production output. Maintenance software is a pivotal tool in facilitating these enhancements. It provides functionalities that simplify the handling of assets—from maintaining an organized inventory to granting mobile access—thus guaranteeing precision in executing maintenance tasks.

Centralized Asset Inventory

Plant managers at a manufacturing facility can benefit from an integrated asset inventory system that delivers a detailed outline of all assets and their respective maintenance schedules.

This complete registry of equipment information guarantees the proper upkeep and tracking of each piece of equipment, thereby minimizing the risk of unexpected downtime and bolstering productivity within the manufacturing environment.

Mobile Accessibility for Technicians

Mobile accessibility in equipment maintenance software has transformed the approach of maintenance professionals toward handling maintenance tasks. Now, technicians working on the plant floor can access work orders, equipment manuals, and records of past maintenance activities via their mobile devices.

This advancement aids in simplifying the execution of maintenance work and dramatically enhances efficiency and productivity.

Accurate Completion of Maintenance Work

Maintenance software is pivotal in achieving precise execution of comprehensive maintenance tasks, which is critical for sustaining equipment performance and complying with regulations. By recording each maintenance action, this software enhances operational effectiveness and prolongs the service life of manufacturing machinery.

Empowering Maintenance Teams with Key Features

Essential characteristics of manufacturing maintenance software play a pivotal role in strengthening maintenance teams. Providing immediate entry to maintenance data, the ability to tailor maintenance timetables, and seamless interaction with different sections represent some of the instrumental tools that facilitate the fulfillment of maintenance objectives and enhance efficiency throughout manufacturing operations within production sites.

Instant Access to Maintenance Information

Having immediate and easy access to extensive asset details and maintenance logs is transformative for maintenance professionals. It empowers them to manage repairs more efficiently, facilitating decisions based on solid data that can result in substantial cost reductions.

Customizable Maintenance Schedules

Maintenance software, utilizing predictive modeling tools, facilitates the proactive scheduling of preventive maintenance tasks and allows for quick resolutions of issues. This customization of maintenance schedules is crucial for meeting the unique demands of a production line in manufacturing plants while promoting safety and compliance with standards.

Accessible Communication with Other Departments

Maintenance software delivers a host of advantages for manufacturing facilities. Notably, it streamlines interactions between maintenance teams and various other departments within the facility while promoting a collaborative atmosphere.

Mobile accessibility enables technicians to swiftly access work orders on the go, leading to expedited solutions and enhanced operational efficiency across the entire manufacturing environment.

Evaluating the Value of Manufacturing Maintenance Software

Maintenance software in the manufacturing sector immediately enhances operations and delivers enduring advantages for production companies.

Investing in manufacturing maintenance software yields significant returns in industrial manufacturing by amplifying production efficiency, reducing costs, and prolonging equipment’s service life.

Cost Savings from Reduced Downtime

Manufacturing facilities greatly benefit from the financial savings associated with decreased equipment downtime. By using maintenance software to identify potential failures and perform predictive maintenance proactively, these factories can effectively forestall equipment breakdowns, thereby diminishing operational costs and contributing positively to their profit margins through reduced downtime in manufacturing processes.

Source: Starting Business

Improved Production Line Efficiency

By automating and analyzing real-time data, maintenance software is crucial in enhancing the efficiency of production lines. It allows manufacturing plants to achieve maximum productivity by optimizing procedures and overseeing production activities, ensuring operations run at peak performance with minimal interruptions for maintenance.

Long-term Benefits for Manufacturing Companies

Integrated maintenance software can reap enduring rewards for manufacturing companies. This includes achieving an optimized return on investment and heightening operational efficiency. It also allows for implementing predictive maintenance strategies and using simulation studies to improve performance.

Such software leads to notable cost savings for manufacturing firms. Over time, these companies can also expect better resource optimization due to leveraging maintenance technology in their production processes.

How can CMMS software optimize manufacturing maintenance

A computerized maintenance management system (CMMS), which is integral to enhancing manufacturing maintenance, addresses several issues by providing capabilities for:

- Cutting down expenses on parts

- Refining the management of assets

- Streamlining processes through automation

- Facilitating decisions based on robust data

- Providing a single dashboard to view all work

- Simplifying the preventative maintenance process

- Giving maintenance teams a single view of work orders, health and safety, and documentation

CMMS software equips manufacturers with an extensive tool suite to bolster their maintenance operations. These tools focus on challenges such as reducing unplanned downtime, curtailing steep repair expenses, and refining inventory management practices.

This comprehensive approach can lead to significant cost savings for manufacturing companies.

Summary

We’ve explored maintenance software’s transformative capabilities in the manufacturing sector, uncovering how it maximizes uptime, streamlines maintenance tasks, and enhances asset management.

The value of preventive maintenance software, reinforced by advanced analytics and critical features of CMMS systems, is clear.

Maintenance software is an essential ally for manufacturing companies looking to thrive in a competitive landscape. It can improve efficiency, drive significant cost savings, and bolster long-term operational success.

Frequently Asked Questions

How does preventive maintenance software prevent unplanned downtime?

Maintenance software is designed for preventive maintenance schedule tasks to avoid unplanned downtime. It predicts and addresses potential problems before they result in equipment breakdowns based on specific triggers such as time or usage.

Can maintenance software help with inventory management?

Indeed, by utilizing maintenance software equipped with advanced analytics, demand forecasting and automation of reordering procedures can be enhanced for spare parts inventory. This ensures that necessary parts are on hand precisely when required while preventing excess stock accumulation.

How does mobile accessibility improve the productivity of maintenance teams?

Enabling technicians to utilize their mobile devices on the plant floor significantly boosts maintenance teams’ efficiency.

This mobile accessibility affords them instant access to work orders, streamlining their response to maintenance requirements and ensuring they have all the pertinent information at their fingertips.

What are the long-term benefits of implementing manufacturing maintenance software?

By adopting maintenance software specifically designed for manufacturing, businesses can achieve longer lifespans of their equipment, enhance the return on investment, and boost overall operational efficiency by utilizing predictive strategies for maintenance and better allocation of resources.

This shift towards strategic manufacturing maintenance furthers a company’s longevity and cost-effectiveness and paves the way to enduring success.